|

The Scientist posted:A guy pick's up a horse shoe that the blacksmith's just gotten done shaping and drops it real fast 'cause it was red hot, and the blacksmith says "what, did you burn yourself?" and the guys says "no, it just doesn't take me long to look at a horseshoe." Haha I laughed too hard at that. One of the best lessons I learned in my training is that hot metal looks the same as cold metal (at least at the temperatures I work with.) It hasn't stopped me from making stupid movies sometimes and burning myself though.

|

|

|

|

|

| # ? May 25, 2024 23:20 |

|

Maybe its because I watch a lot of wood turning demonstrations/videos but people touching a couple hundred pounds of spinning material doesn't seem odd. I've seen teachers do things I assumed would kill them multiple times but it apparently is totally normal. I love metal spinning because people do so much cool stuff with turned wood to make objects to spin metal around.

|

|

|

|

Brekelefuw posted:Haha I laughed too hard at that. Edit: somehow I have so far avoided getting sunburned eyeballs, even though I have seen the arc unguarded a few times. It's almost a religious experience; as far as I can tell from reading Revelation, that's what God looks like. Luckily my reaction to a bright light is to close my eyes and jump back, thus breaking the arc and saving my corneas. And I quite often lift the helmet to check the weld while the slag is still molten, and immediately regret it. Chillbro Baggins fucked around with this message at 03:55 on Mar 8, 2011 |

|

|

|

Delivery McGee posted:Also, burning leather smells terrible. Seconded. Also, if you buy those mechanic's gloves with leather palms and fingers, but some kind of synthetic fiber on the backs of your hands, whatever that synthetic fiber is will burn and melt onto your skin if you happen to be grinding high carbon steel, what with its massive burning shower of sparks.

|

|

|

|

Your own burned skin smells worse. I have a scar under my right thigh after I sat down on a red hot 1" bar. I was moving a heavy box with my father and managed to get stuck between the box and bar when I bent down to put the box down. Yes, it was as dumb as it sounds. Welding also puts things in perspective. I've caught on fire several times but after a while you don't freak out as long as you don't get burned. Cotton generally doesn't burn very well so you have time. Welding sparks down the shoes or boots however.

|

|

|

|

When I was in school I was reassembling a trumpet and I was using too much heat. I also was trying to do a lot of solder points at once instead of doing one at a time (because I am dumb) and I went to rotate the trumpet on the jig that was in the vise, and instead of grabbing the arm of the jig to rotate it, I grabbed the vise arm and loosened it. The trumpet fell on my finger for maybe .5 seconds. When I pulled it off all I could see was a white blob on my finger at the bottom of a crater. After dealing with the burn (which didn't hurt for like an hour, but sure hurt afterwards) I went back to my trumpet and had to buff the my skin off of the part with tripoli... Still have a nice scar.

|

|

|

|

I haven't really burned myself badly yet. Worst one was a little piece of scale that flipped up, hit me above the eyebrow, fell behind my safety glasses, and landed to rest on the top of my cheek. Left a tiny little burn, but it's all healed up now. I did however, burn the hell out of my mother's arm with a rivet that I had just hammered into something.

|

|

|

|

Welding and boots with unprotected laces is another good one. I remember going to lunch and wondering why my shoes were loose after a morning of welding spear castings onto round bars for a railing, then i saw that pretty much all that was left of the laces was the knot and bow at the top.

|

|

|

|

The worst burn I've had was when I peeled the saran wrap off a bowl of green beans I'd just microwaved, releasing the steam right onto my hand. I've never burned myself on hot metal around the forge. Probably I've done a lot less hours of work than you guys, but part of it was good safety lessons and habits that were drilled into us from the start. When you're taking a metalworking class and everyone is sharing the same forge, you have to assume pretty much anything around you might be scorching hot. You hover your hand over any piece of metal before touching it, whether its the vice, a pair of tongs, the surface of an anvil, whatever. We also had strictly-enforced safety rules. Like, there was a yellow line on the floor when you entered the shop, and if you were past that line you had to have safety glasses on and earplugs in at all times, no matter what. No exceptions. Also leave the safety components of your gear intact. Don't take the shield off your grinder. Don't defeat the third prong on your grounded tools. That kind of thing. It's just totally ingrained in me now. I guess I'm the only one on my block who wears safety glasses while mowing the lawn, but gently caress it, they're my eyes and I need them. I've thrown plenty of stones and bits of sticks and stuff while mowing, and while they've not come near my eyes, it just takes one ricochet or weird wild throw or bit of carelessness (bending over to fiddle with a control, lifting up the back to get over a root, whatever). Leperflesh fucked around with this message at 20:10 on Mar 8, 2011 |

|

|

|

The worst burn happened while I was working on a rail car doing some 7018 vertical while putting new wear plates into the truck assembly. I was sitting Indian style (mistake number 1) and was wearing thin cotton pants with no leather protection over my legs (mistake number 2). A very large spatter ball landed in that crack type area on the backside of your knee, where when sitting Indian style, your calf meets your thigh. What sucked about that is that I basically got two burns for the price of one. They took a drat long time to heal too.

