|

Beech carves well too, quite cheap, rather hard though, so I'm guessing not too different from maple. If you can find the unsteamed stuff it makes for a nice hard and light carving wood. Linden may be my go-to, but sometimes it's just too much on the soft side.

|

|

|

|

|

| # ? May 30, 2024 17:04 |

|

I'll keep in mind on the wood selection. It wasn't a highly planned project: to fart around in the shop I made a dovetailed napkin holder out of a chunk of scrap cherry to test out my most recent 3d printed dovetail template, and then midway through I saw a Wood by Wright video about doing decorative carving so I printed off a celtic knotwork design and gave it a shot. My very sharp small gouge was causing fewer problems, but I think if I ever decide to carve cherry again I'd do a much much much less detailed pattern because the big thing was that bits just flaked out. It will hold napkins and I will keep it until I decide that I'm in the mood to make a new, better one, and then I'll burn it. I also cut on the wrong side of the line in two places and misused the template as a guide in one other

|

|

|

|

How much value do you think a planer loses in about 18 months? I was considering buying this one, which would come to just under $600 after tax. So I messaged an acquaintance who bought the same planer in 2020 to see if he's still happy with it. He said it's great, but he has since moved to a new house with a better shop space and upgraded to a big boy planer. He offered to sell me his for $450. I wouldn't pay $450 to some rando on kijiji, but he's an instructor at the local community center woodshop, so he probably takes decent care of his tools. I'll likely take some of his classes in the future so I don't really want to negotiate too hard. I'm considering accepting the $450 if he'll throw in a free lesson or something.

|

|

|

|

Kaiser Schnitzel posted:These are really cool what's the process for making them like? Hollow out two boards and glue them back together? For the large one, yes. I 3D printed a template:   Carved out the middle. Made a mirror copy. 2 holes are used as registration marks when gluing together. (I use 2 screws and a couple of clamps) I then use the same holes the template and draw it the outline and cut it out on the bandsaw. Just make sure you put the template on in the right direction. (Next one will have 2 holes on 1 side and one on the other to avoid any mistakes). Small ones are just cut from 1 4/4 board. I drill a pilot hole all the way through. Drill for the top brass fitting about 1/2" down and then used a forstner bit to to cut a 5/8 hole from the other side. Used 1/2" piece of a 5/8" dowel to re-plug the whole and then drilled/tapped for a brass crew for filling.

|

|

|

|

Awesome, thanks. There's a distinct possibility this saves me having to look at 47 different teals and 'choosing my favorite', before being informed that the one I chose is not gonna work with our furniture.

|

|

|

|

CommonShore posted:I'll keep in mind on the wood selection. It wasn't a highly planned project: to fart around in the shop I made a dovetailed napkin holder out of a chunk of scrap cherry to test out my most recent 3d printed dovetail template, and then midway through I saw a Wood by Wright video about doing decorative carving so I printed off a celtic knotwork design and gave it a shot. My very sharp small gouge was causing fewer problems, but I think if I ever decide to carve cherry again I'd do a much much much less detailed pattern because the big thing was that bits just flaked out. Did someone say 3d printing in the wood shop?! I attempted to rip off Jonathan Katz-Moses and tried making my own dovetail saw guide. It worked okay, but I opted to buy the real thing.  I got the dimensions pretty close by guessing but the magnets in his are way better. Mine was also too tall limiting the depth of cut if your saw had a spine.

|

|

|

|

Double posting to ask for a long shot, but does anyway have the cutter head from an old planer laying around? I'm toying with the idea of building a 12“ jointer a la Matthias Wandel.

|

|

|

|

NomNomNom posted:Double posting to ask for a long shot, but does anyway have the cutter head from an old planer laying around? I'm toying with the idea of building a 12“ jointer a la Matthias Wandel. Yes, actually. I've got a stock Dewalt 735 head. I also have a jointer 6" cutterhead. Interested?

|

|

|

|

Cannon_Fodder posted:Table done, so what drat that's some nice grain. any closeups? revtoiletduck posted:How much value do you think a planer loses in about 18 months? IDK, go take a look at it, is it worth $450 to you? it's not like shop tools spoil on the shelf like milk, if it's been 18 months of light use it's basically new and that's already a pretty good deal. If it's been 18 months of slamming nailboards in and cranking the cutter head all the way down 24/7 it's all hosed up inside and that's why he's getting rid of it already.

