|

kastein posted:Worth noting is that the copper pipes in grover's pic are probably the conductors - skin effect uber alles! Large-ish radar sets have waveguides between the magnetron and the antenna - basically a copper pipe. Is this what we're looking at? (Although I'm not sure I can reconcile waveguides with omnidirectional antennas, but I just use the drat things, so  ) )

|

|

|

|

|

| # ? May 9, 2024 22:11 |

|

FrozenVent posted:Large-ish radar sets have waveguides between the magnetron and the antenna - basically a copper pipe. Is this what we're looking at? (Although I'm not sure I can reconcile waveguides with omnidirectional antennas, but I just use the drat things, so Radar sets work at much higher (1000x higher) frequencies. grover fucked around with this message at 20:04 on Nov 22, 2013 |

|

|

|

Two Finger posted:Could you tell me more about your comment on the brushless exciter? I'm more of an operations engineer than an electrical, I have a working knowledge of how the thing works but the theory is a little hazy to me. Wow, I am comically bad at visually judging size. Inside a synchronous motor, you have a field. This is basically an electromagnet. It catches onto the rotating magnetic field produced by the stator, making it rotate in sync with the line frequency (hence the name "synchronous motor"). Unless it gets so overloaded it pulls out, the motor will always rotate at a speed based on the line frequency and number of poles in the motor. One way to do this is to have a permenant magnet inside the motor, but a better way is to use an electromagnet. One of the cool things about a synchronous motor is that if you adjust the amount of current you apply to the rotating field, you can adjust the power factor of the motor. With an induction motor, you're generally stuck with a lagging power factor ranging from "lovely" to "more lovely" depending on the motor and how much it is loaded. With a synchronous motor, you can operate at unity (voltage and current are perfectly in phase) or even leading power factor (to compensate for the lagging power factor of your plant's other induction motors, with the aforementioned lovely lagging power factor. There are two ways to provide power to the exciter: Brush rigging and an external exciter You have a set of slip-rings attached to the motor's shaft, and carbon brushes ride on them. The slip rings are connected to the field windings. You connect an external exciter (basically a big DC power supply) to the slip rings. Pros:

Brushless exciter With a brushless exciter, the entire exciter assembly is attached to and "rides" on the motor shaft. Power is transferred from the outside world to the brushless exciter via stator and rotor windings. That part looks like a much smaller motor connected to the same shaft as the main motor. Pros:

Three-Phase fucked around with this message at 21:57 on Nov 22, 2013 |

|

|

|

Forgot to add this: here is a pretty basic diagram of a synchronous motor with across-the-line starting:

|

|

|

|

FrozenVent posted:Large-ish radar sets have waveguides between the magnetron and the antenna - basically a copper pipe. Is this what we're looking at? (Although I'm not sure I can reconcile waveguides with omnidirectional antennas, but I just use the drat things, so Like grover said that's actually just the center conductor - and I actually see that every 90 degree bend has discolored soldered segments right next to it, so yes, that's definitely copper water pipe and fittings being used as conductors. I don't have a good grasp of what size but it looks like 3/4" trade size if I had to guess based on the window frame molding. Speaking of which, notice how there's something odd in the middle of the window and it appears that a pipe goes through it? That's because the window is only there as insulation, the pipe leading to that odd thing in the middle of the window is the output from the antenna transmatch stage (all the inductors and capacitors in the foreground) to the base of that antenna tower. AM radio stations don't typically have an antenna tower that holds up an antenna like an FM station does, the tower is the antenna. Its height is tuned to match the wavelength being transmitted on, it's standing on a giant insulator, and all the guy wires have to be split into multiple insulated segments that are all non resonant lengths compared to the wavelength of the signal being transmitted because otherwise they'd either reflect the signal oddly or absorb it. That's why you'll see large ceramic "egg insulators" spaced out along the guy wires. Radio stations are about the only time anyone does anything industrial with RF - except N0N designator inductive heating systems, I guess. And those mostly live in the ISM microwave bands, so they aren't as awesomely huge.

