|

SmokeyXIII posted:Vertical is the hardest position to learn so practice practice practice. In time you'll have them looking like a machine did them. I'm personally still waiting for that time but I'm told the day will come. In this course I'm taking, once a student masters the structural steel welding, they move us onto pipe. I'm HOPING I can get good enough by course end to pass a 6G test. I think pipe welding is where it's at.

|

|

|

|

|

| # ? May 20, 2024 20:41 |

|

In my Instrument Repair class we have O/A but people rarely use it because it is quicker to just go under our benches and use the Acetylene tanks instead of going and getting a hose and tip and then walking over to the wall to turn the oxygen and gas feed on. Plus the O/A handles are much bigger than the Acetylene torch handles which makes it more tricky to get around tight places when soldering on instruments. Some times I will not even bother with Acetylene and just use a Butane hand torch from the hardware store. It is hard to control the heat with those ones though...

|

|

|

|

dv6speed posted:Speaking of hard positions to learn... can you pass a 6G pipe test with SMAW? Yeah that's what I do for a living :P Once you learn 5G and 2G pipe 6G isn't too hard. It took me about 3 practice coupons to get it to the point where I was passing bend tests. Where as it took me about... oh... 100 coupons to learn my 5G to the point that was required to pass my B Pressure Test. When you're welding pipe it has to be absolutely perfect. Have you put in any open roots yet?

|

|

|

|

SmokeyXIII posted:Have you put in any open roots yet?

|

|

|

|

dv6speed posted:Not yet, I need to finish fillet welds in all positions first, then do open V butts with backing, and then do open root V butts without backing. After all that I can start pipe. Welds with backing are basically the same as fillet welds. Open root welds however are a whole different ball game. Have you done any work with rods other than 6010?

|

|

|

|

SmokeyXIII posted:Have you done any work with rods other than 6010? My arc welder at home is an AC buzz box (Lincoln AC-225S.) One of these days when I have some spare cash (which is probably months away till I finish school and get a welding job) I want to pick up some Lincoln 7018-AC rods and see how they do with AC. The normal 7018's that I have are hopeless with AC, even tho the book says they are supposed to work.

|

|

|

|

I have returned from my vacation. The blacksmith on duty at Fort Steele was just a summer student who started learning 3 months ago. She was good, but she didn't really know much more than me. Though she did have experience with forge welding and such. Thanks for that video Jovial, that's a good explanation of your figurines. Have you considered just using gas welding rod for the necks and such instead of coat hangers? Probably a little easier to get a hold of.

|

|

|

|

Slung Blade posted:I have returned from my vacation. The blacksmith on duty at Fort Steele was just a summer student who started learning 3 months ago. She was good, but she didn't really know much more than me. Though she did have experience with forge welding and such. Maybe easier to get a hold of... but much more expensive, as long as I can keep getting the hangers for free. Not a lot of people are just off-loading welding rods.

|

|

|

|

Here is a picture of that forge cart I made for my buddy with wheels and a forge on it. The forge itself is just a bunch of firebricks stacked together with a Ron Reil type N/A burner. In other news, I'm having issues with my vertical fillet welds. I think it's just me being too hard on myself, considering I've only been at it for a day and a half. I need to keep telling myself tomorrow not to get frustrated and just concentrate on the welding. I'm having a difficult time reading the puddle with the vertical, I can't tell what's metal and what's slag. The good news is I took the saftey and math tests for the NCCER certification and passed.

|

|

|

|

dv6speed posted:In other news, I'm having issues with my vertical fillet welds. I think it's just me being too hard on myself, considering I've only been at it for a day and a half. I need to keep telling myself tomorrow not to get frustrated and just concentrate on the welding. Yeah 6010 is like that, if you were using 7018 it would be much more clear what is actually going on. 6010 isn't really used for structural welds, and I find it odd that you're still being trained on it. Usually at this point where I live you would be welding nearly entirely with 7018. But regardless, are you looking at your rod? You need to be looking entirely at your puddle and see what it looks like when it freezes and then imagine how you need to place the next bit of puddle to make a nice ripple on top of what is already frozen. It's hard to describe.

