|

Yes, countertop paints are pretty heavy duty, but keep in mind your new paint won't be as tough and carefree as your original countertop surface. Use cutting boards with knives and potholders underneath hot pots. You could also look into using some epoxy paint. That stuff is for painting the really heavy duty surfaces.

|

|

|

|

|

| # ? May 10, 2024 07:11 |

|

FogHelmut posted:Does anyone have experience with painting countertops, rather than replacing? Rustoleum has a countertop paint for $20 a can, and there are other kits to do more complex surfaces which cost about $250. I imagine that it's pretty heavy duty stuff and not your typical paint. I'm thinking about different options and just wondering if anyone has had experience with these things, or if it's even worth it. If your counters are a simple L shape, they're not difficult to replace with pre-cut sections from Home Depot. Like $200-300. Laminate counters just start to get tricky or expensive when you need sections beveled on both ends.

|

|

|

|

I went through this whole decision process on countertops a while back as well. Forget resurfacing and just get some new slabs you can cut yourself. I redid about 16 linear ft of counter in a U shape with IKEA slabs that I cut and scribed to size. Took a few hours and tada I had new counters. The most time consuming part was buying one of each slab and trying them out in my kitchen before deciding on one.

|

|

|

|

iForge posted:i recommend just skimcoating that section. if you try to scrape more on that section you will eat through the paper and get into the gypsum and that is a no-no. That section will probably never look right, but just skim it. 4 or 5 coats should make it look decent, sanded smooth in between coats You know, I think I'm just going to replace that section of plasterboard. I looked around yesterday and today, and I honestly had no idea that it was so cheap. This particular section is also where I wanted to move my light switch to, so I guess this will make it easier (or even possible in the first place) to put that in.

|

|

|

|

Thanks for the countertop advice. My girlfriend is against laminate and I'm against spending money, but then our kitchen is pretty tiny because it's a condo. I have a straight 7.5' piece and then 2 individual 1' pieces on either side of the oven. We're probably a few months away from the kitchen, but it doesn't hurt to start looking now.

|

|

|

|

If anyone is interested in my follow-up, I put some window shrink film up in the bedroom yesterday, and there was zero condensation on them when I woke up this morning. Next step living room.

|

|

|

|

keykey posted:

Thanks! I think I ran across that photo initially but the wire going to the ground screw on mine wasn't green the way it was in that photo so I wasn't sure if that meant something was different. The apartment I was in previously (when the dryer was purchased and installed) had a 3-prong receptacle, so that was the cord that was on it. That's a function of when the building was constructed, isn't it? Anyhow I've just moved to a newer building so it needed replacing.

|

|

|

|

I bought a GPS friction mount (one of these things) a couple years back. Now, surprisingly, it has lost its friction and is sliding around all over the place on my dashboard. I'd rather not buy a new one--any suggestions on what I could stick onto the base that would help it grab the dash again without scratching it?

|

|

|

|

the yeti posted:Thanks! I think I ran across that photo initially but the wire going to the ground screw on mine wasn't green the way it was in that photo so I wasn't sure if that meant something was different. What really matters is the where the wires are attached, the sheath color is a formality. Electric dryers come with the metal case grounded to the neutral so that the case will at least have some protection in the event of a short when used with the old fashioned 3-prong dryer plugs. The 3-prongs didn't have dedicated ground wires, but the newer 4-prong ones do. Since the 4-prong cords do have a dedicated ground, the wire inside the dryer grounding to neutral should be disconnected.

|

|

|

|

Childlike Empress posted:I bought a GPS friction mount (one of these things) a couple years back. Now, surprisingly, it has lost its friction and is sliding around all over the place on my dashboard. I'd rather not buy a new one--any suggestions on what I could stick onto the base that would help it grab the dash again without scratching it? Hot glue? Have you tried cleaning it with alcohol?

|

|

|

|

Childlike Empress posted:I bought a GPS friction mount (one of these things) a couple years back. Now, surprisingly, it has lost its friction and is sliding around all over the place on my dashboard. I'd rather not buy a new one--any suggestions on what I could stick onto the base that would help it grab the dash again without scratching it? If that doesn't work... actually, hot glue sounds like a pretty reasonable (and reversible) option! Disclaimer: may damage your car. grover fucked around with this message at 03:37 on Dec 1, 2010 |

