|

So I'm not sure if this is the best place to ask this but I will take the gamble. I am looking to commission a hunk of cut and shaped wood, we can hammer out the details in pm but essentially I am looking for a keyboard wrist rest like this.

|

|

|

|

|

| # ? May 22, 2024 13:29 |

mds2 posted:Creepy. One, this thing is awesome. Two, I'm kind of a wood noob; what kind of tasks is it meant for? Three, purpleheart is always a good choice. It smells kinda funky when you work it, and it's hard as gently caress, but it always looks crazy cool. blunt for century fucked around with this message at 23:43 on Aug 16, 2015 |

|

|

|

|

ColHannibal posted:So I'm not sure if this is the best place to ask this but I will take the gamble. I am looking to commission a hunk of cut and shaped wood, we can hammer out the details in pm but essentially I am looking for a keyboard wrist rest like this. That doesn't look like any great challenge to build but I can't think offhand what kind of finish you'd want on it that wouldn't stick to your hands after typing for a while. Some sort of urethane maybe? On a different stupid note, I had a friend who was making walnut slices into clock faces, and putting a thick coat of polyurethane on them, iirc. His sweat was so caustic it etched fingerprints on the finish wherever he touched them (he was a very heavy drinker at the time- I think the issue was lessened after he cut back)

|

|

|

|

blunt for century posted:One, this thing is awesome. This is purpose built to square the ends of boards. Basically you can only use it with the shooting board. I'll find a video tomorrow to demonstrate. Now there is one thing about this plane. It doesn't work. The way I set the blade has the exact opposite effect that you need. It essentially pulls the cut up instead of pushing down. I can fix it by flipping the handle to the other side, but then it will be a left hand plane. Still easier than making a whole new plane. This was all built out of scraps. The woods are Purple Heart for the handle and wedge, Birdseye maple for the outside of the body, and red gum for the center. I had never used red gum and bought that chunk for like $1 at the wood store. Also all of the brass plugs are 1 1/2"ish long for added weight. And the front sole is brass.

|

|

|

|

Mr. Mambold posted:That doesn't look like any great challenge to build but I can't think offhand what kind of finish you'd want on it that wouldn't stick to your hands after typing for a while. Some sort of urethane maybe? Why not just a good sanding and oil/varnish like you would do a gun stock? The whole point of wood is to not stick to the rest like you would with a solid plastic. ColHannibal fucked around with this message at 04:06 on Aug 17, 2015 |

|

|

|

Hi woodworking goons I've recently got my own workshop and have spent the last few weeks clearing out tonnes of old crap that was left in there. The workshop has a concrete slab as a base which has never been sealed. It has some cracks on it, the widest these get is about 6cm x 3cm. I'm intending to seal with a concrete patch: http://www.diy.com/departments/u-can-concrete-floor-patch-fill-5kg-tub/258255_BQ.prd and paint it with a sealer http://www.homebase.co.uk/en/homebaseuk/ronseal-diamond-hard-pebble-stone---floor-paint---25l-621944 Here are some crappy photos. Any advice on this? Is this the right solution?

|

|

|

|

Finally finished this simple jewelry box for my sister.   The magnetic lid was a late change from my original plan. I should have concealed them but I had too much other stuff to build for my sisters wedding so that got pushed off.

|

|

|

|

ColHannibal posted:Why not just a good sanding and oil/varnish like you would do a gun stock? The whole point of wood is to not stick to the rest like you would with a solid plastic. I've been playing around with oil finishes and that's definitely what I'd use here. BLO or Tung oil would work really well.

|

|

|

|

Oil/wax was my first thought but guitar necks would be analogous. They get a satin finish which has less stiction.

|

|

|

|

wormil posted:Oil/wax was my first thought but guitar necks would be analogous. They get a satin finish which has less stiction. That's usually nitrocellulose, right?

