|

His Divine Shadow posted:Seems easier to just swap the rotation on the motor with an electrical switch. I assume it's a design choice to have redundancy built in, this way it can be run on 1ph outlet if it was exported to another country where this was not an option. You can do that with a single phase motor as well. My South Bend is set up that way (the motor specifically has to be built for that and there's a relay inside of it, etc). So, yeah....must just be some kind of redundancy because I can't imagine there would be much of a difference which way you chose to reverse rotation. One Legged Ninja posted:This one? That only reverses the lead screw. It's for left handed threading and feeding. Oh yeah, if that's the one it's definitely just for the lead screw. Looks very similar to the SB setup.

|

|

|

|

|

| # ? May 25, 2024 17:34 |

|

Yeah that makes all of the sense.

|

|

|

|

somebody talk some sense into me and convince me not to buy a taig lathe b/c its all i can afford now and for the foreseeable future even tho it can't cut threads without substantial modification and doesnt accept standard mini lathe tooling/accessories and is limited to small work and doesn't have the backbone for substantial cuts

|

|

|

|

Have a small lathe. Sucks rear end. Don't do it

|

|

|

|

Ambrose Burnside posted:somebody talk some sense into me and convince me not to buy a taig lathe b/c its all i can afford now and for the foreseeable future even tho it can't cut threads without substantial modification and doesnt accept standard mini lathe tooling/accessories and is limited to small work and doesn't have the backbone for substantial cuts Have you looked into doing turning work by mounting a Taig chuck onto the spindle, and clamping tooling down on your work table? I've been toying with the idea since it seems to be relatively easy to switch between the lathe and mill configurations if I do this. e: something like this

rawrr fucked around with this message at 22:20 on Oct 22, 2017 |

|

|

|

rawrr posted:Have you looked into doing turning work by mounting a Taig chuck onto the spindle, and clamping tooling down on your work table? I've done very minimal impromptu turning in a pinch this way with maybe two small parts that had collet-compatible shanks, but it was limited to very modest grooving and chamfering where the forces involved were negligible. I wouldn't consider doing turning of any substance like that unless someone with first-hand experience doing it for an extended time could vouch for it being A-OK for the spindle, if flycutter use is discouraged because of the toll it takes on the bearings I bet an actual chuck would do a magnitude more harm. Ambrose Burnside fucked around with this message at 22:26 on Oct 22, 2017 |

|

|

|

The taig lathe spindle is the same one they use for mills

|

|

|

|

Is it? Well idk then. I personally still wouldn't on a regular basis but that's because I want to turn stuff manually and my mill is CNCed without a convenient way to use it with handwheels, so far as I know.

Ambrose Burnside fucked around with this message at 22:32 on Oct 22, 2017 |

|

|

|

Yooper posted:I like the room, the beams are a nice touch. Structural and not just pretty I hope? As far as the stove, I'd avoid the paint, it'll smell like burning plastic-paint. We use generic stove black on our wood stove. https://www.lehmans.com/product/stove-black-and-polish/ Yep, supporting - but like most of the house it's not a three hundred year old piece of ship's mast - the house was built in the 30's. The previous vendors (this is their photo) went nuts with the 'Polish country restaurant'-theme, but I think it's got potential with a few rugs and some slightly more tasteful furniture. I didn't know stove-black was a thing, but I am going to try that first. I've asked them to service the stove before they leave but who knows if that'll happen - either way I'm looking forward to a crackling fire in short order so this is going to be high on my list. Many thanks,

|

|

|

|

His Divine Shadow posted:Somebody tipped me off to a £150 Challenger 5" lathe with screwcutting gearbox, but I have no idea if it's worth trying to ship from the UK to Finland despite the price. Also not sure if the top speed of 650 rpm might be a limiting factor, iirc you want to run faster with HSS bits, and even faster with carbide? It all depends on the material and it’s diameter. The equation for rpm is (3.82xsurface speed)/workpiece diameter or cutter diameter for mills. For carbide, you usually multiply that by 4. Surface speed for 6061 aluminum is usually 200+, mild steel is usually 100+. Those are to get you into the right ballpark, you might adjust the figure to get the results you need. It all depends on the machine. On our HAAS mills at work we cut alu at 500+, and a2 tool steel at 150~ depending on the task. HSS blanks are great because you can really grind the hell out of them easily into whatever shape you want, and they are much less expensive than carbide tools. They are likely what you would use. It might be a good fit for what you want to do, but if I were buying a lathe, I would save up for something more capable. When machine shops close down or upgrade their equipment, you can find screaming deals at auction, or however they are being sold.

