|

So my part time job is being an amateur prop maker, and one of the main markets for that is high-end larpers with lots of money. Last summer, the stars were finally right and I got to do a project that included 3d printing. One guy sculpted a spaulder on Zbrush with frankly ridiculous detail as far as larp armor goes. We had it printed out by Shapeways for a relatively high price (around 500$). I made a silicone mold and cast it multiple times in cold cast resin with fiberglass reinforcement. (The result is mildly artistically NSFW, I'll link it instead if anyone complains)  (the metallic effect isn't so great, mostly because of the lighting) Bottom line: 500$ isn't that much considering I would have needed 80$ of super sculpey and god knows how many hours of painful sculpture work to come close to this by classical means. 3d printing is awesome. The future will truly be here once it becomes practical to 3d scan a full suit of gothic plate armor and have a bored video game 3d artist to Zbrush insane embossed detail on it. I had previously used a CNC mill on another armor project, but the Zbrush/3d printing pipeline is much more refined, while CNCs are mostly limited to what can be sketched out in Catia. I can't wait to have one of these babies in my workshop. Super.Jesus fucked around with this message at 19:20 on Jan 23, 2012 |

|

|

|

|

| # ? May 8, 2024 18:58 |

|

That's super cool, and a great insight into actual revolutionizing of a workflow or process (i.e. "something other than bottle openers and coat hangers")

|

|

|

|

Mister Sinewave posted:That's super cool, and a great insight into actual revolutionizing of a workflow or process (i.e. "something other than bottle openers and coat hangers") My only gripe with it is that we chose one of the cheaper white plastic materials for cost reasons, and ended up with a striped master model. Fortunately, it ended up looking like rippled damascus metal once the patina was applied. My first run was 5 spaulders, but if I had 50 to make and wanted them baby smooth, paying 1500$ for the master model would have been possible. Fortunately, it's only going to get cheaper.

|

|

|

|

You know, I gotta say that Ponoko has a pretty baller progress tracker for orders.

|

|

|

|

I don't fully understand how ponoko or shapeways work. If I have my own 3d printer, can I offer my services through either of them?

|

|

|

|

Both of them are fab houses. As in, send them a (for example) 3D design and they will print it on their fancy non-hobby-grade machines. But let's use those fake armour pieces from a few posts above as an example: As the creator/owner/whatever: 1) Open an account 2) Upload the design, possibly indicate which material(s) suitable for making it with 3) Then do one (or both) of the following:

The fab houses just have their system made so that it's the same back-end whether you're sending them a design file and saying "make me one of these" or whether you designed some jewelery and are telling them "hey could you let people order these in plastic, gold, or silver and you make & ship them and handle it all for me?"

|

|

|

|

Be aware that under most circumstances, it's going to be way cheaper to get a master model made and cast your production run with standard production techniques. For example, get a detailed and smooth model made for a ring, make a high temperature silicone mold, and then cast it in wax for lost wax casting or directly in pewter. Sell directly on Etsy. There's also the advantage of choosing the material. Get a part printed in weak UV resin and then cast it in high-performance smooth-on urethanes. Shapeways is pretty much perfect for rapid prototyping. A notable exception exists for stuff that simply can't be molded, such as this insanely awesome dice set: http://www.shapeways.com/model/126266/ Expect most successful Shapeways products to be novel 3d shapes that can't be made with standard techniques.