|

|

|

|

Anyone made a bed? I just went all out on a really nice comforter, sheets, and pillows and I really want to replace my lovely metal bed frame and headboard. There are tons of ideas to draw inspiration from for platform beds out there which is what I'd want to make, and Rockler has some good hardware for attaching a bedframe together to be able to break it down if needed. For a basic queen frame with a not-too-elaborate headboard and maybe a small footboard, how much could that run me in walnut? I would like a nice dark color to it and while I know I could make it for really cheap out of pine lumber I don't know if I could make it look halfway decent with stain, etc. Any other woods that are cheaper that look good that I could finish it in a way that it looked nice I would be up for also. I'm trying to get an idea of how much money I'd need to spend because I'd also need to buy the mattress which is gonna run me a decent chunk of money already. I need to learn sketch up before I do anything that way I have some solid numbers and a plan but any tips or advice on wood selection or general bed frame making would help me out.

|

|

|

|

Pretty sure the wood whisperer made a bed. Can't remember if it was a paid project or free through.

|

|

|

|

|

It really depends on your local hardwood dealer. Out here, the price of walnut has been steadily climbing and I'm looking at roughly $12/board foot for SL1E wide stock. Wild-rear end guess, I'd plan to spend at least $400 on wood. Add hardware, add slats, add etc. Also keep in mind that I pulled that number out of my rear end. edit: I did some slightly more advanced back-of-napkin math. I used Wandel's queen bed cut list as a starting point and replaced all the 2x dimensional lumber with 4/4 hardwood that was equal in the other two dimensions. I assume you'll use cheaper wood for the slats and the internals because no one will ever see them. Using $12/bdft I came up with $444, so I wasn't too far off. Walnut is expensive. King Hotpants fucked around with this message at 04:05 on Aug 18, 2015 |

|

|

|

nosleep posted:Anyone made a bed? I just went all out on a really nice comforter, sheets, and pillows and I really want to replace my lovely metal bed frame and headboard. There are tons of ideas to draw inspiration from for platform beds out there which is what I'd want to make, and Rockler has some good hardware for attaching a bedframe together to be able to break it down if needed. For a basic queen frame with a not-too-elaborate headboard and maybe a small footboard, how much could that run me in walnut? I would like a nice dark color to it and while I know I could make it for really cheap out of pine lumber I don't know if I could make it look halfway decent with stain, etc. Any other woods that are cheaper that look good that I could finish it in a way that it looked nice I would be up for also. I'm trying to get an idea of how much money I'd need to spend because I'd also need to buy the mattress which is gonna run me a decent chunk of money already. I can give you some pretty good info as my father in law made mine. Probably got the plans and everything from Rockler, too. Three drawers on each side that pull out. The bed had a cover over the middle that is hollow. Breaks down to two lengths, headboard, footboard, center cover, 6 drawers, and a multitude of fasteners. I wish he had made it lower to the ground (which he did with his own bed after he made ours as a trial run), but otherwise it is in great shape and should last for a while. I would have wanted to put the drawers in the footboard instead, but we have plans to make stairs for our aging dog so we needed that space clear.

|

|

|

Saw this on Reddit, and it's a video showing a luthier make a violin! Edited to 30 minutes, of course, but still! It's a wonderful little video  https://vimeo.com/22691598

|

|

|

|

|

Mr. Mambold posted:That's usually nitrocellulose, right? Usually but a gloss finish will produce more friction.

|

|

|

|

Geop posted:Saw this on Reddit, and it's a video showing a luthier make a violin! Edited to 30 minutes, of course, but still! It's a wonderful little video Great video. Of course, not shown are the literal hours of tool upkeep and French polishing, among other things, but still. Really cool.

|

|

|

stabbington posted:Great video. Of course, not shown are the literal hours of tool upkeep and French polishing, among other things, but still. Really cool.

|

|

|

|

|

wormil posted:Usually but a gloss finish will produce more friction. Yeah, I'm thinking a gloss finish will seem stickier whatever product you use. I've got a high gloss varnished (oil) dresser I made 30 + years ago that doesn't feel like I'd want my arm or wrists on it for any length of time; but my desk made of jatoba (haha!) with a satin danish oil finish seems dry and non-sticky to the touch. e. correction I think the desser is semi gloss, but still not what I'd use for constant contact Mr. Mambold fucked around with this message at 15:28 on Aug 18, 2015 |

|

|

|

Geop posted:Saw this on Reddit, and it's a video showing a luthier make a violin! Edited to 30 minutes, of course, but still! It's a wonderful little video Really cool video. The thing I find most interesting is how he drills the holes in the head stock.

