|

What a badass post slung blade. That is entirely awesome.Slung Blade posted:Dome is made from salvaged 2x4s. All the ironwork was done in the shop. I especially liked the quote, so I googled it and it turns out its Nietzsche.

|

|

|

|

|

| # ? May 23, 2024 14:12 |

|

Slung Blade posted:awesomeness You should make a new thread here or in AI for that post, so people who dont check into this one can enjoy it.

|

|

|

|

So how'd you get in if it's not open to the public? (i don't know what most of that poo poo does but it still looks hella cool)

|

|

|

|

Ambrose Burnside posted:So how'd you get in if it's not open to the public? Slung Blade posted:Flicker forge and the Canadian Museum of Making had the entire Irricana blacksmiths guild out for a demo and a tour. He's in the guild i assume.

|

|

|

|

Are there any good mastercam interface tutorials? I don't care about doing any design work I just need info on importing iges files, rotating the part, setting offsets and origins, axis of rotation for a 4th axis, etc. Trying to get solidworks files rotated and programed for machining.

|

|

|

|

I am in the guild, yes. Also, I can post the entire set of images un-shrunk if you guys like. What's a good service to upload a ~130ish mB file?

|

|

|

|

Torrent. Or go in to properties, rename it as an .avi file, and upload it to google videos (that probably wouldn't work). I guess rapid share might work, assuming that place is still around. Sure do hate that site though. Also your post literally inspired me to check into local blacksmithing operations. Real general question: If I'm machining mild steel mostly, would I be satisfied by tools like drill bits, taps and dies, etc made out of HSS? I guess its considerably harder than the stock, and as long as I make sure to keep it cool so that neither the tool nor the part lose its temper, would I be in good shape? Or is it necessary that I get "cryo-forged" cobalt or titanium nitride coated bits?

|

|

|

|

In fact, an adjunct question: How do you machine HSS tool blanks? Is it all about abrasion? (BTW I've already trademarked "Its all about abrasion" as the name of my new sitcom)

|

|

|

|

Lots of good questions about machining YAY:The Scientist posted:If I'm machining mild steel mostly, would I be satisfied by tools like drill bits, taps and dies, etc made out of HSS? I guess its considerably harder than the stock, and as long as I make sure to keep it cool so that neither the tool nor the part lose its temper, would I be in good shape? Hss is suitable for mild steels even many tool steels in their annealed state. It is perfectly suitable for mild steels and you can look up speeds and feeds online quite readily for them. (Though for tool steels you'll be running pretty low speeds and feeds and really should be using coolant when you could just be using carbide.) Cobalt bits are HSS bit but with come cobalt added to the alloy. See the wikipedia article on HSS about this. TiN coated bits are HSS bits. The various coatings on drill bits just helps with wear resistance, friction reduction and chip removal except black oxide which stop things from rusting (poorly). Don't confuse black oxide with any of the black or brown in color coatings that do do the things I mentioned above. There are more than one coatings which are black. Also you very rarely see taps that aren't HSS. The Scientist posted:In fact, an adjunct question: HSS tool blanks like the kind you hand grind for turning on a lathe bits are just that, ground. However HSS cutters like endmills are made by milling (with a carbide or maybe CBN endmill) and then sent to heat treat and then ground. After HSS has been heat treated it is generally ground.

|

|

|

|

Jesus dude you are a cornucopia of knowledge. All that just from an AS degree? BTW I'm looking into that machine shop textbook you mentioned.

|

|

|

|

I didnt learn a single thing that I said in college. I learned it in machinist school and through teaching myself (often while IN machinist school.) EDIT: Also everything I said could be found in that book I suggested.

|

|

|

|

Pro-tip for grinding finish quality radius forming tools from HSS blanks: Go ahead and kill yourself now, at least your corpse will have hair and fingernails left.

|

|

|

|

I dunno if it's been mentioned before, but everyone needs to check out nonentity's thread over in TFR in which he restores some firearms that were severely damaged by fire. With absolutely gorgeous photography. Oh and he also machines pens from metal. And some other cool stuff. You don't have to be interested in guns at all, to enjoy what he's doing.