|

|

|

|

Does anyone know what kind of scrollsaw clickspring uses? Or maybe the better question is do you need a fancy scrollsaw to cut thin brass stock?

|

|

|

|

Naw, just a properly fine-toothed blade and plenty you oil should be fine. General rule of thumb is 3 teeth in contact with the work at all times, e.g. cutting 1/4" thick material should be about a 12tpi or finer blade to avoid breaking teeth.

|

|

|

|

You absolutely don't need a scrollsaw to cut thin brass stock- but a better question is, what sort of cuts do you need, and how thin is 'thin'? A scrollsaw with an appropriate blade will be fast and allow intricate cuts, but many scrollsaws will be unable to use jeweller's sawblades, which you'll likely need if you want to saw-cut anything thinner than ~10-12 ga. or so. A jeweller's saw, on the other hand, will let you do the work of a scrollsaw for less than $15 all in, but it'll take 10 times as long to do a given cut. If some distortion of the sheet is acceptable and you don't need high precision or intricate cuts, a pair of tin snips is all you need and it'll work faster than just about any other option. practically speaking, I usually combine several methods to work effectively- if I'm cutting an intricate pattern out of sheet I'll usually do as much bulk material removal as possible with a shear or snips before switching over to a jeweller's saw to do the finicky careful cuts.

