|

Darchangel posted:Looks like the doorframe might be out of square. My house likes to shift and do that (crappy soil on my region with lots of clay - amount of rainfall changes the soil a lot, despite having piers installed.) Easy to check with a square. PainterofCrap posted:Ja whoever installed that door probably used a square & measured & used a level, etc assuming it was all plumb & square. Thanks, that's what I expected.

|

|

|

|

|

| # ? May 30, 2024 21:28 |

|

Finally got around to replacing a kitchen drawer with a busted drawer slide this weekend. The new drawer, which was custom made but not by me, is VERY stiff opening/closing. It looks to me that some combination of my measuring and the manufacturer's building might have made it just a hair too wide, like....1/16" or something. Just wide enough it can still fit into the slides, but it just slightly presses out on them to make the movement so stiff. Plus, it has a "soft close" feature when the drawer is roughly 2" open, and that does not work until the drawer is close to 1/2" open...and I have to actively push it the entire way to that 1/2", if you catch my drift...it's too stiff to just sort of "set it and forget it" as it should work by giving it one big shove. With the tools that I have, I'm thinking the best fix is one of a few things: 1) Mark the width of the slides on the drawer, remove the slides on the drawer (leave the ones on the inside of the cabinet), and use my router table with a 3/4" straight cut bit to just barely route a groove for the slides...like, start at maybe like 1/32" deep on each side and see if that helps. 2) Use my table saw to just rip off a saw blade's width from one or both sides of the entire drawer. Obviously, I'd have to do two passes per side by flipping it since the drawer is ~4.5" tall. 3) The same idea as #2, but just with a hand plane...but I own no hand plane and haven't really ever hand planned in my life, so that's a factor there.

|

|

|

|

DrBouvenstein posted:Finally got around to replacing a kitchen drawer with a busted drawer slide this weekend. Can you tell the manufacturer it doesnít fit and ask them to fix it? Unless youíve got calipers you really donít have any reason to blame yourself for mis-measuring; they just as easily could have messed up their tolerances setting up the machine to make your drawer.

|

|

|

|

is it possible for an LED bulb to have a luminous efficiency greater than 100 lm/W? I've noticed that for converting watts to lumens, the ratio is always between 90-100, i.e. a 5W LED is 450 lumens, and a 8W LED is 800 lumens. But I found one bulb that is 5W and claims to be 550 lumens, which would give 110 lm/W, and I'm thinking maybe it's just a typo this site claims that it's possible, at least? i've just never seen another bulb like this though (it's from satco - https://www.lightbulbs.com/product/satco-11430) https://www.etechbag.com/led-light-efficiency/ "LED bulbs produce 90 to 112 lumens per watt. This Compact fluorescent lamps produce 40 to 70 lumens per watt, and conventional incandescent bulb fixtures only produce 10 to 17 lumens per watt."

|

|

|

|

Lawnie posted:Can you tell the manufacturer it doesnít fit and ask them to fix it? Unless youíve got calipers you really donít have any reason to blame yourself for mis-measuring; they just as easily could have messed up their tolerances setting up the machine to make your drawer. At this point it's been too long since I ordered it, since I slacked off on the install. I did do a quick "dry fit" with the slides when I got it, but since it is off by such a small amount, the dry/test fit seemed like it was fine.

|

|

|

|

PainterofCrap posted:Ja whoever installed that door probably used a square & measured & used a level, etc assuming it was all plumb & square. Considering a forum name change to "creative trim cutting"... nah.

|

|

|

|

So I bought a shed, approximently 4x8 base. I plan on putting it on the side of my house on the pathway but the pathway is not level, it's angled so water doesn't sit on it (concrete slab.) I need to build a platform so I can keep the shed level, any recommendations on adjustable feet? I plan on just building a base that is made out of 2x4s.

|

|

|

|

lol internet. posted:So I bought a shed, approximently 4x8 base. As a total novice, a cinder block base seems like a better choice so the lumber doesn't rot as fast.

|

|

|

|

lol internet. posted:So I bought a shed, approximently 4x8 base. Get some of those concrete pylon feet, put shims on the wooden cap to level it out, put your 2x4s across the shims.