|

|

|

|

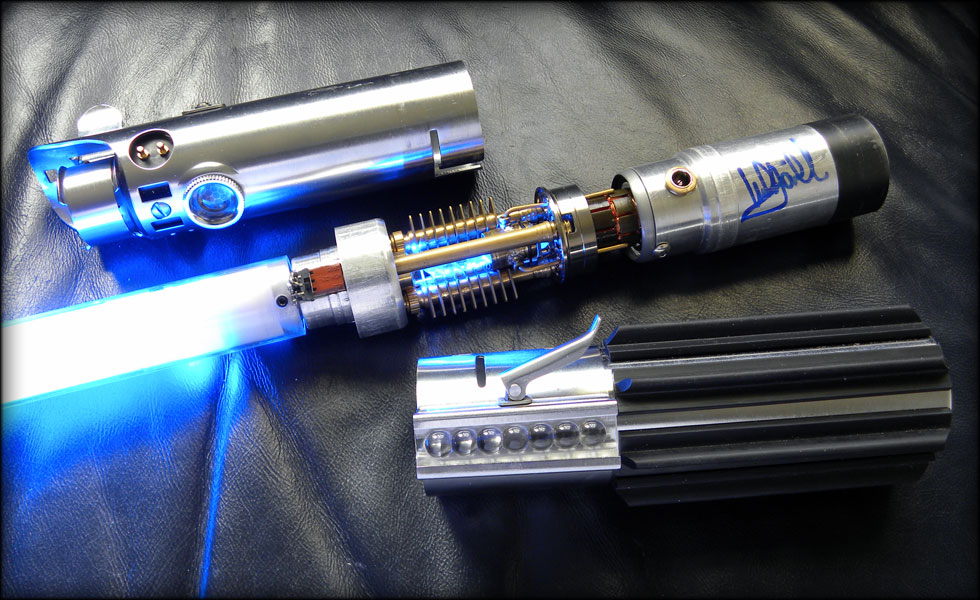

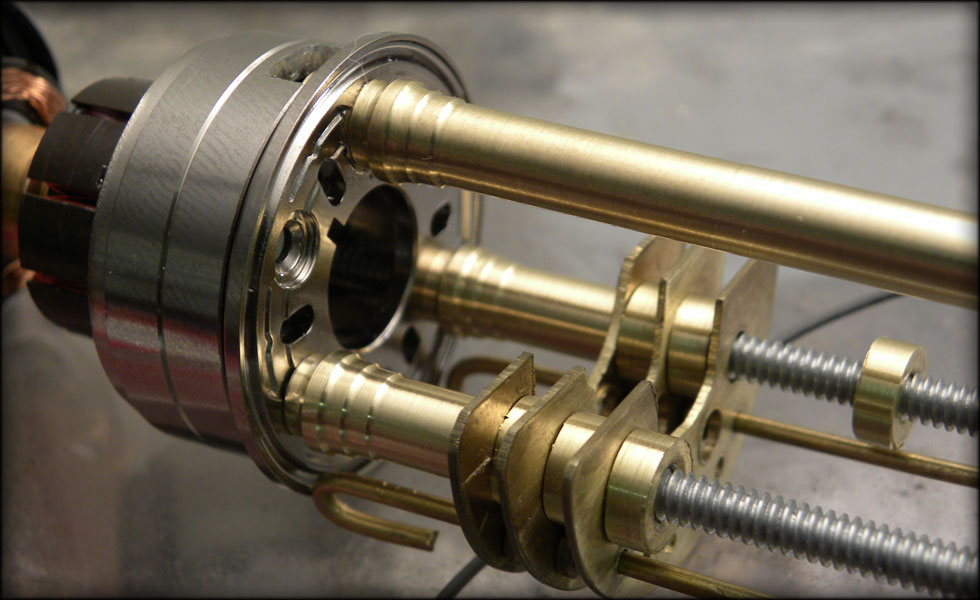

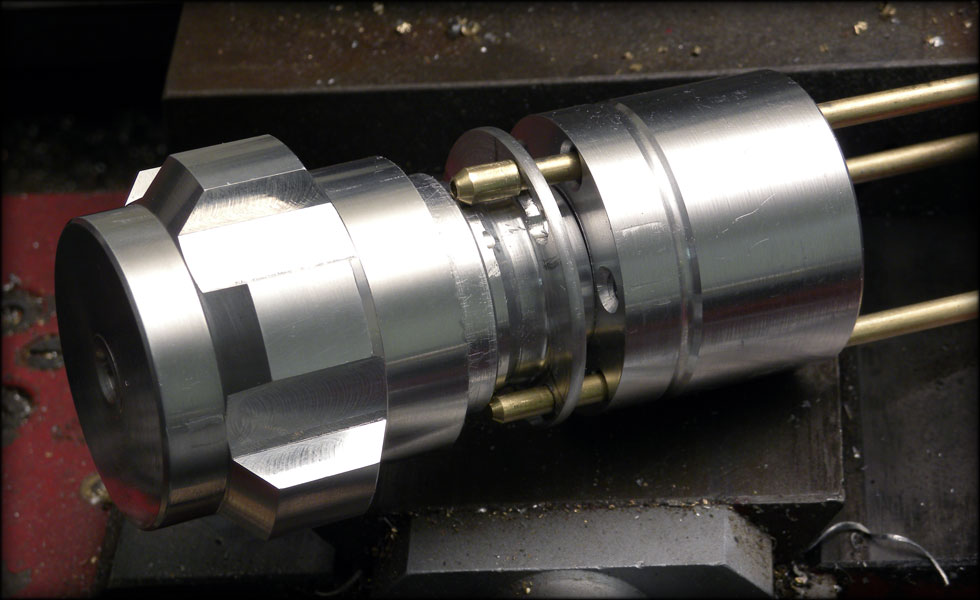

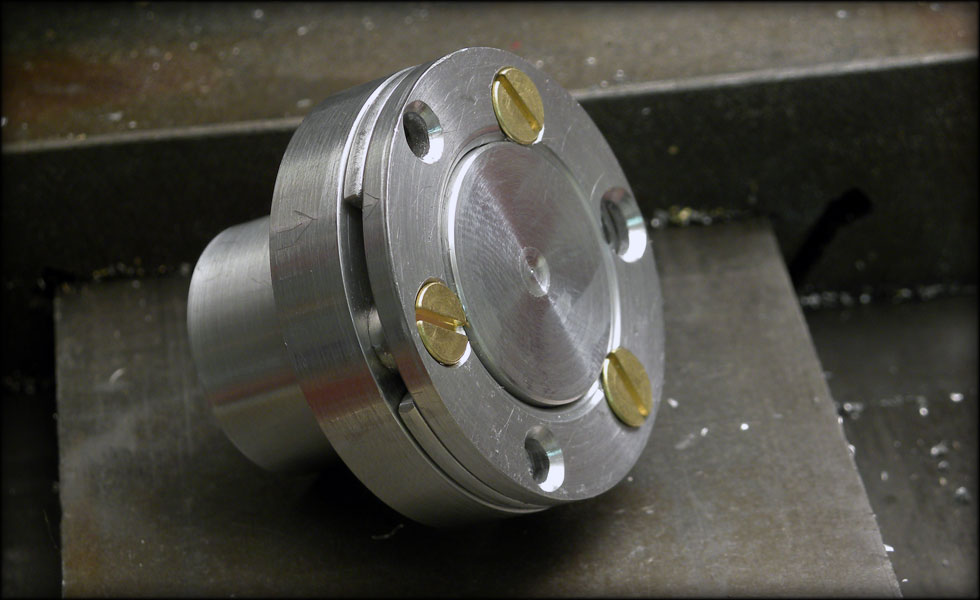

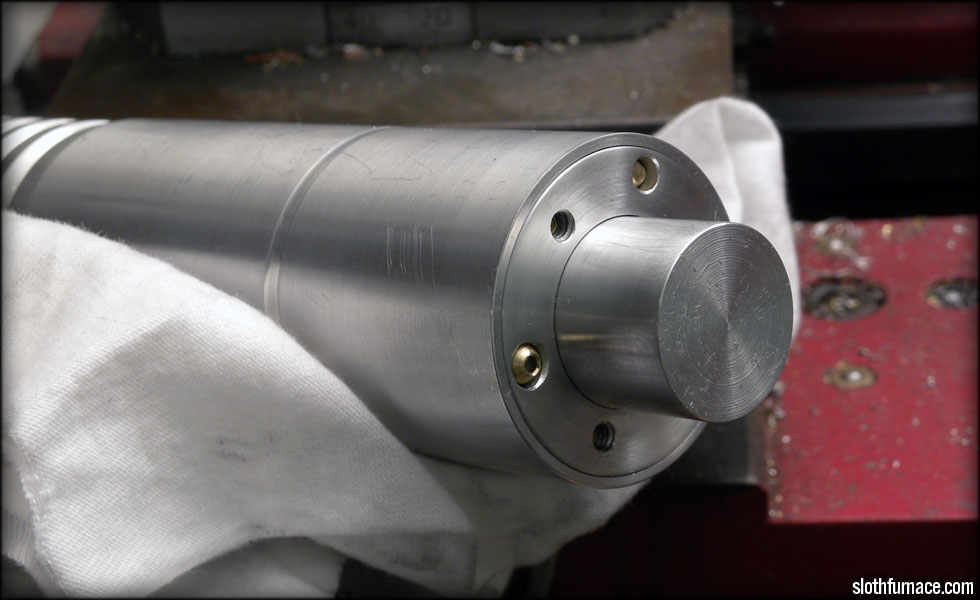

Oh, hi there folks. Leperflesh tells me I need to get my butt in here. I didn't even know this thread was here. (or I did and forgot) Anyway, here's some stuff I have been working on...       More here at https://www.slothfurnace.com or https://www.nonentity.com I JUST got a milling machine in the shop last week, so I'll be cranking out some milled stuff soon too after I finish this Christmas commission I am working on.

|

|

|

|

dv6speed posted:I am not disputing the validity of oxy-fuel rigs as a valuable tool in the shop. It was my first piece of welding equipment and I've cut, welded, brazed, soldered, and heated with it, and still use it all the time. quote:That being said, I want edmund745 to show me pictures of all (or at least some) the welds he's done with his oxy-acetylene torch. I'm particularly interested in seeing some fillet welds on 1/4" steel. I rarely ever bought any metal thicker than 1/8" up until a year or so ago, because that was when I bought the