|

|

|

|

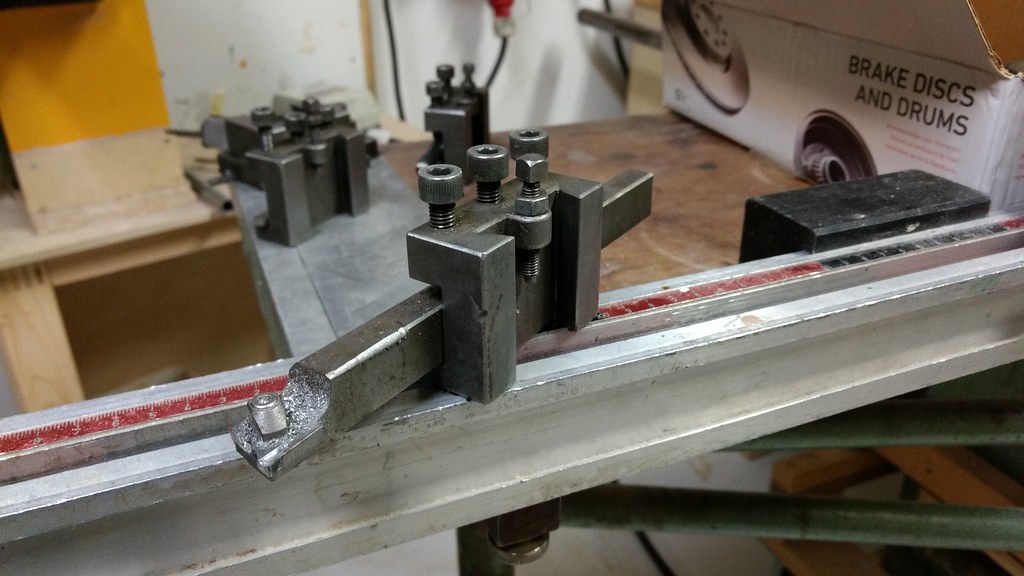

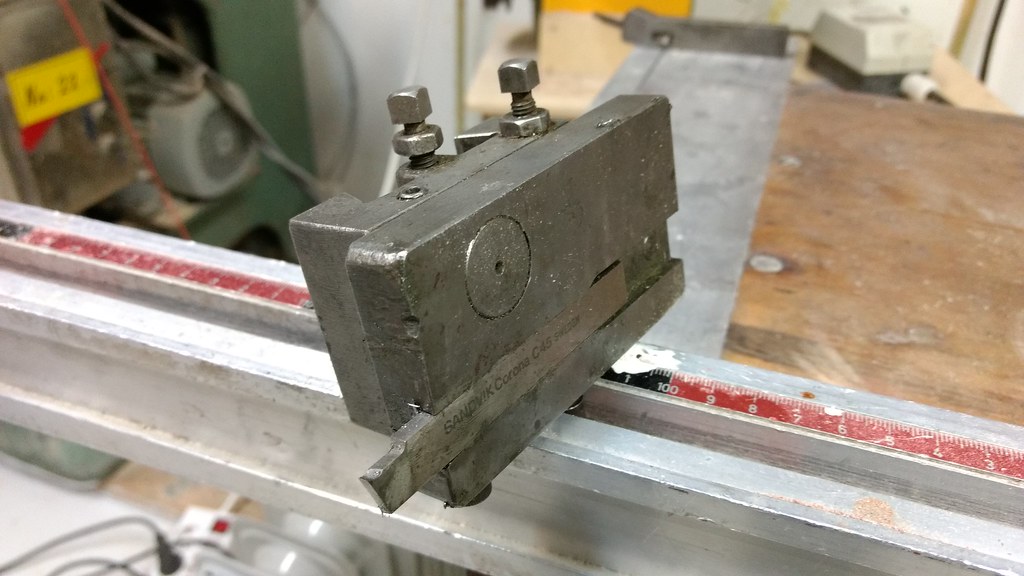

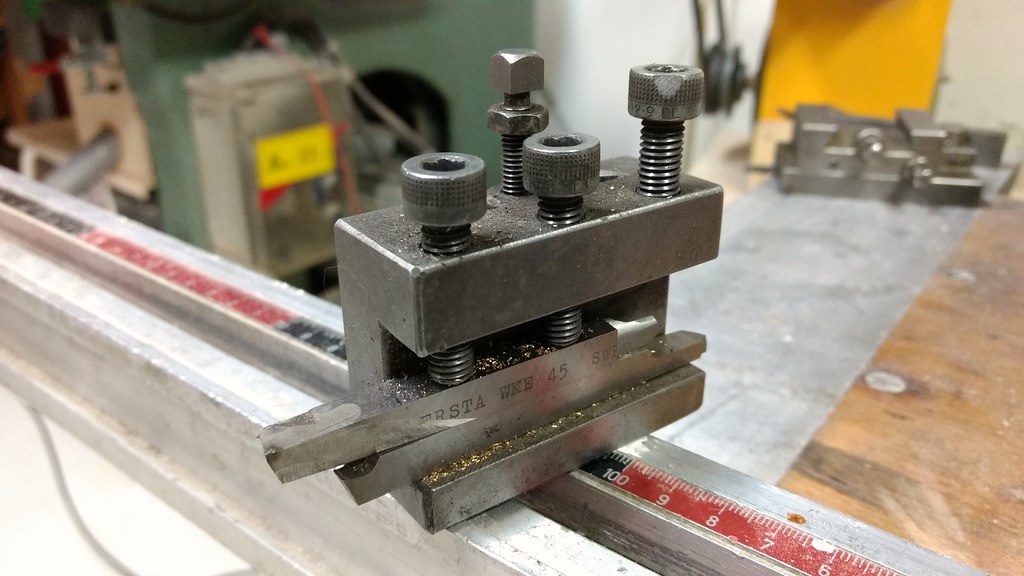

Retrieved the tool cabinet last weekend and all the loose parts of the lathe, so they wouldn't be lost, had a close rinspection of what I got in terms of cutting tools. Seems I got a boring bar that takes carbide inserts: It's a bit hard to see but I believe it uses this insert:  Here's another insert, not sure what type, haven't had time to look at it closely, home alone with kids last night, one is vomiting... Seems there's a support above and below the cutting insert.  This holder is of a different design to the rest with a HSS cutter  And another cutter, not quite sure what this might be meant for  And one with some HSS pieces, this is the one I used to do some test cuts, looking at the geometry there is no back rake so perhaps this one was meant to turn brass.  The quick change tool holders I found out are of swedish make called Bergströms, there's even a lathe.co.uk infopage on them: http://www.lathes.co.uk/bergstrom/

