|

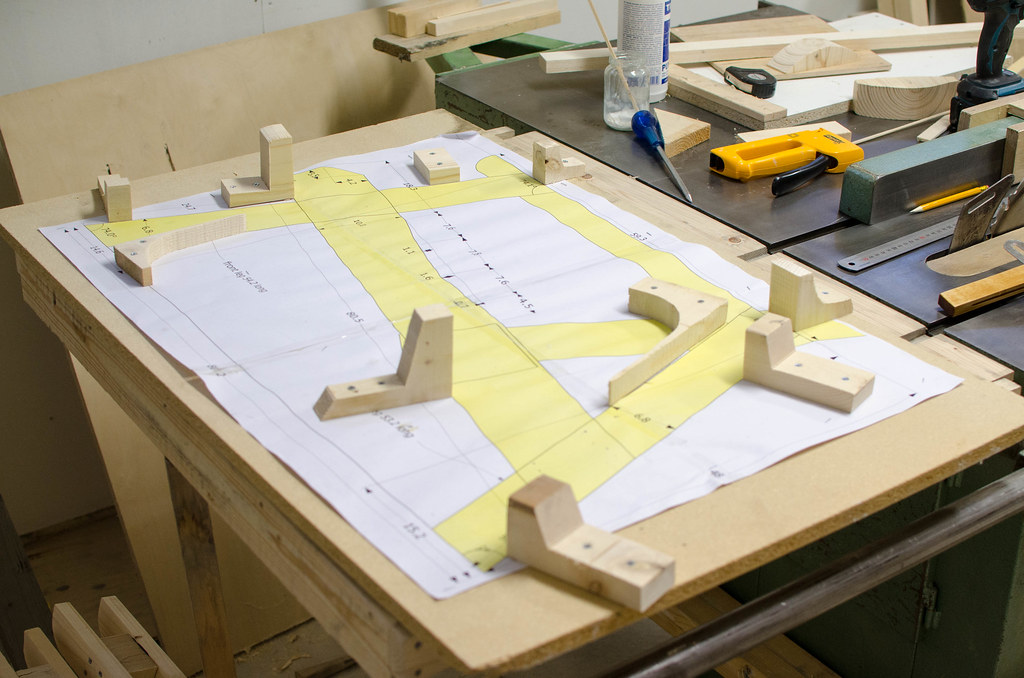

Made my 2nd chair, I ran out of glue when finishing the last chair so for this one I used construction adhesive, we'll see how it holds up over the years vs the wood glue.  Also made a jig for assembling the side frame:  Using a spokeshave to get the rear edge of the seat closer to the back, this wasn't in the plans but something I felt like doing:  Next to the 1st chair, makes a nice contrast:  Also a tool holding panel for the tools I use most while standing at the table saw. I like this method of attaching tools actually, makes them a lot less bulky than using french cleats:

|

|

|

|

|

| # ? May 30, 2024 22:40 |

|

One Legged Ninja posted:Don't try using one of those while holding the wood. Clamp it down firmly. They are not forgiving. Good advice. Also mind the rpm the drill is set at, you want it at 500rpm or so.

|

|

|

|

After the painstaking dresser build I felt like some sort of woodworking tornado when someone asked me to build this. What a relief.

|

|

|

|

taqueso posted:Recommend me a guide/tutorial about making a picture frame with nice corners and straight edges. Lots of youtube videos on making picture frames.

|

|

|

|

I was going to try and wet and bend some plywood but that didn't turn out very well, soaked them for a day+ and they still crack when bent. I assume there's gotta be steam or boiling water for this to work, not just water?

|

|

|

|

One Legged Ninja posted:Don't try using one of those while holding the wood. Clamp it down firmly. They are not forgiving. Thirding this. Clamp the poo poo out of it to your drill press table. Also rotate the cutter a couple times by hand to make sure it doesn't hit the clamps, its easy to do if you have a small workpiece.

|

|

|

|

His Divine Shadow posted:I was going to try and wet and bend some plywood but that didn't turn out very well, soaked them for a day+ and they still crack when bent. I assume there's gotta be steam or boiling water for this to work, not just water? What kind of plywood and how much are you trying to bend it? Does it need to be structural? If not can you get away with kerf bending?

|

|

|

|

Probably best with steam, btw. There are plenty of tutorials on the web for how, depending on how big you're talking.

|

|

|

|

Where do you triangle goons get wood. I was trying to grab some pine for some practice projects at home depot but the wood looked bad, like missing chunks or splitting. I might use some to build a sawhorse, but that's about it. Perhaps I missed where they keep all the furniture quality lumber but I was curious where you guys bought your wood.

