|

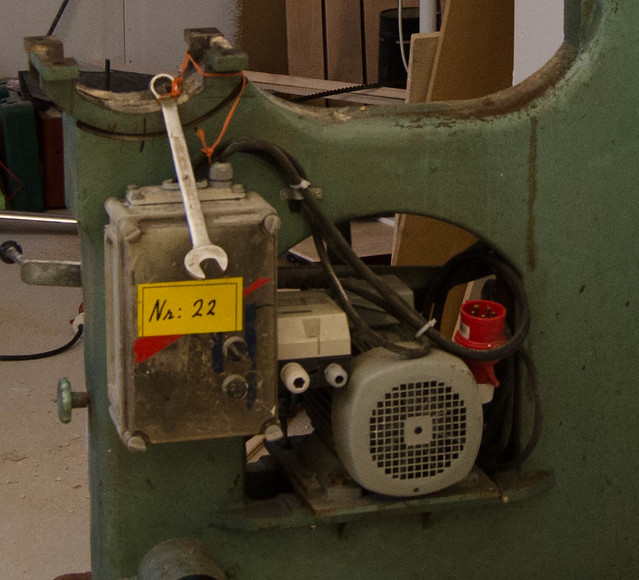

I have a question for any electricians, I'd like an electric brake for my bandsaw and I am contemplating building one myself. The simplest solution seems to be plugging, reversing two phases to change the direction of the motor (this is a 3ph motor and I have real 3ph at home in the walls, no VFD) after shutoff and then reapplying power to brake it. Now I am only after a manual brake, I am happy just pressing a button and doing so until it stops or at least mostly does. Don't need no fancy automatic breaking that turns on automatically and stops when its done. My bandsaws electrical start is a bit strange, it is salvaged from another system I think. There's the motor, a contactor box, and then another panel that has a switch and a button, this bigger panel is used to control the saw:  To start the saw I have to: 1) flip the upper switch 2) press the lower button To stop I turn the switch back and power is cut off and the saw spins down, takes like 10 minutes. You can press the button with the switch in the other way and it will run as long as the button is held down. This feature is not really needed on a bandsaw and probably indicates it came from some other machine after the original motor was swapped out. Now my plan is, what if you put one of these 3-pole 1-0-2 switches between the control box and motor:  You could set it up so that in 1 position it the motor travels one way, and in 2 position it goes the other way. So to break the motor using plugging I'd stop the saw as usual and flip the other switch to two, then I hold down the regular start button and the motor will reverse for as long as I hold it down. That's the general idea anyway, another idea would be to have DC going to two of the phases and use DC injection braking. Not sure what would be better. Atleast with the DC injection you can't accidentally start the saw in reverse. Which is a flaw with my design here and why those commercial solutions cost so much, because they gotta be idiotproof and work in commercial settings. But I am just a hobbyist. Is this a bad idea? Will plugging cause undue stress on my motor to brake those heavy cast iron wheels that also act as flywheels? Will I kill myself? I have wired some 3ph motors before, just fitting them with breakers or a contactor with overload protection and such, never thought out a system like this before. e: my gut feeling is that it's too stressful on the motor, think I a rheostatic brake would be best but I am not sure how to go about that at this point. His Divine Shadow fucked around with this message at 13:21 on Jan 23, 2015 |

|

|

|

|

| # ? May 30, 2024 18:04 |

|

Question for you guys. I have this  In my virtual pinball cabinet. I have a standard PC power cable plugged into that and into the wall. The other side looks like this  The 2 prongs on the top ride side and the one on the right in the center I have a power strip wired into, black/white/green wires basically. Right now it's basically passing the power to the power strip and when I turn the power strip on it works fine. What I want to be able to do is leave the power strip turned on all the time and control the power with the switch on this little plug. There are 4 prongs on the red switch itself. Is it possible to somehow wire it up so that red strip controls the power? edit: So not sure how I didn't find this before but someone had already done the exact thing I wanted to do in the exact same setting(virtual arcade cab).  Works great! So, I guess if anyone else was wondering, that's how you do it! mattfl fucked around with this message at 00:36 on Jan 27, 2015 |

|

|

|

You should really shouldn't use a power bar for this, you should be using plugmold. I'm not doubting your ability to wire anything, nor am I doubting that it's a quality power bar. Electrical code doesn't allow you to do this to your home, and they usually only add poo poo like that if they've had issues with it before(read: a couple houses probably burned) so you shouldn't be doing it to something in your home. You really should be using plugmold. It's virtually the same thing but it's designed to be hard wired. You also wouldn't have to worry about having a redundant switch.

