|

For almost my first woodworking project I bought 20 cheap clamps. Guess how many I needed?

|

|

|

|

|

| # ? May 15, 2024 17:13 |

|

What kinda clamps are we talkin' here

|

|

|

|

Cakefool posted:For almost my first woodworking project I bought 20 cheap clamps. Guess how many I needed? [21-22]

|

|

|

|

|

ReelBigLizard posted:There are already convincing proofs that proximity and use of tools in greater numbers than your own can significantly effect your optimal tool number, both for specific tools and generally.  As the number of tools approaches 0, the Frustration Factor approaches infinity. It decreases as the number of tools approaches the Optimal Tool Ownership point, but increases again as tools first approach, then rise above Available Horizontal Surfaces. Time Spent Maintaining Tools increases exponentially with Tools Owned, the exponent increasing proportionally to the Number of Projects in Your List. And of course, the number of Projects Able to be Finished follows the inverse cube of the number of Tools Owned. As you can see, the Optimal Tool Ownership Envelope indicates the most productive area of the curves, however, after extensive research, it was found that the demand for clamping devices follows no known 3-dimensional geometry, and may, in fact, exceed the current supply of the known universe.

|

|

|

|

Bad Munki posted:[21-22] About 40. That is a good graph.

|

|

|

Cakefool posted:About 40. 2n?! The situation is way worse than we expected.

|

|

|

|

|

One Legged Ninja posted:

There's gotta be a handful of appropriate thread titles that can come from that excellent work. Bad Munki posted:2n?! The situation is way worse than we expected. 2n+1?

|

|

|

|

Bad Munki posted:2n?! The situation is way worse than we expected. Well I had nearly 40 when I finished and I needed 2 more every time I used 2, so I think n+2 holds. I have most of them to my cabinetmaker brother later, at least they see real use now.

|

|

|

|

One Legged Ninja posted:

|

|

|

|

Framing this.

|

|

|

|

swampface posted:Framing this. You'll need some clamps.

|

|

|

|

I need to buy some more clamps, thanks guys

|

|

|

|

|

|

|

|

|

One Legged Ninja posted:

That looks about right. Tested out the newly renovated bandsaw and my new resaw blade today. Worked good, except the new blade I put on has two welds. The saw marks were worse (although no drift still) than the older slightly duller 1/2" blade it replaced. I've never gotten a band with two welds in it before.  Edit Edit: You guys getting the grizzly tablesaws: Check both slots for straightness and dead even width. When I first got my saw I couldn't make a wooden runner that wouldn't bind to save my life. I put it down to inexperience and the vagueries of wood movement. Then quite a bit later I invested in an Incra mitre gauge with adjustable nylon washers and I realized it wasn't me. The slot deviated in width from front to back making it impossible to ever got a slop free or non binding fit. At that point I was past the warranty. I've since gotten it "fairly ok" with a bastard file and patience, but at the very back of the slot it widens considerably and theres nothing I can do about that. Lately I've been considering doing some weird hack with a permanently mounted linear bearing situation somehow but since so many of my jigs rely on that stupid slot it would take a bit of thinking. The right one is the same. Maybe a little better. ChaoticSeven fucked around with this message at 04:38 on Mar 4, 2015 |

|

|

|

That bookmatch is beautiful.

|

|

|

|

ChaoticSeven posted:Edit Edit: You guys getting the grizzly tablesaws: Check both slots for straightness and dead even width. When I first got my saw I couldn't make a wooden runner that wouldn't bind to save my life. I put it down to inexperience and the vagueries of wood movement. Then quite a bit later I invested in an Incra mitre gauge with adjustable nylon washers and I realized it wasn't me. The slot deviated in width from front to back making it impossible to ever got a slop free or non binding fit. At that point I was past the warranty. I've since gotten it "fairly ok" with a bastard file and patience, but at the very back of the slot it widens considerably and theres nothing I can do about that. I spent some extra paranoid time with a dial indicator making sure they're parallel to eachother. The top was thankfully milled well. I didn't even have to adjust the top to get the miter slots parallel with the blade, which was a gigantic shock. The only weird issue I have is that either my fence or fence rails are slightly wacked out and I can't get the outfeed end of the fence to rest close enough to the table. I know they float out at the end with a T-style fence, but it bounces up in the air and doesn't rest down on the outfeed side rail like it should. I would have to clamp the far end of the fence down if I wanted to safely cut something smaller than 1/4 ply.

