|

Ambrose Burnside posted:It's exactly what's called for with the scale/requirements of my typical sort of chased + repoussed sheetwork/jewellery, medium-heavy gauge brass sheet medallions and that sort of thing. parts like freeing the piece from the unworked 'web' that remains from the starting blank, and for cutting out/shaping the tabs connected to the piece that get worked into integrated bails n other hardware. it's a looooot of heavy sheet to do by hand with a jeweller's saw but shears work too roughly and tend to warp the part in ways that are hard to correct. Enter nibbler. Oh I get it, for your use case it makes perfect sense. I thought I would get more use out of mine but I'm mostly cutting silver sheet and I want the smallest kerf possible so I can reuse the offcuts, so I just use a jeweler's saw. I've used mine for some copper sheet work in the past, which is why I got it, but then it just sat around after that really.

|

|

|

|

|

| # ? May 25, 2024 13:33 |

Ambrose Burnside posted:Still, the ability to directly control the airflow with an extremely responsive and precise mechanism like lung pressure is attractive, it's a sort of tactile feedback-equivalent approach that's almost never drawn on for modern metalworking, despite how often we could use a third hand. TIG-style foot pedal? Modulate a constant mechanical flow vs using the foot to run a bellows?

|

|

|

|

|

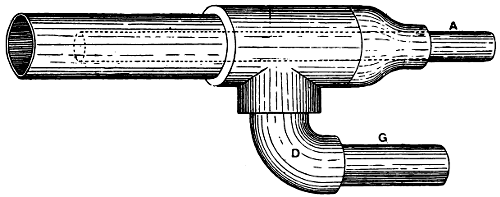

shovelbum posted:TIG-style foot pedal? Modulate a constant mechanical flow vs using the foot to run a bellows? or that, yeah. definitely mechanically simpler than the pneumatically-actuated pinch flow valve thing, cannibalizing the handbrake + Bowden cable + bellcrank from an old bike wheelís brake assembly would near-singlehandedly address the powertrain and mechanical advantage requirements, just add foot pedal. if you're coordinated enough, hey, one foot works the bellows, the other controls flow. e: yessssss found a 102-year old handbook on hot-joining processes and it includes dedicated chapters for blowpipe operation, blowpipe design, and how to assess what sort of blowpipe you need. also blowlamp designs, i.e. torches that self-pressurize by vaporizing a volatile fuel with heat prior to combustion. check out some of these these designs, they seem... familiar somehow... *drums fingers on propane forge burners absentmindedly*  Fig. 69.óLarger and more efficient Blowpipe but yeah the expectation was clearly that you made your own blowpipes from garbage as needed so i don't think i need to drop money on much at the loving-around stage Ambrose Burnside fucked around with this message at 07:17 on Jan 8, 2020 |

|

|

|

doing basically anything at all in pre-modernity seems like it was "difficult" and "complicated" and "man just get a new key"

|

|

|

|

Got the gears back last night from the wire EDM guy, sad to say only 2 of 3 gears went on easily, I saw they missed a spot, looks like the gear got moved or wasn't straight in the machine because on the corner there is a bit that is not entirely removed. But whatever I am not gonna bother going back for that, a few strokes with a diamond file will remove it, we're talking tenths of a mm here. Last night I started by reinstalling the lower gear shaft. Today hopefully I can continue with the upper shaft. Need to buy a diamond file...

|

|

|

|

I'm trying to buy some M2 HSS rectangular bar stock to grind some of my own wood lathe tools (scrapers) but can't seem to find raw stock anywhere for a reasonable price unless I buy entire 6' bars or something. I could buy a new name brand tool and wind up with more steel than buying raw stock, so maybe I'm just crazy for thinking I could do this more cheaply myself. I'd like stuff 1/4"-3/8" thick ranging from 1/4" to over an inch wide, by a foot long or so. Mcmaster has it but for $$$$ all MSC has is round drill rod-is this just not a common item or am I looking in the wrong places?

|

|

|

|

Kaiser Schnitzel posted:I'm trying to buy some M2 HSS rectangular bar stock to grind some of my own wood lathe tools (scrapers) but can't seem to find raw stock anywhere for a reasonable price unless I buy entire 6' bars or something. I could buy a new name brand tool and wind up with more steel than buying raw stock, so maybe I'm just crazy for thinking I could do this more cheaply myself. I'd like stuff 1/4"-3/8" thick ranging from 1/4" to over an inch wide, by a foot long or so. Mcmaster has it but for $$$$ all MSC has is round drill rod-is this just not a common item or am I looking in the wrong places? MSC just keeps the drill rod and the other tool blanks separate- here's what I assume you missed https://www.mscdirect.com/browse/tn/Turning-Boring/Lathe-Tool-Bits-Holders/Tool-Bit-Blanks?navid=12105897 e: poo poo, I didn't see the foot long requirement, welp. that one's gonna be hard to satisfy without buying full lengths of stock. unless you wanted to cut the foot up into smaller segments, in which case several conventional HSS blanks should work that said, those prices still seem fairly steep, i can get the same blanks from Travers Canada for a fair bit less per, and the HSS blanks I got from some chinese exporter for even cheaper seem functionally-identical to the budget blanks I bought domestically, so consider shopping around if quick turnaround isn't your priority prolly Ambrose Burnside fucked around with this message at 03:55 on Jan 10, 2020 |

|

|

Kaiser Schnitzel posted:I'm trying to buy some M2 HSS rectangular bar stock to grind some of my own wood lathe tools (scrapers) but can't seem to find raw stock anywhere for a reasonable price unless I buy entire 6' bars or something. I could buy a new name brand tool and wind up with more steel than buying raw stock, so maybe I'm just crazy for thinking I could do this more cheaply myself. I'd like stuff 1/4"-3/8" thick ranging from 1/4" to over an inch wide, by a foot long or so. Mcmaster has it but for $$$$ all MSC has is round drill rod-is this just not a common item or am I looking in the wrong places? I'd reach out to your local or regional steel supplier. Some of the larger places may have drops you can buy. My specialty steel supplier is not the same as my structural steel dude, but they can point you in the right direction.

