|

|

|

|

|

|

| # ? May 28, 2024 05:39 |

|

Sockington posted:Just an ďanythingĒ table: a base of operations for anything building related, outfeed for the table saw, or the router end table. I wish an image could be a thread title

|

|

|

|

Sockington posted:Just an ďanythingĒ table: a base of operations for anything building related, outfeed for the table saw, or the router end table. Lmao

|

|

|

|

Sockington posted:Just an ďanythingĒ table: a base of operations for anything building related, outfeed for the table saw, or the router end table.

|

|

|

|

Lol

|

|

|

|

|

tracecomplete posted:Water-based finishes usually turn yellow less than oil ones. I haven't used it, but General Finishes has a line they claim dries clear. In particular I'm really interested in their Dead Flat formulation. I can vouch for it drying clear. I've got a hickory tabletop I made, and 3 layers dried pretty darn clear

|

|

|

|

Kaiser Schnitzel posted:

Can it be a background?

|

|

|

Sockington posted:Just an ďanythingĒ table: a base of operations for anything building related, outfeed for the table saw, or the router end table. lmao

|

|

|

|

|

Sockington posted:Just an ďanythingĒ table: a base of operations for anything building related, outfeed for the table saw, or the router end table.

|

|

|

|

Some of my wood has rotted on an out building's roof, what would be the best filler or putty to use to replace it? It's mainly just about keeping it structurally sound (haven't seen any sagging or anything but better safe than sorry), doesn't really matter how it looks.

|

|

|

|

NotNut posted:Some of my wood has rotted on an out building's roof, what would be the best filler or putty to use to replace it? It's mainly just about keeping it structurally sound (haven't seen any sagging or anything but better safe than sorry), doesn't really matter how it looks. I've used bondo and this powderstuff I think it's called rock water putty on exterior trim. None of this stuff has structural value. You want that, sister in pieces of rafters, whatever's rotted.

|

|

|

|

NotNut posted:Some of my wood has rotted on an out building's roof, what would be the best filler or putty to use to replace it? It's mainly just about keeping it structurally sound (haven't seen any sagging or anything but better safe than sorry), doesn't really matter how it looks. Sawing out the wood, putting a new chunk in with an interlocking ship lap or some other joinery+lag bolts/whatevs, and then fix your roofing or watershed issue that caused the rot in the first place.

|

|

|

|

Almost got hit with a piece of wood kicking back from my dado stack, got lucky with the arrangement of the fence and miter gauge deflecting it. Phew. Put everything away and went inside to work on a day where I didn't almost seriously injure myself.

|

|

|

|

I've cut out and replaced larger pieces of rotten wood (we're slowly painting the house and I'm repairing as we go) but for much smaller, nonstructural bits, I scrape and cut away all teh soft punky stuff and then fill with... wood filler. Nasty little can of smelly stuff that you squish into the hole, might need a couple layers if it's really deep. Let it dry, sand, paint & finish as normal. Eventually it'll fail and need to be replaced but it's probably buying me another decade in those spots. Which may well mean it's the next owner's problem. This is the stuff.  store the can upside down per instructions, don't huff it because I'm sure it's extra cancerous

|

|

|

|

Leperflesh posted:I've cut out and replaced larger pieces of rotten wood (we're slowly painting the house and I'm repairing as we go) but for much smaller, nonstructural bits, I scrape and cut away all teh soft punky stuff and then fill with... wood filler. Nasty little can of smelly stuff that you squish into the hole, might need a couple layers if it's really deep. Let it dry, sand, paint & finish as normal. Eventually it'll fail and need to be replaced but it's probably buying me another decade in those spots. Which may well mean it's the next owner's problem. Lol that's the same stuff we used on lovely trim joints. God, it's been around at least 50 years. And yeah, it's solvent based, *edit- I think I can read acetone on the label, which checks.

|

|

|

|

Mr. Mambold posted:Lol that's the same stuff we used on lovely trim joints. God, it's been around at least 50 years. And yeah, it's solvent based, It's basically wood fibers and limestone/quartz filler in nitrocellulose lacquer per the TDS and MSDS. The other really good wood filler-FamoWood-is basically the same but it comes in more and better colors and dries a bit faster IME. If they dry up and get hard, you can add lacquer (not lacquer thinner) to soften them again. There is a good water-based wood filler called Timbermate that smells real funny, dries super fast, and is easier to sand (the lacquer based stuff really clogs sandpaper) but if used with water-based dyes it will soften up and pull out. Works great with oil stains, but I don't think it's as strong as the lacquer based ones. NotNut posted:Some of my wood has rotted on an out building's roof, what would be the best filler or putty to use to replace it? It's mainly just about keeping it structurally sound (haven't seen any sagging or anything but better safe than sorry), doesn't really matter how it looks. If it's structural, cut it out, scab/dutchman in a filler piece, sister another board across the whole joint.