|

|

|

|

Harbor Freight 20% off one item coupon code - 16020081

|

|

|

|

I'm thinking about buying a lunch box planer in the future. I don't think I need a bigger joiner than the one I got (8" but quite short tables), it also planes but the capacity is only 8" and the thicknesses it can do is small. Since space is always a premium I am thinking of a lunch box type that I could put on a mobile base, maybe a swinging top so I could have two tools on the base and just rotate up the one I want to use. I know nothing about these planer types, looking at a makita 2012nb and it seems well liked. Or should I just buy the cheapest thing I could get? And what kind of knives do they usually take? I assume it'd be too much to think any lunchbox planer used a tersa blade system?

|

|

|

|

Does anyone have any plans or recommendations for making a cutting board without a table saw? I'd like to make an end grain cutting board, but I don't know if that would be feasible without having a table saw. If not, best just to settle for a a long grain board? I have a circular saw, a router, and router table. My router table has the split fence to be able to act as a jointer and I know you can make router jigs for flattening boards. I also have a No 4 hand plane but haven't had much practice with it. Any advice? I've dabbled in woodworking for the last year or so making some projects here and there, but haven't made the typical beginner cutting board project yet. But I actually need a cutting board now and instead of buying one I figured I really just need to make it.

|

|

|

|

I've made cutting boards with my bandsaw before, so there's nothing special about table saws. I imagine you could rig something up to do it with the circular saw. The main thing would be to make certain that the piece is held down properly without getting in the way of the saw, since it's a smaller piece than you'd usually cut with such a saw.

|

|

|

|

His Divine Shadow posted:I'm thinking about buying a lunch box planer in the future. Most of the ones I know of have the blades held in with a row of nuts or screws clamping the blade. Some are indexed, so you just pop them in and they are set properly, and some are more difficult like the Makita you are looking at where you have to manually set the length the knife protrudes with a set tool you lay under the cutterhead. The indexed ones like Ridgid, and I think Dewalt uses them too, aren't supposed to be sharpened because it will lower the amount the knife protrudes too much. I wouldn't go cheaper than Ridgid/Dewalt, but I'm not sure too many terrible lunchbox planers exist with the small selection available. bimmian posted:Harbor Freight 20% off one item coupon code - 16020081 There is never not a 20% off coupon. 25% pops up occasionaly but a 20 can always be found by googling the current coupons. lwoodio fucked around with this message at 23:41 on Mar 5, 2015 |

|

|

|

His Divine Shadow posted:I'm thinking about buying a lunch box planer in the future. My plan for a while now has been to pick up a used Dewalt 735 to save a little money and then get the really badass helical cutterhead for it. It'll cost more than the Makita, but not tons more in the long run considering how awesome helical cutters are.

|

|

|

|

lwoodio posted:

Yea I noticed that as I ran through the search results, 20% here, 20% there.... I stopped by after work and picked one up, excited for some actual dust control.

|

|

|

|

nosleep posted:Does anyone have any plans or recommendations for making a cutting board without a table saw? I'd like to make an end grain cutting board, but I don't know if that would be feasible without having a table saw. If not, best just to settle for a a long grain board? I have a circular saw, a router, and router table. My router table has the split fence to be able to act as a jointer and I know you can make router jigs for flattening boards. I also have a No 4 hand plane but haven't had much practice with it. Any advice? Make a jig for your circular saw so you can make nice perpendicular cuts. This is the best picture I could find to illustrate the point. It is basically the same idea as a miter box, but with rails for your saw to ride in to make 90* cuts. Google circular saw crosscut jig for more ideas.

