|

asdf32 posted:A used server/telecom/datacenter power supply is a good option. Its can be a bit of work to figure out the pins to jumper to make it start up, but luckily some battery charging enthusiast folks on the web had documented the pinout for it already.

|

|

|

|

|

| # ? May 9, 2024 20:32 |

|

used industrial power supplies absolutely sound like the way to go, they recommend a generous + rugged power supply with a bigger safety factor irt supplied power than is typical b/c the mosfets like to explode into fireballs the moment oscillation is arrested due to a voltage drop past 12vum excuse me posted:Rewire a microwave oven transformer. Super cheap 60 hz high wattage iron core transformers. excellent, thanks. i think i'd want a 1500W supply minimum, which is getting outside of what i'll likely find in a Salvage Microwave, but I didn't realize winding new coils to suit whatever project is at hand is so straightforward so i'll keep an eye out for one regardless. also for the synchronous motor in the turntable, the magnetron in its belly, the sheet metal shell, keypads and digital displays, etc. we use every part of the animal in this hoarding-prone family Ambrose Burnside fucked around with this message at 19:48 on Oct 19, 2019 |

|

|

|

ante posted:Can anyone tell me wtf the point of tantalum caps are Aside from all the other answers, tantalum caps don't need derate like electrolytics do under high pressure, so when you seal them in a brick of marine epoxy and send them multiple miles under the ocean, they don't violently explode like electrolyics do. (I was on an ocean probe project and we spent a fair bit of time reworking commodity electronics to replace electrolytics with equivalent way-more-expensive tantalums for this reason.)

|

|

|

|

Stabby McDamage posted:Aside from all the other answers, tantalum caps don't need derate like electrolytics do under high pressure, so when you seal them in a brick of marine epoxy and send them multiple miles under the ocean, they don't violently explode like electrolyics do. I've always wondered, for stuff like that do you have like, test machines that apply high pressures so you can check your designs in the lab or do you just have to take a boat out and drop it in a mid-ocean trench to try it out?

|

|

|

|

If I were to try to emulate those pressures, I'd just stick it in a vessel and hydraulically pump it to any depth pressure I wanted with mineral oil. A 10,000 psi hydraulic pump is equal to 4.25 miles of depth.

|

|

|

|

That's exactly what we do. I pack the components in mineral oil, heat-sealed in plastic soft tubing, then pack that in another layer of plastic, then get it pressure tested to 10,000psi for an hour. Once that's done, everything gets cleaned and tested, then soldered. It's a real pain in the rear end for SMD components, but I do it regularly. All components that see pressure (i.e. not in a housing) should get pressure tested, but some folks don't. I build oceanographic stuff for a living, so ask away. sharkytm fucked around with this message at 00:41 on Oct 21, 2019 |

|

|

|

Do you have any kind of motors? Thoughts on bare hobby brushless DC motor, motoring away in the ocean? I know that it is occasionally done, and no technical reason that it doesn't work, other than rusting magnets. But it feels so wrong

|

|

|

|

sharkytm posted:That's exactly what we do. I pack the components in mineral oil, heat-sealed in plastic soft tubing, then pack that in another layer of plastic, then get it pressure tested to 10,000psi for an hour. Once that's done, everything gets cleaned and tested, then soldered. It's a real pain in the rear end for SMD components, but I do it regularly. Other than electrolytic capacitors, what other types of components are bad with high pressure?

|

|

|

|

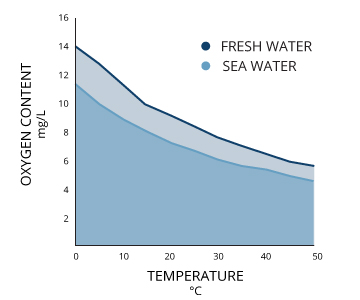

ante posted:Do you have any kind of motors? Thoughts on bare hobby brushless DC motor, motoring away in the ocean? Why would the magnets rust under water? There's no oxygen.

|

|

|

|

insta posted:Why would the magnets rust under water? There's no oxygen. There is though?