|

|

|

grover posted:It may have used all its friction stick to stick to dust, which doesn't stick as well to dashboards as first appears. Or it may just have heat-cycled and hardened the rubber. Try cleaning it; use soap & water if necessary. Can't hurt, right? Clean your dash, too. A bit of dish washing liquid and warm water is the best way to clean these things. Don't clean it with a brush or sponge, but use your hands instead. That way the water won't be too hot, and your hands won't damage the material. Bingo, almost as good as new. On the topic of removing stuck wallpaper a steamer is really the best tool for that job - just steam a patch and use a steel scraper to remove the paper. However, in some cases the previous owners may have used a glue that isn't water based, and set you up for a hellish job. In that case just steam and scrape off as much as you comfortably can, and then run the wall over with low-grit sandpaper. When you can run your hand over the wall and not feel the wallpaper you can paint it over, or put new paper up over it, and you won't be able to tell the old paper was ever there. Crowley fucked around with this message at 13:06 on Dec 1, 2010 |

|

|

|

In September I moved into a newly-remodeled apartment with steam heat. The radiators have been coming on for about a month and a half now, and whenever they turn on, it stinks like paint in my apartment. The first time the radiators came on at night the smell was strong enough to wake me up. It hasn't really gotten any better since then. The building manager told me that the radiators were painted with a water-based latex paint so the fumes shouldn't be toxic. Is this true? Also, how long should it take for the paint to stop smelling when the radiators are on?

|

|

|

|

Crowley posted:On the topic of removing stuck wallpaper a steamer is really the best tool for that job - just steam a patch and use a steel scraper to remove the paper. However, in some cases the previous owners may have used a glue that isn't water based, and set you up for a hellish job. In that case just steam and scrape off as much as you comfortably can, and then run the wall over with low-grit sandpaper. When you can run your hand over the wall and not feel the wallpaper you can paint it over, or put new paper up over it, and you won't be able to tell the old paper was ever there. Yep, the steamer made all the difference, but even so I still wouldn't call it a paintable surface. My replacement plasterboard arrived yesterday, so I might try my hand at putting that in today, plus I've removed a pelmet from over the ranchslider (sliding patio type door) and there was no plasterboard behind that, so new plasterboard needed there too. Fortunately I bought 4 sheets, and hopefully will only need 2 in this room. However, even with new plasterboard for the worst bits I think a skim coat for all the walls is in order as I will be painting. As somebody who has never done any plastering whatsoever in my life, am I crazy to be contemplating having a go at this skim coat myself?

|

|

|

|

Phooney posted:Yep, the steamer made all the difference, but even so I still wouldn't call it a paintable surface. Skim coating is super easy. Buy some ready made compound and a steel scraper and get to work. There is really nothing to it, but if you want a nice guide take a look at this.

|

|

|

|

Crowley posted:A bit of dish washing liquid and warm water is the best way to clean these things. Don't clean it with a brush or sponge, but use your hands instead. That way the water won't be too hot, and your hands won't damage the material.

|

|

|

|

Two years ago my wife built a chair from wood and metal (she thinks it's steel) that is finally out of storage and in our apartment. The problem is that the metal arms/frame have started to rust a little and we're hoping to protect it somehow from future rusting. She remembers some oil they put on it during her class but can't remember the name. Any suggestions on something to protect the exposed metal portions of the chair?

|

|

|

|

FogHelmut posted:Thanks for the countertop advice. My girlfriend is against laminate and I'm against spending money, but then our kitchen is pretty tiny because it's a condo. I have a straight 7.5' piece and then 2 individual 1' pieces on either side of the oven. We're probably a few months away from the kitchen, but it doesn't hurt to start looking now. Splurge on granite, you won't regret it. The difference between a custom laminate counter and granite was only a few hundred dollars for my kitchen. If you want to go cheap then buy one of those preformed laminate counters from Lowes/HD.

|

|

|

|

wormil posted:Splurge on granite, you won't regret it. The difference between a custom laminate counter and granite was only a few hundred dollars for my kitchen. If you want to go cheap then buy one of those preformed laminate counters from Lowes/HD. You just can't beat laminate on price, but the smaller the kitchen, the smaller the delta.

|

|

|

|

vlad3217 posted:Two years ago my wife built a chair from wood and metal (she thinks it's steel) that is finally out of storage and in our apartment. The problem is that the metal arms/frame have started to rust a little and we're hoping to protect it somehow from future rusting. She remembers some oil they put on it during her class but can't remember the name. Any suggestions on something to protect the exposed metal portions of the chair? Just about any oil will work as a humidity barrier on the steel. The only problem is that any oil won't last forever, it will slowly wear away from being touched by skin, clothing, pets, etc. The good news is that now the chair is indoors, it's in a more humidity-controlled environment. You'll also probably want to work on getting rid of the existing rust first. You can do that with either a wire brush, steel wool or sandpaper.

