|

Galler posted:Now I know what I'm doing with all my soldering and other general electronics poo poo. That's so much better than trying in vain to keep it all organized in a cardboard box. Thanks for the tip! This particular one has space for two stow away boxes. Something that integrates those would be great for organizing small components (resisters, etc) if you use parts like that.

|

|

|

|

|

| # ? Jun 4, 2024 01:34 |

|

Something that I've noticed is that companies (e.g. Plano) that make both tackle boxes and toolboxes will charge more for one version of otherwise identical models than the other, so it pays to shop around.

|

|

|

|

Uthor posted:This particular one has space for two stow away boxes. Something that integrates those would be great for organizing small components (resisters, etc) if you use parts like that. All my components are in these kinda things. Got about three of those (not that one exactly but same type of thing) filled with pinball parts. I'm sure in theory it's possible to have too many of those organizers but I've never seen it in practice.

|

|

|

|

I went through like 10 crimps today with my Harbor Freight ratcheting crimpers and could not for the life of me get a solid crimp. I adjusted them all the way to max and they still won't bite down hard enough to complete a crimp. I've tried using it a few times in the past with the same results. I ended up using my trusty stripper/plier/crimper combo from China that everyone has five of and had no problems. What am I doing wrong? I'm going to toss these crimpers if I can't figure out how to make them work. All I've done is take them out of the package and slowly increase up to the max force, testing the entire way and it just can't do the job. They seem really nice, but they're simply not working. PS are crimps IEC approved for light fixtures? I ended up grabbing wire nuts anyway so I can swap to those if it's a problem otherwise I won't bother.

|

|

|

|

Galler posted:All my components are in these kinda things. Got about three of those (not that one exactly but same type of thing) filled with pinball parts. I'm sure in theory it's possible to have too many of those organizers but I've never seen it in practice. This system would be nice to have. https://www.youtube.com/watch?v=1OPSbF6kM9k

|

|

|

|

revmoo posted:I went through like 10 crimps today with my Harbor Freight ratcheting crimpers and could not for the life of me get a solid crimp. I adjusted them all the way to max and they still won't bite down hard enough to complete a crimp. I've tried using it a few times in the past with the same results. I ended up using my trusty stripper/plier/crimper combo from China that everyone has five of and had no problems. 1. what you are doing wrong: buying an HF ratchet crimper. This may be workable, though. 2. what brand crimp terminals are you using? If they aren't fully brazed ferrule crimps and/or are HF brand, toss that poo poo and get crimp terminals that don't suck. Sorry. 3. Make sure you are using the appropriate size crimp terminal for the wire you are crimping it on. I will usually use a size down (red instead of blue, blue instead of yellow) if the wire will fit inside the ferrule without binding. 4. If I can't get a good solid crimp, I strip twice as much insulation off as I need to, then double the end of the wire over. Assuming it will fit that way, of course... it may be too tight. 5. If I'm having issues with a crimper not crimping solidly enough after using the above tricks, I use the next slot down from what the color code says I should use - crimp a blue terminal with the red slot, a yellow terminal with the blue slot, etc. If you're trying to crimp reds and it won't work out after adjusting the pressure all the way up, doubling the wire over, using good crimps, etc, you're pretty much SOL unless you just get a better crimper. e: oh yeah. Crimps don't really work on solid core wire, only on stranded. You have to use other methods on solid wire. kastein fucked around with this message at 02:51 on Mar 9, 2014 |

|

|

|

I tried stepping down from blue to red on the crimpers and that worked better, but still failed to accomplish a proper crimp. When I do a crimp, I pull on both ends very very hard but not so hard I pull a muscle. I've been able to do that using the crap Radio Shack crimpers (even on the solid core wire), but after 20+ failed crimps and 0 successes I'm ready to throw the HF crimpers in the garbage. Also I was using the HF heat-shrink butt crimps which I think very highly of and have had a lot of success working with in the past, but I've also tried a variety of other fittings and have never had a single successful crimp using the HF tool. From what I understand, a proper crimp is an actual cold weld of the wire material, and I've done tons of crimps in the past where I feel like that has happened, just using the stamped-steel generic crimper-strippers even. I also use various ethernet crimpers on a regular basis and they work every single time.