|

|

|

|

Michael Scott posted:Hi, long shot here: Thanks for your answers guys. I found the video! https://www.youtube.com/watch?v=lMuJKsUjD_o Feel free to explain a little more if you can. I see the guy burned his hands a bit in the beginning. Isn't this crazy? I found this explanation on Reddit: quote:RF current does not penetrate deeply into electrical conductors but tends to flow along their surfaces; this is known as the skin effect. For this reason, when the human body comes in contact with high power RF currents it can cause superficial but serious burns called RF burns. Michael Scott fucked around with this message at 01:03 on Nov 23, 2013 |

|

|

|

Sounds about right, and yeah, that's a clear case of crazy russians. I'd prescribe a couple handles of vodka for the whole crew and a higher quality video camera because Russians being nuts on youtube is one of my favorite things ever.

|

|

|

|

kastein posted:Sounds about right, and yeah, that's a clear case of crazy russians. I'd prescribe a couple handles of vodka for the whole crew and a higher quality video camera because Russians being nuts on youtube is one of my favorite things ever. Yeah, they do some really strange things with power lines. Exhibit A The video cuts out awfully fast. Exhibit B

|

|

|

Two Finger posted:Could you tell me more about your comment on the brushless exciter? I'm more of an operations engineer than an electrical, I have a working knowledge of how the thing works but the theory is a little hazy to me. The trip valve and the governor were one valve? Sounds like poor design.

|

|

|

|

|

Yeah, it's something that had never come up before. The overspeed causes the governor to pull back to 0, cutting the fuel that way. It was never envisioned that there would be something physically preventing the governor from being able to pull back. The emergency stop used compressed air to overpower the fuel valve and force it closed that way. This is now being changed.

|

|

|

|

|

Consider doing a Fault Tree. These are useful since you can work them in both directions - from the catastrophic event down, or from the combinations of conditions to a catastrophic event. There are a lot of different things that you can consider:

That would help you see situations where a single failure could lead to a serious incident. Three-Phase fucked around with this message at 12:56 on Nov 23, 2013 |

|

|

|

12MW diesel/natural gas generator taking a 1500km land journey on a 216-wheel flatbed journey from the port to a power plant in Australia: In case you were wondering how they did it, neat 5-minute video about the trip (and some other info about the engine): http://www.enginelabs.com/news/true-story-behind-massive-engine-in-facebook-page-photo/

|

|

|

|

Holy poo poo, 164800 foot pounds of torque. That is 31.2 mile pounds.

|

|

|

|

kastein posted:Holy poo poo, 164800 foot pounds of torque. That is 31.2 mile pounds.  Maximum power: 108,920 hp at 102 rpm Maximum torque: 5,608,312 lb/ft at 102rpm Two stroke engines are big.

|

|

|

|

FrozenVent posted:

The 12MW one I posted above runs at 500rpm. The one you posted is 80MW at 102rpm. A 12MW packaged generator unit that runs at 1800rpm would be probably half the size, but would require a major overhaul over 2 or so years. So, you see "high speed" engines like that more in places they don't run continuously, like construction equipment and emergency generators. grover fucked around with this message at 19:00 on Nov 29, 2013 |

|

|

grover posted:The Australian one I posted was a 4-stroke. They're big because they're low-RPM. Low RPM reduces wear and maintenance intervals (which is very important for high-powered engines that run continuously for ships, trains, power plants, etc.), but since horsepower=torque x RPM, they need a cubic fuckton of torque to put out that power. So everything is super-massive to be able to be able to handle such high forces. Glancing at that it looks very similar to what I work on. For reference, we call an engine like that medium speed rather than low speed - low speed is up to about 150rpm.

|

|

|

|

|

FrozenVent posted:

You know that if Jesse James saw that he'd be trying to figure out a way to put that into a motorcycle.