machine tools I have now. Like I mentioned before--most hobbyists work mainly with thinner metals (1/8" or less) because they usually do not have the equipment to drill, cut or shape thicker metals. -------- Re: gas torches can't weld into slots or corners... quote:Are you being serious about this, or are you joking? Slots: get (or make) a c-channel one inch wide and two inches deep, and try and lay a bead along the two inside corners. Corners: get three pieces of 2-inch x 2-inch angle, bevel one end of each at a 90º "point", and then weld them into a pyramid (like the corner of a cube, that is). Weld the outside edges first, and then flip it over and try to lay three beads all the way into the corner. Doing either of these things would be easy with a mig or stick, but basically isn't going to work with a gas torch or a tig. ~

|

|

|

|

In both of those situations, all you have to do is extend the tungsten out of the holder and pre-fill the area with argon. You can stick the tungsten out as far as you want, provided the current can still conduct through it from the holder, and you have argon displacing enough regular atmosphere. Getting the filler rod in there would be tougher, but just bend a V in it or something.

|

|

|

|

As far as metal thickness goes, I've used quite a bit of 3/16" and 1/4" thick shapes, pipes, and plate in various hobby projects.Slung Blade posted:In both of those situations, all you have to do is extend the tungsten out of the holder and pre-fill the area with argon. You can stick the tungsten out as far as you want, provided the current can still conduct through it from the holder, and you have argon displacing enough regular atmosphere. Extra tungsten stick out and creative filler metal bending. Edit: You can also bend stick electrodes to weld in limited access situations. It will obviously crack the flux at the bend point, but you can always snip off the bare metal wire and finish using the rest of the rod. AbsentMindedWelder fucked around with this message at 01:09 on Dec 14, 2010 |

|

|

|

Slung Blade posted:I am in the guild, yes. Megaupload. Much better than rapidshare.

|

|

|

|

nonentity posted:Oh, hi there folks. Leperflesh tells me I need to get my butt in here. I didn't even know this thread was here. (or I did and forgot) Holy poo poo, these are amazing! This and Slung Blade's picture post are highlights of this thread.