|

|

|

|

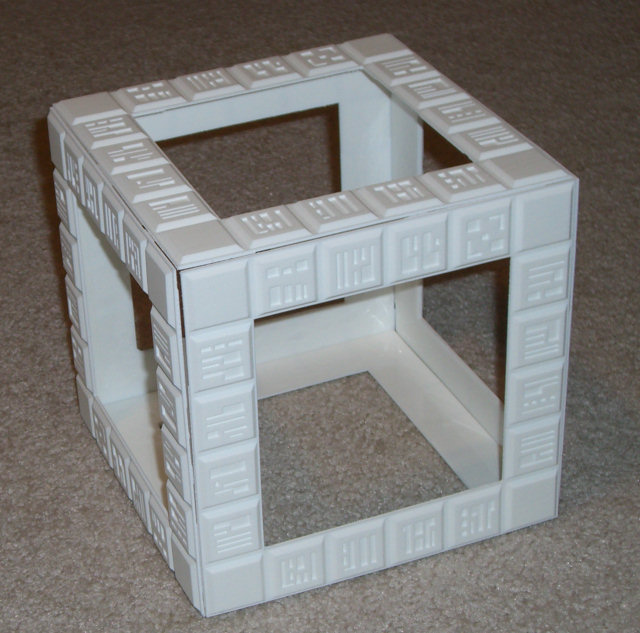

Super.Jesus posted:Very cool prop stuff Shapeways helped me bring a replica of a somewhat obscure Stargate SG1 prop to my workbench. (NERD ALERT) Telchak's Cube was something I always wanted to make. You can get replicas of dozens of other common props pretty readily, but nobody ever made one of those cubey things. I found some nice close-up photos from a prop auction way back in like 2005, and was able to model one face of the cube with excellent accuracy. The problem from there was actually producing one. I'm not a sculptor, laser cutters weren't quite up the the task, CNC wasn't an option for me at the time, so I ended up just shelving the whole project for a lot of years. Last year, after learning about Shapeways, I was able to re-jigger my old Lightwave model into the proper format for them to process. For around $50 and a couple weeks of waiting I finally had a physical item to work with. A quick open-faced mold and a quart of resin later, and I had a full set of cube sides...that are still waiting for me to get to work on them one of these days. Here are the casts all hastily taped together, with a CD in the one pic to give a sense of scale. It's almost exactly 8 inches (20-ish centimeters) square.   So yeah, Shapeways loving rocks. This piece is crisp and sharp, and no CNC machine I could afford to use would have been able to reproduce all those recessed symbols like the 3D printing process can. Well worth the effort and cash to get it manufactured. I'll probably even get around to finishing it someday!

|

|

|

|

There's previously been some talk about 3d wax printing for lost wax casting. I've said before that people have had good success with simply burning out the plastic to make molds instead. Also, that wax doesn't really respond well to FDM extrusion. Well, a SLS wax printer just showed up on the reprap wiki. It's not yet fully documented, so you can't quite go out and build one. He has some video of it in action at http://vimeo.com/user8627618

|

|

|

|

Just out of curiosity, why did you make 4 walls that had to be stuck together instead of having all 4 walls be one piece? It is important that it can be taken apart again?

|

|

|

|

Mathhole posted:Just out of curiosity, why did you make 4 walls that had to be stuck together instead of having all 4 walls be one piece? It is important that it can be taken apart again? Molds aren't free. We're talking about a huge 3d cube mold vs a centimeter thick flat mold. Considering that mold rubber is about 90$ a gallon, that's a huge difference. Aurium posted:There's previously been some talk about 3d wax printing for lost wax casting. I've said before that people have had good success with simply burning out the plastic to make molds instead. Also, that wax doesn't really respond well to FDM extrusion. Given its low melting point, a wax printer could be very interesting compared to an abs printer. For large objects, you can smooth out the lines with a weak heat gun. However, as long as it's not a ridiculously complex print, just make a high temp silicone mold of the plastic original and cast your lost wax sprue out of it.

|

|

|

|

Super.Jesus posted:you can smooth out the lines with a weak heat gun. As long as you don't mind the rest of it "smoothing out" as well, and uncontrollably!  Soft wax is a good example of a material that is really best just buffed or something instead of melted to smooth it out. It's so ridiculously easy to deform and melt that while a heater seems logical, there's really just no control over the process.

|

|

|

|

Super.Jesus posted:Molds aren't free. We're talking about a huge 3d cube mold vs a centimeter thick flat mold. Considering that mold rubber is about 90$ a gallon, that's a huge difference. As long as you don't need to produce multiple copies plaster is a much better molding material for lost wax due to its much higher heat tolerance, and with vibration setting better detail fixing.

|

|

|

|

Linux Assassin posted:As long as you don't need to produce multiple copies plaster is a much better molding material for lost wax due to its much higher heat tolerance, and with vibration setting better detail fixing. I'm not sure you understand. Silicone is used to create a wax model, which is then dipped in the various plaster and ceramics that are used to create a mold for metal. Silicone has no trouble handling melted wax, certain types of silicone can be used to cast molten pewter.

