|

Aren't most jobsite saws direct drive as well? Hence the extra noise?

|

|

|

|

|

| # ? May 14, 2024 00:41 |

|

I was at sears today to pick up a basic set of mechanics tools, and saw this Craftsman table saw: http://www.sears.com/craftsman-professional-10-in-contractor-saw-sears-21833/p-00921833000P?prdNo=2&blockNo=2&blockType=G2 Thoughts? It costs a little more than the Rigid from Homedepot, but I dont know which is built better.

|

|

|

|

Looks like they just rebranded the Rigid

|

|

|

|

/\/\ I find that power tools are going the way of telecom companies. In another decade there will be two companies that re-brand one product to fill a market that has 10 options.LumberingTroll posted:I was at sears today to pick up a basic set of mechanics tools, and saw this Craftsman table saw: http://www.sears.com/craftsman-professional-10-in-contractor-saw-sears-21833/p-00921833000P?prdNo=2&blockNo=2&blockType=G2 It seems to be a decent saw, and a lot of the reviews say that it is sturdy. If you're set on a new table saw, I'd say go for it. Naturally I'd recommend that you check out craigslist/kijiji/whatever to see what is available in your area. You might be able to get something twice as big and heavy as that for 1/2 the price if you get lucky.

|

|

|

|

LumberingTroll posted:Thoughts? It costs a little more than the Rigid from Homedepot, but I dont know which is built better. It is the same saw with minor differences but the same alignment issues. Make sure to read up before buying.

|

|

|

|

Hmm now I am looking at Shop Fox, which is a rebranded Grizzly, they are owned by the same company. http://www.amazon.com/Shop-Fox-W1819-10-Inch-Riving/dp/B004IYJ9Y2/ref=sr_1_2?ie=UTF8&qid=1367514694&sr=8-2&keywords=shop+fox+table+saw for $60 the extended table can be had, but that may be overkill for the size of my shop. http://www.amazon.com/Shop-Fox-W1820-10-Inch-Extension/dp/B004IYJ9Z6/ref=sr_1_1?ie=UTF8&qid=1367514694&sr=8-1&keywords=shop+fox+table+saw LumberingTroll fucked around with this message at 18:29 on May 2, 2013 |

|

|

|

Still if it were me looking to spend that much on a table saw I would get a SawStop. Politics aside, not cutting my fingers off is a huge plus to me. Plus they really are top tier saws.

|

|

|

|

Whats so special about a SawStop? I am not seeing anything that has some kind of special no amputation of fingers attached to it.

|

|

|

|

LumberingTroll posted:Whats so special about a SawStop? I am not seeing anything that has some kind of special no amputation of fingers attached to it. http://www.youtube.com/watch?v=FquL0GG9RGI

|

|

|

|

https://www.youtube.com/watch?v=FquL0GG9RGI Imagine your finger as the hot dog. They are really expensive, and in retrospect I probably should have saved the extra coin to get one. I'm not scared of losing my fingers on my current saw, but are my fingers worth an extra $1000? Yes. Cmdr. Chompernuts fucked around with this message at 18:39 on May 2, 2013 |

|

|

|

Huh that is interesting. I assume it detects the additional material and triggers a stop? How are the fences and alignment?

|

|

|

|

Excellent. To be more helpful here's a review: http://www.finewoodworking.com/tool-guide/article/tool-review-sawstop-contractors-saw.aspx The Biesemeyer fence is a worthy upgrade, as are cast iron extensions Cmdr. Chompernuts fucked around with this message at 18:47 on May 2, 2013 |

|

|

|

I am looking more towards the cabinet models, as I wont be moving it at all. Suggestions between the 3HP and the 1.75HP models? http://www.amazon.com/SawStop-PCS31...eywords=sawstop http://www.amazon.com/SawStop-PCS175-TGP236-Professional-Assembly-Extension/dp/B009C7NF0Y/ref=pd_sim_sbs_hi_5 Not loosing my fingers is a decent investment.

|

|

|

|

3HP is great, especially when dealing with hardwoods, but not necessary. It will require a 220v outlet, factor in an extra $100-$200 to have an electrician do that. IMO if you're going with the cabinet its worth the extra money, but 4 posts ago you were talking about getting a $500-$650 metal stand contractor type saw. Why not get the SawStop contractor?

|

|

|

|

No real reason one way or the other, just evaluation options. When I invest money into this kind of thing I don't want to have to replace it ya know? It also doesn't hurt that through lasercutting work I can tie this into a business expense and as such a tax write off. I own a small software studio, so I am always looking for tax write offs. LumberingTroll fucked around with this message at 19:05 on May 2, 2013 |

|

|

|

That's generally a good way of thinking about tools, but I doubt you'll be replacing the sawstop contractor anytime soon, it will save you $1000 over the cabinet saw, and that's 1/5th of your budget.