|

|

|

|

There was recently a serious accident in Lorain, near Cleveland: Fire Erupts at Republic Steel's New Electric Arc Furnace It started during hot commissioning, no serious injuries but I heard the building is pretty much destroyed. Also amazing is the fact that it sounds like the firefighters didn't have adequate firefighting water available at the site. Three-Phase fucked around with this message at 15:13 on Dec 7, 2013 |

|

|

|

We had a fairly major winter storm event here - lots of ice and freezing rain, resulting in hundreds of thousands of outages beginning Thursday. A handful still aren't resolved. This is more of a poco question I guess, but after something like that, how many other companies will help out - and is it something they're required to do? The majority of the out of state energy trucks I've seen have been from Pike Energy in NC (I'm in TX), though I've also seen some unbranded trucks with Louisiana plates. e: if it matters, I live in Oncor territory. randomidiot fucked around with this message at 10:25 on Dec 9, 2013 |

|

|

|

some texas redneck posted:This is more of a poco question I guess, but after something like that, how many other companies will help out - and is it something they're required to do? The majority of the out of state energy trucks I've seen have been from Pike Energy in NC (I'm in TX), though I've also seen some unbranded trucks with Louisiana plates. I'd guess that Pike does a lot of contract work for other power companies. This was the first nice weather day after a tropical storm last year: Cocoa Crispies posted:I saw three "PIKE" electrical service trucks with North Carolina plates in Miami today.

|

|

|

|

some texas redneck posted:We had a fairly major winter storm event here - lots of ice and freezing rain, resulting in hundreds of thousands of outages beginning Thursday. A handful still aren't resolved. In Quebec, we usually get help from various companies in the NE United States when things go down because we sell some of our power to the region (this happened extensively during the Ice Storm of '98, I remember seeing tons of American plated trucks). I believe one of the stipulations of the contracts is that these consumers have priority over our local market, so in the event of a failure we must first re-establish transmission to the states, so these companies helping us also helps them. I find the hydro Quebec system to be quite fascinating, as 98% of the power generated comes from hydroelectric plants. One of our biggest systems is the James Bay project: quote:Construction costs of the project's first phase in the 1970s and 80s amounted to $13.7 billion (1987 Canadian dollars). The eight power stations of the La Grande Complex generate an average of 83 terawatt-hours (TWh) a year, enough to meet the total demand of a small industrialized economy such as Belgium. The James Bay power stations represent almost half of Hydro-Québec's total output and capacity. The James Bay region is located roughly 1,000KM north of Montreal, and we use extra high voltage (735kV!) transmission lines to transport the power south. Edit: Just to add in, the Ice Storm of 98 caused extensive damage to our grid (the weight of so much ice put way too much strain on the transmission towers), and I remember that this wasn't an uncommon sight on the South Shore of Montreal during the time:

Supersonic fucked around with this message at 17:30 on Dec 9, 2013 |

|

|

|

Supersonic posted:In Quebec, we usually get help from various companies in the NE United States when things go down because we sell some of our power to the region (this happened extensively during the Ice Storm of '98, I remember seeing tons of American plated trucks). I believe one of the stipulations of the contracts is that these consumers have priority over our local market, so in the event of a failure we must first re-establish transmission to the states, so these companies helping us also helps them. We have mutual assistance agreement in place with those companies; when the going gets bad in Vermont or something our trucks will go down there to help. I highly doubt that Hydro, a corporation owned by the government of Quebec, has agreements in place that prioritize US customers over Quebec customers. I could be wrong, but I would be very surprised if it were the case.

|

|

|

|

FrozenVent posted:We have mutual assistance agreement in place with those companies; when the going gets bad in Vermont or something our trucks will go down there to help. I heard this secondhand from an electrician friend (and should have verified!), but it looks like you're right. According to this report, its actually the reverse. quote:Generation: Hydro-Québec Production operates and develops Hydro-