|

|

|

|

Ultimate Shrek Fan posted:You should really shouldn't use a power bar for this, you should be using plugmold. I'm not doubting your ability to wire anything, nor am I doubting that it's a quality power bar. Electrical code doesn't allow you to do this to your home, and they usually only add poo poo like that if they've had issues with it before(read: a couple houses probably burned) so you shouldn't be doing it to something in your home.

|

|

|

|

ThinkFear posted:Out of curiosity, what code do you think he is violating? Cutting the plug off of a UL power strip?

|

|

|

|

So I was trying to remove a bulb from a hanging fixture plugged into some track lighting in my kitchen, I was trying to unscrew the bulb for a bit until I realized it's one where you have to twist it to the right position and then pull it out. Deciding I would wait until I had better light to try and remove it I screwed it back in (trying to unscrew it had loosened the fixture) and flipped the light switch back on. *POP* oops. I reset all the circuit breakers for the kitchen, but no dice. The track light and my under cabinet lights and some outlets aren't working. Since resetting the breakers didn't help, what do I look at next? Do I have to take apart the breaker box and look for something melted?

|

|

|

|

Probably you have to take apart the fixture and look for something melted. Sounds like you caused a short in there. Turn the breaker back off first

|

|

|

|

marshmonkey posted:So I was trying to remove a bulb from a hanging fixture plugged into some track lighting in my kitchen, I was trying to unscrew the bulb for a bit until I realized it's one where you have to twist it to the right position and then pull it out. Deciding I would wait until I had better light to try and remove it I screwed it back in (trying to unscrew it had loosened the fixture) and flipped the light switch back on. *POP* Since you said its a kitchen, make sure there isn't a GFCI tripped somewhere. Sometimes they're installed in stupid places you wouldn't expect (I have personally installed one in a stupid place you wouldn't expect because it was a ton easier than installing it somewhere more appropriate).

|

|

|

|

Cat Hatter posted:Since you said its a kitchen, make sure there isn't a GFCI tripped somewhere. Sometimes they're installed in stupid places you wouldn't expect (I have personally installed one in a stupid place you wouldn't expect because it was a ton easier than installing it somewhere more appropriate). Hmm, reset the GFCI on one of the outlets on the wall that went out and now those are working again. The track lighting and the under cabinet lighting is still dead though.

|

|

|

|

PuTTY riot posted:Cutting the plug off of a UL power strip? Right, and field modifications to UL listed devices happen all the time. The NEC doesn't require that power strip to be UL listed. (though it'd be nice) UL expects your AHJ to rule on the safety of such modifications. Your AHJ doesn't care about the internals of your pinball machine. Is there something that I am missing? It's a setup I've come across somewhat frequently in washdown enclosures, to my knowledge there is nothing wrong with it.

|

|

|

|

ThinkFear posted:Right, and field modifications to UL listed devices happen all the time. The NEC doesn't require that power strip to be UL listed. (though it'd be nice) UL expects your AHJ to rule on the safety of such modifications. Your AHJ doesn't care about the internals of your pinball machine. Just backing you up here. The code ends at the other end of that "standard PC power cord." The NEC doesn't care about what you plug into the wall, your wall will be fine if it's up to code. Now, the thing you just built may burn itself down, but the electrical system of the house will be able to support that poor decision on your part. The NEC doesn't concern itself with anything inside utilization equipment except to mandate that its "normally non-current-carrying exposed metallic parts" are properly bonded to the ground wire. I'm not sure if there's some OTHER code that deals with the stuff you're plugging in. All that said, I think plugmold would look better than a power strip. At this point, however, stuff being plugged into the strip is behind a breaker(house), a fuse (plug), and some kind of MOV(strip), so the setup should be relatively safe, electrically.