|

|

|

|

Leperflesh posted:I guess I'm the only one on my block who wears safety glasses while mowing the lawn, but gently caress it, they're my eyes and I need them. I've thrown plenty of stones and bits of sticks and stuff while mowing, and while they've not come near my eyes, it just takes one ricochet or weird wild throw or bit of carelessness (bending over to fiddle with a control, lifting up the back to get over a root, whatever). I wear them too, but I have shaded sunglass style safety glasses

|

|

|

|

I made a security grate for a client's front door! He was worried about someone smashing the glass and reaching right inside to unlock the door. Problem solved. I had AbsentMindedWelder help me out as an extra set of hands for alignment and welding, as well as holding the torch while I hammered the rivets.

|

|

|

|

Leperflesh posted:The worst burn I've had was when I peeled the saran wrap off a bowl of green beans I'd just microwaved, releasing the steam right onto my hand. This dammit. This. I kinda blew off our shop tech when I was in school, but now that I am doing some of this poo poo on my own, I am a safety nazi. I don't care if it takes me a half hour to find my respirator, I'm not grinding a thing until I find it. I know too many older artists now that are deaf and have to wear full on hearing aids because safety wasn't practiced when they were working. Yeah, I might look like a goof with full leathers, face shield, hearing protection, gloves, and respirator, but I want to see my future kids and their kids. Small things now make big impacts later. Don't be afraid of telling people off if they try to emulate those OCC retards and not wear safety equipment. I do.

|

|

|

|

I just painted the last couple inches of all my tong handles a really dull black/red mix that makes them always look hot - it's really helped me avoid picking up any tongs without first thinking about it/using gloves.

|

|

|

|

I finally got to spend some quality time with a forge. Results: Left to right: -Cat's tail -Fire-poker -unfinished wall-hook, still attached to stock rod -coal rake [little things] -Centre-punch, hot chisel, cold chisel -Iron Cross (heh) -wall-hook [/] -left-handed tongs designed to hold round stock -clinker-poker Blacksmithing is a lot of fun and very rewarding e: and, naturally, I only notice that my cold chisel is really, really wonky now.

|

|

|

|

woah. Did anyone else see that really nice door stop he made?

|

|

|

|

duck hunt posted:woah. Did anyone else see that really nice door stop he made? The noise they make is the best thing ever... Ptwannngggggggg! Sounds like a engine revving.