|

|

|

|

I believe the 3rd one up is a parting tool. Careful with those, get instruction. I used one the other day figuring I'd work things out as I went and broke the tool.

|

|

|

|

Yeah, that's a parting-off tool. They're straightforward to use if you bear in mind that parting off involves very high forces on the tool because you're taking a big full-engagement profile-type cutter and typically plunging it deep into the stock. Turn the RPM way down (not threading-slow but much slower than you'd turn at), lock the carriage + all slides except the one you're using, use lots of cutting fluid/oil, and plunge the tool straight in nice and steady, slower than you think is necessary until you've felt out what you can do before you run into chatter or tool damage. If the carriage shifts while you're engaged or if you take too big a bite through jerky handwheel turning you may break the tool, otherwise all you need is a little patience.

|

|

|

|

Tangentially-related- I've stumbled upon "chatter tools" for wood-turning, handheld turning tools with thin + springy cutters as a design feature, to add regular divots/marks to whatever you've just turned as a deliberate decorative embellishment. I wonder if there's anything similar for metal turning. Physics of it are different enough for it to be a nonstarter, maybe, but

|

|

|

|

Ambrose Burnside posted:Tangentially-related- I've stumbled upon "chatter tools" for wood-turning, handheld turning tools with thin + springy cutters as a design feature, to add regular divots/marks to whatever you've just turned as a deliberate decorative embellishment. I wonder if there's anything similar for metal turning. Physics of it are different enough for it to be a nonstarter, maybe, but Having a long tool ( Related: AvE had a video on a device that changed the speed of a motor to reduce chatter, since resonance of the piece is part of the chatter problem puzzle. It didn't totally remove chatter, but iirc it worked enough as a proof of concept that it was pretty interesting.

|

|

|

|

Measuring and locking out spindle speeds that resonate with the part or toolholder is very much a thing in the high-volume production world now. https://www.youtube.com/watch?v=DyZ7qkC3CIs shame on an IGA fucked around with this message at 20:53 on Oct 31, 2017 |

|

|

|

Rotten Cookies posted:Having a long tool ( Haas lathes can actually program this. I'm going to find time to toy around with it eventually. https://www.youtube.com/watch?v=dXR2wDDFFm4

|

|

|

|

Are the bigger Chinese retail mills any better than the mill drills that are around? In Aus this seems like a cheap option https://www.machineryhouse.com.au/M595D for us, 7k in their annual sale and nice and new. Avoids the used Bridgeport market ($5kish for one). Industries seem to pick them up and list them on our craiglist too. I'm wary of Chinese quality after issues with my Rong Fu 45 clone.

|

|

|

|

shame on an IGA posted:Measuring and locking out spindle speeds that resonate with the part or toolholder is very much a thing in the high-volume production world now. Volkerball posted:Haas lathes can actually program this. I'm going to find time to toy around with it eventually. This is all good and well (and legitimately pretty dang cool), but these are all approaches to reducing chatter. I'm talkin about letting chaos into your heart and embracing the chatter

|

|

|

|

Ambrose Burnside posted:This is all good and well (and legitimately pretty dang cool), but these are all approaches to reducing chatter. I'm talkin about letting chaos into your heart and embracing the chatter Anything that could do, polygon turning could do better. But yes in principle it should be possible to play spring tuning games like grinding a slot in the tool shank and changing the length to create a perfect situation where you can cut hex flats on a piece of stock with a solid tool. shame on an IGA fucked around with this message at 01:26 on Nov 3, 2017 |

|

|

|

Ambrose Burnside posted:This is all good and well (and legitimately pretty dang cool), but these are all approaches to reducing chatter. I'm talkin about letting chaos into your heart and embracing the chatter You should meet one of my coworkers. Louder means faster right?