|

|

|

|

NomNomNom posted:Did someone say 3d printing in the wood shop?! That was exactly what I made hah but I didn't try putting magnets in yet, which is probably why it didn't go so well. I gained a bit of shop budget recently by selling something so maybe I'll order one from him if the shipping to Canada isn't gently caress-you prices. e. I've also printed a set of Paul Sellers style ones and I prefer them so far based on my one use of the JKM style one compared to the n uses of the Sellers ones. You can't use them as cutting guides but I haven't actually felt like a cutting guide was what I needed. For me the biggest challenge is marking the pins once I've cut my tails. CommonShore fucked around with this message at 16:12 on Jan 13, 2022 |

|

|

|

Cannon_Fodder posted:Yes, actually. Yes! Does the dewalt include the bearings still? Just have to source a motor and pulley and I'm in business. Rough plan is to scalp a treadmill for the DC motor, speed controller, and melamine deck. The decks on them are very sturdy and flat, and I think I can laminate some steel plate onto it for a reference surface. Might even have the pulleys I need.

|

|

|

|

A Wizard of Goatse posted:IDK, go take a look at it, is it worth $450 to you? The guy you're buying it from sounds like they're a serious woodworker so I would wager that the planer has seen usage somewhere between those two extremes. Probably lots of proper use (i.e. no nailboards, not maxing out the cutter), and good maintenance. For $450, I'd look it over and maybe give it a run through with a board to see if it acts funny, but otherwise a good purchase. I want to say I've been using my similar style planer now for a bit over a year (or a bit under? I can't remember) and I'm just now at the point where I need to replace the blades and I've been using it about twice a week, but the motor and screws work great because I keep it lubricated and blow out dust and wipe it down after every use. My previous posts about it acting funny are almost certainly because the blades are starting to wear, and some resin build up on the feed tables.

|

|

|

|

NomNomNom posted:Yes! Does the dewalt include the bearings still? Just have to source a motor and pulley and I'm in business. My life is being flipped due to a work thingy so I won't be home for a week at least. PM me your details and I'll check how much it'll be to ship over.

|

|

|

|

Cannon_Fodder posted:Table done, so what Oh that's purdy. My progress is not as interesting -- two trestle shoes for the workbench done. 4 1/2"x3 1/2", same as the legs that are also done and ready to get tenon'd up.

|

|

|

|

Hello! I've found myself suddenly needing to make something out of wood and I have a couple really beginner questions. I hope this is a good place to ask? I want to make some sort of wood version of these single-action retactable casters that this guy has, but I have no tools aside from a power drill. I think I can get away with buying a portable table saw to get me the rest of the way (or asking a table-saw-owning-friend to help me for a day). Does that sound insane? Also I was wondering how I could make some 2x2 inch (actual size) stand-offs to extend the legs of this table I have:  The table is made out of MDF pieces. I've been thinking I could probably use a 2x4 for the legs, but if the sizes are too different, it might look weird. Here's some ideas I've been brainstorming: * Use a 2x4 -> easy, cosmetically painful?? * Cut up 0.5" ply wood and screw two pieces to a 2x2? -> also weird looking? * Make 2x2 columns from pieces of thick ply wood screwed together * The recommended way seems to be to take a 4x4 and rip it down to size on a table saw -> I think this is a good idea, but as someone who's never used a table saw before, this sounds the hardest...

|

|

|

|

Cory Parsnipson posted:Also I was wondering how I could make some 2x2 inch (actual size) stand-offs Not commenting on the caster question, because imo, that leads to "buy more tools," but to make the standoffs you're looking for, you can do that easily with a basic miter saw, or circular saw. Outlay there is less than $60 and you have a good, basic tool afterwards. The problem with working with small pieces and a table saw is that you get your fingers very close to the blade. That's something you should avoid at all costs.

|

|

|

|

You can also use hand saws if you don't want to spend big money. You trace a straight line (straight edge, string, whatever) and saw to it, which you'd do with a circular saw anyway. Any jobbing saw will probably be fine, but Japanese pull-saws are great and quite cheap, as well.

|

|

|

|

I've tried using hand saws before and I had a really hard time making straight cuts. If I practice and get the right stuff could I make cuts with a handsaw that are basically indistinguishable from a power tool cut?