|

|

|

|

babyeatingpsychopath posted:I'm not sure if there's some OTHER code that deals with the stuff you're plugging in. Not that I'm aware of, but your property insurance sill sure be interested in using it to not pay out when it burns your house down. I've been on several jobs where the insurance company is refusing payout because it was being used by the occupant in an obviously broken state or with modifications. If it's a properly functioning UL listed device they typically go after the device manufacturer or importer.

|

|

|

|

We have recessed lights over the kitchen sink. Wife was changing the bulb on one and then stuffed everything back into the ceiling. When she turned on the light, there was an arc and sparks and poo poo and then the breaker blew. The wiring behind the light has what I have identified as a thermal protector spliced in, which looks like this:  There is a burn mark from where it must have contacted the metal can upon said restuffing. I took the other light down beside it, and that thermal protector has a plastic clip over it, obviously to protect it from contacting the metal can or anything else. My question is, can I wrap a thermal protector in electrical tape or will that mess with its temperature gauging? The plastic clip protects it, but is also open, so I didn't know if ventilation was a requirement to make sure the protector doesn't overheat too fast or something. Thanks for your wisdom in advance.

|

|

|

|

ThinkFear posted:Out of curiosity, what code do you think he is violating? It's a a grey zone, I don't think he's violating code, some might. A power strip is a flexible cord for all intents and purposes. You're not allowed to leave the cord unprotected and I could be wrong, but the shape of the leaves me to think the backside might be exposed. Rats or mice or dogs or cats or kids could chew on that fucker. Rip open the power strip cover, remove the flexible cord, throw in some BX and bam, no having to worry about a mouse chewing on a cable and starting a fire.

|

|

|

|

KnucklePuckMe posted:We have recessed lights over the kitchen sink. Wife was changing the bulb on one and then stuffed everything back into the ceiling. When she turned on the light, there was an arc and sparks and poo poo and then the breaker blew. Mind posting a picture of the light?

|

|

|

|

angryrobots posted:What kind of a can light requires you to remove the guts to change a bulb? It is actually inside a metal can right? Sure, it's not a can light but a hanging track light:  You don't have to remove the guts, you are supposed to just press in and twist and pull. But if you do keep twisting the bulb the whole mounting guts part will come out. I figured out that a circuit got tripped in the breaker box at the other end of the house (house has 2), so once I flipped that back on it worked ok. I ended up hosing the hanging light fixture though.

|

|

|

|

So if that's a track pendant light, what part of it gets "shoved back in the ceiling"?

|

|

|

|

angryrobots posted:So if that's a track pendant light, what part of it gets "shoved back in the ceiling"? Whoops, I'm totally the wrong person. Thought you were quoting my post. Disregard!

|

|

|

|

marshmonkey posted:Hmm, reset the GFCI on one of the outlets on the wall that went out and now those are working again. The track lighting and the under cabinet lighting is still dead though. If you've spun and spun the socket, chances are you pulled a wire off of the socket itself. It's a big issue with lights that don't have fixed sockets. That isn't necessarily the case though. If you feel comfortable doing it, turn the breaker off and take the hanging fixture off, make sure all of the connections in the junction box are still good(signs of charring on insulation, the outside of the copper is black, tight connections). If everything in the junction box above the light is good, then take apart the housing of the light you tried to unscrew the bulb from and take a peek at the factory connections to the bulb socket, if it popped off, you'll probably have to just solder the wire back on at worst, stick it in a hole at best. If that still doesn't work, bypass that light entirely, just to see if the lights under the cabinet will turn on. It shouldn't be hooked in series, but with some residential guys, you never know, they might have done it that way to save a buck on wire.

|

|

|

|

angryrobots posted:What kind of a can light requires you to remove the guts to change a bulb? It is actually inside a metal can right? The can light doesn't actually require you to remove the guts to change the bulb. I don't know why she actually pulled it out like that (I was downstairs hanging sheet rock), but in doing that, she revealed that this thermal protector doesn't have the protective plastic clip on it like the other one does. I'm wondering if it is safe / non disruptive to wrap a thermal protector with electrical tape to ameliorate the situation. And yes I can post a picture of the light if you still think its necessary when I get home.