|

|

|

|

Supposedly PLA works ok for molds. According to one of PLA filament providers, the "Natural"(uncolored) PLA: "Used for making mould cores as it will completely vapourise on strong heating."

|

|

|

|

Super.Jesus posted:I'm not sure you understand. Silicone is used to create a wax model, which is then dipped in the various plaster and ceramics that are used to create a mold for metal. Silicone has no trouble handling melted wax, certain types of silicone can be used to cast molten pewter. Perhaps I do not. Scenario as I see it: You have a 3d printer, and some sort of foundry setup, it can print PLA/ABS. There is an object you want to create in metal rather then plastic, and you only need one of them. My suggestion was : Print object Cast directly into plaster Vaporize/melt plastic in foundry while heating metal Add metal You can do that because the plaster will not be damaged as temperatures that will completely incinerate even ABS. What I think you are suggesting: Print object Cast in silicone Use silicone mold to cast a wax copy Cast wax copy in plaster Melt out wax at reasonable temperature heat mold and metal in foundry add metal Now; the upside of doing it that way is that you can make multiple copies without making multiple prints, you keep the plastic original and your foundry won't smell of burning plastic; however from a cost perspective silicone is radically more expensive then either printer ABS or plaster. I'm not sure if there is actually any time savings; as setting up a silicone->wax cast probably takes about the same time as starting the print again; but I think that the 'direct' method is a winner on both simplicity and likely cost (as long as your dealing with a run where 1*plastic+1*silicone+n*wax > n*plastic ) Edit: And evidently PLA will completely vaporize.

|

|

|

|

Linux Assassin posted:My suggestion was : I use this process every day! This is the process we use for jewellery, except we carve the wax objects by hand. The jewellery industry already has some 3D wax printers available that print in insanely small layers to prevent little spheres and other tiny details from being blocky. Although I would go with a different method for anything larger than jewellery size :P

|

|

|

|

Mathhole posted:Just out of curiosity, why did you make 4 walls that had to be stuck together instead of having all 4 walls be one piece? It is important that it can be taken apart again? Super.Jesus pretty much nailed it - $$$. Having one face of the cube printed was about $54, so it would have cost over $300 to have an entire cube made. With a small $50 resin/rubber kit from Smooth-On, I was able to mold and cast copies of the single master for far less money. The polyurethane resin is also a much stronger material than the Shapeways basic white plastic for something this thin. By doing it this way, I also have the option of producing a basically infinite number of cube sides if I ever feel the uncontrollable urge to square off with MGM's intellectual property lawyers.

|

|

|

|

Linux Assassin posted:Perhaps I do not. Yep, my process's only advantage is the fact that you can make multiple prints. If you want a unique model, you can go straight to casting.

|

|

|

|

Finally getting my arse in gear and starting to order parts for my first 3D printer and I have a question: What is the primary advantage or difference between 1.75mm and 3mm filament? I'm looking at a J-head, which can apparently be adapted to do both, so it's sort of irrelevant but I just wondered why you would choose one over the other. Peter Ugsly posted:My roommate, Sparr, has committed a complete redesign of this printer. His MendelMax puts the rest of the printers we have here to absolute shame. He's having problems with it printing too fast and the layers not being solid enough before the next one is lain down. Awesome problem to have. Also, I've started ripping smooth rods from printers and scanners now, since he's built a bunch of scripts to procedurally generate the parts I figure hell... it should work! I'm interested in hearing about this design; I've decided to build a MendelMax after reading up on it, the extrusion construction just makes way too much sense.

|

|

|

|

The short answer is that it's easier to get good results with 1.75mm, where as 3mm is cheaper.

