|

bimmian posted:For corners, you can use a spline which will give you plenty of strength, plus it looks good- This - FWIW biscuits should work fine for the corners, but I'd be inclined to add splines as well, both for added strength and for looks.

|

|

|

|

|

| # ? May 16, 2024 07:12 |

|

Splines or biscuits on the corners. If you do buy a biscuit joiner don't skimp. Porter Cable and Lamello used to be top dogs by a mile, not sure if that's still true. I'm not a fan of modern saws but the Stanley Fatmax gets such rave reviews I wouldn't even consider the Irwin. It's so well liked among woodworkers that it tempts me.

|

|

|

|

wormil posted:Lots of people own this one: http://www.harborfreight.com/12-inch-x-33-3-8-eighth-inch-wood-lathe-with-reversible-head-34706.html Interesting. The collective wisdom of the internet suggests that the only difference between the Jet jw1236 and that Harbor Freight is that Jet actually does QC checks on them when they come out of the same factory. e: poo poo this means I'm probably going to talk myself into a lathe in the next 12-18 months Stultus Maximus fucked around with this message at 00:54 on Dec 29, 2014 |

|

|

|

Uncle Enzo posted:Does anyone own either of those or a comparable saw they can recommend? I've had two Fatmax saws. They cut like crazy when they're sharp, and they stay sharp pretty long, because of the hardened teeth. But when they get dull, you throw it out, because you can't file them. Not really a problem with a $20 saw, but some people have different views. And it's really short. If you're used to a full sized handsaw, you're going to pull it out of the cut quite often. Of course, it's thick enough that you won't bend it when you shove it back into the face of the wood. You said you want it for rough work, and that's good, because that's all it'll do. I've never used the Irwin, but I imagine it cuts the same way, plus you have five more inches of teeth. Boy is it ugly, though BTW, Stanley makes a 20" SharpTooth that is basically a longer version of the Fatmax without the rubber handle. One Legged Ninja fucked around with this message at 02:21 on Dec 29, 2014 |

|

|

|

Broke my first router bit today. I was using a 1/4 inch up cut spiral bit to cut a 1/2 inch deep groove down the middle of some fir on my router table. I heard a weird noise so stopped pushing the piece and shut off the router. The bit had snapped into 3 pieces in the collet. The top 3/4 of the bit looks pristine but the bottom was broken into 2 pieces, one had fallen down into the bottom of the router and the middle piece was lodged in the collet. I had to use a hammer and a screw to get it free. Also it seemed to have beat up the upper lip of my collet. Doh. Had to finish my cuts on the table saw.

|

|

|

|

I've heard of cutting up a dull Fatmax and making scrapers, never done it though.

|

|

|

|

Doctor Zero posted:Questions about biscuits: On the topic of biscuit jointer I just decided to buy a biscuit router bit instead (just a properly sized slot). Paired with the Ryobi 18V trim router I've got I think it will be a decent and cheaper solution.

|

|

|

|

wormil posted:Splines or biscuits on the corners. If you do buy a biscuit joiner don't skimp. Porter Cable and Lamello used to be top dogs by a mile, not sure if that's still true. I don't like speciality tooling like biscuit joiners and dominoes, so couldn't one just use a router and dowels, or a drill press with a fence? Splines are easily done on the table saw so I like that method too, no extra tools required. Probably gonna try dowel joining soon because in the process of making my new tilting router lift I figured out I need to widen the plywood backing plate that the router will glide up and down on. I had already made said component to the original plans though so I need a good way to join the edges of two 3/4" plywood sheets together. Dowel joints and wood glue looks like the best solution to me at this stage, I could do them on my drill press using the fence to keep everything aligned after initial setup. A spline could also work, would be super easy to make on the table saw. Not sure if it's as strong. Pocket hole screws is another.

