|

Voron's beef with Slice now is kind of irritating. I still haven't seen the prior art everyone is insisting exists for the Mosquito.

|

|

|

|

|

| # ? May 29, 2024 08:30 |

|

RabbitWizard posted:Not sure if PrusaSlicer supports it, I use SuperSlicer but can't hurt to mention it: A smart tip, that was what threw me off (I looked at just using a modifier, but apparently Skirt Brim only seems to pop up for shapes.) I'll give that a spin on the next print then, I can just chop a little bit off of the model in maya and use that as the shape. Seems to be possible in prusaslicer as well, it's just that it's a bit unintuitive which options can be used on shapes, and which can be used on modifier volumes. Thanks!

|

|

|

|

SubNat posted:I can just chop a little bit off of the model in maya and use that as the shape.

|

|

|

|

Dr. Fishopolis posted:Hey, your images aren't showing up but if you edit this please thumbnail them this time to keep the thread readable! No images this time. Super deluxe 24k resolution next set. NO TABLES NO MASTERS Nerobro posted:TL;DR: Don't drive yourself crazy. You're still working with shovels and plowshares. If that first layer sticks, you're doing just fine. Right now, I'm looking to get a 3x3 inch solid single layer (with three perimeter walls, also single-layer) to: 1) not scrape the loving bed with the nozzle (first and foremost) 2) not have giant furrows like a Kansas cornfield (seem to have gotten that sorted) 3) actually be solid and not a venetian blind effect with occasional connection between slats First layer in a normal print is going to have more goo piled on top, but 2 and 3, as best I understand, mean there's going to be extra material getting plowed more and more as it gets higher, or a nice sink effect going as further layers keep trying to fill in what;s missing.  Right now, where I'm at is "nozzle very high" - except the lines that *are* laid down adhere nicely - and it's running across most of the print, starting right about where "nozzle way too low" is ending. (Print starts bottom right, ends top left.)  What I'm getting is more like the lower image, except thinner actual lines (so no squish), and at random spots there's tiny bits of material that do reach the next line over - but they're also thin as well, and will break free with almost any flex or pull. (The lines themselves aren't breaking and everything - including the connecting bits - is solid on the bed and I'm having to use the scraper to peel it off.) I'm not looking for "the most pristine first layer every time", I'm still trying to get "a first layer that doesn't have nasty fuckups that will cause issues higher up the stack", as well as "stop loving grinding on the bed in places". (The ABL should be adjusting for areas where the bed might be fractionally higher, right? It's not bent up or bulged, it's that one corner likes to register 0.25 mm high for unknown reasons.) (Bubbled print in that area didn't grind, though, so maybe that's fixed too. But I already have a couple of visible grooves from the Prison Shankomatic 3000, and I'd like to avoid more for the time being.) Also I have to remember to get some 2-gallon Ziploc bags because 1-gallon to too small for a spool, and a metric-labelled tape measure, so I can do that extrusion testing, and otherwise I'm horsing filament and 30-cm-max digital calipers at the same time, and still with only two hands. Oh, and yet another Great Moment In N00bness: I found out there's apparently a *smooth* side to the bed, too. (Via a Facebook post, at that.

|

|

|

|

Ygolonac posted:and a metric-labelled tape measure, so I can do that extrusion testing Make this your top priority. Calibrating your e-steps should be one of the first things you do when you get a new printer or change your extruder.

|

|

|

|

slurm posted:Voron's beef with Slice now is kind of irritating. I still haven't seen the prior art everyone is insisting exists for the Mosquito. Can you post some context for this? I haven't been paying attention and this sounds really stupid.

|

|

|

|

Wibla posted:Can you post some context for this? I haven't been paying attention and this sounds really stupid. This is 2022 so it's all on Discord, lol, but here's the closest I've found to a summary https://www.reddit.com/r/VORONDesign/comments/rpyqpq/voronslice_beef/

|

|

|

|

Here4DaGangBang posted:To be honest, this just seems like a bad use case for 3D printing. Like you said earlier, you could have just bought clay chips and been done with it. They’ll have a better feel and sound than 3D printed chips to boot, I suspect. 🤷🏻♂️ I mean, you're not wrong. It's just that... I guess I don't have any reasonable defense here. I'm a masochist.