|

|

|

|

Hypnolobster posted:My plan for a while now has been to pick up a used Dewalt 735 to save a little money and then get the really badass helical cutterhead for it. It'll cost more than the Makita, but not tons more in the long run considering how awesome helical cutters are. I read this and thought it might be relevant to your plans: http://www.sawmillcreek.org/showthread.php?228340-Upgrade-Dewalt-735-or-go-for-PM-15HH-Planer The 735 is not available outside the US from what I've heard and the dewalts are noisy. I hear the makita is the quietest lunch box planer. I don't mind conventional knives either, non-resharpenable is OK as long as replacements are cheap. Double edged would be a plus. Still if I can find a cheap old cast iron planer for a better price I'll probably go that route. His Divine Shadow fucked around with this message at 10:51 on Mar 6, 2015 |

|

|

|

His Divine Shadow posted:I read this and thought it might be relevant to your plans: I have the Dewalt 735 and I really like it, but boy is it loud. I've been honing my blades recently to get some extra life out of them and it seems to work alright.

|

|

|

|

Look at these. Last year I took a class on segmented turning from this guy and squandered it because my shop needed a remodel. Well the shop is in better shape and I'm taking the same class again. This time I will put the knowledge to use. As impressive as it is in a picture, it's even more impressive in person. 170 hours.

|

|

|

|

Those are drat impressive. Do you need to budget much extra wood for all the resawing needed?

|

|

|

|

|

Any ideas of working spaces for people who want to woodwork but live in an apartment? I'm finding working on my balcony with a collapsing workbench and hand tools leaves me relying on intensive sanding down to get anything even vaguely straight/perpendicular and I'd love a place to work with some space and tools like table saws, etc.

|

|

|

|

Blindeye posted:Any ideas of working spaces for people who want to woodwork but live in an apartment? I'm finding working on my balcony with a collapsing workbench and hand tools leaves me relying on intensive sanding down to get anything even vaguely straight/perpendicular and I'd love a place to work with some space and tools like table saws, etc. You could look for a local co-op space, some cities have those I guess. You could also get practiced at using hand planes/chisels/spokeshaves. With some winding sticks you should be able to get wood flat/square with minimal space requirements. Hand planes give a pretty good workout too!

|

|

|

|

Check local community colleges, they often sell passes/run classes and rent out shop space. e: if you have a local Woodcraft or hardwood supplier, they often have a bulletin board full of people looking to rent out shop space. stabbington fucked around with this message at 07:25 on Mar 8, 2015 |

|

|

|

Techshop has some neat stuff, although they are much broader than woodworking: http://www.techshop.ws/locations.html Pricey too.

|

|

|

|

Blindeye posted:Any ideas of working spaces for people who want to woodwork but live in an apartment? I'm finding working on my balcony with a collapsing workbench and hand tools leaves me relying on intensive sanding down to get anything even vaguely straight/perpendicular and I'd love a place to work with some space and tools like table saws, etc. Find your local hackspace. Or start your local hackspace.

|

|

|

|

Squibbles posted:With some winding sticks you should be able to get wood flat/square with minimal space requirements. What are these? Google is not helpful at first glance.

|

|

|

|

Basically long straight sticks, sometimes or usually of contrasting colors for visibility. You set the first on one end of a board, the other on the far end and sight down them at eye level so you can check to see if everything is in plane. Very accurate, assuming they were made so. https://paulsellers.com/2014/05/making-winding-sticks-by-hand/

|

|

|

|

Bed is almost done. Just have to cut the 3/4" plywood for the actual base, and find the mattress that was shipped 3+ weeks ago. Shipper has no idea who the carrier was, or anything. I also have to re-sand and stain, and poly spots on the headboard where my girlfriend sanded and then repolyed without staining. They got a little of the wrong stain on them from dirty saw horses, and she forgot a step fixing it. Can I sand down just the problem areas to 80, then start over (220, 220 by hand, stain, poly) , and match the rest of the boards if I do it the same, or should I sand the entire boards and start over on the whole thing? Overall, I'm very happy with how it turned out, thanks for the help everyone.  Click for huge.