|

|

|

|

insta posted:Why would the magnets rust under water? There's no oxygen. Mmm, nice, pristine, ferrous-material-preserving salt water

|

|

|

|

To be faaaaaaiiiiir, some of that is iron eating bacteria.

|

|

|

|

Splode posted:Other than electrolytic capacitors, what other types of components are bad with high pressure? I've had basically every component fail under pressure. If there's a tiny air bubble in the potting or epoxy coating, it'll implode and shock the component. IC's usually shatter if there's air in them, axial resistors crack, SMD components show no outward sign, but probably micro-fissure. Crystals often don't work under pressure, likely because the case deforms enough to change the frequency or quartz structure. Glass fuses go pop, but potted fuses are fine. You can fill glass fuses with oil, but it massively affects their rating. There's a reason most electronics in the subsea world are in pressure housings, so they don't have to endure repeated pressure cycles. The problem is, housings are expensive, heavy, and can leak. PBOF stuff is much lighter, much cheaper, and don't let water in (although they usually seep oil), but it's a drat mess. GPS antennae are a tricky one too, the crystals change frequency response under pressure, and although GPS doesn't work underwater, they need to come back to life when the pressure is removed. ante posted:Do you have any kind of motors? Thoughts on bare hobby brushless DC motor, motoring away in the ocean? Seawater is an incredibly rough environment. Between the salt corrosion, galvanic corrosion, rough handling during launch and recovery, sediment abrasion, not much handles it well. Ceramic, glass, plastics, and titanium... And O-rings. Or oil filled boxes, as above. sharkytm fucked around with this message at 14:57 on Oct 21, 2019 |

|

|

|

How do you do like, bulkheads, where you need to connect the electronics inside the potted goopy bit to some sensor or detector or whatever outside?

|

|

|

|

Shame Boy posted:How do you do like, bulkheads, where you need to connect the electronics inside the potted goopy bit to some sensor or detector or whatever outside? Connectors and feedthroughs/penetrators. Available in 1-50+ connections, with prices ranging from $50 to $10,000. They're metal or plastic bases with neoprene-molded pins and a threaded connection with an O-ring. The threaded section seals via the O-ring to the housing. Look up MacArtney SubConn for examples They even make special connectors that take Tygon tubing instead of jacketed cable, and pass oil from box to box. You see, the reason PBOF systems don't let water in isn't just that they're filled with oil. They're filled with oil, have a flexible membrane over them, and often have a spring-driven oil compensator connected to the system. The compensator has a flexible diaphragm and piston, plus a spring that pushes on the piston. That means that the oil is under positive pressure at all times. The water pushes on everything equally, but the spring adds pressure so the oil is at a higher pressure than the water. You don't want each box to have a compensator, so you use PBOF cables/connectors to join everything that's oil-filled. I'll see if I have any photos of what I'm taking about. sharkytm fucked around with this message at 15:07 on Oct 21, 2019 |

|

|

|

What's the design temperature range for that kind of stuff? Seems like if nothing else thermal management would be fairly easy with all the sea water nearby.

|

|

|

|

longview posted:What's the design temperature range for that kind of stuff? It depends. Oil-filled stuff has a high heat absorption capacity, but poor thermal conductivity due to being in thick plastic. Aluminum housings dissipate heat well, stainless less so, and titanium has terrible thermal characteristics: low mass, and poor thermal conductivity. Because the housing has to come apart to work on the electronics, it's often a challenge to bond the heat-producing parts to the housing itself. There are ways of solving these challenges, but it adds to the complexity. Making the internal parts out of aluminum is incredibly common, but getting heat out of the chassis and into the housings and endcaps can be a pain in the rear end. Heatpipes are getting more common, but they're expensive to install and the machining tolerances are pretty tight.

|

|

|

|

sharkytm posted:I've had basically every component fail under pressure. If there's a tiny air bubble in the potting or epoxy coating, it'll implode and shock the component. IC's usually shatter if there's air in them, axial resistors crack

|

|

|

|

sharkytm posted:I've had basically every component fail under pressure. Even inductors? They're just coils of wire.