|

|

|

|

Lemme just stop at Harbor Fright, pretty sure bet they'll have a cheap metric (or dual-marked) tape measure... Off to Walmart, then... OK, Home Despot, won't be cheap, but... <sigh> Lowes? The one three miles away? The one fifteen miles away. Dammit. After work tomorrow, then, if they don't sell out of the seven they claim to have in stock.

|

|

|

|

Lowest common denominator

|

|

|

|

|

Here4DaGangBang posted:To be honest, this just seems like a bad use case for 3D printing. Like you said earlier, you could have just bought clay chips and been done with it. They’ll have a better feel and sound than 3D printed chips to boot, I suspect. 🤷🏻♂️ I want to let everybody know that this post convinced me to just buy the clay chips.

|

|

|

|

Ygolonac posted:Lemme just stop at Harbor Fright, pretty sure bet they'll have a cheap metric (or dual-marked) tape measure... lmao oh no that's insane honestly i would amazon some metric digital calipers, they're good for more than just calibrating extruders.

|

|

|

|

Dr. Fishopolis posted:lmao oh no that's insane I live out in western buttfuck Kentucky. Same thing I go through looking for tools that I want sooner than later. There’s no options for anything out here. Goddam one grocery store in town doesn’t even shelve brown rice because it’s too ‘exotic’. Have to drive thirty minutes through the countryside to get to a Kroger.

|

|

|

|

Dr. Fishopolis posted:lmao oh no that's insane At least those ubiquitous cheap digital calipers all have mm, surely?

|

|

|

|

BMan posted:At least those ubiquitous cheap digital calipers all have mm, surely? Yes, thankfully, but pick up some extra batteries because the cheap ones burn through em

|

|

|

|

Dr. Fishopolis posted:Yes, thankfully, but pick up some extra batteries because the cheap ones burn through em Modded mine so I can actually turn the drat thing off

|

|

|

|

BMan posted:Modded mine so I can actually turn the drat thing off I just now printed one of these myself (well a similar one) and am installing it.

|

|

|

|

Well now I feel silly for doing a mod that requires taking the calipers completely apart and putting them back together (very annoying)

|

|

|

|

Unperson_47 posted:I just now printed one of these myself (well a similar one) and am installing it. This is genius, but looks like I need to remove the USB to use it. Still absolutely worth it as I've used that USB Micro a whopping zero times.

|

|

|

|

I modded mine with a AAA battery pack stuck to the back side. Makes it a little bulkier, but I haven't changed the batteries in like 5 years.

|

|

|

|

Unperson_47 posted:I just now printed one of these myself (well a similar one) and am installing it. What does this do that just pressing the power button doesn't?