|

|

|

|

I feel like a real weldor now... I got my first spatter burn today! It burned thru my jeans on the left side of my left knee, and then made me cuss loud enough that I bet the whole shop heard me... two guys came running to see if I was OK. The good news is that my vertical fillet welds are starting to look sweet. I learned that a good portion of my problem was not having enough heat. The teacher explained it to me as imagine trying to spread frozen butter on some toast, you'll just wind up with a lumpy mess of bullshit. For the vertical, I've been aiming my new puddle at the top of the previous puddle, then letting gravity do the rest, and that seems to be giving me nice even ripples. Most likely he will move me onto overhead tomorrow... that should give my arms a nice workout. I'll have to make double sure to keep my back straight. I'll be using 7018 soon... he showed me and 2 other guys who have been making good progress the basics of running beads with it. Now that me and a few other guys are starting to make good progress and move onto different things, the rest of the class that is still working on horizontal fillets is either concerned or jealous. AbsentMindedWelder fucked around with this message at 00:26 on Sep 17, 2008 |

|

|

|

dv6speed posted:I feel like a real weldor now... I got my first spatter burn today! It burned thru my jeans on the left side of my left knee, and then made me cuss loud enough that I bet the whole shop heard me... two guys came running to see if I was OK.

|

|

|

|

Dongsmith posted:You're not a welder until you actually ignite. Or maybe bursting into flame means you really shouldn't be a welder, I don't know. I'm planning on getting a machinist degree, which should result in fewer gaping holes in my work shirts. Haha hell yes! I can't even remember how many times I've lifted my helmet after burning a rod to see half my arm engulfed in flame. Granted this is wearing heavy winter clothes so you dont really feel the heat from the extreme outer layer burning.

|

|

|

|

Dongsmith posted:You're not a welder until you actually ignite. Or maybe bursting into flame means you really shouldn't be a welder, I don't know. I wear only blue jeans and 100% cotton long sleeve shirts that I tuck in, plus the leather. I am told the bluing in blue jeans is a natural flame retardant. It seems to be true cuz my jeans didn't catch fire, just got a tiny hole burnt in them.

|

|

|

|

dv6speed posted:The head teacher said that in every class he has had, someone manages to catch themselves on fire at least once. I'm waiting to see who it will be... hopefully not me. I'm betting it will be one of the people who wears a shirt that is too big for them and refuses to tuck it in.

|

|

|

|

Finally got some work, and some learning done. I made a chiseling saddle, which is just a piece of 5" plate that I bent the ends down so it straddles the anvil face. It's just to protect the anvil when I'm chiseling or even punching holes. Worked some more on my RR spike knife, I didn't bring it in (it got loving dark at 7:30) so I don't have a picture, but it's pretty ugly anyway. However, I did try to forge weld. Amazingly enough, it worked.  Click here for the full 1280x960 image.  Click here for the full 1280x960 image.  Click here for the full 1280x960 image. No flux used, I just cleaned the surfaces and wired them together. It didn't work completely, I was trying to join 4 pieces at the same time, and 2 didn't take. Next time I will do it two at a time and then join the result. Hopefully I can do a basket twist this weekend sometime. I need to buy some borax... Edit:  Click here for the full 1280x960 image. It's stronger than I thought it was Slung Blade fucked around with this message at 05:12 on Sep 19, 2008 |

|

|

|

They let me use the cutting torch at work today. That thing is too much fun. For next time (so I don't look like such a dumbass, in case anyone watches), how do you adjust that thing? There are three knobs, an acetylene and oxygen at the bottom of the torch and another oxygen in the middle. Adjusting the oxygen at the bottom seemed to have no effect at all on flame. I turned the acetylene on, sparked it, turned the upper oxygen on until I got nice blue cones and the cutting oxygen supply didn't pop the flame out, then just went to town. What should I be doing differently? I was having a somewhat messy/slaggy time cutting through structural galvanized steel studs, probably 20ga.