|

|

|

|

3mm is a bit cheaper per weight and more popular in the reprap crowd. You can get plenty good detail with it on a well calibrated machine. I haven't tried 1.75, but from what I hear it seems it would be more important if you are trying to extrude very tiny amounts at a time, probably like < 0.1mm layer height, which is just silly anyways in my opinion. Miniscule layer heights and nozzle sizes cause print times to skyrocket. so you better have the patience to go with it. Edit: Basically the 1.75mm is about 1/3 the cross sectional area of 3mm, so you have 3x more control over the extrusion volume at very low rates of deposition. But like I said I don't feel you really need any more control than the amount we can get with 3mm. peepsalot fucked around with this message at 19:13 on Jan 26, 2012 |

|

|

|

There's also the advantage that - compared to 3.0mm - you shovel more 1.75mm filament for the same amount of print volume. Which means finer control also because there is less tension built up in the filament itself between the compression of from the feed and the print head because you're not working quite as hard to shove 1.75mm as you are to shove 3.0mm. (The shorter the distance between the feed and the print head, the less backed-up tension you need to deal with as well.) But there's nothing WRONG with 3.0mm. Short answer is that 1.75 seems to be the direction all the new stuff is moving in.

|

|

|

|

OH yeah the other thing about 1.75 is that you need less torque to push it, so you can get away with direct drive (non-geared) extruder, like makerbot does, etc. And as far as retraction stuff, it's more of an issue if you have a bowden setup like ultimaker and some other commercial printers do. Most of the reprap folks shun bowden tubes though, because of the crazy compression/retraction issues.

|

|

|

|

Thanks for the replies guys, I'm hopefully ordering the printed parts tomorrow, along with a big chunk of the 'vitamins'. You guys in the US are so drat lucky with the suppliers you have, the UK is full of companies that sell everything you need, but not unless you're a company. "We don't do end users." So if I was primarily concerned with print quality and durability, and I don't really give a crap about the cost difference or speed, 1.75mm is where I should be going? What kind of extruder should I be looking at to feed the J-Head in this case?

|

|

|

|

ReelBigLizard posted:Thanks for the replies guys, I'm hopefully ordering the printed parts tomorrow, along with a big chunk of the 'vitamins'. You guys in the US are so drat lucky with the suppliers you have, the UK is full of companies that sell everything you need, but not unless you're a company. So make a company (or at least say you are one)? At least in Canada it only costs $70 to register a sole proprietorship; I imagine the UK is similar. Of course the issue may actually be that they don't do lots not in the hundreds-thousands; which will either make your first purchase very expensive (But that will be fine if you plan on doing this for a while; so minimum purchase 25) or outright impossible (if they require you to purchase 1000 spools of 1.75mm ABS cord).

|

|

|

|

Linux Assassin posted:So make a company (or at least say you are one)? At least in Canada it only costs $70 to register a sole proprietorship; I imagine the UK is similar. Currently I'm pretending (I do actually have a separate account I trade with when I'm contracting), so I might get away with it. Registering a company where I am (Guernsey, not quite UK) is somewhere near $600, and then $300 yearly after that... My choices are either to get ripped off here (everything is more expensive than the US suppliers) or get shafted on postage and have to wait 6 weeks for stuff to arrive.

|

|

|

|

ReelBigLizard posted:Currently I'm pretending (I do actually have a separate account I trade with when I'm contracting), so I might get away with it. Registering a company where I am (Guernsey, not quite UK) is somewhere near $600, and then $300 yearly after that... Wait, are you trying to buy filament? There's a great company in the UK called Faberdashery that sells PLA by the metre: http://www.faberdashery.co.uk/ They've got a huge range of colours:

|

|

|

|

techknight posted:Wait, are you trying to buy filament? No, hardware like Aluminium extrusion, 8mm linear shaft, bushings and good quality precision timing belts/pulleys. But! thanks for that link, that's a great selection! Is there anywhere similar for ABS? EDIT: What's the deal with PLA vs. ABS while we're at it? Is one easier to print than the other? better for certain applications? EDIT 2: Update - MendelMax parts and HPB ordered EDIT 3: SS threaded rod, smooth rod, half of the hardware found at a local supplier at lunch  EDIT n: GT2 Precision belts/pulleys, sintered bronze self-centring bushings ordered too