|

|

|

|

LumberingTroll posted:No real reason one way or the other, just evaluation options. When I invest money into this kind of thing I don't want to have to replace it ya know? This is dead on. The most expensive tool is the one you buy twice. From what I've read the quality of SawStop saws are right up there with Powermatic. My local woodworking store carries pretty much all major brands of machinery; Powermatic, jet, sawstop, etc. They told me 90% of the table saws they sell are SawStops.

|

|

|

|

The Shopfox you posted is a much better saw than the Sawstop contractor. When I bought my saw the only options were contractor or cabinet but with hybrids now available there really is no reason to buy a contractor. To clarify, the SS contractor is not a bad saw but is way overpriced, a $1000 saw with a $1000 gizmo. If you really want the Sawstop, go with the cabinet version which by all reports is an outstanding machine.

|

|

|

|

What's the favorite way to make a truly square cross cut sled for a table saw?

|

|

|

|

Wood Whisperer has a great video guide on precisely that, worked for me! http://www.thewoodwhisperer.com/videos/the-cross-cut-sled/

|

|

|

|

|

Tigren posted:What's the favorite way to make a truly square cross cut sled for a table saw? http://youtu.be/UbG-n--LFgQ Slightly involved, but really accurate.

|

|

|

|

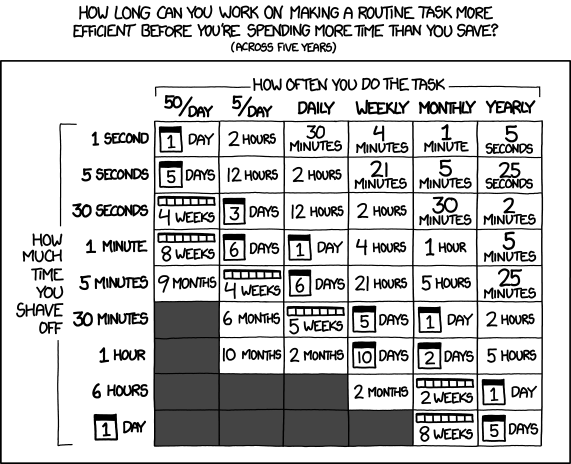

From xkcd.com; posted on our local woodworking site with a comment about jigs. edit; speaking of crosscut sleds, here's one with dust collection. http://lumberjocks.com/projects/83739 wormil fucked around with this message at 04:27 on May 4, 2013 |

|

|

|

Made me a cuttin' board. Hard maple. Not sure why the joint lines ended up lighter than the center areas... but i like it! Doused in mineral oil, and then I used a home-made beeswax+mineral oil paste to put the final protective coat on. There's a few burn marks on the bottom + corners, but bah, whatever, gives it character. Need to adjust the tablesaw before i make the next one(s)

|

|

|

|

Probably the glue is what caused that, it absorbs oil and whatnot less readily than raw wood, and tends to soak in to the wood itself, so you end up with a sort of gradient like that leading away from the glue seams. Looks cool, though, like brickwork.

|

|

|

|

|

Any advice for bending a bit of plywood strip? Like, a strip of 3/4" ply, maybe 1 1/4" wide. Long, though, maybe a full 8' long, and I need to do a couple different bends in it. Alternately I could use multiple segments along the edge I'd like to use this to trim, but it'd be way awesome if I could get it out of one smooth, continuous piece. A piece of solid pine would also work, I suppose, might look better too, and be easier to bend. Still not sure how to approach it, though.

|

|

|

|

|

Bad Munki posted:Any advice for bending a bit of plywood strip? Kerfing is the only way I can imagine. I kerfed some 1/8 ply for bending and it worked okay but even for ply that thin I had to cut most of the way through. Weird tablesaw accident today - I was crosscutting and the plastic spring clamp that was holding my stop block came apart and flew into the blade. Nothing serious came of it but there was that second of wormil fucked around with this message at 03:02 on May 6, 2013 |

|

|

|

Ehh, this is intended to be a bit of trim for a contour, kerfing would kind of spoil the look. I'm wondering if I could rig up a steam chamber of some sort. I don't need a large volume, I think a bit of round 3" or 4" ducting would work, just need a good source of steam. Bad Munki fucked around with this message at 03:08 on May 6, 2013 |

|

|

|

|

Bad Munki posted:Any advice for bending a bit of plywood strip? Like, a strip of 3/4" ply, maybe 1 1/4" wide. Long, though, maybe a full 8' long, and I need to do a couple different bends in it. Alternately I could use multiple segments along the edge I'd like to use this to trim, but it'd be way awesome if I could get it out of one smooth, continuous piece. other than kerfing, maybe steam it? i saw a thing where someone was building something out of long thin strips of bent wood and he had a 6, 8 foot length of pvc pipe with the wood in it and piped a bunch of steam in one end. iirc he steamed them like 4, 6 hours to get them flexible enough.