|

|

|

|

I made a queen size walnut bed with underbed storage, and even using maple ply for non show and walnut ply for the panels on the headboard and footboard put me in the upper seven hundreds with hardware. Figure would have been mid fives with no storage.

|

|

|

|

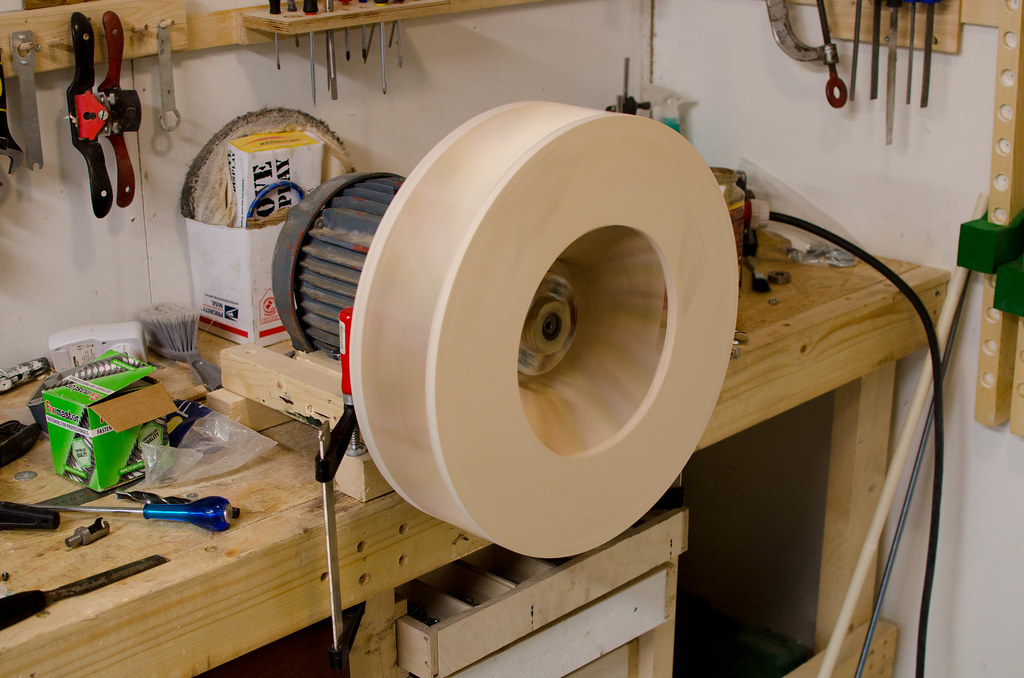

I suppose it's worth mentioning Woodgears.ca just put up a making a queen size bed video too. And in other news, it's alive! And it sounds scary as all hell, 18" impeller and a 5.3hp motor, goes from 0 to full speed at once. I'll be glad to put it in another room, or why not the attic.

|

|

|

|

His Divine Shadow posted:I suppose it's worth mentioning Woodgears.ca just put up a making a queen size bed video too. bro that looks dangerous af massive pucker factor just from a still image. Why in the world does that exist?

|

|

|

|

His Divine Shadow posted:I suppose it's worth mentioning Woodgears.ca just put up a making a queen size bed video too. I am going to need a video of that starting.

|

|

|

|

Cobalt60 posted:bro that looks dangerous af It wasn't under power then, but spinning down. I stood with a 10m extension cord and switched it on outside, multiple times. It's going to be a very powerful and home built DC. Blame Matthias Wandel and other youtubers like Marius Hornberger for putting the idea in my head. Next up is building the enclosure. then a thien separator, then it'll be mounted in another room and turned on remotely. BTW: Anyone know what kind of brush or tool is used to get a brushed/structured finish on wood? I've seen a table top with a mildly brushed finish and it looks real nice. His Divine Shadow fucked around with this message at 06:44 on Aug 19, 2015 |