|

|

|

|

Ultimate Shrek Fan posted:If you've spun and spun the socket, chances are you pulled a wire off of the socket itself. It's a big issue with lights that don't have fixed sockets. That isn't necessarily the case though. If you feel comfortable doing it, turn the breaker off and take the hanging fixture off, make sure all of the connections in the junction box are still good(signs of charring on insulation, the outside of the copper is black, tight connections). If everything in the junction box above the light is good, then take apart the housing of the light you tried to unscrew the bulb from and take a peek at the factory connections to the bulb socket, if it popped off, you'll probably have to just solder the wire back on at worst, stick it in a hole at best. If that still doesn't work, bypass that light entirely, just to see if the lights under the cabinet will turn on. It shouldn't be hooked in series, but with some residential guys, you never know, they might have done it that way to save a buck on wire. I got everything working again, the circuit that I tripped ended up being in a 2nd breaker box. I did break the fixture by spinning the bulb, but the reason I was messing with it was to replace them with LEDs so I'm just gonna go look for some newer lights to stick on the track.

|

|

|

|

angryrobots posted:What kind of a can light requires you to remove the guts to change a bulb? Goddamn stupid 4 pin fluorescent cans. Trying to insert a new bulb in one without taking the can liner down and holding the socket from the back will only snap the socket out of the back of the can. Some brilliant engineer made the socket retention clips weaker than the bulb retention clips.

|

|

|

|

kid sinister posted:Goddamn stupid 4 pin fluorescent cans. Trying to insert a new bulb in one without taking the can liner down and holding the socket from the back will only snap the socket out of the back of the can. Some brilliant engineer made the socket retention clips weaker than the bulb retention clips. Especially after two years with the bulb in and thermal cycling causes the pins to stick. On 4-pin lamps I install, I use dielectric grease on the pins. Enough of the lamps bathtub-curve fail that it's worth it to me to do, and I hope the maintenance guy down the road appreciates my investment.

|

|

|

|

babyeatingpsychopath posted:Especially after two years with the bulb in and thermal cycling causes the pins to stick. On 4-pin lamps I install, I use dielectric grease on the pins. Enough of the lamps bathtub-curve fail that it's worth it to me to do, and I hope the maintenance guy down the road appreciates my investment. drat it, that reminds me, removing bulbs is a pain from these too. It's nearly impossible to remove a bulb from one without tearing one of the 3 tubes out of the ceramic base because it's too tight at the back of the can liner to grasp the drat thing by the base. Whoever invented G24q sockets needs to be drug out into the street and shot.

|

|

|

|

So the last time I asked, I was advised against going LED to replace my 13 old non functional t12 8' two bulb shop lights. How about this deal on amazon? Works out 60 bucks per fixture (minus one bulb) to go LED, and their products are pretty highly reviewed, other than needing center support for the 8 footers. That's a claimed 3600 lumens x2 for $60... Not bad I think. And I can run them on 240v which I absolutely would. quote:8FT 40 Watt T8 LED Tube Double-end Power 96W Fluorescent Tube Cool White Color Looks a 4 lamp 8' t8 fixture will run about $150. Possibly I could get two 4' fixtures and install them end-to-end for less, but still more than this LED retrofit. Priced t5 high bay fixtures and there are some good deals out there, but still more expensive, and I'd end up having to run the circuit again because all the conduit and wire would be too short. Not a big deal, but added expense and time. angryrobots fucked around with this message at 16:23 on Jan 31, 2015 |

|

|

|

Replacement T8 ballasts + T8 bulbs in your existing fixtures should be doable for a fair bit less than $60 each. Edit: Those fixtures aren't 40W because LEDs are crazy efficient, btw - the best LEDs are still only roughly on par with linear flourescent tubes. They're 40W because they're dim. Zhentar fucked around with this message at 17:54 on Jan 31, 2015 |