|

|

|

|

His Divine Shadow posted:I was going to try and wet and bend some plywood but that didn't turn out very well, soaked them for a day+ and they still crack when bent. I assume there's gotta be steam or boiling water for this to work, not just water? I actually read this a long time ago, you need to make a steam box. http://www.instructables.com/id/How-to-make-a-steambox-for-bending-wood/

|

|

|

|

Voronoi Potato posted:Where do you triangle goons get wood. I was trying to grab some pine for some practice projects at home depot but the wood looked bad, like missing chunks or splitting. I might use some to build a sawhorse, but that's about it. Perhaps I missed where they keep all the furniture quality lumber but I was curious where you guys bought your wood. Actual lumberyards. Home Depot/Lowes lumber is the poo poo stuff that they hock to hobbyists who don't know any better. You should at the very least have a place in your area that sells decently straight 2x4s and fencing lumber and the like, and if you're reasonably lucky you'll also have somewhere selling hardwoods.

|

|

|

|

Voronoi Potato posted:I actually read this a long time ago, you need to make a steam box. http://www.instructables.com/id/How-to-make-a-steambox-for-bending-wood/ Yeah I was hoping to keep it simple, if slow, by just soaking. I saw John Heisz did that when he made some clamps, but I guess this plywood is more resistant to that kinda thing than natural wood.

|

|

|

|

I use a piece of 5" PVC for my steam box. All you have to do is buy the PVC caps and stick them on the ends. Do NOT glue them on to avoid a pressure build up and an explosion.

|

|

|

|

What do you use for your steam source?

|

|

|

|

|

Bad Munki posted:What do you use for your steam source? I bought a used fabric steamer at Goodwill for $3. Cut the steamer head off of it, then drilled a hole in the pvc pipe and stuck it in. Works great. Make sure to drill a drain hole in the bottom of the pipe too. Edit: one of these: http://www.amazon.com/Conair-Compac...=fabric+steamer Wall paper steamers work good too and you can find them used cheap.

|

|

|

|

Voronoi Potato posted:Where do you triangle goons get wood. I was trying to grab some pine for some practice projects at home depot but the wood looked bad, like missing chunks or splitting. I might use some to build a sawhorse, but that's about it. Perhaps I missed where they keep all the furniture quality lumber but I was curious where you guys bought your wood. There are lots of geographical areas called "The Triangle". On the off chance you mean RTP, I usually go to Capital City Lumber because it's fairly close and convenient. His Divine Shadow posted:Yeah I was hoping to keep it simple, if slow, by just soaking. I saw John Heisz did that when he made some clamps, but I guess this plywood is more resistant to that kinda thing than natural wood. Heat is what's important. The water carries heat into thicker pieces and guards against scorching. Thin pieces can be bent using a bending iron. edit; I'm not familiar with steam bending plywood. I know they make plywood especially for bending. Usually people kerf it to bend because the alternating grain directions would resist bending. Successful bending is as much about the grain and species as it is heat. wormil fucked around with this message at 06:17 on May 5, 2015 |

|

|

|

I know this guy did it with his build and I was interested in it for the same reasons, looked a solid design. Though perhaps I'll just make my own laminations from normal wood: https://www.youtube.com/watch?v=TnLjVFa4UWM Edit: BTW can you put wax over an oil finish for exterior use, or would it degrade fast? His Divine Shadow fucked around with this message at 11:45 on May 5, 2015 |

|

|

|

wormil posted:I'm no plane expert but I can give a short summary. Thanks, very useful information. When I bought a new Stanley block plane, I think the package said it was good for end grain, what is your opinion about planing end grain?

|

|

|

Crotch Fruit posted:Thanks, very useful information. I hope you have a drat sharp blade. A shooting board will help too.

|

|

|

|

|

Crotch Fruit posted:Thanks, very useful information. Echoing what Frogman said. If you don't use a shooting board, be really careful because you will end up with tear-out / splintering on the far edge. You can put a slight chamfer on the edge to mitigate that (so the blade won't catch the edge fibers and tear them away), but depending on what you're building that isn't always an option. What kind of wood? Apparently Woodcraft owns Japanwoodworker now, didn't realize that happened. I was talking to one of the employees at woodcraft yesterday and he said that some guy has bought $7000 worth of chisels, including this ridiculous $4000 set-

|

|

|

|

Regarding hand planes, someone bought me The Handplane Book by Garrett Hack. It's everything you've ever wanted to know about planes, how to sharpen them, how to use them, what types are used for what and why, their history, etc.

|

|

|

|

Re: bending talk . You can by "bending plywood" it has all the layers running in the same orientation and works really well. I get in 1/8" thickness from my local woodworking store. Then you just build up layers to the thickness you want. I had taken pictures of some experimenting I did with it but I can not find them. You can bend it to a pretty tight radius.

|

|

|

|

mds2 posted:Re: bending talk . You can by "bending plywood" it has all the layers running in the same orientation and works really well. I get in 1/8" thickness from my local woodworking store. Then you just build up layers to the thickness you want. If all the layers run in the same orientation, what makes it different than regular wood?