|

|

|

|

Often potted coils of wire. I can easily see how there would be explosion-prone air bubbles in there

|

|

|

|

peepsalot posted:When you do potting do you cure it in a vacuum oven to bring bubbles to the surface? For hard potting compounds, vacuum and a little heat to loosen up the epoxy. For urethanes, the bubbles matter a lot less because the material will flex instead of cracking/shattering, but they're commonly vacuum cured as well. The vacuum also cooks off residual moisture, which can cause issues. In the summer, you vacuum the individual liquids before they are mixed to get rid of the moisture. They foam up pretty aggressively as the water boils. I don't do a lot of urethane potting other than 3M 82-F1 and F2 cable splices, which are cured at STP. I've got colleagues who do a shitload of urethane work in vacuum. Most of my gear is in housings, so no need to pressure test the electronics or worry about potting compounds. I use epoxy to reinforce modified cables or secure components, but it never sees pressure. If it does, something has gone horribly wrong. I'm about to start a project that needs to be clear-urethane potted, maybe I'll document it and post it. I'll probably be 3D printing the molds, machining the base plates, and soldering the PCBs in house.

|

|

|

|

ante posted:Often potted coils of wire. I can easily see how there would be explosion-prone air bubbles in there  kid sinister posted:Even inductors? They're just coils of wire.

|

|

|

|

Shame Boy posted:I've always wondered, for stuff like that do you have like, test machines that apply high pressures so you can check your designs in the lab or do you just have to take a boat out and drop it in a mid-ocean trench to try it out? We had a small one, but the issue is that our stuff was big, and wide-mouth pressure vessels are hard to come by. So we used the ocean as a test device a number of times. ante posted:Do you have any kind of motors? Thoughts on bare hobby brushless DC motor, motoring away in the ocean? Brushless DC motors, if treated with a corrosion sealant, were surprisingly robust. Splode posted:Other than electrolytic capacitors, what other types of components are bad with high pressure? sharkytm answered it really well. This guy has a good talk on the topic: https://medium.com/supplyframe-hardware/building-pressure-tolerant-electronics-pte-for-deep-ocean-vehicle-applications-da42869a5c78 The one thing I'll add is that we didn't just pot our electronics in a bit of epoxy -- we built the whole structure of pods around huge volumes of epoxy, so the deformation felt by our electronics was much less than if we had it in an oil-filled bag the way the guy above describes. Shame Boy posted:How do you do like, bulkheads, where you need to connect the electronics inside the potted goopy bit to some sensor or detector or whatever outside? We didn't have many such connections needed, always with low voltage and no sensitive communications. So we had a super janky approach: we'd use solid-core wire and strip the insulation at the site where it exits the epoxy, the thinking being that the epoxy will deform more than the copper, so water won't be able to walk up the wire. It would of course corrode like crazy, but our stuff wasn't that long-lived. I can't vouch 100% for the approach, as other issues prevented us from fielding pods with that design. I will say that the ocean pressure will push water up anything. We had it walk up 5' of molded USB cable to foul a debug connection on a test pod. peepsalot posted:When you do potting do you cure it in a vacuum oven to bring bubbles to the surface? We did use a vacuum chamber to remove bubbles, but we can't just cure in vacuum, because the liquid epoxy will boil at that pressure. We got good at telling the difference between air bubbles growing and surfacing versus the frothing effect of boiling epoxy. We'd vacuum pump the chamber til a hint of froth, then crack open the valve just enough to walk it back.

|

|

|

|

I have a couple of old tracked RC cars. Remember them? I picked them up years ago from op shops with no controller with the intent of building a robot. I had a failed attempt a bit before uCs were a hobbyist thing. I used the small one because it took 4XAA batteries. But it is very small and one of the motors has the death screech (shaft walk?). I want to use the big one but it took a battery pack which it didn't have, and the battery cover door was missing too. It'll be stripped of all electronics anyway and s double H bridge module used for the motors, driven with PWM. But the problem I have is I have no clue what kind of battery would be good to power it. It'd be going up top with everything else. What would be cheap and usable for this?

|

|

|

|

Just use hobby speed controllers/lipos.