|

|

|

So this year is the first time in forever where I've actually had disposable income, and vowed to spend it on exploring a bunch of hobbies and poo poo that I've always wanted to try. Earlier in the year, I did an introductory blacksmithing/metalworking class, which was fun, but didn't quite grab me the way I'd hoped. The next thing on the list was woodworking, which seemed a bit harder to get into without spending a bunch of money on tools and whatnot, and introductory classes were often too broad and tried introduce too many concepts and things at once, so I just said gently caress it, went big, and signed myself up for an acoustic guitar making course that I could do on weekends. Oops. I'm absolutely loving it, and the first thing I'm doing when I finish is to setup my own shop. I have a huge garage which is just full of boxes and random poo poo we don't need from when we moved in. I'm pretty proud of what I've accomplished so far, considering I had literally zero experience doing anything like this. The teacher has been great, basically letting me do everything, which has been quite rewarding because I had envisioned that it would require him to give me a lot more help than I've actually needed and it really feels like my project, rather than something I've participated in while he took the lead. I've been taking a bunch of pictures of my progress here http://imgur.com/a/6bgYh/all Last weekend I finally joined the back and sides which are Tasmanian blackwood.   The soundboard sanded down, which is NZ Kauri  CLAMPS!

|

|

|

|

screaden posted:So this year is the first time in forever where I've actually had disposable income, and vowed to spend it on exploring a bunch of hobbies and poo poo that I've always wanted to try. Earlier in the year, I did an introductory blacksmithing/metalworking class, which was fun, but didn't quite grab me the way I'd hoped. Nice!

|

|

|

|

I spent most of the day today staining my soft maple cabinet doors and ran into a bit of a problem I don't quite understand. On many of the doors, I'm getting these little dots that aren't picking up the dye. They're all on the edge grain, and there's a clear distinction between the glued up maple boards within the panel of each door. One board may be dot free and the adjacent board may have a bunch of them. This is a portion of the worst one: My finishing schedule. I used a washcoat with 1:2 mixture of waterlox:mineral spirits to minimize splotching, waited 24 hours, then dyed with a water based transfast dye. The dye was flooded on with a brush and the excess wiped off. I used the same process on the cabinet face frames and veneered end panels last fall without any issue (ran out of warm weather last year and decided to just finish the cabinet doors when I finally had time to). The only differences compared to when I finished the face frames is that I used odorless mineral spirits and the dye was close to a year old. I'm inclined to think it's just from the grain of the wood in conjunction with the washcoat, but I haven't seen it before and wondered if I hosed something up. The doors don't look bad otherwise and I'm probably going to just go with it and finish the doors anyway. dyne fucked around with this message at 00:00 on Aug 20, 2015 |

|

|

|

Tim Thomas posted:I made a queen size walnut bed with underbed storage, and even using maple ply for non show and walnut ply for the panels on the headboard and footboard put me in the upper seven hundreds with hardware. Figure would have been mid fives with no storage. His Divine Shadow posted:I suppose it's worth mentioning Woodgears.ca just put up a making a queen size bed video too. Well I don't think I want to put 500-700 in a bed right now, so I need to see what the possibilities are to make one using cheap hardwood or home depot lumbar look decent. The style of Matthias' frame looks pretty straightforward and is basically what I'm looking for. I'd probably make a different headboard design and may still want to find/design a plan with some storage drawers. Are there any tricks for staining lumbar to make it look decent, uniformly dark, and not blotchy? I'd like it to end up like a deep walnut color. The grain won't look right obviously but as long as it doesn't look really ugly I'm fine. I guess some other options would be using higher quality plywood or veneer. Veneer can be expensive too though I don't have any experience with it. Thanks for the advice so far. nosleep fucked around with this message at 03:49 on Aug 20, 2015 |

|

|

|

nosleep posted:Well I don't think I want to put 500-700 in a bed right now, so I need to see what the possibilities are to make one using cheap hardwood or home depot lumbar look decent. The style of Matthias' frame looks pretty straightforward and is basically what I'm looking for. I'd probably make a different headboard design and may still want to find/design a plan with some storage drawers. Are there any tricks for staining lumbar to make it look decent, uniformly dark, and not blotchy? I'd like it to end up like a deep walnut color. The grain won't look right obviously but as long as it doesn't look really ugly I'm fine. I guess some other options would be using higher quality plywood or veneer. Veneer can be expensive too though I don't have any experience with it. Thanks for the advice so far. Home depot is your worst bet for hardwoods. Shop around Craigslist and see if there arent some small mills in your area or distributors

|

|

|

|

Mr. Mambold posted:Home depot is your worst bet for hardwoods. Shop around Craigslist and see if there arent some small mills in your area or distributors At which point, you should have an experienced friend with a moisture meter or you're apt to get screwed, glued, and tattooed (Sorry for the self-quote)

|

|

|

|

This Jet JJ-6CS jointer popped up on craigslist this morning, $125. Assuming it runs fine, it appears to be a steal. Surface rust should clean up easily enough. I'm going to look at it tonight or tomorrow hopefully. Aside from checking table flatness, table/fence adjustments, motor, blades, anything else I should keep an eye out for? I've never actually owned a jointer before.