|

|

|

Ambrose Burnside posted:This is all good and well (and legitimately pretty dang cool), but these are all approaches to reducing chatter. I'm talkin about letting chaos into your heart and embracing the chatter How many lobes of chatter would you like? I can totally gently caress up a centerless grinder and get you 3, 5, or 7. Beyond 7 and the harmonics get weird and the measurable size becomes difficult to measure with anything other than a Talyrond or similar device. To make it visually interesting will be challenging, though we've made parts that had such weird lobing and harmonics that the surface finish looked like strands on a rope. And the lobing will be measured in tenths max.

|

|

|

|

|

Yooper posted:How many lobes of chatter would you like? I can totally gently caress up a centerless grinder and get you 3, 5, or 7. Beyond 7 and the harmonics get weird and the measurable size becomes difficult to measure with anything other than a Talyrond or similar device. To make it visually interesting will be challenging, though we've made parts that had such weird lobing and harmonics that the surface finish looked like strands on a rope. And the lobing will be measured in tenths max. this is what i'm freakin talking about

|

|

|

|

Today this arrived, now to make a temporary gantry crane and move it off the pallet:

|

|

|

|

Look how clean it is! All of it! The last time I bought a machine in someones garage it looked like a bomb went off that was filled with grease, metal shavings, and titty calendars.

|

|

|

|

|

I mostly do woodworking, and this area has until a few weeks ago been separated by a wall. The floor which is painted in the other room is pretty dinged up and stained after a year. Though I try to keep clean and organized, I hate coming into an unorganized and dirty workshop, even know there are fifty-eleven different things that bug me about the shop I want to get to some day.

|

|

|

|

Southern Heel posted:This is only somewhat related but hopefully covers the expertise of the thread. My new house has a wood burning stove in the livingroom, the chimney is swept and certified - but the stove itself is looking a little sad: There is stuff that you can get at most auto parts stores called "header paint" that's specifically designed not to offgas, or smoke at high temperature, but... Yooper posted:I like the room, the beams are a nice touch. Structural and not just pretty I hope? As far as the stove, I'd avoid the paint, it'll smell like burning plastic-paint. We use generic stove black on our wood stove. https://www.lehmans.com/product/stove-black-and-polish/ Yooper's right. This. In fact Williams' is the best, and I go through about 2 tubes per season. As far as I can tell, it's a paste made up of carbon black, and graphite. Rub it on, let it dry, and then buff it to the coolest grey/black sheen you've ever seen. Just don't get it from Lehman's. They're down the road from me, and it's basically a massively overpriced hardware store in the middle of an Amish area, and basically a tourist trap. A google search will turn up gobs more places that will sell it to you super cheap. I bought 12 tubes a year or so ago at about $1 per tube. This is mine:  I go through about 5 cords per Winter.