|

|

|

|

SkunkDuster posted:If all the layers run in the same orientation, what makes it different than regular wood? Keep in mind it is usually pretty thin. Only 2 or 3 layers and I dont know what is used for the core. Different? Well it bends easily right from the store. No re-sawing or anything required, it's cheaper, it comes in 4x8 sheets so you can make big things. Really just depends on the application. You wouldnt make a Maloof rocker from the stuff.

|

|

|

|

Crotch Fruit posted:When I bought a new Stanley block plane, I think the package said it was good for end grain, what is your opinion about planing end grain? I don't really have an opinion ... pro, I guess.  Kidding. The other guys seem to have covered it. Block planes are sort of catch all tools. They are small and can be carried on a belt or in a small toolbox. They come in different lengths, adjustable, not adjustable, low angle, high angle, normal. I personally don't have a specific use for block planes, as in: 'I always use a block plane for xxxxx.' I use them for chamfering, on end grain, for smoothing; but I also use larger planes for the those things, just depends on what's handy, what's sharp, and how big the wood is. SkunkDuster posted:If all the layers run in the same orientation, what makes it different than regular wood? It's made with contractors and cabinet shops in mind. Buying by the sheet is cheaper than the labor and shop space to do it from scratch. Here's a cool chair made from bending ply: http://www.instructables.com/id/Ramified-Armchair-bending-plywood/

|

|

|

|

So I made this small patio table from some 2x4s and some alder boards from the sauna, I just threw it together and looking at it now, well there's something off about it Not sure what it is, maybe it's that there's nothing connecting the legs lengthwise at the top of the legs... perhaps a board there, would also be good for stiffening the whole construction... Or maybe I should have made it a compound angle.

|

|

|

|

Made a work bench. Everything done by hand, planing, lamination, joinery. =)

|

|

|

|

keepitlikeitwas posted:Made a work bench. Everything done by hand, planing, lamination, joinery. =) Looks good! Looks like Paul Sellers' cut in half. I was thinking of a similar style myself.

|

|

|

|

His Divine Shadow posted:So I made this small patio table from some 2x4s and some alder boards from the sauna, I just threw it together and looking at it now, well there's something off about it It's the skinny legs. Throw some stretchers along the sides maybe, it just needs a little bulk on the bottom. It wouldn't hurt for stability/rigidity either.

|

|

|

|

keepitlikeitwas posted:Made a work bench. Everything done by hand, planing, lamination, joinery. =) How are the legs attached?

|

|

|

|

keepitlikeitwas posted:Made a work bench. Everything done by hand, planing, lamination, joinery. =) Why does Paul Sellers type of bench need such beefy vertical sides?

|

|

|

|

bimmian posted:It's the skinny legs. Throw some stretchers along the sides maybe, it just needs a little bulk on the bottom. It wouldn't hurt for stability/rigidity either. Actually have that addition in sketch-up. It needs weight, still shakes when planing. wormil posted:How are the legs attached? Dados on the aprons. iv46vi posted:Why does Paul Sellers type of bench need such beefy vertical sides? The dado joinery on the aprons. Long aprons and long dados lock the legs in place.

|

|

|

|

bimmian posted:It's the skinny legs. Throw some stretchers along the sides maybe, it just needs a little bulk on the bottom. It wouldn't hurt for stability/rigidity either. Yeah I think I'll add stretchers along the sides and perhaps also another board to the legs to make an L-shape, maybe a taper too...

|

|

|

|

iv46vi posted:Why does Paul Sellers type of bench need such beefy vertical sides? Google English or Nicholson Workbench.

|

|

|

|

His Divine Shadow posted:So I made this small patio table from some 2x4s and some alder boards from the sauna, I just threw it together and looking at it now, well there's something off about it I think something that small looks kinda weird with splayed legs, myself. I also think the angle of the photo makes it look a bit like the legs aren't square to the top, lengthwise, but that might just be the angle of the photo.

|

|

|

|

thespaceinvader posted:I think something that small looks kinda weird with splayed legs, myself. Yea I thought the same, must just be the perspective.

|

|

|

|

I'm less and less enthused with the whole design, thinking of redoing the legs completely and add proper rungs.

|

|

|

|

His Divine Shadow posted:So I made this small patio table from some 2x4s and some alder boards from the sauna, I just threw it together and looking at it now, well there's something off about it I think it's okay but would benefit from thinner or tapered legs and slightly shorter rails/aprons. Or make it longer. Basically it's a proportion thing.

|

|

|

|

I'd also say that it looks a little weird with widthways rails, but not lengthways ones. It's a perfectly functional design, it's just non-standard, so it looks a little odd.

|

|

|

|

|

| # ? May 30, 2024 22:40 |

|

Well I had use for it today so I am using it as is for now.   Maybe just some lengthway rails (now I know what's the proper word for it in english) would help.

|

|

|