|

|

|

|

bimmian posted:This Jet JJ-6CS jointer popped up on craigslist this morning, $125. Assuming it runs fine, it appears to be a steal. Surface rust should clean up easily enough. I'm going to look at it tonight or tomorrow hopefully. Aside from checking table flatness, table/fence adjustments, motor, blades, anything else I should keep an eye out for? I've never actually owned a jointer before. I dont know if you can shim those tables, but id bring a long enough straightedge to make sure they aren't skewed terribly. I guess thats part of table adjustments. Otherwise your checklist is really complete, and I would worry least about condition of the knives. Looks like a hella deal, good luck!

|

|

|

|

wormil posted:Oooh, door chat. The door on my shop is made from pine 2x6's with a skin of 1x6's; it's heavy as hell and I love it. It basically looks like this but on hinges and not quite as pretty. Resurrecting this from earlier -- by "skin" do you mean that you used 2x material throughout and then layered the 1x6s on top of that? Or that you used 2x material for the framing and then filled in the panels with 1x material? At 33 pounds/cubic foot, filling in the door space (89"x45") with seasoned douglas fir at 2x width would make for a door that weighs about 115 pounds. I can just about imagine that that could work, but it's a pretty  number. Dunno how easy it'd be to hang! number. Dunno how easy it'd be to hang!

|

|

|

|

nosleep posted:Well I don't think I want to put 500-700 in a bed right now, so I need to see what the possibilities are to make one using cheap hardwood or home depot lumbar look decent. The style of Matthias' frame looks pretty straightforward and is basically what I'm looking for. I'd probably make a different headboard design and may still want to find/design a plan with some storage drawers. Are there any tricks for staining lumbar to make it look decent, uniformly dark, and not blotchy? I'd like it to end up like a deep walnut color. The grain won't look right obviously but as long as it doesn't look really ugly I'm fine. I guess some other options would be using higher quality plywood or veneer. Veneer can be expensive too though I don't have any experience with it. Thanks for the advice so far. Hickory is half the price of walnut and can get pretty close to what you're looking for if you use an aniline dye and gel stain. I'm using dyed hickory as the secondary wood for a chest of drawers I'm making. dye, followed by a sealer, then gel stain, then arm-r-seal varnish is what you want to do.

|

|

|

|

TooMuchAbstraction posted:Resurrecting this from earlier -- by "skin" do you mean that you used 2x material throughout and then layered the 1x6s on top of that? Yes, although I didn't build it. The shop was here when we bought the house. I misremembered a bit, it's a 2x6 frame, with 1x3 (actual) then 5/8 plywood. The plywood is unnecessary but like I said, I didn't built it. Ugly but sturdy.

|

|

|

|

Great, thanks. I'm thinking what I may end up doing for my door is 2x6 frame, plywood panels (I have so many .75" plywood scraps left over), covered with 1x6s (also leftovers) to make it look prettier.

|

|

|

|

I suppose while we're on the topic, do you guys have any recommended books/resources to learn about making interior doors? My house was from the early 80s, and many of the doors are super-cheapo. Kind of curious how I would go about making practical ones. By interior doors, I mean just regular things like bedroom doors & bathroom doors. I've seen information on making, say, a ginormous front door, but that's for a ways down-the-line.

|

|

|

|

|

All I know is that a Domino would make building a door a lot easier.

|

|

|

|

|

| # ? May 22, 2024 13:29 |

|

mds2 posted:All I know is that a Domino would make building a door a lot easier. Hadn't heard of these, so I looked it up (Festool Domino mortising tool). I am not putting down $800+ on a tool for one job.

|

|

|