|

|

|

|

It sounds like those crimpers just blow rear end then. Welp, poo poo happens I guess... It isn't really a cold weld IMO, more of a swage, but either way, the NASA 8739 spec for crimp testing iirc is that the wire must break before the crimp pulls out. If it does, you are good to go. I've never used the HF heatshrink crimps... just tried their regular crimps once and realized they were basically worthless. No opinion on the heatshrink ones, but if you've had good luck with them in the past I'd blame the crimper at this point.

|

|

|

|

The ratcheting crimper is not a bad unit, though it seems like yours certainly is. I'd take it back for a swap rather than tossing it.

|

|

|

|

kastein posted:the NASA 8739 spec for crimp testing iirc is that the wire must break before the crimp pulls out. If it does, you are good to go. This has to be a joke, or at least a significantly higher standard than what most corporations use (especially automakers).

|

|

|

|

Splizwarf posted:This has to be a joke, or at least a significantly higher standard than what most corporations use (especially automakers). This is the terminal crimp itself, not pulling the terminal out of the housing. And no, 100% testing is not required iirc, though I should probably read that section of the standard again. There are specs in there for how many pounds of tension to put on each gauge of wire while testing, but my recollection was that they said "if the test fails because the wire broke that is fine, but if the test fails before you reach this tension because of crimp pullout, you need to fix it."

|

|

|

|

Uthor posted:My electrical box was getting kind of full and I wanted a place to consolodate some computer hardware. I heard about using a fishing tackle box for tools, so I picked one up. Fairly happy how it worked out. I can organize bits and cables and there is plenty of space in the bottom for my multimeter and bigger tools. I think I'm going to take a Dremel to the bottom tray and cut away some of the dividers to fit my pliers and soldering iron and such up there. I'm a little concerned about tipping, however. The stuff in the lower two trays should be secure, but I'm keeping plugs, splices, and screws in baggies in the top tray so they don't go flying all over. I need one of those fan headers so bad right now

|

|

|

|

revmoo posted:I tried stepping down from blue to red on the crimpers and that worked better, but still failed to accomplish a proper crimp. When I do a crimp, I pull on both ends very very hard but not so hard I pull a muscle. I've been able to do that using the crap Radio Shack crimpers (even on the solid core wire), but after 20+ failed crimps and 0 successes I'm ready to throw the HF crimpers in the garbage. Typically heatshrink crimps are a bit smaller than normal insulated crimps. You'll need different dies if you want to make reliable crimps. I'd try using non-HF crimps for starters, as that design of crimper is used by a few other companies and is actually pretty decent. If you still can't make a decent crimp, see if you can exchange it. (...crimps)

|

|

|

|

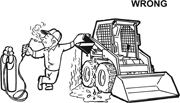

iForge posted:Gonna preach for a minute here, since I am a retard and should learn to follow safety procedures more. I have used angle grinders 1000s of times and know how to not maim myself, despite my lapse in judgement today. Also, according to OSHA you were using the wrong tool: "Operating Controls and Switches The following hand-held power tools must be equipped with a constant-pressure switch or control that shuts off the power when pressure is released: drills; tappers; fastener drivers; horizontal, vertical, and angle grinders with wheels more than 2 inches (5.08 centimeters) in diameter; disc sanders with discs greater than 2 inches"

|

|

|

|

iForge posted:Gonna preach for a minute here, since I am a retard and should learn to follow safety procedures more. I have used angle grinders 1000s of times and know how to not maim myself, despite my lapse in judgement today. morethanjake32 posted:Also, according to OSHA you were using the wrong tool: Ouch. To take this one step further, Metabo has the WEPBA series with an auto-brake. Even with a non-locking switch, there is still a danger of the wheel spinning after you release the switch. The WEPBA automatically brakes the wheel in 2 seconds or less. If you go to 2:20 of this video, it shows it in action: https://www.youtube.com/watch?v=u8SIXxyhz_A I have a customer that does work at a power plant, and this is the only angle grinder they will allow on site. They are about $260 dollars, but the safety guys love them because everyone goes home with all of their fingers.