|

|

|

|

Kinda far afield for this thread- ok really far afield but it involves cool machine pictures ok- but I picked up an ignored Remington Noiseless No. 10 typewriter from the early 50s at an estate auction for pocket change and I'm gonna try to restore it to working condition. The appeal for this thread is the really cool typebar action it used. the generic typewriter you think of used a 'frontstrike' action, where the typebar swings up and away from the keyboard towards the paper on a long, thin arm and uses inertia to confidently print each letter. It's also noisy. This type of Remington used this really neat 'thrust' action with a parallel linkage to move against the paper in a linear way, which is much quieter, allows faster typing, and gets more consistent results. it's also got some crazy articulation down below that lets it come in at two different angles such that each typebar doubles up on the letters it carries. Most typewriters put upper/lowercase on one typebar; this one puts four characters total on each. Oh yeah, it's also ridiculously well-made and incredibly elegant in action  The visible typebar action- there's an extensive system of levers, bellcranks, solid linkages and springs for each underneath.  a closeup of the typebar faces, you can see how each has 4 characters at different levels. the level of detail/complexity here is a magnitude greater than w most typewriters, though. each typebar has a very specific bevel to its face- or rather, each upper/lowercase character set has a distinct bevel in two axes to account for the two thrust angles- so it impacts the paper square and parallel, and each character has tiny steel ramps at appropriate places to account for any minor issues with alignment and to direct the type through the guide and onto the paper at the desired spot. Each individual typebar can have its action and the placement of its type adjusted in 3 separate axes. Several parts of the machine must be calibrated to specified thousandth-of-an-inch spacings w specified tolerances to achieve the intended results, and the machine originally shipped with a 0.060" spacer tool for calibrating the typebars which i'm gonna have to manufacture before I get going, lol Also didn't get a picture but the carriage rides on dovetail ways, adjustable gibs and all, and it looks at least as well-machined as a modern import lathe's bed would be if anyone's curious, here's what goes into each typebar, and there's 22 of em  All the hardware is there and in good shape aside from the mouldering silencing felt on the interior and some of the rubber rollers, even the delicate coil springs seem pretty free of rust. just needs to have the guts rinsed out with naptha or carb cleaner or sth to get rid of the old oil and cracked rubber replaced w built-up shrink tubing surrogates and then it's just a matter of calibration. tl;dr INTRICATE OLD MACHINES ARE REALLY COOL OK Ambrose Burnside fucked around with this message at 21:30 on Nov 3, 2017 |

|

|

|

Ambrose Burnside posted:Kinda far afield for this thread- ok really far afield but it involves cool machine pictures ok- but I picked up an ignored Remington Noiseless No. 10 typewriter from the early 50s at an estate auction for pocket change and I'm gonna try to restore it to working condition.

|

|

|

|

this thing is ridiculous, I dug up a technician's maintenance manual and assembly from loose parts has 128 distinct steps, most of which have lots of bullet points and sub-steps. No detailed/comprehensive part lists, either, but I'd be amazed if there aren't something close to 1000 mechanical components all told, between those typebar assemblies plus all the really intricate gearing n so on that governs the carriage/platen's travel. The best thing to do would be to remove any/all external casing and plastic/enamel components so i can really thoroughly degrease all the moving parts somebody negligently oiled at some point in the past, but I actually can't 100% tell how many internal components use the remarkably-sturdy shell as an attachment/mounting point- no detailed exploded diagrams of the whole thing out there that I can find, just of individual mechanical assemblies- so I'm terrified everything will collapse into a heap once I take the final case screw out and this machine'll never clack out a letter ever again. i'm not sure what i'm gonna do with it when (lets be honest, slash if) i get it in good working order, it's a loving tank (maybe 2 feet deep by a foot and a half or so wide) and must weigh at least ~40+ pounds. It was designed to ahve a permanent spot on a desk and be used by a clerk or accountant day in, day out for the rest of time and be none the worse for wear, and I don't have room or a need for that. On top of that I've already got a Smith-Corona Silent portable from the 30s that types wonderfully and can get shoved under a bed when I'm not using it. Unfort this Remington is also not a 'classic'-styled design, so the aesthetic-eye-candy antique shop resale value probably isn't much regardless of its condition.  This is almost identical to mine, the main difference being that mine was a special Canadian-manufactured run so the badges are a little different. It really is a freakin' tank.

|

|

|

|

estate auctions are so loving dangerous for a packrat like me. i couldn't possibly NOT snag up something this cool for $2.50, it'd be immoral not to. i'm also now the proud owner of this guy's shop drawer fastener-mason-jar collection, a small fraction of which legitimately isn't rusted garbage, but that isn't as noteworthy

|

|

|

|

There's a documentary about typewriters playing at Hotdocs at Bloor and Bathurst right now Ambrose. Probably on for another week.

|

|

|

|

I bought a bridgeport clone https://www.machineryhouse.com.au/M593D and now I have to move it down a driveway that is verging on steep and it has uneven concrete (many large cracks, some holes, very lovely). Any ideas on how to get it down? I was thinking of laying down some sheetmetal and sliding it across it. I don't think a pallet jack would work, as the wheels really need to be tyres on this surface.

