|

dv6speed posted:Believe it or not, Monday's xkcd is semi-related: http://xkcd.com/556/ ah, cool! I actually made a figurine that the xkcd guy now owns. One of my client is/was a friend of his and purchased it as a gift for him. It was a scene from one of the strips.

|

|

|

|

|

| # ? May 23, 2024 08:42 |

|

jovial_cynic posted:ah, cool! That's cool, I love xkcd. Which strip was it? Got a picture?

|

|

|

|

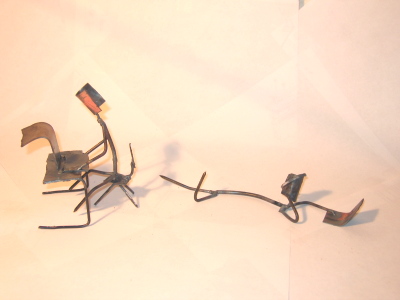

Slung Blade posted:That's cool, I love xkcd. Which strip was it? Got a picture? I don't have the URL for the strip, but here's the scene:  This is before I had a better camera to take photos. Also, I think that the client may have said that they were actually the girl in the scene, and that the scene was inspired by an actual conversation between the girl and Mr. xkcd. But I don't remember... Note that this was done in true stick-figure style, which isn't MY style, but it is the xkcd style.

|

|

|

|

That's great. I've seen a scene similar to that one in several strips, so it could apply to many.

|

|

|

|

I'm gonna be registering for a welding course this summer. It runs 8 hours a week for a few months, and the course description says it covers MIG and TIG on stainless, mild, and aluminum. Assuming I have some potential (I think I do) and the teachers are good, should that be enough (coupled with my blacksmithing and a year of part-time fabrication) to get me an entry-level job somewhere while I pursue a machinist degree? I've heard good things about the school, both from machinists and from my brother-in-law who's in a pipefitting apprenticeship. I'll take the course even if it's not gonna employ me, because it will be cool as hell, but my summer job runs out in October and I'd like to start doing some skilled labor in the off season.

|

|

|

|

Dongsmith posted:I'm gonna be registering for a welding course this summer. It runs 8 hours a week for a few months, and the course description says it covers MIG and TIG on stainless, mild, and aluminum. Assuming I have some potential (I think I do) and the teachers are good, should that be enough (coupled with my blacksmithing and a year of part-time fabrication) to get me an entry-level job somewhere while I pursue a machinist degree? I've heard good things about the school, both from machinists and from my brother-in-law who's in a pipefitting apprenticeship. I'll take the course even if it's not gonna employ me, because it will be cool as hell, but my summer job runs out in October and I'd like to start doing some skilled labor in the off season. I think that any courses you have will be very beneficial to helping you secure employment. Many people get starter positions in trades with zero experience, so you'll be one up on them. The only negative thing I have to say about the course is that SMAW is the most commonly used process, so it would be nice if they taught that too. I think it sounds like a great idea.

|

|

|

|

SmokeyXIII posted:I think that any courses you have will be very beneficial to helping you secure employment. Many people get starter positions in trades with zero experience, so you'll be one up on them. The only negative thing I have to say about the course is that SMAW is the most commonly used process, so it would be nice if they taught that too. I think it sounds like a great idea.

|

|

|

|

Dongsmith posted:There's also an Acetylene/SMAW class available. I had the impression that those processes were associated more with outdoor structural work and I guess the "dirtier" or heavier jobs, where you're out in the field and it's easier to work without having to drag Argon cylinders around in addition to generators. I'd eventually like to be working on more precision stuff (robots or kinetic sculpture or something, hence the machinist degree I'd like to pursue in the fall), and I assumed that kind of work used MIG and especially TIG more often. I've got a couple months before registration even opens so my options are pretty much wide open. I'm not above hard work or paying dues, but I'd like to find a job that's pretty close to my final career. Plus, Minnesota winters don't make outdoor jobs very appealing. Then again, I know more about 1820s ironworking than modern stuff, so I could be totally off-base here. Acetylene welding is effectively a dead technology. However, as a machinist you'll find yourself needing to repair parts that have been eroded down to a size smaller than spec, more often than not that will have to be built up with SMAW. It's great for high deposition and the only way that it's dirty is if you lack the manual skill to produce a clean weld. Also it's cheap, all you need is rods. I assure you that SMAW would be a useful skill to have for a person pursuing that line of work. But don't get me wrong, learning to TIG and MIG are going to be great assets, and you will use them a lot. I'm just saying don't under estimate how much SMAW is used in shops, as well as field. As for news from me, I got my Stainless Steel tig ticket for pressure piping the other day. So I'm headed back up north for a shut down that is supposed to run 80 days or so at 12 days on 2 days off. From the sounds of it I'll make about the same on this job as I did all last year. All I have to say to that is... Neat. Even with all the slow down in activity with oil sands projects being shut down all over the place, with all these TIG tickets I have it's still not very hard to find work.