|

|

|

|

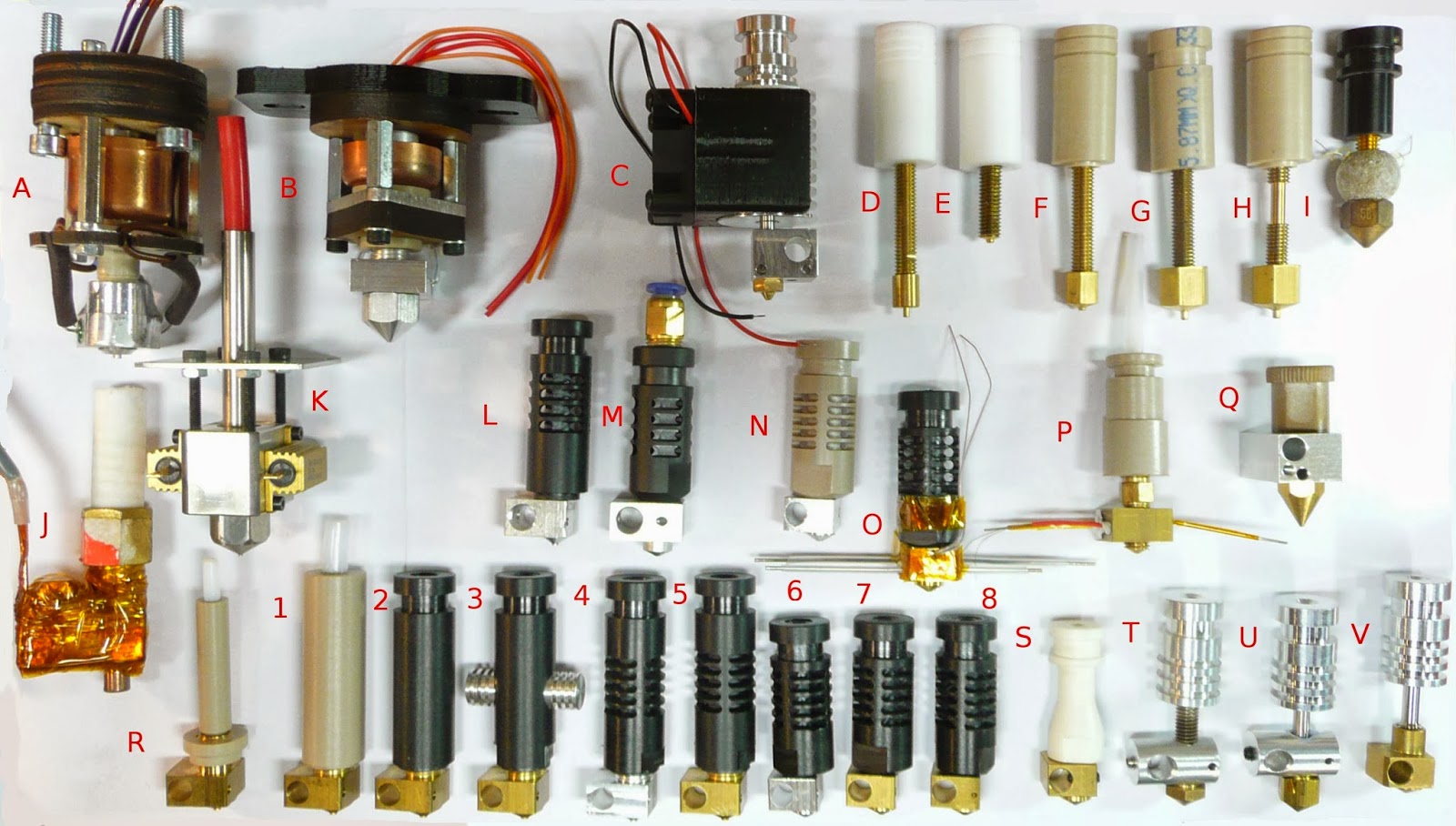

slurm posted:Voron's beef with Slice now is kind of irritating. I still haven't seen the prior art everyone is insisting exists for the Mosquito.  Slices patent is screws and tubes to hold the heater block to the heatsink. It looks like some prior art there in the Budaschnozzle (A & B) and the MakerBot one (K). The Slice patent specifically "innovates" by making the tubes separate from the screws, and is inclusive of 2-5 tubes holding them apart. Nobody had issue with Slice going after the NF Crazy. That was a complete knockoff. Going after the Dragon was quite a stretch, considering that Creality hotends already fixed the heaterblock to the heatsink via screws too, and the Dragon was a rigid-mount V6-style hotend with V6 heaterblock. Completely different form factor and target machine. Then the fact that they went after literal "man in his garage" vendors with cease and desists and forced licensing, instead of going after bigger companies, just soured us quite a bit. insta fucked around with this message at 13:08 on Sep 2, 2022 |

|

|

|

Acid Reflux posted:I modded mine with a AAA battery pack stuck to the back side. Makes it a little bulkier, but I haven't changed the batteries in like 5 years. Digital calipers with a lantern battery would be a pro move IMHO.

|

|

|

|

Apocalipers

|

|

|

|

Vaporware posted:Apocalipers Priscilla! Bring the wheelbarrow over here, I need to measure a screw. No no, the 3 volt one.