|

|

|

|

My puppy is currently teething and is trying to chew everything in sight when the urge strikes her. We usually shove something to chew on in her mouth when we see her getting agitated, but the other day we didn't notice and she went and did this: What are my options for repair? Do I need to replace the corner bead or can I just sand the area down and apply new drywall mud and then paint?

|

|

|

|

Mud and paint.

|

|

|

|

Whats the name of the stuff thats not shoe molding and not quarter round? It typically goes in the same spot, at the bottom of the wall and/or next to baseboards. Its quarter round but in the opposite direction?

|

|

|

|

wesleywillis posted:Whats the name of the stuff thats not shoe molding and not quarter round? Are you talking about inside corner moulding? https://www.homedepot.com/b/Building-Materials-Moulding-Millwork-Moulding-Corner-Moulding/Inside-Corner-Moulding/N-5yc1vZcbjfZ1z1rurt

|

|

|

|

Motronic posted:Are you talking about inside corner moulding? https://www.homedepot.com/b/Building-Materials-Moulding-Millwork-Moulding-Corner-Moulding/Inside-Corner-Moulding/N-5yc1vZcbjfZ1z1rurt YES! Thats the stuff. Thanks!

|

|

|

|

Also called Cove Molding.

|

|

|

|

TooMuchAbstraction posted:Get some of those concrete pylon feet, put shims on the wooden cap to level it out, put your 2x4s across the shims. Ughh was not looking for something that high since it's already on a concrete slab. Beef Of Ages posted:As a total novice, a cinder block base seems like a better choice so the lumber doesn't rot as fast. If there is an option sure, but I don't mind just re-doing the floore 5 years from now or just potentially getting ground treated wood.

|

|

|

|

lol internet. posted:Ughh was not looking for something that high since it's already on a concrete slab. Then use PT (or otherwise ground-contact-rated) 2x4s and put shims between them and the shed  The shims don't need to be ground contact rated so long as they're an inch or so above ground level and things dry out on a reasonably regular basis. The shims don't need to be ground contact rated so long as they're an inch or so above ground level and things dry out on a reasonably regular basis.

|

|

|

|

I used paving stones stacked or recessed into the ground as needed with paver sand underneath for my 10x20 shed, but itís entirely on dirt. 2x6 PT platform, with flashing between the pavers and wood to limit insect interest. You could still use the pavers to if you need the 1Ē or so of lift, various steel shims if less? Like they used to adjust the piers on my house foundation. Itíll rust, of course, so be ready for that.

|

|

|

|

If you put steel in contact with pressure-treated wood, make sure that steel is galvanized or stainless. Mild steel will have a chemical reaction with PT wood that will cause it to rust much more quickly.

|

|

|

|

Oo, good call. I forgot about that.

|

|

|

|

My husband keeps breaking the stone coasters. What's the best adhesive to repair them? Based on the 1977 fix it book I have super glue would be less than ideal, due to the stone and cork being porous, compared to hot melt glue or epoxy. Has that advice changed since then?

|

|

|

|

Maigius posted:My husband keeps breaking the stone coasters. What's the best adhesive to repair them? Based on the 1977 fix it book I have super glue would be less than ideal, due to the stone and cork being porous, compared to hot melt glue or epoxy. Has that advice changed since then? thistothat is a good resource for what adhesives to use for various materials. It doesn't have entries for stone or cork, specifically, but it suggests using epoxy for gluing ceramic to wood, and that makes sense to me.