|

|

|

|

evil_bunnY posted:Just use hobby speed controllers/lipos. I already have the H bridge. Just had a look at the prices of the hobby battery packs. Holy hell. Might be better off with some 18650s or something like a power bank, except the output voltage would probably be too low. Forgot to mention it's a temporary construction sort of thing to mess around with. Electronics wise I've got plenty of options with what I have already, but very little in the way of battery power. I just plan on lashing a breadboard to it (at least initially) and seeing what works for it.

|

|

|

|

General_Failure posted:I already have the H bridge. If you're looking at those hobby batteries being sold from a US based hobby retailer they're going to be unreasonably priced, but if you look somewhere like hobbyking or amazon for off brands they're comparable to what you'd pay for a similar number of 18650 cells that are rated for the kind of discharge that the hobby batteries are capable of. I'm not sure I would trust cheapo power bank batteries to not trip their protection circuits from over current if this thing weighs more than a few pounds, some of those old brushed hobby motors have surprisingly high stall currents if they're larger than the ones you found in $15 RC cars. In my foray into lovely robot building I used SLA Batteries but those are so heavy the thing had to be geared down to a maximum speed of about 4 miles an hour.

|

|

|

|

Dairy Days posted:If you're looking at those hobby batteries being sold from a US based hobby retailer they're going to be unreasonably priced You make a good point. quote:In my foray into lovely robot building I used SLA Batteries but those are so heavy the thing had to be geared down to a maximum speed of about 4 miles an hour. What I want to do is just make a fun little test platform. I've got ATMega and Arduino based things, esp8266 and esp32 things, a couple of k210 boards, a Pi Zero and a Pi Zero W. What'd be neat is running Micropython or Lua on a uC, connect some WiFi or BT connectivity to the UART (or redirect if the uC has it) and do some things like use it as a turtle, a line follower, simple object avoidance etc. Partially for me and partially to get my kids interested.

|

|

|

|

sharkytm posted:I build oceanographic stuff for a living, so ask away. this stuff is super interesting, thanks for posting. ROVs really catch my interest in a way that other RC vehicle/drone stuff doesn't, i figure because aquatic environments are uniquely challenging for people to access and overwhelmingly unexplored beyond diver-magnet wrecks n reefs. of course even "consumer-level" underwater ROVs w video feeds are 4 figures minimum, but i got really interested when i found out there are actually some cheap DIY-friendly ROV designs out there that people have already developed, ie https://www.youtube.com/watch?v=TfJ0Y3oZTzQ it's neat to contrast the hobbyist and professional solutions to problems like pressure at depth; this dude bought a 'waterproof' junction box, stuffed it full of the electronics and then potted everything with paraffin wax, effectively a PBOF design except solid at room temp without being permanent like typical potting. other electronics are bought pre-waterproofed as other consumer crap; thrusters are cheap magnetically-coupled bilge pumps w RC boat screws instead of the stock impellers, the camera is a diving bell-type tethered "fish cam", etc. even attitude control is hugely simplified (pitch and roll essentially eliminated) by using PVC pipe 'buoyancy tanks' at the top of the ROV frame and weighted tubes at the bottom, with the weighting adjusted until gentle buoyancy is achieved; a single downward-pointing thruster permits diving, with ascent being automatic once that thruster turns off. lovely station-holding (altho a microcontroller could handle this) and limited camera angles, but hey, small compromise given the whole build is priced out at sth ridiculously cheap like $250-300 USD i haven't done any work towards my own version beyond putting together an aliexpress-friendly BOM, but this is giving me the Pond Exploration Itch again Ambrose Burnside fucked around with this message at 01:51 on Oct 25, 2019 |

|

|

|

Ambrose Burnside posted:Pond Exploration Itch This sounds like something you get after exploring a pond.

|

|

|

|

I was looking at AliExpress for geared wheels and bases and came across a rather expensive two wheeled balancing robot. One of the photos was of the board it used. All the important electronics plugged into it as modules, which were plugged in. Nice things about that is it gave me ideas. I already have everything on the board, and had planned on doing something vaguely similar. Funny thing is there's only about $10 of electronics total on it.