|

|

|

|

babyeatingpsychopath posted:They let me use the cutting torch at work today. That thing is too much fun. The kind of torch you are using has different heads, so you are using the cutting head but there are welding and gouging heads too. The bottom oxygen is set to full open when you are using the cutting head. So that's normal that you have to adjust the top oxygen. To set your flame, turn on the acetylene first. Give it enough gas so that it stops putting out heavy black smoke. There will be a fine point where it starts looking a lot cleaner. Then you turn on your oxygen till you get the two cones of flame to line up. It should look pretty good at this point. Now pull the oxygen handle, and adjust the oxygen back so the flame has a nice cone. In new torches there should be almost no adjustment required after you pull the handle, but on old beat up ones it could be a lot. As for making nice cuts make sure you preheat the area, but don't expect galvanized to cut too clean that is some dirty dirty stuff. Also make sure you wear respiratory protection when cutting galvanized because that stuff will F you up. Hope that makes sense.

|

|

|

|

babyeatingpsychopath, Take a look at this website... it has everything you wanted to know about using an O/A rig for cutting and welding. It also takes about O/A rig safety too. http://www.esabna.com/EUWeb/OXY_handbook/589oxy1_1.htm I've made a good amount of progress this week at welding school... but I'm pressed for time this morning so I'll give ya an update when I get home today.

|

|

|

|

So this week, I've made lots of progress. My fillet welds, horizontal, vertical, and overhead are looking loving sweet. I was also started on working with 7018 (stringer and weave fillets) as well. I REALLY like that 7018, what a freaking nice electrode!!! I don't know how to describe it... it's "easy" while being "tricky" at the same time. The bad news is that I decided to take my 6010 stringer bead 2F, 3F, and 4F weld tests today and I failed... the beads looked beautiful, I had the 2nd and 3rd passes perfectly centered in the toes of the root pass, but my angles were a little off which made the fillets too concave to be passable. It was funny, I was making PERFECT fillet welds yesterday and the day before, so the first thing my teacher said when he saw my test coupons today was "If you were going to gently caress your girlfriend and she said this is a test, would you do anything different?" The good news is that the other 3-4 people who took the tests today failed too (Must have been something in the air of the shop). Also, the good news is that I can take them as many times as I need to, so I'll do some practice this weekend and go in Monday morning and kick some rear end.

|

|

|

|

dv6speed posted:So this week, I've made lots of progress. My fillet welds, horizontal, vertical, and overhead are looking loving sweet. I was also started on working with 7018 (stringer and weave fillets) as well. I REALLY like that 7018, what a freaking nice electrode!!! I don't know how to describe it... it's "easy" while being "tricky" at the same time. Do the instructors limit you on how many passes you can make to complete a fillet weld? We were told exactly how many passes to use to make a weld which was something I never really liked. They always said to do a 6 pass 2G but I always did 7 and they never knew the difference. Suckers.

|

|

|

|

SmokeyXIII posted:Do the instructors limit you on how many passes you can make to complete a fillet weld? That being said, the test uses 3 beads... the root pass goes all the way, the 2nd pass goes 2/3 the way, and the 3rd pass 1/3 the way. The idea is so the instructor can see all the 3 passes clearly. I'm kind of glad I failed the tests in a morbid sort of a way... now I will no longer fear failure!

|

|

|

|

dv6speed posted:Well they tell us that the fillet weld needs to have leg sizes that equal the base metal thickness. You do as many passes as you have to to accomplish that. Until your first x-ray.

|

|

|

|

SmokeyXIII posted:Until your first x-ray. I did some blacksmithing today. First, I made some tongs out of rebar that are sized perfectly for holding railroad spikes. Then I used the tongs to make a slag chipping hammer out of 2 railroad spikes.

|

|

|

|

dv6speed posted:Our teacher told us "A weldor who says they have never failed an x-ray has either never had his welds x-rayed, or is a liar." Ah, cool! I can't wait until I have some time to try forging some stuff. I was at an estate auction today, and there was an anvil and a bunch of blacksmith tools, but I got to the auction with my three young kids and my wife, and the auction didn't start showing the good tools until HOURS into it. The kids were getting very bored.. so we ended up leaving before they showed them. Boo. I'm looking forward to getting through all of my welded-figurine orders so I can have a few hours at the forge to see what comes out. Fun fun.

|

|

|

|

I found a buffalo forge bellows at an antique place this morning. 48 bucks and works fine. I'll make a mounting stand for it tomorrow and post some pictures. I'm still planning to use my electric fan for most work, as it works really well. I want the manual one for finer work, the electric one puts too much air into the fire and oxide forms too quickly. I want to be able to control the fire so I can forge weld with it easier. Dv6, was that chipping hammer forge welded or did you arc that? Looks nice either way man.