|

|

|

|

Doctor Zero posted:Questions about biscuits: I know you already made up your mind, but i had to get my two cents in anyway. First off, those miters will be fine with just biscuits. Splines are not necessary, but they can add a certain aesthetic value. Second, never skimp on a biscuit joiner. The most important part is the fence, if it's not solid or accurate, the entire tool is worthless. If your biscuit holes don't line up, you've bought yourself a paper weight. E: That being said, the dewalt joiner is quite good. It's a good mid level tool that will handle most tasks well as long as you take good care of it. Porter Cable is basically the go-to in most professional shops. If you're going to buy lamello, you might as well get a festool while you're up in that end of the price range. Skinny Bins fucked around with this message at 12:16 on Dec 29, 2014 |

|

|

|

What kind of wood is this? I think it's sinfully ugly but my Dad loves it. I can take more pictures of his various furniture if there is interest but its really nothing special (not handmade) besides the wood grain.

|

|

|

|

His Divine Shadow posted:I don't like speciality tooling like biscuit joiners and dominoes, so couldn't one just use a router and dowels, or a drill press with a fence? Splines are easily done on the table saw so I like that method too, no extra tools required. You can use dowel tenons, as long as you can line the holes for the dowels up properly. Specialty jigs really make that a lot easier. Nothing says you can't make them yourself, though.

|

|

|

|

Okay, thank for the input. I actually wanted a Porter Cable biscuit joiner originally but couldn't find one locally (and I wanted to get building this week so I didn't want to order it). After goon feedback, I put a little more effort into calling around and found one (the last one) in stock, so I'll be getting that instead. I'll do splines if for no other reason as I can play with them to learn on something I won't punch myself in the nuts for screwing up. Splines on the table saw would be a good idea if it weren't for the fact that the thing is 6.5' x 4.5' so I don't think that's an option.  I should be able to do the splines with the biscuit joiner, no? I should be able to do the splines with the biscuit joiner, no?

|

|

|

|

Cutting them accurately on the corner of the frame would be challenging. You could maybe do them with a slot-cutting bit and a router? Or not bother, given the size. E: or try this trick: http://www.ibuildit.ca/Workshop%20Projects/Shop%20Tricks/tricks-28.html but that works a lot better for the butt joint application as there's very little material for it to grip on a mitre. Biscuits would probably do fine. thespaceinvader fucked around with this message at 18:51 on Dec 29, 2014 |

|

|

|

I'd like to have a corner spline attachment for my PC biscuit joiner. I don't know if PC make such things but they should. I think Lamello has something like that along with special biscuit.

|

|

|

|

Thanks for the planer help on the last page. I ended up ordering the DEWALT DW735 Thickness Planer. Dewalt even had a further $25 off at checkout that wasn't listed. So I scored it for under $500. Which about $200 off from the local retail price. Now I need people to convince me not to put end grain through it. I've read the horror stories, but god it's gonna be tempting when making cutting boards. keep it down up there! fucked around with this message at 19:31 on Dec 29, 2014 |

|

|

|

wormil posted:I'd like to have a corner spline attachment for my PC biscuit joiner. I don't know if PC make such things but they should. I think Lamello has something like that along with special biscuit. They're pretty easy to make, its on my list. http://tnvalleywoodclub.org/Plans/Strong%20Miter%20Joints%20with%20a%20Biscuit.pdf

|

|

|

|

Elston Gunn posted:They're pretty easy to make, its on my list. Nice, I'm making one.

|

|

|

|

Elston Gunn posted:They're pretty easy to make, its on my list. Yeah, thanks. I got a stack of frames I need to make and wanted to use splines.

|

|

|

|

On the subject of splines, I made a jig similar to this one for doing dovetail splines and it turned out pretty nice.

|

|

|

|

Oh, I like that a lot.

|

|

|

|

|

Elston Gunn posted:On the subject of splines, I made a jig similar to this one for doing dovetail splines and it turned out pretty nice. Norm Abram would be proud.