|

|

|

|

SmokeyXIII posted:Acetylene welding is effectively a dead technology. However, as a machinist you'll find yourself needing to repair parts that have been eroded down to a size smaller than spec, more often than not that will have to be built up with SMAW. It's great for high deposition and the only way that it's dirty is if you lack the manual skill to produce a clean weld. Also it's cheap, all you need is rods. I assure you that SMAW would be a useful skill to have for a person pursuing that line of work. But don't get me wrong, learning to TIG and MIG are going to be great assets, and you will use them a lot. I'm just saying don't under estimate how much SMAW is used in shops, as well as field. Wow. All I hear up here these days is how all the companies are canceling their projects and laying off people. Syncrude even backed out of the mine ops program at Keyano. That is a big deal since they are 1/3 of the hiring companies at the school.

|

|

|

|

Brekelefuw posted:Wow. All I hear up here these days is how all the companies are canceling their projects and laying off people. Yeah the shutdown is at syncrude actually. It's the cokers... Again... All I can say is that I no longer regret those hundreds of hours I spent practicing on my own time. Because it is really paying off now.

|

|

|

|

I can make rings now. These are made of Japanese stainless steel, bent over a ring mandrel. Fun. I love tools.

|

|

|

|

Question for the TIG folks: A while back, I picked up a WP-17 tig torch off eBay, planning to eventually get around to setting up back-door power-supply tig machine, using big ac/dc arc welder as the power supply. Anyhow, I finally got around to stopping by the weld shop to get an argon regulator and hose, and the guy in the shop looks at my tig torch and says, "well... this is going to be a problem." Apparently, my eBay tig-torch is set up for some very specific machines, so it uses what appear to be a non-standard gas fitting -- non-standard as far as argon regulators and hoses go. Here's a picture of the power/gas fitting on the left (the right is for the foot-pedal control):  Anybody know where I can pick up a male-threaded/female-seated adapter fitting so I can actually hook this thing up to a gas hose?

|

|

|

|

jovial_cynic posted:Question for the TIG folks: I don't mean to sound condescending or anything but, are you sure you're trying to hook it up right? The pedal should go into the welding machine's remote port. Then the negative lead will connect to a tig torch which should have room for the lead and gas hose and continue on to the torch itself. Again I'm not sure what you're dealing with as far as equipment goes but that's how it typically works.

|

|

|

|

That's the Torch setup for the Chinese machines. (WSME, Super, and CT series) If you're using a foot pedal obviously you'd leave the one unplugged and if you're doing Tig you should have a foot pedal. The only way you're going to get an adapter is to have one made or google and see if there's one out there. Whats the thread for gas coming out of your machine? EDIT: What the gently caress is a back-door power-supply tig machine? AnomalousBoners fucked around with this message at 03:20 on Mar 25, 2009 |

|

|

|

Do you have a hose that came with the TIG torch? If so you can cut off one of the odd fittings and have the welding shop crimp on a standard fitting. Then you'll have a hose with the funky fitting to hook up to your torch on 1 end, and the standard fitting on the other. Edit: don't throw out the fitting you cut off in case you ever have a need to recrimp it on the hose. AbsentMindedWelder fucked around with this message at 03:44 on Mar 25, 2009 |

|

|

|

SmokeyXIII posted:I don't mean to sound condescending or anything but, are you sure you're trying to hook it up right? The pedal should go into the welding machine's remote port. Then the negative lead will connect to a tig torch which should have room for the lead and gas hose and continue on to the torch itself. Ok -- disregard the foot-pedal piece of my last post. I just had that in my head for some reason, and now taking a closer look at the torch head, I don't think that can be it. Here's the head -- it has a switch on it that's connected to that two-plug connector. I'm not 100% sure what it does, since I don't have the machine it plugs into.  RealKyleH posted:That's the Torch setup for the Chinese machines. (WSME, Super, and CT series) If you're using a foot pedal obviously you'd leave the one unplugged and if you're doing Tig you should have a foot pedal. The only way you're going to get an adapter is to have one made or google and see if there's one out there. Whats the thread for gas coming out of your machine? I'm using an ac/dc arc welder as a power supply, and simply clamping my welder to the torch. From what I've read, you hook it up to a "power block" which connects to that brass fitting... or you could just clamp directly down on that brass fitting if your clamp can get around it. But a power-block usually has a strip that your work clamp can bite onto. Using an ac/dc arc welder as a power supply for a tig is what is meant by "back-door power-supply."