|

|

|

|

As I am kind of new to the hobby I have a few questions about the marketing claims of 3D printers, mostly in regards to speed. Are speed and quality inexorably linked? Such that if I have detailed pieces the speed needs to be around 50mm/s or lower, regardless of rated speed of the machine? For example my Anycubic Kobra boasts having speeds of up to like 180mm/s, but is there a use case in which you would ever actually run it that fast? Are most of the marketing claims about being faster than the competition all kind of bullshit, or based on weird stuff no one would print regularly? Like you can print a giant rectangle with no detail really fast, faster than others with this printer? But not something useful. For terrain printers, do you like adaptive layer height? I sliced a few pieces with adaptive layer height and it seems to cut down on time and add detail to things like lamp posts, columns, stele, etc, but for other things it is not so much adaptive as it is the lowest setting for most of the piece and then a few areas widen up. Like an Obelisk has so much slope that the adaptive layer height has the whole model as the finest layer height allowed.

|

|

|

|

IncredibleIgloo posted:As I am kind of new to the hobby I have a few questions about the marketing claims of 3D printers, mostly in regards to speed. Speed is mostly linked to quality, in essence that "acceleration is linked to ringing". There's no real quality difference on a big, long run at 50mm/sec & 250mm/sec. The difference comes from the toolhead changing direction rapidly around corners. Since most prints are not big, long runs -- your speed comes from mostly getting up to velocity quickly after direction changes (and slowing down quickly before direction changes). This is acceleration. The more powerful your motors are, the faster you can accel/decel. The lighter your motion system, the faster you can accel/decel. The more rigid your motion system, the faster you can accel/decel. There is an area long before the motion system is physically incapable of changing direction, where the parts just look bad. This is usually from backlash and ringing/ghosting, where the rubber belts and flexible frames act like literal springs on direction changes and vibrate/ring at the machine's resonant frequency. An example is here:  The cheapest way to fix ringing is to just lower the acceleration of the machine so the frame & belts can't really build up the kind of stresses necessary to cause it, but this lowers the average perimeter speed. Beyond that, replacing linear rods with linear rails helps. Isolating the printer from its surface helps (the paver + foam system). Klipper's Input Shaper helps by attempting to model the ringing in software and generate motion moves to counteract it. This is the reason "Klipper makes machines faster". It doesn't allow the machine to move physically faster, that was always there (*), it allows the machine to change direction quicker while maintaining the original quality it had, by compensating for the ringing entirely in software. The other limitation on speed is flow rate, and this you can easily hit on any machine during the infill. The hotend can only melt the plastic so fast, and engineering tradeoffs between thermal mass / hotend melt zone / retraction performance / price are fierce. Creality printers use cheap Mk8-style hotends that top out around 6mm^3/s of flow. If you have 150% infill width through a 0.4 nozzle @ 0.2 layers, 6mm^3/s gives you a max of 50mm/sec infill before you start to outrun the performance of the stock Ender3 hotend. This is partly why the stock profile and firmware are so conservative, it just physically can't melt plastic fast enough in some cases. Outrunning during infill isn't a huge deal, you can probably push it to 80mm/sec before you suffer too much drop in extrusion, and the outer perimeters won't go fast enough to hit the limit. On a delta or corexy, the perimeters can move fast enough that you will outrun lower performance hotends like the Mk8, so higher performance hotends exist. I run a Dragon HF with a 0.4 CHT nozzle in my Voron, and I can actually outrun that during infill moves (I limit them to 50mm^3/s for reference -- 0.3 layers, 0.72 infill width, 227ish mm/s infill is IIRC where it ends up). You don't see the infill, so let it go as fast as your machine can move. (*) old, cheap boards with 8 bit microcontrollers sometimes couldn't generate step pulses fast enough to go fast while still doing all the other work of reading SD cards, doing motion planning math, etc. Klipper/RRF offload these higher-level calculations to a full on microprocessor like an ARM chip, which sends "move here at this time" instructions to the onboard micro. The micro can just worry about sending pulses at the right time, so it can generate much more accurate pulses at a much higher rate to boot.

|

|

|

|

ToxicFrog posted:What does this do that just pressing the power button doesn't? The cheap ones will turn back on if you so much as bump them, so this blocks the connection so it can't do that.