|

|

|

|

Mr. Mambold posted:Lol that's the same stuff we used on lovely trim joints. God, it's been around at least 50 years. And yeah, it's solvent based, I work at a woodworking company and we fill in a lot of imperfections and knot holes with black sikaflex of some kind, before it's processed in the CNC. Turns out looking very natural on the wood we use which is heat treated pine (the pine turns dark all through from it). I also saw this week how they applied a quick fix job to some damages on an otherwise good part. They have Tupperware boxes of sanding dust, which they mix with polyurethane glue of some kind, then fill in the damage with that. I couldn't find the flaws the next day when I came to look at it.

|

|

|

|

Mixing sanding dust with glue to fill damage is a time honored tradition and works better than it has any right to.

|

|

|

The junk collector posted:Mixing sanding dust with glue to fill damage is a time honored tradition and works better than it has any right to. yeah it's great and you almost certainly have all the ingredients already

|

|

|

|

|

I haven't been impressed with the results from PVA glue personally. I think it turns too white-ish looking and if you put any finish on it it often stands out as a brighter patch. I assume polyurethane works better.

|

|

|

|

Brought all the tops outside and sanded them down yesterday. Oh, so thatís what it is supposed to look like

|

|

|

|

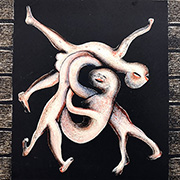

I thought the porn subforum had closed.

|

|

|

|

anatomi posted:I thought the porn subforum had closed. Yeah, no homegrown allowed!!!!

|

|

|

|

Aww shucks fellas. Fixed up the old 14Ē bandsaw with a new insert and some newer style guides that arenít just grindy noise makers.  Previous owner had duct tape bandsaw tires and all guides waaaay outta whack, so his zero clearance insert was quite something.  Iím thinking Iíll get the Kreg fence kit for it eventually to make life easier.

|

|

|

|

Mederlock posted:an interlocking ship lap or some other joinery+lag bolts/whatevs Kaiser Schnitzel posted:scab/dutchman in a filler piece, sister another board across the whole joint. Is there any place to learn about carpentry so I can understand stuff like this? Basically all I know is screwing in shelving, sawing two-by-fours and maybe nailing them to some plywood.

|

|

|

|

Just google the jargon, apparently everyone has their own doofy name for a butterfly joint https://jonpeters.com/how-to-make-a-dutchman-joint/ For the kind of home maintenance you're doing there's a bunch of basic Popular Mechanics/Better Homes and Gardens etc. books on keeping a house up that cover timber framing and roof repairs and everything in between. they'll treach you enough to at least start to have an idea what you're looking for.

|

|

|

woah tinkercad has physics simulation. lets try it out on my project

|

|

|

|

|

such accuracy...

|

|

|

|

NotNut posted:Some of my wood has rotted on an out building's roof, what would be the best filler or putty to use to replace it? It's mainly just about keeping it structurally sound (haven't seen any sagging or anything but better safe than sorry), doesn't really matter how it looks. Can you send us a picture of what you're seeing? If it's roof sheathing/decking you'll want to remove the affected area and then plug it with a board and sheathing patch between the rafters/trusses

|

|

|

|

NotNut posted:Is there any place to learn about carpentry so I can understand stuff like this? Basically all I know is screwing in shelving, sawing two-by-fours and maybe nailing them to some plywood. If you're a beginner, I'd recommend trying something more like this, then. It's called sistering, and it's easier than making a fancy joint to do a pretty in line joint. It's basically sandwiching the damaged joist/rafter/whatever with 2 fresh boards. Heres a decent video. https://youtu.be/bqYTf4QHc8w But yeah, it'll certainly help if you could post some pictures and we can point you in the right direction

|

|

|

|

Been a while since I've done much in the shop, was procrastinating on adding this router table to my table saw wing With that done, let's make a Moravian foot stool!  First time trying a sliding dovetail. This will be a good test run for a dining table I want to build. I'll post a follow up once I finish the legs.

|

|

|

|

Finished up a toddler tower a few weeks ago - it's getting good reviews. I built it out of a leftover half sheet of 3/4" plywood and a little dowel, and too many coats of polyurethane to protect the wood and the toddler from each other. Lots of lessons learned on this thing.