|

|

|

|

I was just googling around on steaming and it sounds like kiln-dried wood just won't steam-bend on account of something being set during the kiln process? If so, boo. I'd consider some sort of glue-lam process, but it's a complicated enough bend that I don't know how well that would actually work out.

|

|

|

|

|

yeah, I honestly think the best way is to glue veneer strips together in the curve shape you want... trim it once it is glued in place. the other option could be to glue-laminate three strips of 1/4" ply together for the same thickness, or use 1/2" ply instead which should take the bends a bit better. last ditch option would be to set up a template for the curve, and then go slow and steady with an iron and hope it can penetrate the 3/4" (it may not, but you could try). sort of a poor man's steam chamber. in arch. school a lot of people had success bending wood by holding it over a kettle, but it was't 3/4" thick. Eventually the school built a steam chamber for the furniture design/build classes

|

|

|

|

Ever use bending plywood? That is 6 pieces at a 3" radius. Each ply is 1/8th inch. I've done a little bending, this week even, and bent laminations are a lot easier than steam bending. For my steam source I went to goodwill and got a fabric steamer for $4. Or look for used wallpaper steamers. mds2 fucked around with this message at 03:29 on May 6, 2013 |

|

|

|

Part of the difficulty is that the bend doesn't exist in just a plane, it's a compound bend. I'm, uh...well, I'm building a miniature dog chariot for my daughter. I'd like this strip to curve around the front lip of the shield and down the sides.

|

|

|

|

|

Do you have a picture of what you're trying to attempt? I've never tried compound bending. But Iove to experiment with that stuff.

|

|

|

|

Bad Munki posted:I'm, uh...well, I'm building a miniature dog chariot for my daughter. i dont care how you do it but this needs to happen, goddammit

|

|

|

|

Bad Munki posted:Ehh, this is intended to be a bit of trim for a contour, kerfing would kind of spoil the look. I suspect your plywood will delaminate. Kiln dried will bend but you're right, it doesn't bend well. From what I understand the drying process collapses the cells and makes the wood brittle. I tried steam bending kiln dried poplar, which doesn't bend well anyway, and I could only get a slight curve before it would break. And it's the heat that allows wood to bend, water just helps heat penetrate. Matthias Wandel used a rice cooker with a PVC pipe chimney to do steam bending. The best way might be to use green lumber as it bends very easily. If you haven't seen it, here is an awesome Nova documentary on some folks building a chariot and the troubles they had steam bending. http://www.pbs.org/wgbh/nova/ancient/pharaoh-chariot.html

|

|

|

|

Well that's a stupid product! How the hell am I supposed to cut 1/4" hotdog slices with that?

|

|

|

Blistex posted:Well that's a stupid product! How the hell am I supposed to cut 1/4" hotdog slices with that? With your bandsaw, obviously. Far less waste, and plus you can resaw the dog to make awesome sandwich stackers. rotor posted:i dont care how you do it but this needs to happen, goddammit Yeah, my dog loves skijoring and bikejoring and canicross and all other forms of pulling things. I won't be setting him loose with the chariot or anything, but I think it'd be a freakin' awesome way to walk him and my daughter, especially since she could basically come and go from the chariot at will. I'm thinking I'll need to fashion a nerf spear or some sort as well.

|

|

|

|

|

Bad Munki posted:With your bandsaw, obviously. Far less waste, and plus you can resaw the dog to make awesome sandwich stackers. I guess if it's good enough for Iranian public amputations, it's good enough for me.

|

|

|

|

Bad Munki posted:With your bandsaw, obviously. Far less waste, and plus you can resaw the dog to make awesome sandwich stackers. It's more likely than you think. http://qualityfoodequipment.com/bandsaws-meat-c-1.html

|

|

|

|

|

| # ? May 14, 2024 00:41 |

|

wormil posted:I suspect your plywood will delaminate. Kiln dried will bend but you're right, it doesn't bend well. From what I understand the drying process collapses the cells and makes the wood brittle. I tried steam bending kiln dried poplar, which doesn't bend well anyway, and I could only get a slight curve before it would break. And it's the heat that allows wood to bend, water just helps heat penetrate. Matthias Wandel used a rice cooker with a PVC pipe chimney to do steam bending. The best way might be to use green lumber as it bends very easily. If you haven't seen it, here is an awesome Nova documentary on some folks building a chariot and the troubles they had steam bending. I'm working on a composite bow atm, and I also have a bit of steambending experience. Go along what Wormil said. Kiln dried wood isn't good for steambending. If you don't find an alternative, you can soak the pieces in water for 2 weeks. Also, add a little Lysol and make sure that it's covered by water for the whole time. Air dried wood will have to be watered for a week. Green wood is the best. Bending it is almost effortless. There's also the question what wood you want to use. Some woods bend better than others. Maple, Mulberry, Ash, Elm etc. will be your first choice. General rule of thumb is that you steam or cook the piece for an hour per inch thickness. Also watch out how the grain runs if you want to bend over smaller radii.

|

|

|