|

|

|

|

morethanjake32 posted:Also, according to OSHA you were using the wrong tool: Yup, these things are supposed to not have a locking operating switch. Tell that to the manufacturers though. We had to either drill out the locking mechanism on about 100 Fein angle grinders (tampering with tools, a no no) or send them back. It was a prime example of procurement not following the rules. Not that the purchaser ever got in trouble for buying the wrong thing though, nope. The welders weren't happy about it.

|

|

|

|

Uthor posted:My electrical box was getting kind of full and I wanted a place to consolodate some computer hardware. I heard about using a fishing tackle box for tools, so I picked one up. Fairly happy how it worked out. I can organize bits and cables and there is plenty of space in the bottom for my multimeter and bigger tools. I think I'm going to take a Dremel to the bottom tray and cut away some of the dividers to fit my pliers and soldering iron and such up there. I'm a little concerned about tipping, however. The stuff in the lower two trays should be secure, but I'm keeping plugs, splices, and screws in baggies in the top tray so they don't go flying all over. Take apart some lovely 3" speakers. Epoxy the magnets to the bottom. Now it'll stick to metal objects, too.

|

|

|

|

Dear AI tools thread, Universal Spline sockets/wrenches: New hotness, or over-hyped crap? fake edit: bought a cheapo set from HF to test, will report when I get some time with them.

|

|

|

|

MRC48B posted:Universal Spline sockets/wrenches: I have seen them in action and they seem to do pretty well; a couple co-workers have the Gearwrench ones and use them constantly.

|

|

|

|

MRC48B posted:Dear AI tools thread, For low torque application, new hotness, you can be lazy with tool selection and it works as advertised. For anything that actually requires anything resembling torque, over-hyped crap that'll gently caress up the heads on your bolts.

|

|

|

|

If you live in the rust belt don't you loving dare. Unless you are just spinning something off after breaking it loose with a real wrench. Spline drive = rounds every fastener off equally well.

|

|

|

|

Recommend me a soldering iron. Gas powered or otherwise cordless would be useful, needs to be available in the UK or not ridiculously expensive to have shipped. Amazon UK would be ideal, as I just found a £30 gift card I'd forgotten about. Portasol are good, right? How about the SuperPro 125 kit? http://www.amazon.co.uk/gp/aw/d/B00687TMHG/ref=mp_s_a_1_1?qid=1394540954&sr=8-1&pi=AC_SX110_SY165

|

|

|

|

What do you intend to do with it? My go to is a weller wes51 or wesd51 station, not sure you can get those though.

|

|

|

|

General automotive wiring, perhaps the odd simple electronics/pcb repair. Those Wellers are available in the UK, but I really would prefer something cordless if at all possible. They're also quite expensive, which I'm on with if it's a major step up in terms of quality and performance, but if I'm honest it's not really necessary for me to have the absolute best out there, my use is going to be occasional and relatively basic. InitialDave fucked around with this message at 15:04 on Mar 11, 2014 |

|

|

|

You really don't want a gas powered for wiring and PCB/electronics stuff. Those are great if you need to solder nothing but 14ga and heavier wiring, but they'll melt the insulation off smaller wires and burn traces off PCBs in a fraction of a second. Unfortunately that means battery powered (shite) or corded.