|

|

|

|

BUGS OF SPRING posted:Now I need people to convince me not to put end grain through it. I've read the horror stories, but god it's gonna be tempting when making cutting boards. I put an end-grain cutting board through my benchtop planer. I figured two or three passes would be a lot faster than monkeying around with a belt sander. I would take the shallowest passes I could to just take down the high spots. I was never warned about doing it, but it just... felt wrong. Broke the cutting board after about four inches into the first pass, throwing a little more than 14 inches of cutting board back into my gut. No injuries that day, and the planer came out okay, but I learned two valuable lessons that will stick with me: never stand behind the planer when feeding stock, and never feed end grain on a project you want to keep. v v edit: To be fair, I'd be singing a different tune if I had a helical freestanding planer like this guy v v Unibrow fucked around with this message at 13:16 on Dec 30, 2014 |

|

|

|

Just to be contrarian, this guy does it. I have no experience of my own to add, my jointer planer is too small to do stuff like that anyway https://www.youtube.com/watch?v=QJ2LSj4RhAs

|

|

|

|

I've done it. But I wouldn't recommend it. A far better approach would be a thickness sander.

|

|

|

|

|

Bad Munki posted:I've done it. But I wouldn't recommend it. A far better approach would be a thickness sander. Sadly I don't think I can convince the wife on that kinda purchase for a while. Not after dropping $500 on the planer. I guess i'm sticking with the belt sander for a while. Maybe I'll try and make my own one day. Stumpy Nubs doesn't make it look too hard. After I finish some of the Matthias plans I've bought and haven't done anything with... Alternatively I should make some sort of router sled system. Nick Offerman has a massive one that makes me wish I had a bigger shop. keep it down up there! fucked around with this message at 16:24 on Dec 30, 2014 |

|

|

|

This is easily the coolest of the router sled designs I've seen. Still inexpensive, but probably much more pleasant to use. http://lumberjocks.com/projects/22104 I've got two pieces of aluminum flat bar .5x6" 6 foot long, and they're very straight. I'm going to mill a couple slots in them and when I get around to making a torsion box table, use them as bolt-on rails for the table whenever I need to flatten something, and use that design for a sled.

|

|

|

|

Is it really that difficult to keep an end grain cutting board flat? Couldn't you rig up a press or use a big piece of melamine as a caul?

|

|

|

|

One of the things that I've learned is that you need to do a hell of a lot less sanding if the prep work is done correctly. This goes double for glueing. Every woodworker should have a couple sheets of melamine as a glueing surface.

|

|

|

|

So you can glue right on the melamine and it won't stick? That's convenient. I guess it makes sense since it isn't wood, but it never occurred to me. I've been relying on my pipe clamp bars for the most part. I do put a piece of wood above and below with clamps to prevent bowing, but I always seem to get 1 or 2 peices out of alignment and then I gotta sand/hand plane like crazy. I'll try a melamine sandwich next time. I do have a lot of it leftover from some closet shelves we put in.

|

|

|

BUGS OF SPRING posted:I guess it makes sense since it isn't wood, but it never occurred to me. It's not that it isn't wood, but more that it is just wonderful, wonderful stuff. There are plenty of non-wood surfaces you could glue on that would be absolutely awful.

|

|

|

|

|

Bad Munki posted:It's not that it isn't wood, but more that it is just wonderful, wonderful stuff. There are plenty of non-wood surfaces you could glue on that would be absolutely awful. Just use wax paper.

|

|

|

|

Years back I worked at Kinko's and customers would spill glue and contact cement all over the counters, pops right off with a scraper. Plastic packing tape works even better, glue doesn't stick to it at all.

|

|

|

|

A good night tonight, got all the interior walls in the garage put up so I've finally sectioned off the storage room from the workshop, and then I got a whole 7 foot bench built. Very simple construction with butt joints and glue only. Only front legs, screwed the back into the wall studs. Put an OSB board on top. I've read several sau OSB is better than people give it credit for and I plan to sand and varnish the top to make it smoother anyway, and hey it was completely free. Finally it's starting to look somewhat like a workshop in here and next week I am finally getting the electrics done properly so no more relying on an extension cable for everything. Now I desperately need to start making drawers and getting stuff put away.