|

|

|

|

iForge posted:Megaupload. Much better than rapidshare. I thought those were exclusively for porn. But ok, maybe once I get home tonight I can start it uploading.

|

|

|

|

nonentity posted:Oh, hi there folks. Leperflesh tells me I need to get my butt in here. I didn't even know this thread was here. (or I did and forgot) whoa, Whoa, WHOA, WOW! WHAT DOES THIS MEAN? WHAT DOES THIS MEAN

|

|

|

|

nonentity posted:I JUST got a milling machine in the shop last week.

|

|

|

|

dv6speed posted:What kinda mill ya got? A "prestige" benchtop micro mill... good enough for what I am doing for now anyways....

|

|

|

|

Wow. It looks like that Harbor Freight mill works pretty good. Are their any immediate limitations you've noticed so far?

|

|

|

|

The Scientist posted:Wow. It looks like that Harbor Freight mill works pretty good. Are their any immediate limitations you've noticed so far? Not really, I am not all that experienced with a milling machine, but I hope to test it up soon. The one thing I notice is there's a fine up/down adjustment that I can't seem to get working. I don't know if I am not pushing the plunger in far enough or what, so reaching up to turn the crank to go up and down is a bit of a stretch.

|

|

|

|

I'm gonna use Christmas to actually get my foot in the door, so- what's a good blacksmithing book or two, the kind of thing you ought to start off with? Some were posted earlier in the thread, but fat loving chance of me finding them. I realize hands-on classes would be a lot more useful- and I'd like to get into one of those too- but I figure it's a decent start.

|

|

|

|

There's some youtube video series' I've been digging lately: http://www.youtube.com/user/MarkAspery?blend=2&ob=1 There's this dude, his name is Mark Aspery, he seems pretty skilled (check out that rose) http://www.youtube.com/user/MrIronman1979 And this dude has a good series "Blacksmithing for the broke beginner" He does things real ghetto but I am continually surprised by how knowledgeable he is. If anything has any others I'd be interested in takin' a look at them, as well.

|

|

|

|

The Art of Blacksmithing by Alex Bealer, and the New Edge of the Anvil are good. The Complete Modern Blacksmith is also a good one. All the major online book retailers have them, maybe your local library does too.

|

|

|

|

Ambrose Burnside posted:I'm gonna use Christmas to actually get my foot in the door, so- what's a good blacksmithing book or two, the kind of thing you ought to start off with? Some were posted earlier in the thread, but fat loving chance of me finding them. I realize hands-on classes would be a lot more useful- and I'd like to get into one of those too- but I figure it's a decent start. Most of the blacksmithing books on Amazon have at least something to offer. I'll run through the ones I have: The Art of Blacksmithing: This is a nice book to have but will not teach you how to blacksmith. It's a reasonable introductory primer into what blacksmithing is, though, which is an important thing for someone who wants to do this stuff. And it's $10. I'd call it a decent "second book". New Edge of the Anvil The first half of this book is pretty good as a beginner's primer. The second half is pretty much useless except as nice reading (lots of stuff about really advanced technique you really can't hope to learn from a book). This is definitely a good book, don't get me wrong, but probably best as a classroom text. Worth the $25 just for the first half though, I'd say. Complete Bladesmith If you're going to make blades this is a fantastic book. Again not exactly an introduction to blacksmithing, but lots of bladesmiths who do nothing else, could get everything they need from this book. It's also got photographs as opposed to the typical line illustrations in the other books I've got, which is nice. Hrisoulas covers theory and practice, in a logical progression, and has chapters on each important area around blade-making, including making handles and sheathes, a (really excellent) bit on selecting metals, etc. I also have Hrisoulas' follow-up book on pattern-welded blades, but it is not for the beginner. Practical Blacksmithing This was my first blacksmithing book and I'll swear by it. It's absolutely a "manual on how to learn how to blacksmith" which is different than just a manual on blacksmithing, in that it's not just telling you what to do, but how to learn to do it and get better at it. Kinda dry in many places, very much a textbook like what you'd read in college, except for blacksmithing. My copy is battered and worn because I actually brought it with me to every class and lab (I took classes at The Crucible in Oakland for a couple years). For $20 I'd say this is the best book I've come across to be your "first blacksmithing" book. I've thumbed through other books from time to time, but not well enough to be able to give a review. All this said, though: I think the best way to approach blacksmithing is to try it out first. The very basic introductory safety talk we got on Day 1 of Intro to Blacksmithing took 30 minutes, and then after a 15 minute demo, we were making things. If you can find a class you will learn far more in the first hour than you can possibly glean from a book. Books are great to take you past that first step, to study technique you've just been introduced to, or I suppose they're good for people who just want to learn about what blacksmithing is, without becoming a blacksmith (or trying it themselves). Nothing wrong with that. Leperflesh fucked around with this message at 01:02 on Dec 15, 2010 |