|

|

|

|

Cory Parsnipson posted:I've tried using hand saws before and I had a really hard time making straight cuts. If I practice and get the right stuff could I make cuts with a handsaw that are basically indistinguishable from a power tool cut? Yes. It helps to mark and prepare properly. It's a skill to learn, for sure, but you get the hang of it pretty quickly. A hand-plane will basically clean up the cut if it's not right, or you could do a lot of sanding if it's softwood. Edit: obviously not *indistinguishable* but functionally the same as a circular saw cut. Power tools often make use of dead-straight metal tracks, and therefore making and adapting jigs and tracks is the skilled part of power tool use, which some people are super into. SimonSays fucked around with this message at 23:05 on Jan 13, 2022 |

|

|

|

Yes - there are a number of hand-tool workers in this thread who never use a power saw for anything. That said, there's a learning curve for any tool/technique. I'm not 100% clear on the standoffs you want to make, but I'll second that a table saw is in no way an entry-level tool, and the cheaper/smaller one is, the more dangerous it is.

|

|

|

|

Cory Parsnipson posted:I've tried using hand saws before and I had a really hard time making straight cuts. If I practice and get the right stuff could I make cuts with a handsaw that are basically indistinguishable from a power tool cut? Yes. And I've found that the simple technique of using your thumb knuckle as a guide works wonders.

|

|

|

|

meatpimp posted:Not commenting on the caster question, because imo, that leads to "buy more tools," but to make the standoffs you're looking for, you can do that easily with a basic miter saw, or circular saw. Outlay there is less than $60 and you have a good, basic tool afterwards. SimonSays posted:You can also use hand saws if you don't want to spend big money. You trace a straight line (straight edge, string, whatever) and saw to it, which you'd do with a circular saw anyway. Leperflesh posted:Yes - there are a number of hand-tool workers in this thread who never use a power saw for anything. That said, there's a learning curve for any tool/technique. Ah I see. I thought getting a table saw would be quickest for me to get started. Thanks for the replies, everyone! I am still doing research and there's a lot of good leads to look into here. SimonSays posted:Yes. It helps to mark and prepare properly. It's a skill to learn, for sure, but you get the hang of it pretty quickly. A hand-plane will basically clean up the cut if it's not right, or you could do a lot of sanding if it's softwood. I didn't word that very well. I was wondering if I could use a hand saw to make precise, straight cuts so the pieces would fit together flush like if I was making a box or something. I can see that there's tons of people making amazing stuff with hand tools, so that was kind of a dumb question. My bad.

|

|

|

|

Cory Parsnipson posted:

Yes, and a hand plane with shooting board will guarantee the fit.

|

|

|

|

Power tools tend to be very good at doing one thing repeatably. A miter saw is great if you want a bunch of cross cuts at the exact same angle and a table saw is great for ripping a bunch of pieces to the exact same size. But if you don't need that "a bunch of ... exact" part, the power tool doesn't actually save that much time or effort compared to the hand tools on many tasks. E.g. if I want to cut off a chunk of 2x4 I can go to my miter saw, but if I only need one, I'll often just grab a hand saw because once you set up the miter saw the amount of time saved, if any, is in the magnitude of tens of seconds. This isn't true of every task obviously. If I want to rip an 8 foot chunk of 2x4 into two 2x2s I'm going to set up the table saw for that cut. And I own several bits-and-braces but I usually just grab a power drill for most holes.

|

|

|

|

Also, a handheld circular saw with a clamp-on fence will do nearly everything the table saw will do anyways, and do it a lot safer. Lay your plywood over a 2" thick sheet of foam sheet board(not the polystyrene beads one, the dense polyurethane stuff), and set your blade depth properly and you'll be set.

|

|

|

|

Other option I am sure someone locally could cut down lumber to size you need. My local wood store will run something on table saw for $1 a cut if purchased the lumber there. The will run stuff though a planner and jointer for 10cents a board ft

|

|

|

|

And don't forget your blade kerf. If you cut a 2 foot board in half then put them back together, you will not have 2 feet of length.

|

|

|

|

THE BANDSAW CUTS

|

|

|

|

Look for a ryoba saw. It's a Japanese 2 in one pull saw. It has a crosscut side and a rip cut side. It costs like 20 bucks. It works on the pull stroke making it much less clumsy than a 'regular' (European) saw. Honestly, I love these. The blades are super thin so you're not eating time cutting through more waste, and are always in tension so they track straight. Watch a video on how to saw straight with one and throw $20 bucks at the experiment. I'd argue they saw better with no real experience than a push saw. Also, make your life easier and bust out your pocket knife and make a notch on the corner of what you want to cut. Drop the saw into that tiny notch and just slowly start the cut. Always let the saw do the work and do long easy strokes. Saws go all over the place regardless the kind if you try to force the cut. The weight of the saw will be enough to get great results in smallifying wood.