|

|

|

|

Slung Blade posted:Dv6, was that chipping hammer forge welded or did you arc that? Looks nice either way man. I attached the handle by drilling a shallow hole in the head portion, then grinding a tiny bit off the handle to fit in the hole, which made setting it up for welding ALOT easier. I hope my "heat treat" on the hammer head works out well, I got it as hot as my forge could get, then quenched it in water. Since I do nearly 35 hours of welding a week at school, I'll see pretty fast how well it holds up. Edit: Oh, in addition to doing a water quench to harden the hammer head, I tempered it by putting it in an oven at 425 then letting it cool down naturally. AbsentMindedWelder fucked around with this message at 17:37 on Sep 21, 2008 |

|

|

|

I'm planning to cross post this to GWS, so expect images of meat. I wanted to do a bunch of work today, but first up, I had to smoke a (very cheap) eye of round beef roast.  Click here for the full 1200x900 image. All spiced up.  Click here for the full 1200x900 image. The coal isn't lighting fast enough.   Click here for the full 1200x900 image. Guess I'd better turn on the forge blower and turbo that poo poo   Click here for the full 1200x900 image. Here's the buffalo forge bellows I bought yesterday, works quite smoothly, but I didn't have enough time to make a mounting bracket for it before the rain started.  Click here for the full 1200x900 image. Meat's on the grill.  Click here for the full 1200x900 image. Before I went on vacation, I took my trailer in to get the roof checked for warranty work, it's developed a small leak. When I got it back, I noticed that a rivet underneath the bench seat in the main cross member had popped. So, instead of doing something boring like drilling out the hole and putting in a bolt, I made this the night before we left to go camping. I cleaned and painted it today, hopefully it didn't get ruined in the rain, wasn't able to get it from the painting area before I went inside.  Click here for the full 1200x900 image. Here's the railroad spike knife I'm working on. I wanted to grind it and clean it up today, but again the rain got in my way.  Click here for the full 1200x900 image. I bought a cheap 20 dollar pocket watch while at Fort Steele, which was nice while I wasn't carrying my cell phone. But now that I'm back at work, I don't really need to carry the watch with me. So I built a little stand to keep on my desk at work for decoration.  Click here for the full 1200x900 image. Sanded and clear-coated.  Click here for the full 768x1024 image. Doesn't look too bad.  Click here for the full 768x1024 image. Also baked a loaf of beer bread.  Click here for the full 1200x900 image. Meat's done   Click here for the full 1200x900 image. All in all a good day. Didn't get everything that I wanted accomplished, but I'm still happy.

|

|

|

|

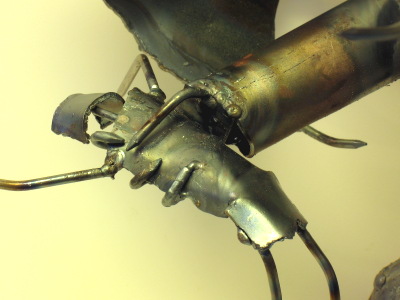

I got a bunch of work done this weekend, too. Namely, finishing up my latest large cthulhu figurine:    My welded figurine queue is getting clearer, so I think there might be some forging going on at my place in the near future...

|

|

|

|

Holy poo poo the quality of your figurines just gets better and better. Nice stuff man. Also, I really like your new avatar, where did you get it? Draw it yourself?

|

|

|

|

Slung Blade posted:Holy poo poo the quality of your figurines just gets better and better. Nice stuff man. Thanks! Yeah - I've looked back at some of my older stuff, and I've come a long way. This one turned out pretty nicely, I think. Nindoze made it during one of his "I'll make you an animated avatar" threads last year, but I didn't get around to actually using it (and then paying him for it) until recently, when he reminded me that he still had it. I love it.