|

|

|

|

On those Chinese tigs you have two options. You can use set the amperage on the machine, hook up the torch based switch and use it with no foot pedal. You wont be able to control amperage as you weld. You'll just have what the machine is set to. You can also leave that switch unplugged and that switch will do nothing because you'll use a foot control where that wood plug into. That brass fitting is your air line for your argon, I am confused as to whether you're aware of this or not. *goes and checks how his is set up* .jpg) .jpg) .jpg)

|

|

|

|

RealKyleH - what you are describing involves using an actual TIG power source for the TIG torch. I'm talking about using a stick-welder as the power source, and when done in that fashion, the brass fitting (where the gas hooks up) is also where the stick-welding work clamp connects. Here: http://www.az-zbum.com/welder.upgrade.shtml Running DC, I'd have to scratch start the weld, but for AC, I have a high-frequency arc starter that I can run between the stick-welder and the torch, so I can weld aluminum. Hope that link explains what I'm doing, exactly.

|

|

|

|

Wow, that thing is designed to have the arc welder clamp attach to the gas hose? Man, that is messed up.

|

|

|

|

Slung Blade posted:Wow, that thing is designed to have the arc welder clamp attach to the gas hose? ... but that's how the torch works. If you take apart any tig torch, the power and shielding gas are in the same place within the head. If you have a torch that simply twists into the tig machine for the gas, the power is going through that same location, unless you have a torch that happens to have a separate line for power... but most I've seen don't. having the arc welder clamp to the brass fitting (or a block attached to that fitting, so the clamp can actually bite down) is identical to having the brass fitting connected directly to the power supply within the tig box. Here's a diagram: http://en.wikipedia.org/wiki/File:GTAW.png

|

|

|

|

40% off metalworking at MSC today only.

|

|

|

|

Slung Blade posted:Wow, that thing is designed to have the arc welder clamp attach to the gas hose? it's actually extremely common. If you think about it, it's a lot simpler to leave the argon line out of the power supply than inside it. We use it all the time in the field as well as the shop. The only thing you miss out on is the pre and post flow control. Which you just swap to always on and problem solved. Jovial, Is it possible the trigger acts as a remote? A foot pedal for your thumb. I've heard of them but never seen one.

|

|

|

|

Mine didnt seem to work this way and my foot pedal actually has two connections like that on it.

|

|

|

|

SmokeyXIII posted:Jovial, Is it possible the trigger acts as a remote? A foot pedal for your thumb. I've heard of them but never seen one. It's possible. The connector is has two prongs, and since it runs up the torch line to the switch, I believe that it may function as a remote. I looked at a diagram of the machine that connects to this torch, but I couldn't tell for sure. Page 8 of this pdf (http://www.rilandusa.com/tig200wsemanual.pdf) shows the diagram. On the model shown, they have the power and the gas on separate lines, but the 2-prong terminal is shown on the machine connecting to the torch. On the 2a explanation on the page, I believe the symbol shown means "switch," which would make the switch on the torch a remote trigger. On/off.

|

|

|

|

Does anyone in here have the ability to do some turning, drilling, and tapping on a piece of rod in 316 stainless? I'm trying to think ahead for a project for a project I want to do next year and I figure should start making connections early rather than leaving it until the last minute like usual.

|

|

|

|

I have a pretty basic 13x40 manual lathe.

|

|

|

|

Not a metalworker personally but I love this stuff. I may look at going back for some welding/metalworking since I get tuition reimbursement (working for a university has its advantages). Anyway, I thought you guys might enjoy this: http://home.comcast.net/~jeshern/index.htm He's trying to apply modern methods to Japanese styles of blade making. He's got quite an amazing set of pictures. What led me to his site was specifically this series: http://home.comcast.net/~jeshern/tatara.htm where he outlines in detail the process he used to forge steel out of iron oxide from a ceramic supply store (it's used in the glazes but you guys already know that), all the way to where he makes a tanto. He built the forge by hand from an old water heater (the water heater is used primarily as a cast). Anyway he's got a lot of great show-me's on how he does the patterns, quenching, etc to get the various effects. It got me interested in forging my own steel for a bit and I found this link on how to make charcoal: http://www.twinoaksforge.com/BLADSMITHING/MAKING%20CHARCOAL.htm Basically he gets scrap wood from construction sites (untreated), puts it in a horizontal barrel that has a pipe fit to the bottom. The pipe bends underneath the barrel and has holes punched into it, the idea being that you start a fire under the barrel which releases gas from the wood which comes out the pipe and ignites from your fire. This way your fire is kept going for a long time, and once the gasses are expended you're left with charcoal. As long as your barrel was sealed well, if you get any flame inside you're sunk. The spelling and grammar on those sites leaves a bit to be desired...