|

|

|

That Remington is awesome. I got this from my grandmother's house a while back, looking forward to being able to restore it as well: Way less complicated! I don't have the serial on hand but I think it was from 1901 or so

|

|

|

|

Mudfly posted:I bought a bridgeport clone https://www.machineryhouse.com.au/M593D and now I have to move it down a driveway that is verging on steep and it has uneven concrete (many large cracks, some holes, very lovely). Any ideas on how to get it down? I was thinking of laying down some sheetmetal and sliding it across it. I don't think a pallet jack would work, as the wheels really need to be tyres on this surface. Chainfall to control the slide. Sheetmetal is possible, but they are tippy fuckers. I'd even look at a pair of chainfalls or winches up hill. If you can get a pair of pinch bars that'll help a shitload too. http://www.easternrigging.com/prybar.htm We have a pair of two meter bars with notches so we can lever poo poo off of anchors. Love em. If it feels like it's going to go for a ride, let it go. Ain't no stopping an angry machine tool. You can also dis-assemble the machine and take it in parts.

|

|

|

|

|

Holy poo poo Ambrose. $2.50?

|

|

|

|

|

| # ? May 25, 2024 17:34 |

|

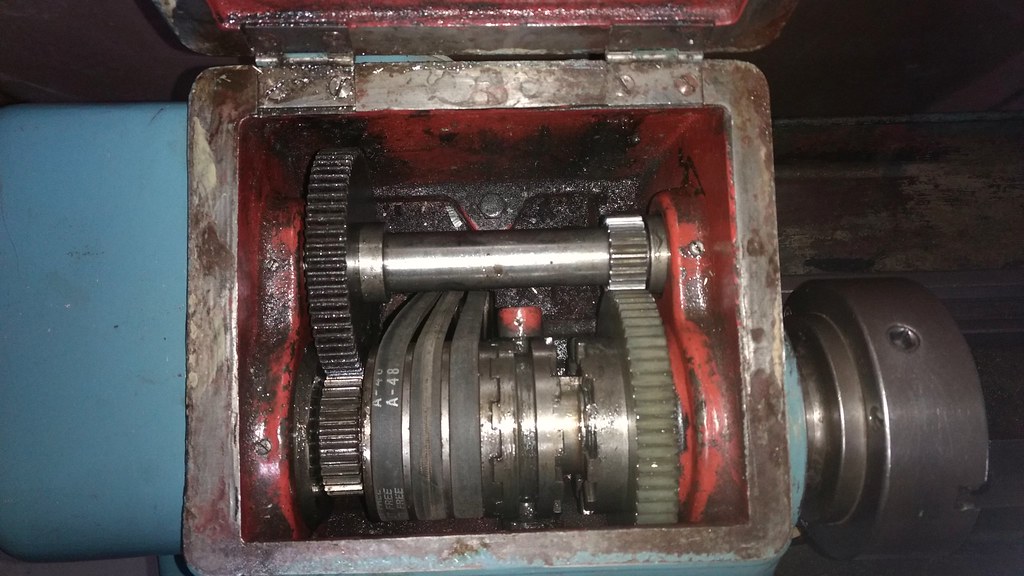

I have disassembled and cleaned the as many of the parts as I could in degreaser, oiled and reassembled the lathe again. I think the color on the lathe is in quite good shape, only bits that are really worn is the cross and top slides. The spindle housing seen from above:  Apron and lead screw ready for reinstall, had the whole thing submerged in degreaser:  Assembled, using ballistol for now to oil in moving surfaces.  This little chapman kit from Brownells I got many a year ago has been such a useful piece of kit, all kinds of slotted screw drivers and the hollow ground shape instead of a chisel shape prevents cam out.    Removing the chuck showed me this, someone apparently lost one of the screws for the cover plate and put a badly fitting phillips screw there....    Reassembled, next step is to get the pallet away from under it.

|

|

|