|

|

|

|

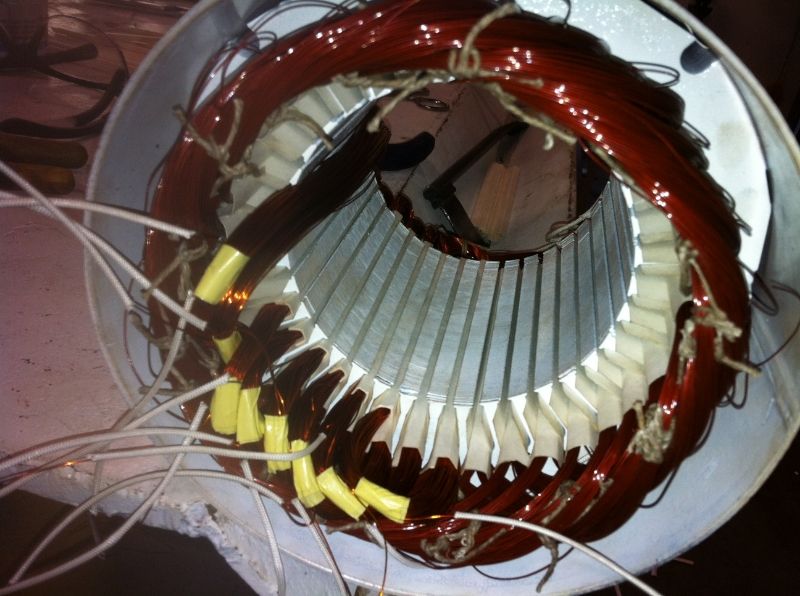

So I've been rewinding electric motors for a couple years now, any interest in pics mid-rewind? Most of what I see is in the 30-100hp range, and rarely above 400 hp.

|

|

|

|

Yeonik posted:So I've been rewinding electric motors for a couple years now, any interest in pics mid-rewind? Most of what I see is in the 30-100hp range, and rarely above 400 hp. Yeah! That would be cool! I was reviewing some photos of a larger motor (medium voltage, 1000 HP range) that had rub damage on the stator and rotor yesterday. (Where the spinning part in the middle slides against the stationary part - that's not good.)

|

|

|

|

Yeonik posted:So I've been rewinding electric motors for a couple years now, any interest in pics mid-rewind? Most of what I see is in the 30-100hp range, and rarely above 400 hp. Definitely.

|

|

|

|

Three-Phase posted:Yeah! That would be cool! I see that sort of thing alot. That failure can make a motor a terror to re-wind - if it shifts the teeth in the laminations they end up like razors trying to cut through every wire/insulation that you put back in.  [timg] [timg]There's a neat little two speed, two winding hoist motor. The low speed is the top set of coils, and the high speed is the bottom set. This is at least a year old so I don't even remember the speeds ;p 4 and 12 pole or something fun.  Same little hoist motor waiting for internal connections to be made. There's a bit of brazing to be done ;p When I say internal connections - we braze every third group of coils together (phase A, phase B, phase C etc. around the winding. This is called a jumper) then either wye the end of the phase or delta it, or bring them out as leads so we can do either =p  Halfway through a 200hp. This is the non-lead end. Note the coils on the top - we leave them hanging out because when we get back to that point we have to tuck coils under them to finish the lap winding. The yellow stuff sticking out of the winding is phase insulation. Glove for scale =D  Same 200hp, coils all inserted, getting ready for internal connections. I apparently didnt photobucket as many pictures as I thought so... more to come! In general though, once you've seen one you've seen em all =p

|

|

|

|

Is it all done by hand?

|

|

|

|

Do you have a vacuum impregnation tank on site? Do you guys do any synchronous motors? Do you do heat run and vibration/balance testing in your shop? I was at a larger shop awhile back and they had a huge tank that could do larger-frame motors (10,000+ HP) and also "vertical" motors and generators for pump/hydro applications. It was wild seeing such massive machines being built. They had four and eight-pole rotors (salient pole) being assembled that weighed many tons. Pvt Dancer posted:Is it all done by hand? Where I visited, yes, a lot of the assembly work is done by hand. I've seen coils that are made by machines, but many of the steps like adding corona tape (for high voltage machines) and installing the coils were done by hand. It's really a craft more than an industrial process. Three-Phase fucked around with this message at 12:37 on Dec 20, 2013 |