|

|

|

|

vlad3217 posted:Two years ago my wife built a chair from wood and metal (she thinks it's steel) that is finally out of storage and in our apartment. The problem is that the metal arms/frame have started to rust a little and we're hoping to protect it somehow from future rusting. She remembers some oil they put on it during her class but can't remember the name. Any suggestions on something to protect the exposed metal portions of the chair? Johnson Paste Wax

|

|

|

|

wormil posted:Splurge on granite, you won't regret it. The difference between a custom laminate counter and granite was only a few hundred dollars for my kitchen. If you want to go cheap then buy one of those preformed laminate counters from Lowes/HD. The thing about granite, while it is awesome, is that I'm not going to live in this condo forever and it would be too nice for the neighborhood.

|

|

|

|

grover posted:Personally, I favor quartz composite (like silestone over granite. It looks GREAT and has all the pros of granite combined with all the pros of solid surface, and none of the cons of either, for about the price of solid surface. I prefer Quartz also but it is now more expensive than most granite which is why I didn't mention it. Five years ago quartz and Corian were comparable in price but not anymore; at least not around here.

|

|

|

|

wormil posted:I prefer Quartz also but it is now more expensive than most granite which is why I didn't mention it. Five years ago quartz and Corian were comparable in price but not anymore; at least not around here.

|

|

|

|

I just got sucked into paying $1300 for laminate to replace my stupid counters wrapping around four sides plus a bar (all those bevels, so much money). The cheapest manufactured stone option, which I think was quartz, was more than double. "Just a few hundred more," I WISH. Hopefully with a "european edge," (curved under, but flat on the face) and no blacksplash "L" it'll look a little like stone from across the room. eddiewalker fucked around with this message at 04:40 on Dec 3, 2010 |

|

|

|

wormil posted:I prefer Quartz also but it is now more expensive than most granite which is why I didn't mention it. Five years ago quartz and Corian were comparable in price but not anymore; at least not around here. Corian is $2 a linear foot more expensive than granite around here. I can't figure out why anybody would ever consider intalling corian over granite.

|

|

|

|

eddiewalker posted:The cheapest manufactured stone option, which I think was quartz, was more than double. "Just a few hundred more," I WISH. grover posted:Man, that sucks. I'm glad I bought 5 years ago, then; my counter was expensive enough as it was! I wonder why the price went up. Just because they can, and people will still pay it? I think it's just a matter of granite dropping in price and demand for quartz decreasing.

|

|

|

|

wormil posted:I think it's just a matter of granite dropping in price and demand for quartz decreasing.

|

|

|

|

I'm turning a mini fridge into a dry storage chamber that I can pump nitrogen through. I drilled a hole through the door and have my brass air flow stuff. Basically a compression fitting on either side and a brass pipe going through the door. I'm putting tight-fitting washers on the brass pipe on either side of the door and then sealing the crack between the plastic door/washer interface and the washer/brass interface. Because I just wanted to try it out fast I used some sealant/adhesive silicone caulk, but it didn't seem to hold very well. Does anyone know anything that will act as an adhesive and sealant between plastic/zinc plated washers and the zinc plated washer/brass? Or maybe just any other ways to create an air tight seal with the hole I drill. Too bad the door is all insulation and nothing I can tap into

|

|

|

|

Crazyweasel posted:I'm turning a mini fridge into a dry storage chamber that I can pump nitrogen through. I drilled a hole through the door and have my brass air flow stuff. Basically a compression fitting on either side and a brass pipe going through the door. I'm putting tight-fitting washers on the brass pipe on either side of the door and then sealing the crack between the plastic door/washer interface and the washer/brass interface. Because I just wanted to try it out fast I used some sealant/adhesive silicone caulk, but it didn't seem to hold very well. Does anyone know anything that will act as an adhesive and sealant between plastic/zinc plated washers and the zinc plated washer/brass? Or maybe just any other ways to create an air tight seal with the hole I drill. Too bad the door is all insulation and nothing I can tap into

|

|

|

|

Arriviste posted:Here's the first place I check for adhesive recommendations: This to That (Glue Advice). Also, have you looked at how people put DIY kegerators together? That may yield some ideas for securing your line through the door. Yeah, kegerator was my initial inspiration. I was just looking at shanks but I'm not sure how to reconcile their specific use with the fact I need it to be compatible with compression fittings and all that jazz. Thanks for the site, though, that'll be a help

|

|

|

|

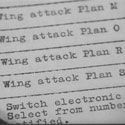

One of the things I need to do in regards to my bedroom to office conversion is move the light switch. I've taken the face off, and took a photo of how it was wired up for later reference:  Click here for the full 720x540 image. So I see there: 3 red wires, 3 black wires and also two green wires that were sealed off and not connected to anything. I went up into the ceiling and yanked all the wires through. Turns out one black and one red go to the light itself, one red, one black one green appear to go back to the fuse box... all good so far.... One black appears to go to the hallway light... but this switch never had any effect on that light before. One red wire and one green wire are now missing. What the hell have I done...it's like a lovely magician's trick.

