|

Wolfy posted:So I had an interview today to be a project engineer for a construction company. I'm going to be a fresh graduate. I know it's not really engineering, but close enough. One, that's usually a good sign right? Two, how the hell do I figure out how much to ask for? An interview is a good sign, but it doesn't really mean anything until you're hired. As far as how much to ask for, look up starting salaries/wages in your area and/or field for that position. From what I know, around $60k or $25-30 per hour might be a good ball park to start with for any entry level engineer and then pick a number slightly higher. Here's a link that might be worth taking a look at: https://www1.salary.com/Project-Engineer-I-Construction-salary.html

|

|

|

|

|

| # ? May 17, 2024 23:03 |

|

Wow I'm such a gently caress, and couldn't form a coherent statement. It was my second interview, and we got to the salary part. I was totally blindsided and didn't have an answer. But it's a decent sign that we got that far?

|

|

|

|

Kiewit? Granite? Mortenson? Flatirons? PCL? Honestly you are going to do negative engineering work and if you are a civil you probably have no one to verify experience (if it counts) towards getting your license (there is a construction portion of the PE though). I know a lot of people who work at those places and they pay is pretty meh until you move up and the project engineer title doesn't have anything to do with being an engineer usually (many of your peers will be construction management majors). Depending on the job location I would expect around $60K. A lot of people burn out from the bigger companies as well. If it is a smaller player all bets are off. A good friend was making under $40K at a small company in michigan as a project engineer. It is fun to be out on site every day instead of stuck in an office though!

|

|

|

|

Wolfy posted:So I had an interview today to be a project engineer for a construction company. I'm going to be a fresh graduate. I know it's not really engineering, but close enough. One, that's usually a good sign right? Two, how the hell do I figure out how much to ask for? Folks working under the umbrella of Construction are referred to as Construction Engineers or Field Engineers. (Most have an engineering or construction management degree. We also get some folks who come up through the construction crafts.) Pay for fresh college hires was low to mid 60s circa 5 years ago.... (Not counting dental/medical benefits or retirement.) I recently had an offer come in to go work in San Francisco, I think I will take it. I've been helping write nuclear procedures for the last 7 months and it is driving me absolutely nuts. (Lack of real leadership on the project to say the least. One of the college hires who came here circa 2.5 years ago is effectively a secretary. Procedures have to be 'group' approved. It is driving me nuts.) I don't dislike nuclear work but these guys are just being... stupid. Its all about the people.... and my last job/project (same company) we had such a great team... I miss them a lot.... When working on the Construction or Project side of things, you just have to enjoy it while it lasts... Senor P. fucked around with this message at 06:17 on Nov 8, 2017 |

|

|

|

The correct answer to any salary question is “negotiable”.

|

|

|

|

Frinkahedron posted:The correct answer to any salary question is “negotiable”. Correct. If they press you, always say you work for compensation not just salary, and it will depend on health coverage, retirement stuff, all benefits etc. Honest question to working engineers in this thread, what is your opinion and/or perception of people working in metal casting?

|

|

|

|

I'm a chemical engineer who works in an oil refinery and I have no idea what metal casting engineers do. All I know is most of my equipment is made of metal so if you're responsible for making one of our thousands of pieces of 60+ year old equipment that is still running thanks! If you're responsible for making one that keeps breaking, gently caress you!

|

|

|

|

Frinkahedron posted:The correct answer to any salary question is “negotiable”. Ehhhhh I think you at least need to give a range within which you're willing to negotiate.

|

|

|

|

Noctone posted:Ehhhhh I think you at least need to give a range within which you're willing to negotiate. Plus straight out of school you have minimal leverage.

|

|

|

|

First job, I wouldn't push too much with salary, especially if it's something you think you can leverage into a new, better job. OTOH, it's really easy to get complacent and just stay at a lower paying job so be careful of that.

|

|

|

|

My first job, I didn't negotiate at all and I don't regret it for one second, even though I was shafted on pay for a couple of years. In the grand scheme of things it's peanuts. The HR person called me and said a number, expecting a counter, and I said yes when can I start.