|

|

|

|

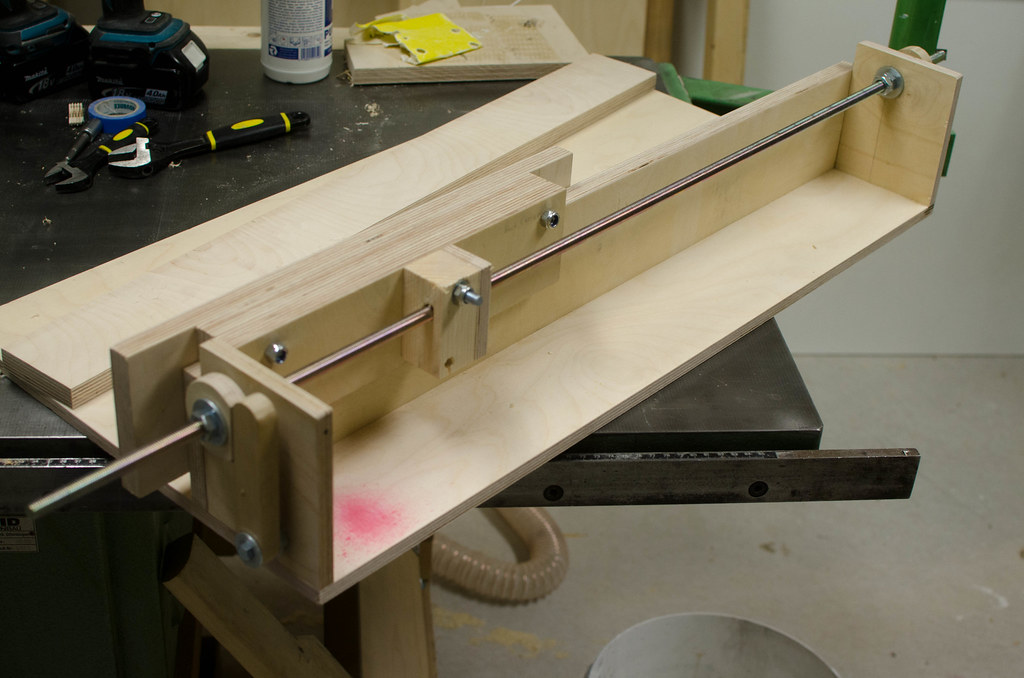

I'm building the box joint jig by Ed Stiles (on youtube) and here's what I got so far.   The basic function is working now, turn the handle and it advances 1.5mm, the cam makes sure one turn is always identical. I still need to make a handle for pushing the sled, the runners, the front fence and also the front carriage plate to keep the pieces in place, and a stop ofcourse. Base is 12mm birch plywood and the rest is a combo of 18mm and 12mm plywood and some pieces of birch. I'll cut the threaded rod to size later too.

|

|

|

|

John Heisz is working on another box joint jig. I want to build one but can't decide whose I want to build --- Woodgears, Heisz, Stumpy Nubs, Stiles, they all have interesting designs. I see advantages to all of them.

|

|

|

|

Most of the box joint jigs I've looked at fail on one thing mostly, they are built with the assumption that I can use a dado blade stack. So far it's only this and the woodgears jig that can get around that. This one was simpler and the plans are free.

|

|

|

|

|

| # ? May 15, 2024 17:13 |

|

Any tips on building out my dust collection system? I've got the collector where I want it, so now it's time to buy piping and fittings and adapters and so forth. I plan on running 4" main, split a 4" off to the table saw, 2.5" to my bandsaw... For any tools that don't have a dust port, should I just run 4"? I know it won't hurt, but is it necessary to run 4" to my drill press? I'm probably run a section along the length of my bench and have a couple 2" or 3" ports to use for various floating tools, sanding, etc.. I want to do it right, but my bank account is looking sad and 4" pvc and fittings are expensive. I'll probably do it in stages, but I want it (mostly) planned out first.

|

|

|