|

|

|

|

Phooney posted:One of the things I need to do in regards to my bedroom to office conversion is move the light switch. The 2 red wires are the "hot" and appear to be using the terminal as a wire splice, too- one is always powered and the other is probably going to something that's always on, like a receptacle or the input of another switch. The one by itself is going to the light this switch controls along with one of the black wires. You can probably see them leaving the box together. The green wires are ground wires and there for safety. In the US, the switch is supposed to be grounded, and the green wire run to every box the other wires are. In your house... they didn't do this. One of the green is coming from your box, the other is going... somewhere else. Hope this helps!

|

|

|

|

Crazyweasel posted:I'm turning a mini fridge into a dry storage chamber that I can pump nitrogen through. I drilled a hole through the door and have my brass air flow stuff. Basically a compression fitting on either side and a brass pipe going through the door. I'm putting tight-fitting washers on the brass pipe on either side of the door and then sealing the crack between the plastic door/washer interface and the washer/brass interface. Because I just wanted to try it out fast I used some sealant/adhesive silicone caulk, but it didn't seem to hold very well. Does anyone know anything that will act as an adhesive and sealant between plastic/zinc plated washers and the zinc plated washer/brass? Or maybe just any other ways to create an air tight seal with the hole I drill. Too bad the door is all insulation and nothing I can tap into I recommend Dow Corning 832 Multisurface RTV/Adhesive. It's very thick, sticks to everything, and makes a very good seal once it's cured.

|

|

|

|

Thanks, Grover, that is a big help. I'm in New Zealand, I can only hope it is all legal. The former owner was a real tinkerer/hands on/engineery kind of guy, so not sure how much inspection all this work went through. Figured out what was going on here, reached up inside the wall and pulled out the missing red, green.... and another black wire! Looking at the picture again, it does look like 4 black wires, so now all are accounted for. By the looks of things, this red,green and black set don't go up to the ceiling, which is why they didn't appear at the other end when I pulled the wires out. Oh no, instead they go horizontally to the light switch in the next room. Unfortunately for me, this means that this particular wire is not long enough to connect up to where I am moving the light switch in the first room too. I guess I will have to drop a string down from the ceiling through the wall, connect an extension to the existing wires, draw it back up to the ceiling and push the now-longer wire down through the hole where I am putting the new light switch. I am dreading this, it is hellishly hot up in that ceiling and I had hoped that I wouldn't need to go back so soon! Alternatively... Maybe I should just forget about these wires. The light switch in the next room appears to be the last in that particular series, so it is now not connected to any power. Plus, the plan in the next room is to move the light switch and the location of the light anyway... and I'll have professionals and/or a friend who is an electrician on site by then too. Yes, I think option two sounds better! (This post was brought to you by Plan-in-Progress productions and the letter E)!

|

|

|

|

When I turn my shower on, there is still a lot of water pouring out of the bathtub nozzle. How can I fix this?

|

|

|

|

I'm remodeling one of the converted attic rooms in my 1915 house. It's about 20ft by 8 or 9 feet (I don't have my measurements handy). Naturally, being older than all my living relatives, it has plaster walls. I've skimcoated one room and decided I never want to do that again, so I'd like to try the alternative, remove the plaster and drywall the lathe instead. The ceiling is very low, so it's not a big deal to get up high with just a single person holding the board up. I attached a picture as well, for your viewing pleasure. This is the condition I got it in, with ugly, ugly wood paneling. e: Wow, meant to include a question, sorry. Does anyone have any tips for this?

Dragyn fucked around with this message at 14:11 on Dec 7, 2010 |

|

|

|

TheAngryDrunk posted:When I turn my shower on, there is still a lot of water pouring out of the bathtub nozzle. How can I fix this?

|

|

|

|

Dragyn posted:Does anyone have any tips for this? If you're removing the plaster down to the rafters, then you may want to put up some better insulation while you're at it. Think about redoing any electrical work while the walls are bare. You can also think about putting some panels and midget doors in place so that you can use the closed off spaces for storage. For drywall, ceilings are usually put up before walls so that the ceiling edges will rest on top of the walls.

|

|

|

|

|

| # ? May 10, 2024 07:11 |

|

kid sinister posted:If you're removing the plaster down to the rafters, then you may want to put up some better insulation while you're at it. Think about redoing any electrical work while the walls are bare. You can also think about putting some panels and midget doors in place so that you can use the closed off spaces for storage. Also, if the walls are truly lathe and plaster, likely the lumber will be dimensional and very uneven. Consider planing the wood to get a good level on the new drywall -- or be prepared to use massive amounts of shims. The little tiny nails used for old lathe are problematic too so watch out when you're planing so's not to waste your $30 bits.

|

|

|