|

|

|

|

ToxicFrog posted:What does this do that just pressing the power button doesn't? Cheap calipers have a relatively high draw even when off, particularly compared to expensive ones. I've seen measurements like 1 microamp versus about 14 microamps. Small currents, but small batteries, and enough to make it go flat in the drawer much faster. Hard off switch, no vampire draw.

|

|

|

|

That was very helpful, thank you!

|

|

|

|

I think I thoroughly fuckered my ender 3's nozzle, and it has me wondering if I should just upgrade the stock hotend at the same time. Any recommendations? It's my main workhorse printer for printing out wargaming terrain and dice towers. Generally printing at .2mm on a0.6 nozzle w00tmonger fucked around with this message at 18:07 on Sep 2, 2022 |

|

|

|

w00tmonger posted:I think I thoroughly fuckered my ender 3's nozzle, and it has me wondering if I should just upgrade the stock hotend at the same time. If you've been happy with the Ender3's stock setup, keep it as-is. Entire replacements are single-digit dollars. If you want a drop-in upgrade replacement, the MicroSwiss is pretty good if you go for the steel nozzle too, you can throw about anything you want at that. If you want a bit more of an upgrade, go for the Dragonfly BMS.

|

|

|

|

Dr. Fishopolis posted:lmao oh no that's insane I actually have a legit Mitutoyo one (garage sale find, probably walked out of a manufacturing plant up here), but it's 30 cm max. I'd rather clip the filament to the end of a tape measure with a bulldog clip and run both out at the same time to whatever length I need to clip again. I'm at work now, so it's only an additional 8 miles round trip distance added to my commute.

|

|

|

|

insta posted:If you've been happy with the Ender3's stock setup, keep it as-is. Entire replacements are single-digit dollars. Every time I order pretty much anything from Creality, they send a couple extra nozzles. I think they figure you're going to need to replace them somewhat regularly. I went ahead and replaced mine when I swapped out the feeder, because it was like 30 extra seconds. I'll probably put the old one back on as soon as I have an actual reason to replace a nozzle, since it was probably fine.

|

|

|

|

insta posted:If you've been happy with the Ender3's stock setup, keep it as-is. Entire replacements are single-digit dollars. welp, I'm grabbing a dragonfly. I didn't realize they made a drop-in replacement and I'm loving my phaetus hotend on my voron so why not worst case it'll get integrated into the ender to switch-wire conversion I eventually want to do

|

|

|

|

w00tmonger posted:I think I thoroughly fuckered my ender 3's nozzle, and it has me wondering if I should just upgrade the stock hotend at the same time. Nozzles are consumables, you should keep a bunch on hand and replace them pretty regularly. Definitely don't replace your whole hotend just because your nozzle wore out. The only reason to replace the stock hotend is to move to an all-metal for stuff other than PLA. The stock ender hotend will generally do PLA better than those replacements by default.

|

|

|

|

Dr. Fishopolis posted:Nozzles are consumables, you should keep a bunch on hand and replace them pretty regularly. Definitely don't replace your whole hotend just because your nozzle wore out. I hear ya, but I've been getting pretty wacky with thicker layers, higher speeds, and fancy materials anyways. I have extra nozzles around to get it up and running, but grabbing a hardened steel 0.6 and the dragonfly opens Me up to print in pretty much anything.

|

|

|

|

w00tmonger posted:I hear ya, but I've been getting pretty wacky with thicker layers, higher speeds, and fancy materials anyways. Doesn't steel have worse thermal properties than brass? Not trying to dissuade w00tmonger from anything, just trying to square something that got in my brain against reality.

|

|

|

|

cruft posted:Doesn't steel have worse thermal properties than brass? Yes. Solid tungsten carbide is the drop in replacement for brass, but it's expensive and lots of people print happily with hardened steel.

|

|

|

|

|

| # ? May 29, 2024 08:30 |

|

cruft posted:Doesn't steel have worse thermal properties than brass? Definitely, but it's your only reasonable option for abrasive filaments, which is a LOT of filaments.

|

|

|