|

|

|

Pvt Dancer posted:Is it all done by hand? Yes, everything except making the coils. Inserting, connecting, etc. all requires a human touch. Manufacturers ARE able to wind motors with a concentric winding rather than a lap, and can use automation for that - hence the comparatively low cost of new motors. I can't compete with new motors on most standard frames up to about 60 hp. Turnaround time makes the difference - if it takes a week to get a motor shipped here and I can have it wound in a day or 2, that makes a big difference to a customer if one of their processes/oil wells/whatever is down less time. Form coils (my pictures, and the bulk of my work, is random wound) are made by an outside manufacturer. I believe most of that is automated. Three-Phase posted:Do you have a vacuum impregnation tank on site? Do you guys do any synchronous motors? Do you do heat run and vibration/balance testing in your shop? We do not have VPI. I wish we did, but we don't. We see very, very few synchronous motors. I don't really know what you mean by heat run - I'm assuming you mean a dynamometer... put a load on and see how the motor reacts? If so, that is outsourced if it's requested by the customer. Vibration and balance testing yes, we've got a balancer setup. We balance anything large (200hp I think? I don't get involved in that end of the world too much) and anything that has had shaft work done (bearing journal buildup, new keyways cut, etc.). We've got a few 585KW generators out of a local hydro power plant in for rewind - I'll grab some pictures later on tonight when I go back in. Three-Phase posted:I was at a larger shop awhile back and they had a huge tank that could do larger-frame motors (10,000+ HP) and also "vertical" motors and generators for pump/hydro applications. It was wild seeing such massive machines being built. They had four and eight-pole rotors (salient pole) being assembled that weighed many tons. It's amazing seeing some of that stuff. We don't deal with HUGE HUGE motors, and it's always fun seeing how it scales. This thread is great because I rarely get a chance to go out in the field and see the other end - both controls, and what the motors actually *do*. I still haven't read the whole thread =D

|

|

|

|

I deal with some really big motors. Primary heat transport pumps are 11,000 hp at 6.6kv with across the line starting and you have to start all 4 at the same time to prevent flow reversal in parts of the process.

|

|

|

|

helno posted:I deal with some really big motors. Primary heat transport pumps are 11,000 hp at 6.6kv with across the line starting and you have to start all 4 at the same time to prevent flow reversal in parts of the process.  took a second before I remembered you work at a power plant. That's an insane amount of energy! I take it the plant isn't black start capable? took a second before I remembered you work at a power plant. That's an insane amount of energy! I take it the plant isn't black start capable?

|

|

|

|

helno posted:I deal with some really big motors. Primary heat transport pumps are 11,000 hp at 6.6kv with across the line starting and you have to start all 4 at the same time to prevent flow reversal in parts of the process. Wow, that must hammer the system when they all start. I'm surprised, the equipment I've seen over 10,000 HP typically has some sort of soft-starting implemented (electronic drive/soft-start, autotransformer, reactor, delta-wye, and soforth). Do they hit the bus simultaneously or is there any sort of delay? I've seen huge peak current (from the subtransient reactance) even on relatively soft-started motors.

|

|

|

|

Why do you guys talk about motor power in HP? I've always used kW when talking about electric motors.

|

|

|

|

Because we Americans have to do things differently.

|

|

|

|

Yeonik posted:Because we Americans have to do things differently. I also never understood why everything has HP ratings, contactors, breakers, etc. Aren't we beyond that by now? Code says everything must be HP rated, but it seems like there are instances where that's not sufficient to size things properly. I usually size things based on nameplate FLA, and even that's flawed since your inrush curve is different for different motors. Seems to me that the HP or kW rating are missing gobs of important information on the electrical side.

|

|

|

|

image dump!

Some Guy From NY fucked around with this message at 17:08 on Dec 21, 2013 |

|

|

|

DaveSauce posted:I also never understood why everything has HP ratings, contactors, breakers, etc.

|

|

|

|

DaveSauce posted:I also never understood why everything has HP ratings, contactors, breakers, etc. HP and KW are a function of the motor properties. HP= (1.73*volts*amps*efficiency*Power Factor)/746 KW= (1.73*Volts*amps*PF)/1000

|

|

|

|

|

| # ? May 9, 2024 22:11 |

|

grover posted:

It can keep going without the grid but cant start. PHT pumps take more power than the standby generators can deliver. We need around 40 Mw to run up. Very few power plants can darkstart. I worked at a hydro plant that could, they had a battery box with jumper cables you could hook directly to the brushgear and a mechanical governor.

|

|

|