|

|

|

I have "The Blacksmith's Craft" which I thought was okay. The Complete Modern Blacksmith is a great book. For learning about steel, a Fe-C phase diagram is invaluable. Learn how to read phase diagrams, they're really helpful.

|

|

|

|

That phase diagram, and others like it, is a fantastic resource for a practicing blacksmith (or anyone who works with metal). However, it is a daunting and scary thing that I would never show to a rank beginner who just wants to get an introduction to metalwork. Start with banging on mild steel and you need not concern yourself with any of it yet.

|

|

|

|

Do you guys use IR thermometers to measure the temperature of the steel when its most critical, like when quenching? I can't seem to find any that go up past 1000o F. Also I dunno even know if IR would be most ideal for measuring the average temperature of a billet, like maybe the surface temperature is so different from the internal temperature that an IR Thermometer would tend towards giving an inaccurate or incomplete picture.

|

|

|

|

Leperflesh posted:That phase diagram, and others like it, is a fantastic resource for a practicing blacksmith (or anyone who works with metal).  Color is a built in thermometer for steel and the easiest to use. Just make sure you have a dim area where you can easily see the colors. Also, if your billet is thick, make sure to let the steel soak in the temperature so the inside can be close in temperature to the outside. There are IR thermometers that go over 1000, but they are very expensive. http://www.amazon.com/Ruby-Electronics-ST-677-NIST-Professional/dp/B001VZJW52/ref=sr_1_24?ie=UTF8&qid=1292376015&sr=8-24 This one goes up to 3000ºF and is completely unnecessary for blacksmithing.

|

|

|

|

Carbon Copy posted:this... this thing. hmm quote:That phase diagram, and others like it, is a fantastic resource for a practicing blacksmith (or anyone who works with metal). I'll probably get one or two of the comprehensive ones, as well as the bladesmithing one just as a huge cocktease (so I hurry up a bit and actually do more than just admire other people's work).

|

|

|

|

This is the water cooled torch I ended up picking up. It's a rebranded Weldcraft WP20, good for 250 amps, with a 25 ft hose. I picked up a leather hose cover, and an "accessory kit", too. The accessory kit includes collets, gas cups, and tungstens in 1/16", 3/32", and 1/8". The torch has three hoses. The blue hose supplies fresh coolant to the torch directly from the water cooler. The red hose is the coolant return line, and also has the electrical conductor. The water lines have left hand threads. The black hose is for shielding gas.  I picked up this Miller Coolmate 4 off E-bay, good up to a 600 amp torch! When it came in the mail today, it was a little bigger then I had expected, but that isn't a problem. The outer shell also serves as the coolant tank, with the pump, radiator, and fan inside, which I thought was pretty neat.   It needs to be filled with special coolant which prevents against freezing and algae.  Being a used item off E-bay (albeit in excellent condition), I wanted it test it out ASAP. Unfortunately, I don't yet have the correct fittings to hook up the coolant return line, so for the test it can flow directly into the coolant tank.  We have a winner! I had initially planned to pick up a Miller Coolmate 1, but I read alot of complaints about it being very noisy, so I decided to go with one of the larger models. I was very pleased to find that this Coolmate 4 is fairly quiet. Also, whenever I get a larger TIG power supply, I won't have to upgrade the cooler.  I should have bought one of these YEARS ago! It really makes being in the garage at these cold temps much more pleasant.