|

|

|

|

Finished my dovetail jewelry box today. I'm pretty happy with how it turned out. Peruvian walnut is beautiful wood and the curly maple grain pattern on the front looks really cool. My Dad and brother got me a router/router table for Christmas so I'll be able to make a lot more stuff now without needing to use their shop. I posted on here asking about dovetail layout before and someone commented to make the area where I cut the lid off a kerf width wider and I just kinda blew it off because I was thinking of too many other things, but that became obvious that I should have paid attention to that. I did order a box slotting bit from lee valley which made it really easy to cut the bottom and top panel dadoes without needing to worry about stopped dadoes and location. Any other tips/advice/comments welcome.

|

|

|

|

nosleep posted:Finished my dovetail jewelry box today. I'm pretty happy with how it turned out. Peruvian walnut is beautiful wood and the curly maple grain pattern on the front looks really cool. My Dad and brother got me a router/router table for Christmas so I'll be able to make a lot more stuff now without needing to use their shop. Looks great, nice job.

|

|

|

|

Well I'd had my new planer for about 10 minutes before I created a complete and total disaster. The wife told me it had come during the day. Arrived a week earlier than the shipping order said. So I was excited to get home and try it out. I get home, set it up. Everything is going smooth. Decide to try it out on some hard maple I had lying around. Turns out using a power planer without some kind of dust/chip collection is an absolutely terrible idea. The blower was pointed right at the bulk of my shop. Which now looks like a wood and dust grenade went off. Every single thing is just coated in chips. Oops! Works great though, thanks again for the suggestions  Time to make a million cutting boards. Time to make a million cutting boards.

|

|

|

BUGS OF SPRING posted:Turns out using a power planer without some kind of dust/chip collection is an absolutely terrible idea. The blower was pointed right at the bulk of my shop. Which now looks like a wood and dust grenade went off. Every single thing is just coated in chips. Bad Munki posted:I recommend putting some debris collection on the chip out-take: mine came with a little blast thing that goes on there that just shoots the chips everywhere. It does a really good job of clearing the chips (the fan inside is pretty good) but it makes a pretty expansive mess. A simple vac on there will move debris like crazy with little trouble, between the blast of the planer's own turbine and the vac's suction.