|

|

|

|

Man those are great links. I've always wanted to try to make my own steel some day

|

|

|

|

Sweet a thread for me I'm a machinist, did it all through highschool and now I'm working as a mold-maker while going to college for Manufacturing Engineering. Primarily I work on a manual lathe doing short runs and re-work holding tolerances as tight as .0005" (a half thousand, or a quarter of a hair, lengthwise.). I've been getting a little training on the 3 cnc lathes we have in our shop, a little daewoo, a midsized mazak, and a midsized wasino. I've got a decent amount of experience with vertical milling machines, mostly manual though. I'm hoping to eventually be running the fifth axis Mazak at work since the guy that runs it now is poo poo at his job and only has it because he's a brother of the bosses. So if anyone has mold making or machining related questions feel free to PM me or ask here.

|

|

|

|

What kind of molds? Like plastic injection molds? That's pretty neat. Welcome to the thread and please post pictures if you have any.

|

|

|

|

Slung Blade posted:What kind of molds? Like plastic injection molds? Yeah plastic injection molds, It's a pretty good job and while the machining industry is suffering the plastics industry is doing a little better, hell, my part time rear end hasn't got laid off. The best part about being a machinist is really the jack of all trades aspect I find. I'm great at machining, but i can also do okay welds, I can operate all manners of grinders and metal fab equipment, it's pretty nice knowing how to do all that, I don't really think you get that kind of crossover in other metalwork jobs. As an addendum, gently caress hard turning steel. I had to cut chamfers (angles, normally 45 or 60 degrees. used to break sharp edges) on a bunch of strippers (Parts used to strip a finished part off of an extended core, in this case for kool-aid lids) that were about 56 rockwell. gay as gently caress. Getting pictures might be pretty hard, my bosses are kinda anal about loving around, at least before about 3 in the afternoon.

|

|

|

|

I recently got a huge amount of old files (about 200 of them), but not many of them seem to be in very workable condition. About half are really rusty, and the ones that the teeth aren't rusted off look to be clogged to hell and back with god only knows what. Is there an easy way to clean up the clogged files to be useable? Can I take a wire wheel to them and call it good, or are they well and truly hosed? I'll get pics as soon as I get off work if that helps explain things.

|

|

|

|

Buddy, you just got yourself a huge supply of knife-blanks. Files are really nice, high carbon steel that you can make all kinds of cool tools out of. But yeah, try to use a file card to clean them and see if some are salvageable, a wirewheel will work, but be very careful about how you try to clean it. The file might grip the wires and go flinging into the grinder / your leg. Go parallel to the teeth. If it's a cris-cross pattern, forget it.

|

|

|

|

In the instrument repair field we take old files and grind the teeth down and then polish them until they are super smooth. Then we can use them to burnish tubing back into round, or whatever shape the metal is.

|

|

|

|

I know! I was super excited when I got them because I can use them as knife blanks, but some of them look like they may be salvageable. If not, I am not going to be very broken up about it. Out of all 200, only one was a cross cut, two were square, and four others had teeth that I can actually use. Most of them look like they have been buried on oil sands for half their life, but I will still use em for something.

|

|

|

|

Zquargon posted:I know! I was super excited when I got them because I can use them as knife blanks, but some of them look like they may be salvageable. If not, I am not going to be very broken up about it. Out of all 200, only one was a cross cut, two were square, and four others had teeth that I can actually use. Most of them look like they have been buried on oil sands for half their life, but I will still use em for something. you should be able to clean some of them up passably well with just ethyl alcohol and a couple different wire brushes of varying rigidity. Best bet would be to find a parts cleaner though. Just a reminder, files are brittle as gently caress.

|

|

|

|

Random Number posted:Just a reminder, files are brittle as gently caress. That reminds me... I am only vaguely aware of the process of annealing metal... essentially, if I understand it correctly, you get the metal really hot, then stick it in a bucket of ashes so that it will cool down really slowly. Is there much more to it than that?

|

|

|

|

Zquargon posted:That reminds me... I am only vaguely aware of the process of annealing metal... essentially, if I understand it correctly, you get the metal really hot, then stick it in a bucket of ashes so that it will cool down really slowly. Is there much more to it than that? that's pretty much it.

|

|

|

|

Zquargon posted:I recently got a huge amount of old files... I've heard of putting dull files in a bucket of vinegar, or some other diluted acid, and letting them sit for a while. I don't remember which acid, though. Phosphoric, maybe. For a couple bucks for a jug of vinegar, it can't hurt to try, and it's not as if it's you don't have enough to experiment with. Oh, and great thread. If I ever find a store that sells Round Tuits, I could post some pics of my foundry, and my forge, and my lathes, and my mill, and my...

|

|

|

|

|

| # ? May 23, 2024 08:42 |

|

Who says round tuits anymore? Way to be old. Also post pics.

|

|

|