|

|

|

|

That looks fantastic, nice job on the adjustable step tracks.

|

|

|

|

That looks great and yeah, plugging pocket hole screws fuckin suckkks. If I canít cover the whole row of them with a little 3/16Ē thick piece of trim I donít use them.

|

|

|

|

How sketchy is it to plunge cut with a circular saw? I had to cut a trapezoidal pocket in plywood, and the way I did it was to clamp down a straight-edge, tip up the saw with the shoe aligned along the straight-edge, pull up the guard, hold the trigger, and tip the saw back down till it was flat against the wood. It Worked, and well enough that I'd rather do this than gently caress around with a jigsaw and a router. Exposed blade on an unconstrained saw is probably not great, but how bad is it really? e: Also, I'm stepping back to finishing the table saw sled I abandoned a few years back and it's a giant pain in the rear end. Building it was easy enough, but gently caress if I can align the rear fence to cut square. I can't get the hang of the "make x number of cuts, do trig on them to calculate how much you need to adjust", and I have no idea how to actually apply a fine adjustment to the fence. I'm at the point where I'm going to just buy a few parts to rig up a simple differential screw to adjust and hold the position of the rear fence until I can screw it to the base. HolHorsejob fucked around with this message at 08:42 on Apr 24, 2023 |

|

|

|

It's a tried and true technique that is a bit sketchy. It's safe enough if you go slow, use a fence like you did, and make sure there's nothing in the path of the blade/saw if it were to kick. Some old framers wouldn't ever lock the sole plate of their circular saw. Can use it like a mini chop saw that way.

|

|

|

|

A Wizard of Goatse posted:Just google the jargon, apparently everyone has their own doofy name for a butterfly joint https://jonpeters.com/how-to-make-a-dutchman-joint/ Thanks, I'm going to look at Basic Carpentry by Better Homes and Gardens

|

|

|

|

I need a bigger lathe. I love my current ancient lathe, but it only has 12Ē of swing (more like 8Ē over the banjo) and for an upcoming job I need at least 14Ē and would love to have more down the line. I mostly do spindle turning so bed length is important too. From what Iíve gathered, the two companies that make lathes with basically infinitely expandable beds are Oneway and the Laguna REVO line. I used to turn the occasional porch column and it would be nice to have that capability again if needed. It looks like Nova has 20Ē bed extensions you can theoretically add on forever, but that seems less ideal than the Oneway or Laguna systems of just slapping a whole nother bed on the end. I know very little about Nova except that they make good chucks-nothing at all about their lathes. I know Oneway is top of the line and priced to match. Iím 100% certain it would be a great lathe and do everything I could ever need, but for as little turning as Iíve been doing lately itís probably way overkill for my needs. If I found a used one for a good price that would be ideal, but that seems unlikely. Iím a little concerned that the Laguna beds/ways are some kind of welded steel instead of cast iron-anyone have opinions? Especially hands-on experience with the Laguna Revo lathes? All the features seem nice and well thought out but my experience with Lagunaís prosumer market stuff from Taiwan hasnít really blown me away.

|

|

|

|

Im planning to re do my quite small pantry to get rid of the wire shelves. Its about 35" wide, Ill make the shelves about 20" deep. I figure ill do wall battens with 3/4 ply shelves and edge banding. The battens would support on 3 sides. Right now looking at plain sliced red oak ply as its one of the cheaper light colors plain sliced plys available near me. My question comes down to wall batten sizing. I figure the battens are really only supporting a vertical load mostly directly over the fasteners going into the studs. So I should be able to get away with a pretty small batten right? Maybe even using some L shaped aluminum extrusion, it can be had pretty cheap, and I imagine it would be able to tuck mostly behind the boards. Ideally I like the floating shelf look, but I dont really want to spend the time and effort on framing the whole thing out, covering in ply, and mounting. I have limited space already so 3" thick shelves are a turn off. EDIT: I may be using the wrong word? Battens, cleats? Just a horizontal strip of material whos whole goal in life is to transfer load from a stud, through a fastener, to a shelf. Sadi fucked around with this message at 15:05 on Apr 25, 2023 |

|

|

|

|

| # ? May 28, 2024 05:39 |

|

Sadi posted:Ideally I like the floating shelf look, but I dont really want to spend the time and effort on framing the whole thing out, covering in ply, and mounting. I have limited space already so 3" thick shelves are a turn off. You'll probably be fine with small battens if you go that way at only 35" wide, but with how popular floating shelves have become there's a lot of brackets available reasonably now that will get you most of the way to the floating shelf look without needing a super thick box if you dig around on Amazon or wherever.

|

|

|