|

|

|

|

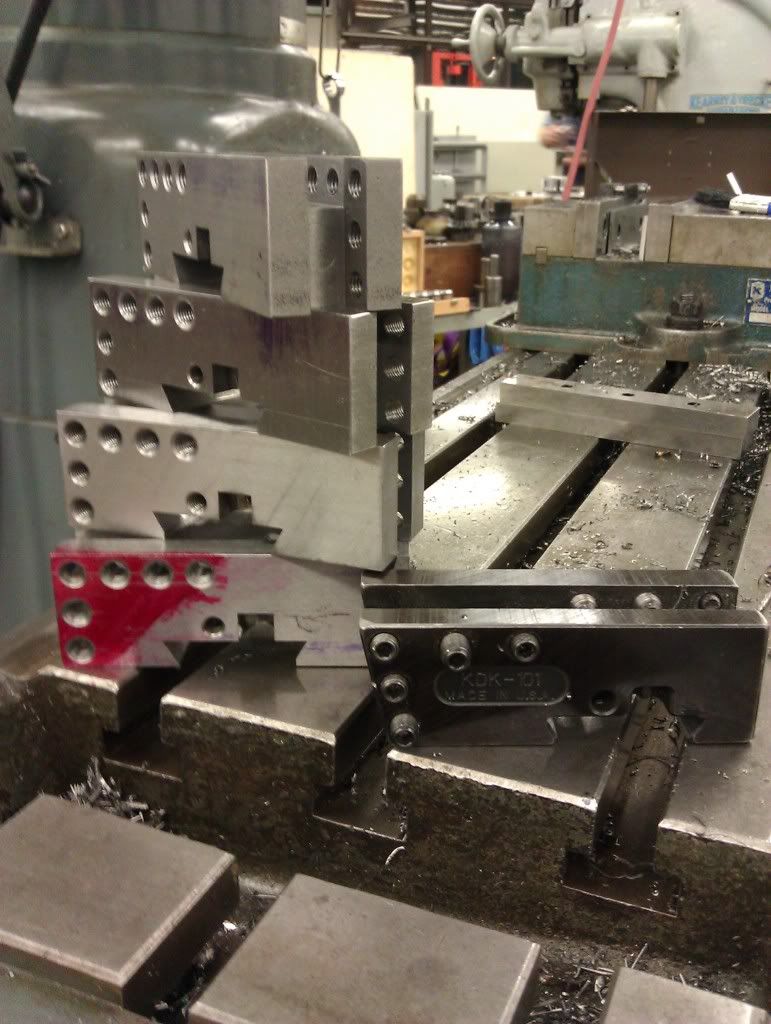

I finished some lathe tool holders. The last step today was drilling and tapping all the set screw holes. 6 holes per side, 4 operations per hole, 4 pieces. 192 total operations, each one requiring pulling the part out of the vise to rotate or replace it. I've got a bruise on my hand from smacking the vise wheel to loosen it. 3.5 hours of spot drill, drill, chamfer, and tap.   Three things I learned today. 1. How to sharpen a drill bit on a bench grinder. 2. How to power tap. 3. I don't really like production style machine work.

|

|

|

|

Power tapping is awesome. It just seems wrong though, seeing that motor all of a sudden stop and reverse direction. I always think something is going to break horribly. Ambrose: nice work. Is the cold chisel tempered already? If it's not you could just fix it up before you do. If it is, you can use it as is, just be careful when striking it.

|

|

|

|

Ambrose, nice job man. You are a machine, how long did that take you? Here's a general question: If you knew something was gonna mushroom (like its something that you'll be hitting hard with a metal hammer), what would you do? Anything?

|

|

|

|

The Scientist posted:Ambrose, nice job man. Well that depends on what it is and how I'm hitting it and how changing its design might affect its purpose... I mean, the tail end of a chisel, you can just give it a slight taper around the edge, so hammer blows don't start to mushroom it. Dunno if that'd be appropriate for whatever it is you're gonna be hitting.

|

|

|

|

Slung Blade posted:Ambrose: nice work. Is the cold chisel tempered already? If it's not you could just fix it up before you do. If it is, you can use it as is, just be careful when striking it. The Scientist posted:Ambrose, nice job man. Bastard who ran the course knew exactly what he was doing, too- on the last day he showed us all the cool poo poo we'd make in his intermediate course, stuff like bolt-headers, drifts, scroll jigs, you know, actual production tools. Good thing it doesn't run until the fall, it'll give me time to gently caress around on my own.

|

|

|

|

My cheapass chisels/punches all mushroom a little bit eventually. I just grind the offending bits off from time to time. If the temper is too soft, you can always just use it as a hot chisel. Hell, I've got that one hardy tool I made out of a piece of flat bar mild steel, I ground a "sharp" edge on one side of it and I use it to cut things all the time, I just have to dress it occasionally to keep it sharp. It works quite well for what I use it for. Drifts are something I need to work on. Round, no problem, just get some bar the right size and taper both ends. But I need to make an elliptical one for hammer handles, and it's something I haven't worked up the nerve to attempt yet

|

|

|

|

I took a crack at a mini-tomahawk drift on the last day, when we had an afternoon for a personal project, but it kept getting worse and worse 'cause my hammer control was/is awful. I gave up and used it for twisting practice. Tomahawks seem pretty easy, relatively speaking, and I want the forge-welding experience. Plus they're cool and people will love them as gifts Now I wanna do it on my own. I figure I'll end up running any forge I build off of charcoal ('cause my parents own a cottage with lots of trees and a cord or two drying/dry at any given time, and free fuel is free fuel)- are there any particular caveats to building a forge with charcoal in mind? Does it matter? And is there an accepted 'economy' pattern of improvised forge? I've heard a few mentions of brake-drum forges, but beyond that not much.