|

|

|

Question: I was out 2 days ago running my electric snowblower for the 2nd time in as many days when it went "click" and stopped working. It was plugged into a GFI on the outside wall of the house. When I tried to reset it, I found that the buttons were both stiff and that it could not be reset. I then went inside and found a number of lights inside the house nearest the receptacle were also not working. Figuring the GFI to have failed, I went to the store and bought a new one and installed it, but I found that inside the receptacle box there was only one line entering the box. I hooked it up and it still did not work, and neither did the lights inside. I discovered that a number of interior lights on that circuit still work but the ones inside near the GFI outside do not. My multimeter is not giving me consistent results, but I seem to be getting anywhere from 0-60V on various light switches and receptacles that are affected by this problem. My no-contact tester goes crazy anywhere in the vicinity of any of the affected receptacles and switches, but not around any other normally functioning junctions. I also discovered behind one light affected light fixture a huge rat's nest of wiring including 8 wire nut connections. I suspect the problem exists somewhere in this box, but I didn't find any loose connections in this particular box. I suspect the outside plug is fed from this box and that this is where the line from the panel feeds the area. My internet electrician friend is suggesting there is an open neutral or open hot somewhere, but I have checked all accessible connections and haven't found anything resembling a loose connection. I also live in an isolated area where access to an electrician is pretty much nil.  Does anyone have any advice on how to proceed?

|

|

|

|

You can buy a simple gfci light up tester. Like this http://www.amazon.com/GE-50957-GFCI-Tester/dp/B002LZTKIU Also, that new gfci outlet you installed should be WR and TR rated if it's outside. There's still power going to the outlet? Might help if you showed some pictures of the problem. The Gardenator fucked around with this message at 01:21 on Feb 8, 2015 |

|

|

|

The GFI stopped working completely from the point the blower went click and hasn't been back on since, though the no-contact tester still goes wild near it. The voltmeter says nothing at all. I just went out to buy a tester and it doesn't light up at all in the affected outlets; upon closer investigation with the meter, all of the affected receptacles are now only registering about 5v from hot to neutral. I'm not sure what I did to provoke that change except possibly disturb the rat's nest light fixture. Other lights on the same circuit still seem to work fine. The no-contact tester still goes wild near any affected switches and receptacles but not near non-affected ones. I'll come back with some pictures of the wiring a bit later, just need to get some things taken care of.

|

|

|

|

Sounds like you have a junction box upstream that is shared by all of the affected circuits. Chances are good something when poorly in there like a badly done wire nut. Your snowblower created enough load to heat it into failure. Are these all on the same breaker? And have you check if one of the breakers has tripped? Any places around that outlet (above a ceiling, in a basement or attic) that you could look?

|

|

|

|

These are all on the same breaker, which did not trip. The panel is a Federal Pacific Stab-Lok; so I think there exists the possibility that it would not have / is not tripping despite a possible short in the system. There are other lights on the same circuit/breaker that are still working fine. I don't know of anywhere else I can look at the moment; the attic isn't exactly accessible, but I will try to take a look if possible. It's a real mess up there as it is full of blown-in insulation. Is there any likelihood that something may be arcing right now and may cause a fire?

|

|

|

|

Please don't become another statistic of the Stab-Lok Wars

|

|

|

|

bokchoi posted:The panel is a Federal Pacific Stab-Lok bokchoi posted:Is there any likelihood that something may be arcing right now and may cause a fire? Yes. Switch off the breaker right now and hire a professional ASAP.

|

|

|

|

On the advice of my electrician friend I systematically worked from the working parts of the circuit to the non-working parts. I eventually came to a working receptacle near a non-working one, and I took it apart and tightened the connections. I flipped the breaker and now all the lights work and the receptacles show as working properly. I probably wouldn't have guessed to check this receptacle as it's almost on the other side of the house and I wouldn't have checked it without my friend suggesting to work from known working locations to non-working ones. Now I just need to make arrangements to change out that goddamn FPE panel. Thanks to everyone for their help!

|

|

|

|

Glad you found it, and that you're gonna get that fire panel changed out. It kinda sounds like, at least that circuit you're working on, has the potential to be overloaded. Might be a good time to map your circuits (always easier while everything is working) and maybe your electrician could also pull some more circuits in, at the same time he changes the panel. Help to balance your load, and make runs more logical.

