|

senrath posted:Each color was a separate print and later assembled. The link has a gallery of in-progress shots. it's misleading to characterize it as "straight off the p1p" in that case  looks great though

|

|

|

|

|

| # ? May 28, 2024 05:41 |

|

Thanks for the help, everybody! This is what you helped me fix, a 75 year old radio.

|

|

|

|

If you're charging money for these repairs, I would keep tuning that printer; that piece isn't the greatest. If it's just for you and you're happy with it, then it's as good as it needs to be (but also keep tuning that printer) Is the gold cone thing it's attached to also a print?

|

|

|

|

|

Javid posted:Is the gold cone thing it's attached to also a print? Sure is. My first two designed parts. That only took several... dozen attempts to get right. For what it's worth, the other side looks better. This is a rotary dial. It's possible to turn 180 degrees. How do I tune it? kid sinister fucked around with this message at 02:19 on Sep 4, 2023 |

|

|

|

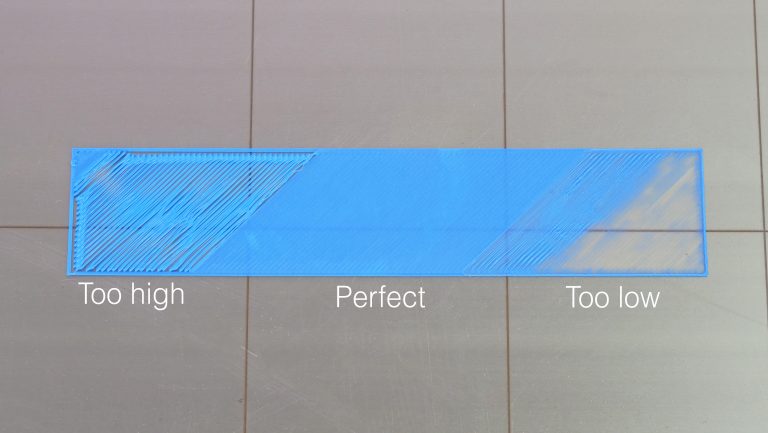

Gold cone looks fine, I can't tell if you're using a giant layer height or the part is supposed to have the ringed steps in it but that could maybe be smoother if you want it to be. this, though.  Since the visible gold piece looks fine, I'm guessing that's your bottom layer. It looks like your nozzle is too far off the print bed, which is why you've got the very clearly separated spaghetti lines visible. My printer is not perfect, but here's about how much smoother and cleaner a bottom layer can reasonably be; you want the nozzle close enough that each line is squishing into the one next to it.

|

|

|

|

|

Javid posted:Gold cone looks fine, I can't tell if you're using a giant layer height or the part is supposed to have the ringed steps in it but that could maybe be smoother if you want it to be. Eh. I might leave the cone. The radio case is actually kind of art deco and it fits. Let me try adjusting the first layer myself instead of letting the printer find it.

|

|

|

|

read this article https://help.prusa3d.com/article/first-layer-calibration-i3_112364

|

|

|

|

kid sinister posted:Any FreeCAD experts here? I'm trying to cut away a Sketch from a Pad. I can't figure out how to do it though. I think it's because the cut away sections are on the outside? Not sure about that one, but save yourself a lot of hassle and use Onshape. The free included elearning is excellent.

|

|

|

kid sinister posted:Eh. I might leave the cone. The radio case is actually kind of art deco and it fits. Yeah, the layer lines actually look like I would expect that knob to look. Only that it was not dirty gave it away as a new addition. I like it. At a certain point it is easier to just adjust the bed around the nozzle rather than self-flagellating by fighting with configs and firmware, imo. Good luck e: seconding onshape as a free babby's first cad software. Just be aware that any file you make is public unless you pay them, so if you're cooking up custom replacement parts for money I would probably not leave it hanging out for anyone to find and steal

|

|

|

|

|

Yo thread thanks for the help! Turns out I was too dumb even for your advice and come to find out my biggest problem was the lovely nightstand I have it on was wobbling too much during print. I tried flat on the floor with much better first layer results. I'm still getting some melting / curling on the extreme edges of angles but I feel way better about dialing it in now.

|

|

|

|

Curling tends to be too hot / not enough cooling. Does that printer have a part fan or whatever? That's a slicer setting to enable if so.

|

|

|

|

|

Javid posted:Yeah, the layer lines actually look like I would expect that knob to look. Only that it was not dirty gave it away as a new addition. I like it. I just realized the filament color I picked matches the numbers. Nice coincidence! edit: Does fixing the first layer height affect the rest?

|

|

|

|

Javid posted:Curling tends to be too hot / not enough cooling. Does that printer have a part fan or whatever? That's a slicer setting to enable if so. Yeah, and this was another thing I was testing since the fan on these things is loud as hell so I had it set to 50%. I'll blast it next time and see if that fixes it.