|

|

|

|

Is there any hope for finding double stage 20k volume and 50k tone audio pots that actually fit the 1x6TH + 2MH footprint of vintage ALPS pots? I tore down a Pioneer SK-350 boombox hoping a deoxit blast would fix them but turns out they were designed terribly and cut through their own traces over time. I think my only option is to buy some modern pots and use the old pot substrates to adapt to the old footprints, but it sounds like a pain in the rear end to get good mechanical functionality when I put the PCB back in the case. Fun microscope pic of the failure

|

|

|

|

resident posted:the 1x6TH + 2MH footprint edit: Are none of these the right one? https://www.mouser.com/ALPS/Passive...1yhozxtZ1yzvm31 peepsalot fucked around with this message at 04:45 on Oct 27, 2019 |

|

|

|

peepsalot posted:No idea what that means. Do you have a pic of the overall pot? 6 through holes in a row for the 2x3 double pot terminals plus 2 mounting holes for mechanical support.

|

|

|

|

resident posted:6 through holes in a row for the 2x3 double pot terminals plus 2 mounting holes for mechanical support. We need hole diameters and spacing to help any further

|

|

|

|

Ambrose Burnside posted:I got myself one of those chinese 1000W zvs induction heaters with the water-cooled coil just to gently caress around with; I do a lot of delicate forging of v small titanium rod (1/4" dia and under) and i'd love love love to replace compressed gas + torches w something flameless and electric, and the stock i work has so little mass that 1000 watts should actually be more than enough for anything I could want to work on, assuming titanium heats up even a quarter as fast as a ferrous metal will. i've been doing more research on small/portable induction coil heaters and found this, which is great + very close to what I'd like to end up with: https://github.com/hardboiledfrog/smt-zvs-driver i didn't expect reasonably-portable and affordable batteries to be able to keep up with a ~700W induction heater that can heat up a titanium dab nail to yellow-orange heat in less than 5 seconds, but apparently it's nbd with some decent-quality LiFePO4 cells: https://www.youtube.com/watch?v=JgyBOaOe5og he uses 4x 18650s or 26650s, w 30 or 50A rated continual discharge respectively the short duty cycles aren't a problem for me b/c i don't need continuous heating, if it heats that fast id think the irl working duty cycle would be around 5-10% tops, maybe less if i'm doing cold work simultaneously. if i'm working at a bench i can also obviously just use water cooling, i already have the usual fountain pump + rubbermaid bin coolant sump. my main reservation is how many full heats I can realistically get before the batteries die, theyre expensive enough that i wouldn't buy spares / a hot-swap set at first, and this would just be frustrating if i can only work for 45 minutes before having to tap out Ambrose Burnside fucked around with this message at 21:55 on Oct 27, 2019 |

|

|

|

That seems like a lot when you're used to working with microcontrollers and other smaller projects, but quads and other RC stuff routinely draw that much and more, so your batteries are intentionally designed for that kind of thing.

|

|

|

|

If you're not exceeding the rated continuous discharge for the battery they really should last their normal life. But are they really rated for 50 Amps continuous? That's insane, I'm used to working with much smaller lipo batteries that are usually only rated for 1 or 2 times their capacity

|

|

|

|

I’m working on a big LED video wall type project, probably 576 neopixels— at 70% brightness that sets me at a max of <25A@5v. This is the biggest electronics project I’ve worked on and definitely pushing the boundaries of my comfort zone I bought a 40A/5V power supply, it has three outputs, which I was planning to run to a bus bar to then distribute power to the eight LED strips, with disconnects on either end The current snag I’m hitting is on finding an appropriate connector to use on the power supply side such that I can disconnect the power supply quickly if I need to disassemble this thing. I imagine the normal plastic barrel jacks I have aren’t going to want to deal with all that current, though i suppose it would be distributed across three wires so 8A@5v? This is going to be a public installation so I’m super concerned about safety with this, don’t want anything melting, so I’m also thinking 16AWG from the power supply to the bus bars and then 20 from the bus to the strips? Is that overkill?

|

|

|

|

|

| # ? May 9, 2024 20:32 |

|

You could go with XT60 or XT30 (RC battery connectors 60/30A nominal rating) if you are concerned about the barrel connectors but want to keep it disconnectable. Also those have a much more firm mechanical connection IME.

|

|

|