|

|

|

|

I'm fixing these two short overhanging roof sections bracketing my garage door. Based on similar homes in my neighborhood, these were originally constructed with fascia nailed to the ends of the beams, and the roofing material should have lapped over the edge. I am adding new fascia as well as drip-edge flashing. As you can see, although these segments of roof are pretty narrow, due to the false gable over the garage door, they actually drip all the water that lands on the field of roof from the entire width of the garage up to the main hip at the top. But there's some problems. The biggest problem is on the right-hand rooflet (right as I face the house):  The beam on the left has some rot at the end, and is also a bit loose. I can lift it a couple inches at that end, which brings the rooflet back to level across the face.  I'm thinking about replacing this beam. But I'm not sure what it's attached to. The stucco is built up around the base of the beam, so if I try to pull it out, I may damage the stucco. I may also damage whatever's behind it. The wall behind this is boxed in and finished, so I'd have to move a bunch of poo poo in the garage and tear open that wall to get a view from behind. Also, the flashing on the side of the rooflet is nailed through a small piece into this beam, so I'd have to pull that off, maybe gently caress it up too.  These filler boards are set at an angle, e.g. they're square to the roofline, not to the wall. Can I pull one off and see the construction behind it? Are they cosmetic, or structural? Basically... anyone know how this is likely to be constructed? This is a 1957 California cheap wood frame construction house. The second issue is on the other side:  On this side, the rooflet is more or less square. But the outside beam, which is very long (I wanna say at least 16 feet, although I haven't measured it) has a bit of rot at the end, and also a twist. My wife wants me to just buy fascia board large enough to cover up the twists and rot and poo poo and not worry about it. We'll likely need a new roof within the next ten years anyway, and we can get this fixed properly at that time. I, on the other hand, hate to cover poo poo up, and in particular on the right-side with the sag I think the fascia board is either going to highlight the sag or make it worse or both. Any quick fix to this? I have tools for carpentry and fine woodworking, I can cut lumber to any shape needed, I have ladders, etc. and I even have half a pack of matching roofing asphalt tile if I need to pull off some... but I would like to not damage the intact stucco and I'd also really like to get this fixed in one day, because we need to paint the house really really soon.

|

|

|

|

Maigius posted:My husband keeps breaking the stone coasters. What's the best adhesive to repair them? Based on the 1977 fix it book I have super glue would be less than ideal, due to the stone and cork being porous, compared to hot melt glue or epoxy. Has that advice changed since then? e6000 multipurpose craft glue is supposed to glue stones and other jewelry together and to mountings. Maybe look into that.

|

|

|

|

Leperflesh posted:I'm fixing these two short overhanging roof sections bracketing my garage door. Based on similar homes in my neighborhood, these were originally constructed with fascia nailed to the ends of the beams, and the roofing material should have lapped over the edge. I am adding new fascia as well as drip-edge flashing. As you can see, although these segments of roof are pretty narrow, due to the false gable over the garage door, they actually drip all the water that lands on the field of roof from the entire width of the garage up to the main hip at the top. With the caveat that my brain is roughly mush right now: For your first problem, my inclination is to cut the rotten board short, leaving a foot or so of it exposed. Then butt a new board up to it end-to-end, and nail gussets (another board, or a sheet of 1/2" plywood) across the two to hold them together. You want the gusset on both sides of the join, though. And this will only work if the rotten board is actually sound (not rotten) closer to the house. That board is, at minimum, attached to the sheathing of the house. It's entirely possible (in my limited experience, likely) that it's actually a rafter, meaning that it penetrates the sheathing and is supporting the roof deck. Notice that it's the same size as the outermost rafter? If that's the case, you're not replacing that without a lot of careful demolition work first. I'd save that for when you re-roof the house; at that point, you can have the roofers remove the old roof and expose the roof deck, which should make working on things a lot easier. For your second problem, the good news is that that board (called a "barge rafter") is not structural. Its dimensions were chosen for aesthetics; it only needs to be big enough to provide a reasonably rigid nailing surface for the shingles and flashing of the roof. You can do a lot of "surgery" to the board without compromising your house, in other words, and the rot doesn't really matter. The bad news is that it's supported by nailing through it into the ends of some 2x4s, probably something like this:  If you want to replace it entirely, you'll need to remove whatever bits of the roof are nailed to it, and then pry it off of those 2x4s. Then you get to reverse that process to install the new board. This is not really a one-person job and is kind of a pain in the rear end. Again, what I'd recommend instead is cutting off the rotten parts of the board, and then butting up a new board onto the end, with some gussets or straps to hold the two together.