|

|

|

kid sinister posted:edit: Does fixing the first layer height affect the rest? It shouldn't. Only the first layer cares about the nozzle-bed distance. Once you get that first layer down, each additional layer will just be 0.2mm on top of the previous one

|

|

|

|

|

Gold cone looks good but I'd move the seam (currently at 12 o'clock) to the 3 o'clock position, hiding it under the red indicator piece. And if the pattern on the bottom of the red piece bugs you, you might be able to print the red indicator in two halves and glue them together, so both visible sides are the "top" of the print. But dunno if you want to bother with that.

|

|

|

The Eyes Have It posted:Gold cone looks good but I'd move the seam (currently at 12 o'clock) to the 3 o'clock position, hiding it under the red indicator piece. good point on the cone seam but that spaghetti bottom layer can be waaaay more easily fixed than flat gluing stuff together

|

|

|

|

|

I printed the red piece again. The bottom looks great! It's just the top that looks so wonky.

|

|

|

|

show us, "looks wonky" doesn't help us help you fix it

|

|

|

|

|

Javid posted:show us, "looks wonky" doesn't help us help you fix it Looks wonky = it looks like the same picture as before, the one you complained about. The first layer comes out beautifully. Is it because this part is so thin?

|

|

|

|

kid sinister posted:Looks wonky = it looks like the same picture as before, the one you complained about. The first layer comes out beautifully. Is it because this part is so thin? Wait, that picture is showing the top? HOW?

|

|

|

|

No idea man. I just work here. Is this a nozzle thing? I'm still using the factory installed one. I haven't even taken it out to see the size. I did come with a spare 0.4. Do I have to match that size in the slicer?

|

|

|

|

If that's the top layer, it definitely looks like something is set wrong in the slicer. It's possible that the slicer is configured for a 0.6 nozzle and you're using a 0.4, for instance (or maybe vice versa). Or maybe somehow the top infill width parameter got messed up. What slicer are you using? Can you reset it all to defaults? For comparison's sake, here is the top layer of a similarly sized flat red part I printed the other day:

Sagebrush fucked around with this message at 18:19 on Sep 4, 2023 |

|

|

|

Am I missing something, or is OnShape just a choice between "your designs are all public" (free tier) and "Over $100/month forever, please"? Because I'm solidly somewhere in the vast middle ground of that.

|

|

|

|

The Eyes Have It posted:Am I missing something, or is OnShape just a choice between "your designs are all public" (free tier) and "Over $100/month forever, please"? This is when you download Fusion

|

|

|

|

BMan posted:This is when you download Fusion Man, I wish there was another option. Nothing beats Fusion 360's features, but having so many locked behind a $tupid $ubcription drives me insane. Just make a hobby tier and charge something reasonable. Also, being unable to export because it can't phone home is peak corporate BS.

|

|

|

|

The Eyes Have It posted:Am I missing something, or is OnShape just a choice between "your designs are all public" (free tier) and "Over $100/month forever, please"? As mentioned, Fusion is an option. Autodesk are notoriously lovely, even for paying customers. Iíd really only recommend it if youíre doing CAM/CNC work. Also almost every person doing a Fusion 360 tutorial video is not following best practices. Thereís a free version of NX if youíre running Windows. Itís the same kernel as Onshape and SOLIDWORKS and like the biggest boy CAD option out there. They do have elearning but I havenít gotten around to trying it: https://blogs.sw.siemens.com/nx-design/nx-student-edition-free-download/ Same for SolidEdge: https://solidedge.siemens.com/en/solutions/users/hobbyists-and-makers/ Paid options are: SOLIDWORKS Makers Offer, which Iím not wild about because itís still underbaked. Itís $99/year. Came a long way in the last year, but unless youíre a person with PDM needs, itís hard to recommend. The CAM application it comes with is still buggy, but theyíve just come out with a bunch of post processors if youíre doing CNC work. Youíve got full data control on this one, thankfully. Itís just a non commercial license: https://www.solidworks.com/solution/3dexperience-solidworks-makers Alibre CAD starts at $150 as a one time payment, they have a version which comes with MeshCAM again if you have CNC work: https://www.alibre.com/atom3d/ Thatís everything off the top of my head, if you want more CAD opinions come join us in the thread: https://forums.somethingawful.com/showthread.php?threadid=3962532&perpage=40&pagenumber=1&noseen=1

|

|

|

|

Fusion is... okay. It never really gelled with me for whatever reason. I had never heard of NX, maybe I'll check it out if I end up kicking FreeCAD to the curb  Ditto Atom3D Ditto Atom3De: a $99/yr option for something like OnShape would definitely be worth it to me, maybe $199 even. Honestly my need for CAD is very off and on. The ease of sharing a design over the web that OnShape has is really nice sometimes. The Eyes Have It fucked around with this message at 18:52 on Sep 4, 2023 |