|

|

|

|

I used to work at a wiring harness company where we had butane soldering irons, and yeah, they were an enormous pain in the rear end. Never wanted to start, and you had to be very quick with them on smaller wires or you'd melt the insulation in a second or two. Also, ours had an exhaust vent near the tip (useful for heatshrink) that would also burn things near what you were working on if you weren't paying attention. Edit: We apparently used nice ones, too: http://www.amazon.com/Master-Appliance-UT-100Si-TC-Ultratorch-Professional/dp/B0012B51JG They were still a pain in the rear end. boxen fucked around with this message at 16:41 on Mar 11, 2014 |

|

|

|

Those gas powered things are on par with a $10 30w "pencil iron." If you're going to spend more than $10, get something with at least some temperature adjustment. I see a Hakko 936 at Frys for $60. If it's a similar price where you are, that would be my vote.

|

|

|

|

InitialDave posted:Recommend me a soldering iron. Gas powered or otherwise cordless would be useful, needs to be available in the UK or not ridiculously expensive to have shipped. I got the gas one they sell at maplin on some sort of offer that was pretty cheap. I've found it to be really useful for general soldering tasks. The container did start leaking though at one point near the top, however filling with araldite and wrapping in electrical tape fixed it up. I've been using it for a few years now at least and it's OK. I think I may have got spare tips for it from amazon.

|

|

|

|

The general consensus does seem to be against the portable ones. How do we feel about the Weller WHS40?

|

|

|

|

eddiewalker posted:Those gas powered things are on par with a $10 30w "pencil iron." Seconding Hakko--you would have to pry my 936 from my dead hands to get it away from me. I thought I sucked at soldering until I got a nice station and realized the iron really does make a huge difference.

|

|

|

|

I really need to get a sponge to use with my soldering iron, rather than just letting oxidization build up on it forever.

|

|

|

|

I have one of these: http://uk.rs-online.com/web/p/soldering-iron-kits/4335978/ I use it most days. Ive never melted insulation or lifted PCB traces. It's useless for joining wires over 1.5mm≤. The flame attachment is good for shrinking heatshrink when used with care.

|

|

|

|

Double post. Still loving my gas iron. Haven't used my corded iron in over a year.

|

|

|

|

mod sassinator posted:Seconding Hakko--you would have to pry my 936 from my dead hands to get it away from me. I thought I sucked at soldering until I got a nice station and realized the iron really does make a huge difference. ShittyPostmakerPro posted:I have one of these: A friend of a friend who has more involvement with electronics says that the WHS40 is decent enough, and it would cost me ~£50 out-of-pocket with having that additional £30 to go toward it. I can get the 51 series which kastein mentioned, but they're significantly more (over double the price). Coming from a  Maplin iron, which itself replaced one I got from Woolworths (really), practically anything reasonable is going to be a revelation, but I'm of the "spend it once and spend it right" mindset much of the time. Maplin iron, which itself replaced one I got from Woolworths (really), practically anything reasonable is going to be a revelation, but I'm of the "spend it once and spend it right" mindset much of the time.

|

|

|

|

InitialDave posted:I can't really find Hakko in the UK that easily, by the looks of it, but I did find someone selling the FX888D, which would cost me about £120 plus delivery. Ouch I wouldn't pay over $100 for the FX888. The WHS40 doesn't look too bad, it's a good brand and it seems to have temperature control so it should work reasonably well.

|

|

|

|

Yeah, some stuff is cheap in the UK, other stuff is massively overpriced. The Weller WESD51, for instance, is a little over $300.

|

|

|

|

Jesus christ, I wouldn't have recommended it if I realized it cost so much over there. I believe I paid like $120 for my WES51 when I got it.

|

|

|

|

Well, just imagine how the Aussies feel. Anyway, with the pricing factor in mind, how 'bout that WHS40, then?

|

|

|

|

I use a WES51 at work, and a WT-CPT at home. 1/32" Tips only! I have an 60W Hakko pencil with a 3/16" chisel tip for large cabling, and a propane torch for really large cabling.

|

|

|

|

|

| # ? Jun 4, 2024 01:34 |

|

mod sassinator posted:Ouch I wouldn't pay over $100 for the FX888. The WHS40 doesn't look too bad, it's a good brand and it seems to have temperature control so it should work reasonably well. The FX888 were $59.99 on clearance @ Fry's recently, not that this helps him now.

|

|

|