|

|

|

|

OK, so fun fact: this house has no sheathing. None. It has stick construction, with angle bracing to fight shear forces: a felt/paper wrap with wire in it, and then stucco applied directly on top. There's also no insulation. The board on the left side of the right-hand rooflet moves when I lift it, it's definitely just a couple feet of 2x6. Notice that there's a little gable above the garage, I think that's why there's no rafter there that they could have run out the front to be that support. I'm just not sure how the end of it that penetrates the stucco is attached to the house, so I'm loathe to start trying to rip it out. And I think only the last two or three inches of the board are rotten, from water running across and getting sucked in by the endgrain for a decade or two. As for the barge board, I suppose I could cut the rotten end off and add a new piece of wood using gussets as you suggested for the other board.

|

|

|

|

Leperflesh posted:OK, so fun fact: this house has no sheathing. None. Having the gable right on top of that means it's probably kind of complicated construction and only accessing it from below means it will take you 2 days and alot of cussing whereas the roofer's carpenters can replace it in 45 minutes with part of the roof deck removed. There's a pretty decent chance that has sagged since the house was built and I wouldn't worry about it. That's what trim is for. Taper or angle the fascia to minimize the visual appearance of that sag. If you can really lift the rafter up, you may be able to get some shims under it when you remove the little trim pieces to explore. I'd do what your wife says and just hide the twisted/rotted rafter until you do roof work. E: just saw that the rooflet rafter thing is toe nailed in? If that's the case it should be much easier to replace-still going to involve cutting/replacing the nails from the roof deck because the roof deck (and theoretical fascia) is what's really holding it up.

|

|

|

|

Yeah I wasn't really thinking about that part but you guys are right, the roofing is nailed into that piece so replacing it means getting up there and pulling the roofing back, removing or cutting the nails on the decking, etc. Probably not gonna bother with that poo poo for now. Thanks for the consult.

|

|

|

|

Pulled off a ledger board for the old closet shelving and found a surprise! Am I right in thinking this is not trustworthy and should get cut out before I patch the drywall? Is it just a big blob of solder slapped over a pinhole leak?

|

|

|

|

lwoodio posted:Pulled off a ledger board for the old closet shelving and found a surprise! Am I right in thinking this is not trustworthy and should get cut out before I patch the drywall? Is it just a big blob of solder slapped over a pinhole leak? I don't see any reality in which that isn't a badly patched pinhole leak. Especially from behind a ledger board (whoops, we missed and hit the pipe with a drywall screw!). If you can just cut that out and sweat in a female-female connector. Depending on what movement you have in that pipe it could be easier said than done though. Are you taking more/the rest of that sheetrock doing above and below? Or was that hole already there? If so lol it's what I said above.

|

|

|

|

I don't give a poo poo about my lawn, mostly. That said, taking the dog out to play when it's very wet has left a lot of bare spots. I'm assuming grass seed will fix this but I don't know where to begin. I'd appreciate any advice, thanks.