|

|

|

I need to recalibrate this thing. I'm trying to do Z Calibrate with adjusting it to just touch a sheet of paper, but I can't get my nozzle to go low enough before the printer says "out of bounds". What am I doing wrong? edit: never mind, a factory reset fixed it kid sinister fucked around with this message at 18:59 on Sep 4, 2023 |

|

|

|

Yeah, itís a bummer about public projects. Iím not really doing any secret squirrel stuff, so I donít mind for the projects I care to do on there. I wish theyíd do a low cost hobbyist option when they get CAM released this year. Iím a weirdo who uses several CAD systems at a time, so AMA about Ďem I guess

|

|

|

|

I maintain that Rhino is still the best all around CAD program for serious amateurs and up. It's $1000, which is out of the question for a hobbyist, but that's a relatively small sum if you're using it to make money...and that is a permanent, non-expiring, non-subscription, entirely unlimited commercial license for professional software with extensive industry and community support. If you buy Rhino 7 now, you get free updates through Rhino 7.99, and when 8 comes out you can still keep on using 7 as long as you like, and the files are backwards and forwards compatible so there's no problem there either. So few companies still do it that way. However, you can also get an educational license of Rhino for $150! It is also a permanent, non-expiring, non-subscription, entirely unlimited commercial license. Yes, commercial -- you can continue using it after you're not a student and you can use it to make money! It's just cheaper because McNeel is a great company and they want to be nice to students. I have an educational license through my job, and if you're remotely associated with a school you can probably get one too, but I've often wondered if you could just sign up for an inexpensive or free community college course and use your class schedule to get the discount that way. Absolutely worth looking into imo. (Buy it from novedge.com) Seriously more people need to look into it. It isn't a parametric modeler like SolidWorks, but it can do precision drafting just fine, and it is incredibly powerful in its own way. I use SolidWorks and Fusion on a regular basis, but Rhino is my default unless there's a really good reason to use something else. like, that little red part I posted is the lid for a sliding box design I put together the other night because I needed a box with a sliding lid. It took me a couple of hours maybe? And it's fully 3D printable and adjustable in width and height and depth and all that to any size you need. ♥🦏

Sagebrush fucked around with this message at 19:10 on Sep 4, 2023 |

|

|

|

Iím also a Rhino freak since it was my first design package, but Iím not sure that Iíd recommend it for mechanical assemblies for hobbyists.

|

|

|

|

I dunno. Depends how complicated your assembly is and how many interrelated dimensions you need. I will use SolidWorks first if I know it's a highly mechanical part that will benefit from SolidWorks' superior drafting tools, or if it has a lot of moving parts, because Rhino doesn't have a good equivalent to SolidWorks' mates. But Rhino is perfectly capable of making precision models with critical dimensions, like that box with the sliding lid. You just have to think a little more about your modeling technique.

|

|

|

|

Oh yeah itís extremely capable, I guess itís just sorting the right tool for the job. Iím craving a new Rhino license for a few projects, accidentally activated my old one on too many computers so they revoked my license

|

|

|

|

Is there any difference between nozzle materials regarding print resolution? Or does that come down to the aperture size?

|

|

|

|

kid sinister posted:Is there any difference between nozzle materials regarding print resolution? Or does that come down to the aperture size? Thatíll be the nozzle hole size. Material is really only relevant for abrasive materials because most fillers will abrade brass nozzles.

|

|

|

|

Prusa Support told me that I would be able to configure my XL preorder (which has already reached my place in line and is ready to finish) as a 5-extruder model by the end of August. It's September and I have no option to set 5 extruders! Goddamnit what's the loving deal!!!

|

|

|

|

Sagebrush posted:Prusa Support told me that I would be able to configure my XL preorder (which has already reached my place in line and is ready to finish) as a 5-extruder model by the end of August. It's September and I have no option to set 5 extruders! Goddamnit what's the loving deal!!! No ship, only buy!

|

|

|

|

NewFatMike posted:Thatíll be the nozzle hole size. Material is really only relevant for abrasive materials because most fillers will abrade brass nozzles. JFC, how close do you have to print to abrade the nozzles?!?

|

|

|

|

kid sinister posted:JFC, how close do you have to print to abrade the nozzles?!? It's from the material pushing through the nozzle, not scraping on the existing print. Stuff like glow in the dark filament is basically rocks embedded in plastic.

|

|

|

|

|

| # ? May 28, 2024 05:41 |

|

Will I get smoother results with a tiny nozzle then? Like 0.2mm? I noticed quite the difference in Cura slices. I had it set on 0.2mm, yet had a 0.4mm nozzle in. I assume that smaller nozzles will result in longer print times?

|

|

|