|

|

|

|

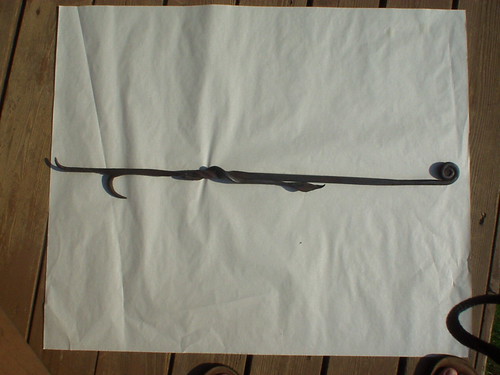

Finally got some pictures of the fire poker I made last year. It took me 3 days. The poker end is forge-welded loop that was cut and drawn out, and the leaf accent is something I'd made months before, it's riveted on by a tenon. here is some detail of the poker - this is the easiest kind of forge weld to do, fyi

|

|

|

|

Dongsmith posted:Finally got some pictures of the fire poker I made last year. It took me 3 days. The poker end is forge-welded loop that was cut and drawn out, and the leaf accent is something I'd made months before, it's riveted on by a tenon. That's gorgeous man. How did you make the tenon? My (crappy) tenon former was posted earlier in the thread, I'd like to see yours (if you used one). Did you use a monkey tool to form the shoulder?

|

|

|

|

Neat stuff Slung Blade, jovial_cynic, and Dongsmith! Great news! I passed my horizontal, vertical, and overhead 6010 stringer bead fillet weld tests! I'm quite happy. I did pretty well with them too. Oddly enough, my vertical and overhead came out better then my horizontal. EDIT: Now, I'm currently working on 6010/7018 weave vertical fillets, and 7018 stringer fillets in all positions. AbsentMindedWelder fucked around with this message at 21:30 on Sep 22, 2008 |

|

|

|

dv6speed posted:Neat stuff Slung Blade, jovial_cynic, and Dongsmith! Thanks Dv6, and congrats on your test, that's awesome!

|

|

|

|

dv6speed posted:Neat stuff Slung Blade, jovial_cynic, and Dongsmith!

|

|

|

|

I'm looking for a cheap welder to learn on and for a little automotive work. I've asked this question at some point (but I don't remember if it was in this thread or not...) The only work I'd be doing is minor exhaust work (just connecting pipes together) and welding stuff together just for fun, so I don't need anything spectacular, just something that will get the job done in a semi-reasonable amount of time. I found this one that looks decent. Would this do it for me or would I be better off finding an O/A welder? I don't have a much money to spend on this and honestly I would just bring my car to a muffler shop but I like buying tools and learning to do this stuff myself

|

|

|

|

two_beer_bishes posted:I'm looking for a cheap welder to learn on and for a little automotive work. I've asked this question at some point (but I don't remember if it was in this thread or not...) That welder can only burn 1/16" rod, which is nothing, just barely enough to do your exhaust. Not to mention that it's not really the type of welder you want to use for exhaust, you want to get a GMAW (also called MIG) machine. They're not really as cheap as a buzz box like you're looking at. I would recommend just getting it done professionally as the investment in equipment isn't going to be worth it considering the money you'll pay just for getting the work done. Edit: http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=55525 this is probably a piece of garbage welder, and personally I wouldn't even waste my time let alone money on it, but that is more the style you're looking for. SmokeyXIII fucked around with this message at 02:39 on Sep 23, 2008 |

|

|

|

two_beer_bishes posted:The only work I'd be doing is minor exhaust work (just connecting pipes together) and welding stuff together just for fun, so I don't need anything spectacular, just something that will get the job done in a semi-reasonable amount of time. 1.TIG (GTAW) 2.MIG (GMAW) 3.O/A (Oxy-acetylene) two_beer_bishes posted:I found this one that looks decent. Would this do it for me two_beer_bishes posted:I don't have a much money to spend on this and honestly I would just bring my car to a muffler shop but I like buying tools and learning to do this stuff myself Honestly, you are probably best taking your car to a shop to have the exhaust work done for now, and then getting yourself a used stick welder off craigslist to start learning how to weld with. Stick welding takes a good amount of practice and patience, however it is the absolute cheapest way to start putting 2 pieces of metal together. Get back to us with a dollar amount on what you are willing to spend and your electrical situation, and we can give you some more exact ideas of what to look for.

|

|

|

|

|

| # ? May 20, 2024 20:41 |

|

I only have 110v available  I have about $200 at my disposal for this, so not much...

|

|

|