|

|

|

|

|

Yeah I was too excited to try it out and wasn't thinking

|

|

|

|

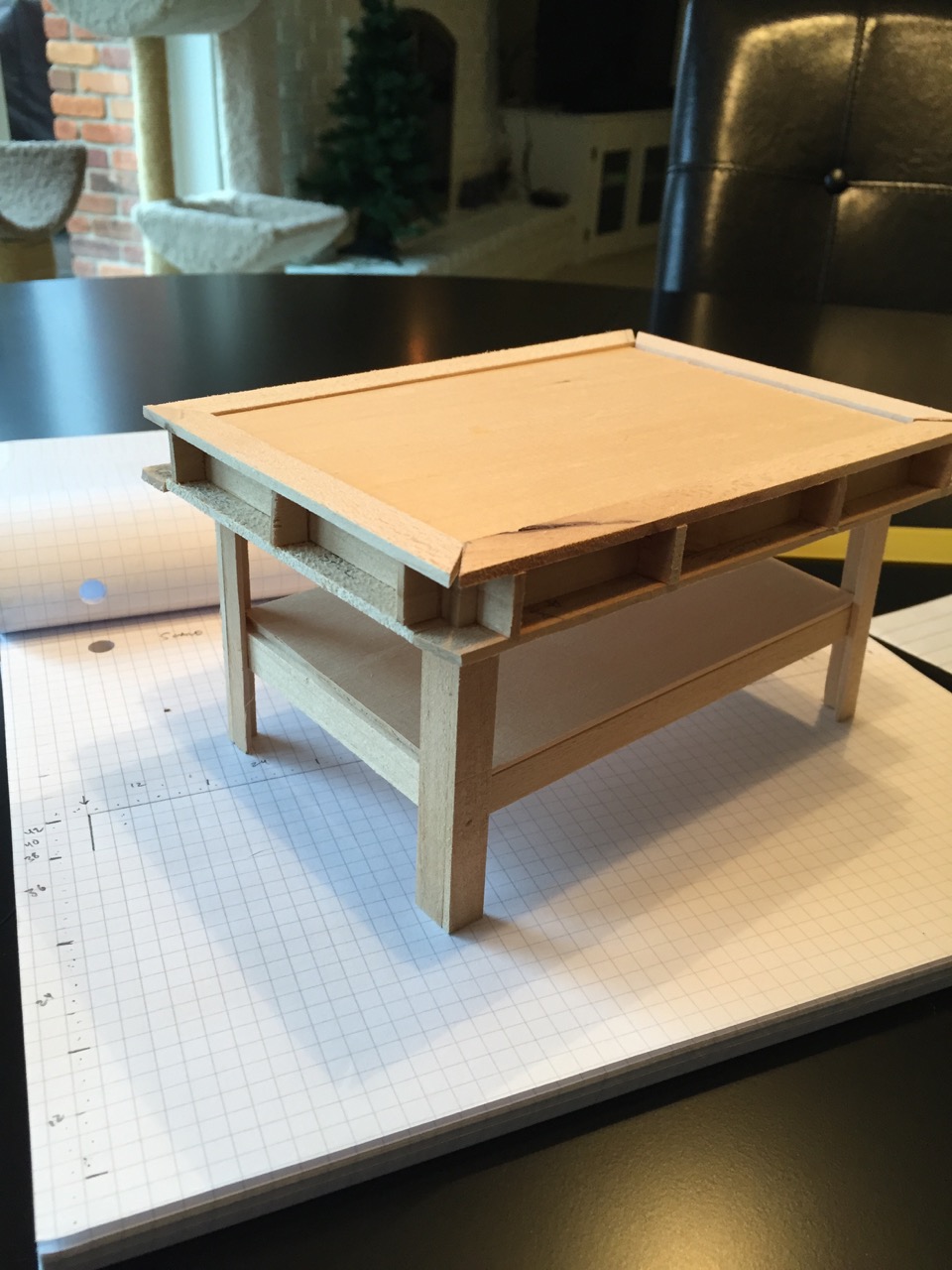

I have a few projects on my list intended to give me an extra hand holding things, supplementary lighting, hoses, also a wall-mount for my pc monitor. Finally got around to thinking about how to tackle all those and realized I would need an adjustable arm for basically all of those. So, the Mk.I prototype- It'll slip onto a dowel to mount (height adjustment and lateral movement, 3/4" for dog hole mounting option), another lateral movement joint, and up/down (full 180*). The hardware is a chest lid guide/support, works great for the estimated load I'd be putting on it. That could be made out of wood as well, but that hardware is under $2 and is likely more compact than anything I could make. From there, it's just a matter of making the individual mounts for whatever I'm using it for. Really customizable, add/remove links, make them longer... etc. Add another guide on the other side if it is going to be supporting something heavier or if the arm is longer. This one is going to be used as a monitor wall-mount, so it'll connect to a vesa plate I've made and, using the same hardware, provide a mechanism for tilting the screen up/down independent of the vertical adjustment. Really quite easy to make too. I was just improvising while making this, but I can now easily make templates of whatever length in sketchup which will save a bunch of time measuring. I used 1.5"x1.5" poplar which turned out to be a great size, no need to make any additional cuts. bimmian fucked around with this message at 17:37 on Dec 31, 2014 |

|

|

|

|

| # ? May 16, 2024 07:12 |

|

I made something similar last weekend. I have lovely lighting in my shop so I'm always needing better task lighting. I made this boom arm out of scrap plywood and a rare earth magnet to hold the cheap harbor freight light. I've since mounted my shop vac hose to it which I've been wanting to get up out of the way for a long time.

|

|

|