|

|

|

|

paternity suitor posted:My first job, I didn't negotiate at all and I don't regret it for one second, even though I was shafted on pay for a couple of years. In the grand scheme of things it's peanuts. The HR person called me and said a number, expecting a counter, and I said yes when can I start. Yeah. My first job I took what they gave me, it came with decent benefits. Pay wasn't even bad, a coworker basically quit cause I made as much as he did and he'd been there three years and had a masters (I didn't). My company was not good about salaries. Some people would get inflated salaries compared to their experience/workload, others got screwed (especially our CAD designers). It's not just about people getting paid too little relative to the industry, it murders morale to find someone with less experience and capability than you hired on at a higher salary. It was a relatively small company, but even with a bigger company if there's not an organized HR dept there's really no way to tell wtf will happen salary-wise with new hires.

|

|

|

|

spf3million posted:I'm a chemical engineer who works in an oil refinery and I have no idea what metal casting engineers do. All I know is most of my equipment is made of metal so if you're responsible for making one of our thousands of pieces of 60+ year old equipment that is still running thanks! If you're responsible for making one that keeps breaking, gently caress you! ASME stamped pressure vessels may have components forged then welded together, or be rolled plate and welded. Pumps and turbines have forged parts(shaft, the flanges) and cast parts (the casing). Shafts on control valves are forged. Valve bodies are typically cast. I have heard older equipment (pressure vessels and pumps) is considered "better" in that in the 60s, 70s, and 80s it was not uncommon to oversize components, also Energy itself was considerably cheaper. (Forges, mills, etc use a lot of energy to make their goods. Also transportation is a considerable sum.) With time... extra energy = extra money the manufacturers were spending. So now they pretty much make exactly what you specify... (You ordered wrong? Too bad soo sad.) Although stuff like a pump and control valves you can change out the internals (pumps have impellars, control valves have trim and other stuff.) Pressure vessels...may have some allowance but that is usually up to how much wall thickness is left (losses from corrosion) and what is allowed by code. (It is possible to re-build wall thickness on stamped vessel per a long story with one of my HSB co-workers. But it is a considerable amount of work to do so...) IF something is constantly re-occuring breaking in the plant, it might be worth investigating... Senor P. fucked around with this message at 07:07 on Nov 9, 2017 |

|

|

|

Senor P. posted:I have heard older equipment (pressure vessels and pumps) is considered "better" in that in the 60s, 70s, and 80s it was not uncommon to oversize components, also Energy itself was considerably cheaper. (Forges, mills, etc use a lot of energy to make their goods. Also transportation is a considerable sum.)

|

|

|

|

I much prefer AutoCAD Inventor compared to Solidworks, but the university I'm at mainly focuses on Solidworks, and I absolutely despise it. The UI is less intuitive than Inventor, it frequently crashes, making a simple assembly takes 10x longer on Solidworks than on Inventor. With Inventor, I can quickly and easily dimension / add relationships / change on the fly. Should I stick with Solidworks or can I change to Inventor and just do all my projects for uni on Inventor? AFAIK, uni doesn't care which program it's done on. The only issue would be with cross-compatibility, if I were to do a group project, all my team would have their stuff as Solidworks files.

|

|

|

|

A, you're wrong. B, stick with Solidworks. It'll be much easier with group projects. In the "real world", you will be using whatever your company and/or customer wants you to use, not what your preference is. Best learn to suck it up.

|

|

|

|

I worked at a company where everyone used Solidworks except the ME manager. He used IronCAD because he was a special snowflake and it was the cause of so many easily avoided headaches.

|

|

|

|

spf3million posted:I'm a chemical engineer who works in an oil refinery and I have no idea what metal casting engineers do. All I know is most of my equipment is made of metal so if you're responsible for making one of our thousands of pieces of 60+ year old equipment that is still running thanks! If you're responsible for making one that keeps breaking, gently caress you! Thanks for the feedback! What i do overall, is make sure that castings can be made soundly and cost effectively, so the insides dont look like swiss cheese. A lot of castings these days are made in china, and you always get what you pay for. As a an example, depending on the type of part, a chinese foundry can afford to run 20-40% scrap/reject rate, where only "good" castings are shipped, and bad ones are remelted. Cad talk: Both of those platforms suck, i use powershape like a real manly man. Though autodesk just bought them out and its getting worse. Solidsworks, while not great, is pretty much the most widely used.

|

|

|

|

Right, will learn to love Solidworks.

|

|

|

|

Q8ee posted:Right, will learn to love Solidworks. Wrong, learn to tolerate solidworks and be able to put it on your resume without lying.