|

|

|

|

I just used a big stainless bowl with a pipe through it and built up some refractory cement in it. Just make it concave and put an air supply in it somehow. You'll want a way to have deep fires, and shallow fires. Deep for big/awkward pieces and shallow for all the times you're just doing little stuff and don't want to use an entire bag of fuel. I made a crappy ring of flat iron on its side to make my fire deep enough to handle big things. Doesn't look pretty, but it works. You'll need an air supply too of course. Hair dryer, bellows, hand-crank fan (look at antique shops) squirrel cage blower out of a car, whatever you can find that will work. Now, most solid fuel forges have these clinker breaker things and an ash dump, yours will not. Coal/coke still has some non combustible mineral content that will melt out as slag/clinkers, whereas charcoal is basically pure carbon. You will get some ash, and a little scale that falls off your iron workpiece. So to get rid of that without putting out the fire, it helps to have the ability to put a blast of air through the pipe and blow all the ash away. Don't do this when the grass is dry, it'll throw sparks/embers a long way. The fan I use is powerful enough to usually keep the ash content low as long as I stir it regularly. If that doesn't get enough of the ash out, I usually just take a deep breath and blow it out after digging around a little with my coal rake. Compressed air would work too, but don't use those cans of computer dusting gas (fun fact if you flip your can upside down and blow the compressed dusting gas at your fire when it's really hot, it will burn like a little flamethrower I think you could make one easily enough from a thick ceramic flowerpot with no glazing. Run your airline through the hole in the bottom, build up the walls with clay maybe, or if you have a wide and shallow pot, it would probably run fine without any modification. It might not last very long, but flowerpots are pretty cheap. There's not a whole lot of knowledge about running charcoal anymore, at least not on the north american continent. Most of the pro/amateur smiths I know all use either propane/NG or coal/coke and sometimes both. A guy who's been working as a fulltime pro smith for years was asking me about it because he had never done it. edit: or just go to a fireplace / hardware store and get some firebricks like this dude did:

Slung Blade fucked around with this message at 21:23 on Mar 10, 2011 |

|

|

|

I didn't think of not needing an ash dump. That'll make things way easier. I think I'm gonna drill a dozen holes in some 1 1/2" steel pipe, throw an end-cap on one end, and bury it in a wheelbarrow-ful of earth. I'll rake up some river-clay (yes I know there's plenty on our property) to line the firebowl with, and that should work for anything simple. If I leave the end-capped end protruding I can unscrew it to clean the pipe out, too. e: with the obvious caveat being that it won't be portable or relocatable at all, but I'd only be needing it for weekend stretches at a time so it doesn't sound entirely unreasonable to just build a new one for every weekend project I want to do.

|

|

|

|

I have just acquired a 4 ton punch press. Guitar riff for old/outdated/extremely dangerous machinery!!!! lovely cell phone pictures, as I cant find my charger for my digital camera.      Current plan is to clean up/restore and put into operation making useless crap. All the grease on this thing has turned to stone and it hasn't been used in 30+ years. Weighs a solid 300+ pounds and was a bitch to load/unload by myself. If you don't know what a punch press does, read THIS wikipedia article.

|

|

|

|

Ambrose Burnside posted:I didn't think of not needing an ash dump. That'll make things way easier. Make the capped end stick out the other side of the barrow or whatever you end up using, then just unscrew the cap once every couple months and turn on the air source. Whatever small amount of ash, dust, spiders or whatever do accumulate in there will come right out. I did that with mine, works fine. Plus if water gets in there (try to avoid this) you can get rid of it before it freezes if it's winter. iForge, that's a lovely ironworker. I wish more old machinery was available around here

|

|

|

|

I was productive today! First I finally hung up my pegboard, put up a nail for my apron, and put a shelf in the hole where there used to be a door going into the house. Now I just need to find the pegs and remember what tools I had hanging there. Putting the toolbox on the doorwayshelf frees up counter space. Also I used a scrap of rebar I found and a bit of my 1" square tube to build a hatrack.  Note the empty screw hole -- I got a beat-up Cold-War-era Bosch drill (made in West Germany) for $20 at a pawnshop a few days ago, and I snapped two bits and that screw in the making of that thing. Drill still works just fine, it appears. That's the wife's welding helmet on the right. She wanted the classic style, but it was too plain, so she dressed it up a bit.  Then I added holders for cutting tools to my welder cart.  And now for the actual project: I started on some digitigrade stilts for a friend (not furry, they're for a Warhammer 40k Chaos demon costume). All the ones we've seen were made of 2x4s. By my calculations the steel will be slightly lighter, and infinitely cooler.  Edit: Also I taught said friend to weld. She's more an electronics-soldering type, but once she got over the sound of it ("you're using the power of letting the smoke out for constructive purposes," I explained) she managed to melt some metal.