|

|

|

|

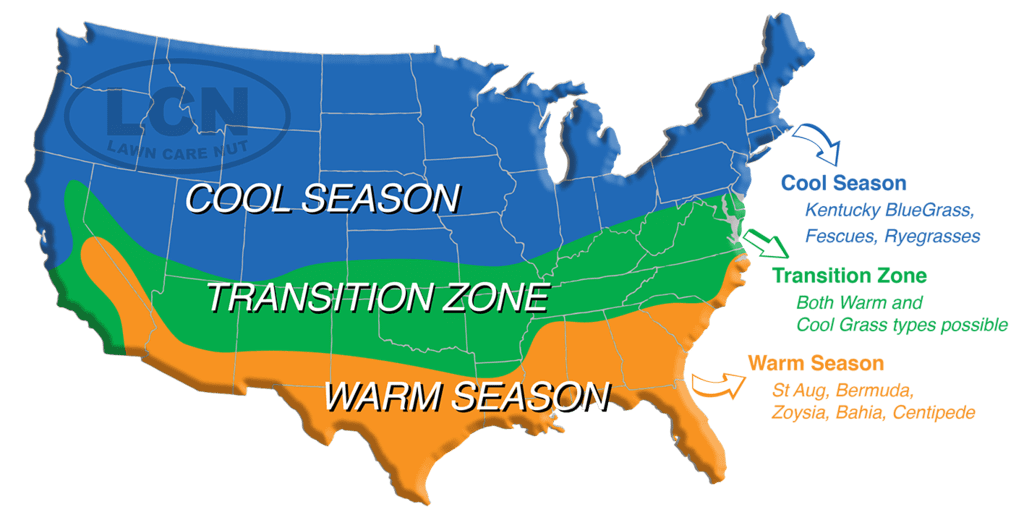

Where are you located? Is the ground warm there already? It's pretty easy to grow grass, you need to keep the seeds moist until they sprout and the ground needs to be warm enough. If it is dry, mulch helps enormously in keeping the seeds moist. Your location will dictate if you want to use cool-season or warm-season grass.  If you don't care too much, seeds from the hardware store will be fine and they probably won't even stock seeds that aren't appropriate for your area. Grab 'starter fertilizer' to go with the seeds. If you decide you do care, you can order modern cultivars that are designed for heavy activity like football games or public parks that will survive a dog better. This is a deep hole to start down, enter with caution. taqueso fucked around with this message at 03:15 on Mar 4, 2022 |

|

|

|

lwoodio posted:Pulled off a ledger board for the old closet shelving and found a surprise! Am I right in thinking this is not trustworthy and should get cut out before I patch the drywall? Is it just a big blob of solder slapped over a pinhole leak? Always a possibility that there was actually a saddle tap installed on that pipe to get water to run an icemaker, humidifier, laundry steamer, sauna etc... in the closet at one point. Any weird electrical outlets or junction boxes in the closet as well? Could have even been something like a half-assed way to turn a whole house humidifier's water supply on and off from in the closet if that was the nearest place to tap into a water line for it. Definitely sweat in a new copper union if you are going to drywall over it as already suggested.

|

|

|

|

lwoodio posted:Pulled off a ledger board for the old closet shelving and found a surprise! Am I right in thinking this is not trustworthy and should get cut out before I patch the drywall? Is it just a big blob of solder slapped over a pinhole leak? Anyone that would hire squirrels to cut an access hole for their lovely pipe repair is, by nature, untrustworthy. Ask your future self this: are you sure you want to (at random, but many times, and always at 3AM) have Brain weave for you your Tell-Tale-Drip nightmare, envisioning the ten tons of crap that you will eventually have to ship out of that closet to repair this properly?

|

|

|

|

PainterofCrap posted:Anyone that would hire squirrels to cut an access hole for their lovely pipe repair is, by nature, untrustworthy. This, plus also imagine all that stuff potential damp/wet/ruined. Also the mold in the carpet and drywall. Why, no, of course I've never experienced this.... I have. Edit: they were comic books. Nothing rare, but still.

|

|

|

|

Elviscat posted:Pop rivets like you'd get in a regular rivet gun won't match.

|

|

|

|

[moving to wiring thread]

ryanrs fucked around with this message at 08:07 on Mar 8, 2022 |

|

|

|

I have a 1200 lb lathe that I want to lower into my basement by way of a temporary ramp then justbwinch it down the stairs. There is a man door from my garage that is a straight shot to my stairs. If I were to make a plate with a shackle and sink 3 drop in anchors into my garage floor, bolt to plate to my floor and use it to hook the qinch or come along to what are rhe odds of failure? I have no idea how thick the floor in my garage is though :/

|

|

|

|

I won't take odds, but please film this either way. Is there any existing structure that you could use? 1200lbs isn't a lot in the scheme of things. I'd probably try to attach it to the opposite wall, ideally through several framing members.

|

|

|

|

|

| # ? May 30, 2024 21:28 |

|

fps_bill posted:I have a 1200 lb lathe that I want to lower into my basement by way of a temporary ramp then justbwinch it down the stairs. There is a man door from my garage that is a straight shot to my stairs. If I were to make a plate with a shackle and sink 3 drop in anchors into my garage floor, bolt to plate to my floor and use it to hook the qinch or come along to what are rhe odds of failure? I have no idea how thick the floor in my garage is though :/ Can you bring a vehicle into your garage and hook it up to that? I'd imagine a trailer hitch would be rated for 1200lbs pulling on it no problem?

|

|

|