|

|

|

|

Uthor posted:A, you're wrong. I use CATIA exclusively. I can't imagine how many people have cursed my name when they get to the line in my spec documents that say "all models and drawings shall be CATParts and CATDrawings"

|

|

|

|

I'm a chemical engineer that moved to automation with no formal programming training and have now become exclusively the "comms" guy. I just spent 3 days making a float that was passed as a UINT convert back into a float. In DeltaV which has no native type conversions and which explicity disallows bitsetting on float types. No advice needed...just needed to lament.

|

|

|

|

Tnuctip posted:Wrong, learn to tolerate solidworks and be able to put it on your resume without lying. I really like Solidworks. I work at an NX company and did a class on Pro E in college. Both are much worse when it comes to quickly making something with a limited number of parts (e.g. not a plane) That said Solidwork simulation sucks and I never get results I trust from it. ANSYS Workbench > NX FEM/SIM > Solidworks SImulation

|

|

|

|

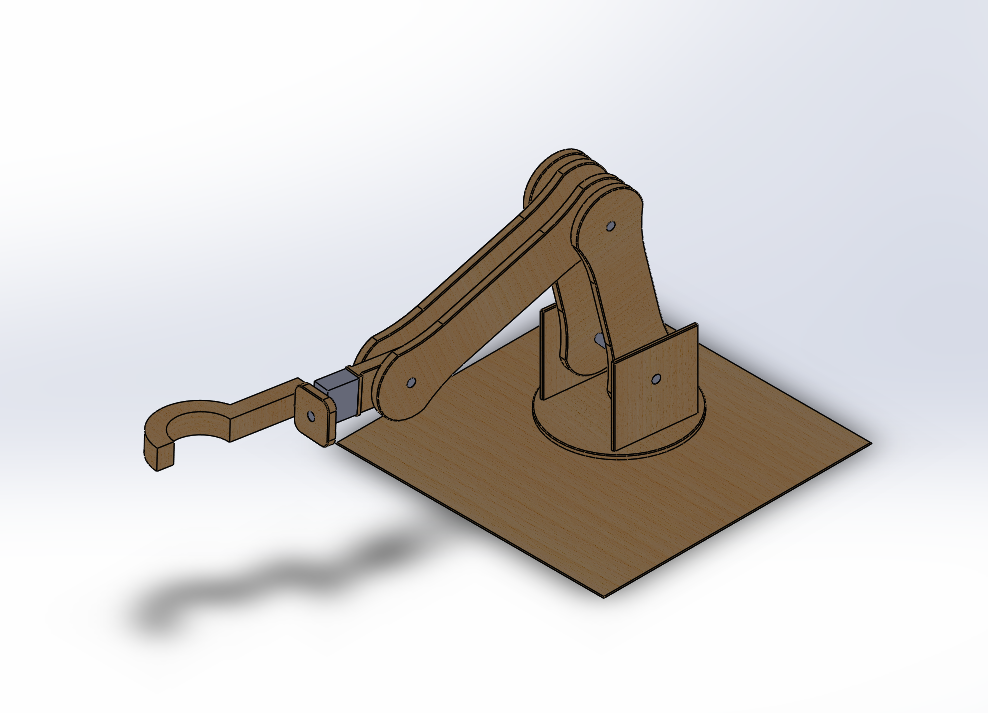

I'm really proud of this. It took me way longer than was necessary because I'm still learning my way around the UI, and there doesn't appear to be any keyboard shortcuts for stuff like dimensioning, snapping the camera and various other tools. Solidworks is also a fan of hiding things neatly away, whereas Inventor just sorta has it all in subcategories, so I spent a lot of time figuring out where the stuff I'm used to using was. Basically, it's a robotic arm capable of picking up a coke can. It's not finished yet, but it has servo motors that control the arms and base (pretty much anywhere you see a metallic shaft, I'll be sticking a servo on that to apply torque), to allow it to rotate and move. It also has a little servo motor near where the grips are, to allow 360 degree rotation of the coke can. I'm trying to figure out a smart solution for the other gripper that will allow it to tighten and loosen on the can, cause I don't like the idea of sticking another servo on the side of the gripper head, but I think that's the only way I can do it. I need to come up with 3 other concept designs, but I've seen a bunch of reports my friends have written, and they've used basic sketches and no one assembled it in Solidworks. So I'm just going to make basic changes to this one and try and eek out another 3 simple concepts from this main design. I figure I'll be alright since I'll have in depth drawings and exploded views and fully assembled views. So basic stuff like: changing the gripper head configuration, changing the arms to only consist of one, thicker piece of wood as opposed to two, and then change the rotating base (servo powered) to a gear based one.