Chillbro Baggins fucked around with this message at 05:51 on Mar 12, 2011 |

|

|

|

Your wife owns.

|

|

|

|

Slung Blade posted:Your wife owns. Also the garage/shop caught fire like two hours after we finished welding; the Fire Marshal absolved me of all blame, and is putting "unexplained" in the report. There were scorch marks on that wall when we moved in. He said something along the lines of "I've been doing this for ... way too long, and this is one of the cases where I don't know  " There is apparently nothing on that wall that could be a heat source, yet it has burned twice. All my welding sparks were falling straight down under the bench four feet away from the fire, and even my grinding sparks were going toward the back wall, and I was annoyed at coating my toolbox in grinder dust. He also commended my job of putting it out; when the FD got there they didn't run any lines from the trucks, they just used my melted-through-and-cut-at-the-leak (for it was hanging on the wall that burned, on that hook you can see in the first pic) garden hose to mop up. " There is apparently nothing on that wall that could be a heat source, yet it has burned twice. All my welding sparks were falling straight down under the bench four feet away from the fire, and even my grinding sparks were going toward the back wall, and I was annoyed at coating my toolbox in grinder dust. He also commended my job of putting it out; when the FD got there they didn't run any lines from the trucks, they just used my melted-through-and-cut-at-the-leak (for it was hanging on the wall that burned, on that hook you can see in the first pic) garden hose to mop up.  Turns out I know the Fire Marshal from my newspaper work -- I've interviewed him when somebody else's house burned down; and firefighter Mauldin there is one of my fellow part-time photojournalists -- he shoots high school football for us. Edit: I totally did not recognize S. Mauldin. He said asked if I recognized him and I said "Y'all all look the same in bunker gear," then he took off his helmet so I could see his face and I bluffed my way through until he turned around and I saw his name on his coattail. The wife has an excuse, she can't see faces; I'm just dumb. Also when I saw the Fire Marshal's nametape I knew I'd met him before when somebody else's house burned down, but I could swear he had a buzzcut and a moustache -- tonight he was clean-shaven everywhere I could see. I remember him because there was a bit of confusion over his first name for the cutline -- James, Jim, or Jimmy? Chillbro Baggins fucked around with this message at 09:42 on Mar 12, 2011 |

|

|

|

Congratulations! If I recall correctly, you are the first one of us to bring the fire dept out! It took us two and a half years to get to this point. Edit: I'm glad your barn didn't burn down! Edit2: You can't call yourself a metalworker till you burn yourself and start a fire. AbsentMindedWelder fucked around with this message at 12:47 on Mar 12, 2011 |

|

|

|

AbsentMindedWelder posted:Congratulations! If I recall correctly, you are the first one of us to bring the fire dept out! It took us two and a half years to get to this point. You were pretty close to needing the FD with that pan of gasoline.... :-D

|

|

|

|

iForge posted:You were pretty close to needing the FD with that pan of gasoline.... :-D

|

|

|

|

Do you think I could use an acetylene torch (note: just acetylene, not o/a) to get a piece of steel hot enough to do hot work on it? As in hot forming, not like forge welding.

|

|

|

|

Probably...? If you're decent at playing the flame right? I don't have any acetylene experience, so maybe this is all dumb navel-gazing, but it isn't too hard to punch past oxidization colours and get into a low-red glow with a boring old propane torch (depending on the stock, natch), if you've got patience and don't mind wasting a lot of propane for a single kinda-half-heat. Acetylene burns hotter, so yeah, it's worth a shot. Ambrose Burnside fucked around with this message at 01:44 on Mar 13, 2011 |

|

|

|

The Scientist posted:Do you think I could use an acetylene torch (note: just acetylene, not o/a) to get a piece of steel hot enough to do hot work on it? As in hot forming, not like forge welding. Acetylene is DIRTY by itself. SOOT everywhere. As in, your entire workspace and your lungs will be covered in black dust.

|

|

|

|

jovial_cynic posted:Acetylene is DIRTY by itself. SOOT everywhere. As in, your entire workspace and your lungs will be covered in black dust. An air acetylene torch will not produce any soot. An oxy-acetylene torch before you open the oxygen valve will. And no, the acetylene torch isn't going to get it hot enough to work. Plus it's an expensive gas for that purpose.

|

|

|

|

Yeah, the little B-tank acetylene torches absolutely rock. For any real hot metal work you're not going to get any large piece of steel uniformly hot enough without o/a. It'll be better with an air-acetylene over propane, but it'll still be a struggle.

|

|

|

|

|

| # ? May 25, 2024 23:20 |

|

If all you had was a regular propane or acetylene torch, you could stack up some fire bricks to make yourself a mini-forge, and then you could heat some steel.

|

|

|

Bad Angus! Bad!

Bad Angus! Bad!