|

|

|

|

Crossposting from the Interior Design Q&A Thread I'm not sure what to do with these side tables. I made them for my old sofa and they don't fit with my new sectional. The one in the back is 23.5" tall and looks weird. The one in the front I've stacked to 20.5". I think that might be a better height? I know the classic mid century look is with the really low side tables, but I always felt like tables that low aren't really functional.    I also don't like the leg style I went with. I'm thinking maybe something like these: https://www.etsy.com/listing/1003166312/set-of-4-table-legs-high-quality-metal or these: https://www.etsy.com/listing/952129437/18metal-table-leg-coffee-table-leg

|

|

|

|

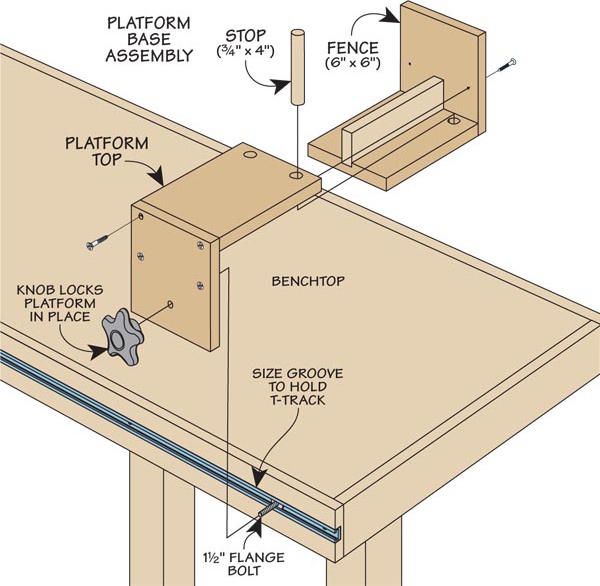

I donít see myself ever putting a face vise or really any kind of wood working vise on my work bench(it more an assembly table than proper bench). I would buy/build a proper bench first. So do put a piece of plywood on the front and add my extra t track to function as a poor manís face vise?

|

|

|

|

can't picture what you're describing but t track isn't going to serve any function on a vise more than once, you might as well just get a couple extra bar clamps

|

|

|

|

Calidus posted:I donít see myself ever putting a face vise or really any kind of wood working vise on my work bench(it more an assembly table than proper bench). I would buy/build a proper bench first. So do put a piece of plywood on the front and add my extra t track to function as a poor manís face vise? Donít rule it out. Getting a face vise has been transformative for me. Easily one of the most important things in my shop.

|

|

|

|

imo good workholding is like the most important thing

|

|

|

|

A Wizard of Goatse posted:can't picture what you're describing but t track isn't going to serve any function on a vise more than once, you might as well just get a couple extra bar clamps Kinda like this.I could use clamps to hold a piece and work on a edge or end.

|

|

|

|

Calidus posted:Kinda like this.I could use clamps to hold a piece and work on a edge or end. I mean... that's just a lovely vice, right? Your screws are bound to flex horribly or break if you're actually trying to hold something down. Same with the thin bits of wood.

|

|

|

|

You can get a cheap 7" face vise for like $50 or less and it will hold stuff well enough.

|

|

|

|

if you have it in your head you 100% don't want a vice, that's totally doable. I just think your solution won't be very robust for beefier work... https://www.youtube.com/watch?v=kzv27STMnvY Here's an example of clever and proven work-holding features for woodworking. A good chunk are super useful even if you do have a vice.

|

|

|

|

You could also do a moxon vise, depending on the size wood you're working with.

|

|

|

|

|

| # ? May 30, 2024 17:04 |

|

Cannon_Fodder posted:if you have it in your head you 100% don't want a vice, that's totally doable. I just think your solution won't be very robust for beefier work... I have a bench with most of the features in this video, and it also includes a leg vise. I use the holdfasts about 90% of the time now that I've learned how useful they are.

|

|

|

EVERYWHERE

EVERYWHERE