|

|

|

|

CarForumPoster posted:I really like Solidworks. I work at an NX company and did a class on Pro E in college. Both are much worse when it comes to quickly making something with a limited number of parts (e.g. not a plane) That said Solidwork simulation sucks and I never get results I trust from it. ANSYS Workbench > NX FEM/SIM > Solidworks SImulation Ive never had to deal with NX personally, but yes you are right solidworks simulation sucks. Better than nothing, and maybe good if you forgot to fillet a corner, but lol if you have to use it for anything important. I hope i never have to try to do complex surfaces in solidworks though, and good luck fixing a crappy parasolid. CATIA cough cough.

|

|

|

|

KetTarma posted:If you need the work, sure. However, direct hiring of contractors is not common practice... especially in the middle of a massive layoff period. Supposedly this is all part of a hiring surge of thousands of people. Just heard today about a bunch of job fairs in Washington Boeing is putting on to bring in a ~new wave~ of employees. Sounded like they were advertising for pretty much every niche of manufacturing you could think of.

|

|

|

|

.

Thoguh fucked around with this message at 16:28 on Aug 10, 2023 |

|

|

|

Volkerball posted:Supposedly this is all part of a hiring surge of thousands of people. Just heard today about a bunch of job fairs in Washington Boeing is putting on to bring in a ~new wave~ of employees. Sounded like they were advertising for pretty much every niche of manufacturing you could think of. What? Boeing has been hurling salary workers off the roof all year

|

|

|

|

shame on an IGA posted:What? Boeing has been hurling salary workers off the roof all year It's just what I heard in the news. https://www.seattletimes.com/business/boeing-aerospace/boeing-holding-washington-state-job-fairs-to-recruit-manufacturing-workers/ I don't have any experience with Boeing, so I can't read between the lines.

|

|

|

|

That's just for more assembly line workers. Salaried workers are still in a rough spot with more cuts looming.

|

|

|

|

Yep, good luck with that Boeing. This is a crisis that's been brewing for years. In every facility that I've worked at/with, the manufacturing base is mostly 50-65 years old. There isn't a qualified talent pool waiting to fill those positions. There *could* be, because it's not magic, it's just a lack of training, but I don't see anyone doing that outside of the military.

|

|

|

|

Also the Boeings of the world are clearly looking to shed older expensive employees. Pensions are long gone, but they still have expensive healthcare and high salaries. The benefits where I work are getting revamped, and it's clearly at the expense of older employees. They're better for me, oh well.

|

|

|

|

paternity suitor posted:Also the Boeings of the world are clearly looking to shed older expensive employees. Pensions are long gone, but they still have expensive healthcare and high salaries. The benefits where I work are getting revamped, and it's clearly at the expense of older employees. They're better for me, oh well. I was actively courted by defense contractors when I was fresh out of school, and they were basically looking for carbon copies of their older dudes that could work for another 40 years. I went with one of them for my first job out of undergrad because I thought it would be a good chance to travel for work and learn from some of the old dudes It was a mistake. They had no training program in place, they just assumed that by being in the same room I'd acquire all of this (admittedly insanely smart) old dude's experience and knowledge by osmosis. I instead learned how bloated government budgets pretty much exist to justify themselves year over year while most workers put in maybe 20 weeks of honest work a year. I stuck it out for a year and a half before jumping to consulting. The demographics are still heavily in my favor here, or so it seems. If I had to guess, it's been a good few decades since anyone has bothered investing in my niche -- I'm the only person my age I know with my set of skills/education in this field, and everyone else I've met that understands this kind of work is in their mid-50s at least.

|

|

|

|

paternity suitor posted:Also the Boeings of the world are clearly looking to shed older expensive employees. Pensions are long gone, but they still have expensive healthcare and high salaries. The benefits where I work are getting revamped, and it's clearly at the expense of older employees. They're better for me, oh well. They should ask Samsung how that worked out for Sony when they mass RIFd all their senior engineers. HINT: It was great for Samsung and not so good for Sony.