|

|

|

|

I have been looking at step-up transformers as a potential solution for me wanting to bring a ridiculous coffee machine back from Europe. The machine's technical specifications state that it wants 220-240v 50-60 Hz power, and will draw at 1,600W (this is peak load when it's boiling water to make the coffee, otherwise off-demand it apparently sits at something like 5W to run a screen). Unfortunately the machine isn't available in the US so selling and re-buying locally is out. Doing the math, it looks like I can nab a 120v 20A GFCI breaker, run a dedicated line to a NEMA 5-20 outlet, and then grab a step-up transformer at something like with a built-in German Shuko outlet on the front to make this as safe as possible. This would give me roughly a 33% current padding for peak output on the machine - I know that the pump in the coffee machine will (momentarily) pull higher than what it is rated for (unless it's a DC setup and they do some sort of tiny DC drive in it, which is entirely possible), however I'm certain the real power draw is with the heating element. I'm no EE but (those who are EE's please feel free to call me an idiot here) I'm pretty sure electric heating elements are linear loads which shouldn't pull with a nasty starting current draw, nor will too much further than what it is rated for. However, the problem I'm finding is sourcing a decent step-up transformer. Insofar I've found one company that seems to be producing a decent setup, a company called Kriėger which uses Chinese-manufactured step-up/step-down transformers with an IEC plug on the back so you can source the best plug for your solution. Also, they claim CE certification as well as conforming to UL 1012 via CSA testing, which is more than any other transformer claims. However, it seems the largest transformer they make is 1,700w which I don't like as it's very close to it's limit when the coffee machine is going peak draw for that 30 seconds or so of coffee making.  http://www.amazon.com/Transformer-Converter-connection-certified-ULT1700/dp/B00HDVIHIG So let's take a look at the competition, shall we? Oh hey here's a 3,000W unit that looks like it'll do the job! poo poo, let's run a 30A GFCI breaker to a 5-30 outlet and have lots of room for safety!  http://www.amazon.com/dp/B0022U0MSQ?psc=1 Why does it have a 5-15 plug for input power? Why does a supposed 3,000W transformer have a 15A plug? Alright well gently caress that thing, let's look at what else there is out there. This one's from a company called Rockstone, another 3,000W unit.  http://www.amazon.com/dp/B00CLYMMCC?psc=1 Oh but gently caress you, it's a clone with another 15A rated plug on the back! Amazon is absolutely flooded with these cheap pieces of poo poo in all sorts of power ratings. In short, I don't trust these poorly-designed transformers that are dumped on the market for anything short of blowing up as part of a science experiment to scare the hell out of people about electricity. Is there such thing as a good step-up transformer supplier that is UL approved, and uses the proper connectors, etc.? Or is it something like a step-up transformer can never be UL approved? For what it's worth, I wanted to ask everyone here before consulting a professional electrician about wiring in the breakers, etc. I know it sounds dumb but I really like that stupid coffee machine. funeral home DJ fucked around with this message at 18:42 on Feb 8, 2015 |

|

|

|

Why the hell would you run a dedicated 120v circuit with a step up transformer instead of just running a 240v circuit?

|

|

|

|

Zhentar posted:Why the hell would you run a dedicated 120v circuit with a step up transformer instead of just running a 240v circuit? Seriously. If you're already going to spend $circuit to get it dropped, just get a 240V and an adapter cable.

|

|

|

|

Zhentar posted:Why the hell would you run a dedicated 120v circuit with a step up transformer instead of just running a 240v circuit? Whoops, I forgot to expand on that: As was explained to me, European power is 240v on one wire, neutral other. I was thinking in the off-chance that the unit depends on a neutral for internal grounding that having a draw on what it normally wants as a neutral might be a bad idea. Therefore having a 240v output on the one wire with a neutral on the other would be the easiest thing to emulate Euro power. Unless the neutral thing is complete bullshit and the machine won't care, in which case, yeah I'll get the electrician to run a 6-15 or whatever and be done with it. Edit: Now I'm thinking I'm full of poo poo because the Europlug doesn't have polarity, and I flipped the plug upside down and the machine worked just fine. Maybe I'm overthinking it. funeral home DJ fucked around with this message at 19:04 on Feb 8, 2015 |

|

|

|

|

| # ? May 30, 2024 18:04 |

|

The current draw always applies to both wires equally. Neutral just means the one that is connected to ground back at the panel. Sometimes the neutral is attached to a specific part of the appliance for safety reasons, like the outer ring in a light bulb socket. But your coffee maker doesn't assume anything about which one is neutral, because of the non-polarized plug that you mentioned. Just run a regular 240 circuit and enjoy not having a large bomb in your kitchen.

|

|

|