ReelBigLizard fucked around with this message at 16:06 on Jan 27, 2012 |

|

|

|

ABS is cheaper. PLA shrinks (and thus warps) far less. You can compensate for ABS warping with a heated build area, which is all but standard these days. PLA is made of corn, not oil, and is "biodegradable." In quotes because it needs special conditions, not just a landfill or by the side of the road. Also, there is clear PLA which looks all crystalline, while no clear ABS filament is available.

|

|

|

|

Have any of you used the clear PLA before? I am wondering just how well it works. I wouldn't expect it to be crystal clear or anything, but can you at least see through to the other side ok once it has been printed or is it really more just something that light will pass through after being severely diffused?

|

|

|

|

nesbit37 posted:Have any of you used the clear PLA before? I am wondering just how well it works. I wouldn't expect it to be crystal clear or anything, but can you at least see through to the other side ok once it has been printed or is it really more just something that light will pass through after being severely diffused? It looks like this: Here's Another example. You can see the other half of the sail through the support, but it's highly diffused. Aurium fucked around with this message at 17:38 on Jan 27, 2012 |

|

|

|

If you want crystal clear PVA (though that sailing ship looks like it's made of glass which is pretty snazzy) it SHOULD be possible to do the following: 1- Print object in clear PVA, include some extra material at the top (like a spru but for a different purpose). 2- Cast in plaster, vibrate constantly to make the fit VERY tight 3- Heat to a high melting point but non-burning point for the PVA while vibrating (the extra material should settle into the mold as air is released) 4- Allow to cool to room temperature slowly 5- Dissolve plaster in water. 6- Admire revealed crystal clear structure

|

|

|

|

Why doesn't anyone sand their prints before posting pictures of them?

|

|

|

|

Goldwarf posted:Why doesn't anyone sand their prints before posting pictures of them? I'm actually glad that the standard is not to sand prints before posting them. Show what your 3d printer does; not what you can do by sweat, skill, and file. If it were not for people not sanding prints I would not know that a properly configured ultimaker can do the level of detail I would really like without requiring extra effort on my part. https://www.hive76.org/insane-3d-printing-resolution-ultimaker-under-the-micro (yes, the layers are more then 5x thinner then the grooves in his fingerprints) now admittedly every one of those yoda's probably takes like a day of solid print time, but a huge problem for me and 3d printers is the lack of high detail requiring sanding/rub downs with solvent/etc in order to get something that actually does not look like a layered rendition of what it is supposed to be.

|

|

|

|

I really like the unsanded look, but some people I've shown items to seem to hate it.. The only object I've sanded (and smoothed with acetone) is the blade piece for the sword of omens print.

|

|

|

|

Linux Assassin posted:https://www.hive76.org/insane-3d-printing-resolution-ultimaker-under-the-micro (yes, the layers are more then 5x thinner then the grooves in his fingerprints) Well crap. That's about the level of detail I told myself I would wait for, before shelling out bucks for a machine... I guess I'll wait until they're below $1,000? Still tempted though.

|

|

|

|

Locus posted:Well crap. That's about the level of detail I told myself I would wait for, before shelling out bucks for a machine... Yea i'm waiting for this too...If I can print out rings and necklace designs from a machine that costs less than $1,000 i'm going to be one happy camper. Right now jewellery level printers go for $35,000 with $5,000 required cost per year for maintenance and tech support :S EDIT: Looking more into it, I think this might be my break into buying my first 3D printer! Time to start saving... Claes Oldenburger fucked around with this message at 05:46 on Jan 28, 2012 |

|

|

|

I finally got an opportunity (read: excuse) to order something from Shapeways. My old slide rule's plastic case insert ended up breaking under some books (and yes, I keep one as a last-ditch backup in case my calculator fails during a test or something, which has happened much more often than I'd like), so I took some measurements, loaded up Inventor, and slapped a replica together. It only cost me $2 to get it in Strong & Flexible, which was a lot cheaper than I thought it would be, although the $6.50 shipping kind of kicks it up a notch. We'll see how it ends up working when it gets here, I guess. edit: Welp, exported in centimeters instead of millimeters. It's more ungodly expensive than I expected. E4C85D38 fucked around with this message at 20:26 on Jan 31, 2012 |

|

|

|

|

| # ? May 8, 2024 18:58 |

|

|

|

|