|

|

|

|

Not a Children posted:I was actively courted by defense contractors when I was fresh out of school, and they were basically looking for carbon copies of their older dudes that could work for another 40 years. I went with one of them for my first job out of undergrad because I thought it would be a good chance to travel for work and learn from some of the old dudes Holy poo poo, are you me? I had basically the same experience from college through now as a consultant / contractor in a totally different, niche field. My old dude was not that smart, though.

|

|

|

|

Sometimes being an engineer is painful. A faulty compliance document that will damage large construction projects and trigger mass unemployment has been sneaked through to avoid the new Minister understanding the changes. I've had to contact the private secretary of the Minister (who has only been there for 3 weeks) to request that the document be stopped to allow consultation. If that fails I will have to seek an injunction to stop the document which will be costly and will need multiple expert witnesses. I'd rather be working on designs and shouldn't need to need to intervene legally in the corrupt and undemocratic activities of Government Departments.

|

|

|

|

Not a Children posted:It was a mistake. They had no training program in place, they just assumed that by being in the same room I'd acquire all of this (admittedly insanely smart) old dude's experience and knowledge by osmosis. Honest question, not trying to be a dick. Have you ever been anywhere with a useful formal training program? I've never experienced one. The (very) few formal training programs I've done have been worthless. IMO, it's much more useful to figure stuff out on your own and ask the experienced guys questions when you hit a snag. I'm in a new area of design that I had no experience in, and that is literally the training program - ok, well, here you go, we set up your software, experienced guy A sits there, experienced guy B sits there. If you have any questions they'll help you out, but they're super busy, so respect that. Ok bye! And it's actually worked really well.

|

|

|

|

paternity suitor posted:Honest question, not trying to be a dick. Have you ever been anywhere with a useful formal training program? I've never experienced one. The (very) few formal training programs I've done have been worthless. IMO, it's much more useful to figure stuff out on your own and ask the experienced guys questions when you hit a snag. I agree most places don't have formal training program (nuclear plant equipment operator training pipeline aside), but the typical mentoring system depends a LOT on the company's philosophy toward training and the quality of the mentors themselves. My first engineering job's workplace was allergic to anything besides billable work. Training was that thing you did in college, now you knew enough to go out and DO. So DO, Philadelphia, so DO. My current job's old boss was amazing at mentoring. He was a recognized expert in a niche field, and he had a high tolerance for the learning curve needed to teach the stuff. I'd have been turbo-hosed if the training philosophy from my first job were in place here when I arrived. Unfortunately things have fallen a bit since he left, and now we're really in danger of backsliding to where it's a rotating door of new hires trying it for a year, doing less than great because nobody trained them well, then getting another job because the new management sucks. It depends way more on the company and mentor than on the mentee.

|

|

|

|

paternity suitor posted:Honest question, not trying to be a dick. Have you ever been anywhere with a useful formal training program? I've never experienced one. The (very) few formal training programs I've done have been worthless. IMO, it's much more useful to figure stuff out on your own and ask the experienced guys questions when you hit a snag. I have been exactly zero places with a decent formal training program, but I guess I didn't phrase my frustration that well. It wasn't that I didn't know how to do work given to me, it's that I was literally delegated no explicit tasks or goals, so I had to figure out on my own what I was supposed to even be doing. The management would tell me to talk to the old guys, and the old guys would tell me to run automated tests on their equipment that would verify the work they'd already done. A typical day was me checking around the office to see if people had work to pass my way -- most would say "I'll get back to you" and I'd usually get a few clerical tasks that I could help out with. I had nothing useful to do until they started sending me out into the field many months into it, and I had to pick up those skills on the fly -- which I could have been learning to do that whole time. I finally managed to pick up enough clout to finagle my way into doing regular data collection/analysis and putting together testing tools, but that was after spending 9 months doing approximately nothing. Shortly after I started doing real work, the sequester kicked in and I got the hell out of government work for greener pastures. I do understand that you have to earn your stripes as a new employee, and work lulls happen in most industries, but my skills and work ethic just plain stagnated while I was there.

|

|

|

|

|

| # ? May 17, 2024 23:03 |

|

I have my new guy (1.5 years out of school) working with two guys with 12 years experience on two big projects. They are expected to train him via this process. Going pretty good so far. He has had good feedback for me. I have made the expectation pretty clear to the older guys. I also have him doing a small project with a mentor.

|

|

|