|

|

|

|

The Scientist posted:Do you guys use IR thermometers to measure the temperature of the steel when its most critical, like when quenching? I can't seem to find any that go up past 1000o F. Also I dunno even know if IR would be most ideal for measuring the average temperature of a billet, like maybe the surface temperature is so different from the internal temperature that an IR Thermometer would tend towards giving an inaccurate or incomplete picture. One of the things that phase diagram shows, which happens to be very convenient to know about, is the "magnetic point". You can see it for steels of about .5% carbon or less, at 1414 degrees F. This means that above 1414 degrees F, a magnet won't stick to the metal. This is somewhere in the mid-reddish orange colors, and (as I was taught) is a useful way to decide when carbon steel is hot enough to quench and achieve hardening. You can see that line at 1333 degrees F, and it runs right the way across the chart. For normal carbon steels, above that line you have austenite in your metal, and when you quench you are locking that structure in place. (There's other interesting phases of things too, but for hardening ordinary carbon steel, austenite is the important bit. Which is why sometimes you'll see a much simpler chart that just shows you where the austenite shows up...) The austinite basically dissolves the carbon in the iron which is what you wanted to happen. Anyway, the cool thing is that you can just stick your carbon steel in the heat and test it with a magnet every minute or so once it starts glowing. When the magnet won't stick you know for sure it's hot enough that you're into an austenite phase and you can quench. Since you're usually quenching because you want to harden a piece that is finished (or nearly so), you don't want to leave it in the forge any longer than you have to because the surface will scale. So when you're quenching you are waiting until you hit that non-magnetic point and then you immediately pull the metal out and quench (and you do that loving quick, because the instant you remove it from the heat it starts to lose temp to the air). Everything I just said is a simplification, because there are complicated alloys and there's more lines on that chart and you might be doing something fancy with balancing cementite and delta iron and whatever, I don't know. I'm really still just a beginner. Also, for carbon steels with higher or lower than .5% carbon, at the magnetic point you do not necessarily have ALL the metal in austenite phase - but you'll have at least some austenite, and therefore you'll achieve some level of hardening. And above 2% carbon, there is no austenite phase, you're looking at cast iron which is not suitable for tools. Point being, a thermometer is nice, but not a required piece of kit, at least for the basic forging, hardening, and tempering of non-exotic carbon steels. Leperflesh fucked around with this message at 06:09 on Dec 15, 2010 |

|

|

|

Leperflesh posted:[redacted] Wow, that's really good to know. But also, I'd be concerned about the point at which a piece is so hot that if I stick it in the quench it will crack. How do you know when your at that point? Also, it seems strange to me that cast iron is above 2% carbon. If that's the case, what is iron with 0% carbon? I wonder if that's even possible to attain, anyway.

|

|

|

|

Also, dv6, lookin' good, that's a hell of a setup. Do you think you'd be able to make any of that money back with such a nice rig at home? How's the lathe?

|

|

|

|

The Scientist posted:Wow, that's really good to know. I've never heard of carbon steel "cracking" because it was too hot when you quenched it. But, if there is such a point, its hundreds and hundreds of degrees above the point where you'd want to quench it, and you'll know it's too hot by the bright yellow glowing like the sun coloration it has. Iron with 0% carbon is called "iron". Commonly you can get "mild steel" which is an iron alloy with such a low carbon content (if any) that it cannot be hardened by quenching. Mild steel is incredibly common and pretty much anything that is made of steel and not used mechanically (e.g., not a tool, a mechanical part, or a face against which tools will be used) is made of mild steel. Back in the olden days, people used "wrought iron" for exactly the same things as we use mild steel today; the difference has to do with how it was made, which resulted in different impurities left in the metal which gave it different properties. The invention of the modern blast furnace provided a vastly cheaper and more efficient way to make regular-plain-old-steel, and hence, true wrought iron is vanishingly scarce today. (Most things you see in stores that claim to be made of "wrought iron" are actually made of mild steel.)

|

|

|

|

|

| # ? May 23, 2024 14:12 |

|

The Scientist posted:Wow, that's really good to know. Iron with 0% carbon is just that, iron. In order of least carbon to most carbon: Iron->low carbon steel->high carbon steel->cast iron And honestly? I've never used a thermometer either.

|

|

|