|

|

|

|

|

Does anyone here do any casting? Of cast iron? It's not something I am likely to pick up this year or next year or the year after. But once I get my new shed / storage house built I had planned to take up some smithing, but recently I've been looking at casting. It's not something I have given much of a drat about because casting aluminum and the like doesn't seem like it has any use for me. But it's apparently possible to cast iron at home and this guy is pretty good at it. I've seen plenty now on youtube that mostly seem to make crap, this guys castings come out good: https://www.youtube.com/watch?v=user?luckygen1001 Anyone here got some casting experience, it seems like it could open up some possibilities being able to cast iron, making my own cast iron straight edges for instance, making small machine parts and smaller tables like for a die filer. All this is probably 2-3 years away at least if I ever bother with it. Need to get that new storage built.

|

|

|

|

Start with aluminium, explore copper/bronze to become accustomed to higher-temp casting processes, and keep iron as a stretch goal to work towards. Aluminum can definitely stand in for a fair chunk of the projects you mentioned, but more critically, casting iron is considered the daunting holy grail of backyard casting for a variety of good reasons. any Content Pig can smelt some aluminium with a hideous $20 cat-litter smelter from youtube, more or less, but DIY practical iron casting has a lot more failures than successes, and most of the experimenters have prior casting experience to boot. Attaining and sustaining the required temperatures can be extremely challenging using conventional propane burner designs, and my impression is that iron smelting functionally requires working at a larger scale than other backyard casting does to be sensible/practical, which usually means giving all this stuff permanent real estate on your property. It also means the basic expense/investment floor at which you can ever hope to cast anything is many times more expensive than any substitute metal's. On top of that, you'll consume prolly at least a magnitude more fuel than you would for a comparable aluminum melt- the only economic iron casting I've seen done by home warriors is when they had secured a reliable source of free waste oil for fuel, if you can't lock that down the propane costs will be obscene (and burn colder than you really want in the bargain). Start with aluminium, melt some scrap, cast that die filer body, see how you like it and if it feels like it's worth your time. Get a proper crucible, upgrade your burner, cast some small ornamental things. Now see how much you want things to get like 5x harder and costlier to produce an identical casting in a more resilient metal. Ambrose Burnside fucked around with this message at 22:54 on Jan 10, 2020 |

|

|

|

hosed around and designed a miniaturized two-chamber grand bellows scaled to supply a blowpipe, based on antique British jeweller's bellows examples I found from the 19th century, except 1) designed for quick manufacture on the laser cutter or CNC router from sheet stock, and 2) departing from the traditional teardrop profile to permit a larger-volume upper "receiver tank" section btw, here's a grand bellows cutaway, so any of this makes sense:  baaaaaasically it was a medieval european improvement on the single bellows or multiple single bellows used in concert; it provided a much-smoothed stream of air compared to single bellows systems b/c the upper chamber acted like an air receiver, storing a couple seconds' worth of air and buffering supply pressure changes, and with the weights on top being used to fine-tune the delivery pressure  basic layout, sans bellows membrane- red board is the fixed middle board, separates the two chambers. below is the bellows pump, which uses leather flap valves to pull in atmospheric air and push it upwards. above that is the 'receiver tank', a cylindrical accordion-lookin chamber with a weighted lid and an air outlet in the base. the blue boards on top of the middle board are 'plenum boards'- they're thinner slices that are used to build up an enclosed air pipe, into which a hose can be fitted. green is the lower board, fitted with a one-way valve to pull air into the device, and is worked with the foot in a treadle motion. (spring underneath for return compression). orange members are ribs or the tank lid, and 'float'- they're glued to the bellows membrane which covers them (not shown here) and constrains the bellows fabric from going all balloon on you, so it expands in a controlled and predictable way.  here's the ribs and upper boards removed to show the plenum  shown w extremely tentative mortise/tenon and wedge-joined legs that keep the whole affair elevated as required Ambrose Burnside fucked around with this message at 06:04 on Jan 11, 2020 |

|

|

|

I'll probably build a forge before I do any smelting, I am hoping to use the same burner for the forge and smelter and move it between them as is needed. I have already decided that it will run on diesel oil. I will build it from one of these home oil furnaces that now and then can be had cheaply, just like TorbjŲrn Ňhman did with his forge, I think this is better than gas. Cheaper and puts out more heat. I'm having a hard time caring about smelting aluminum personally, just doesn't motivate me. It's also super expensive and hard to find because recycling of aluminum is nearly 100% efficient in Finland. Even when I find it at the scrap yard I end up paying more than 2x what I pay for scrap steel or iron. I guess in america you can amass quite a lot of aluminum scraps from cans and such, but here they are all recycled, you won't find scrap aluminum easily. We'll see if I bother doing any smelting or not, if the investment for cast iron is going to be too much I probably won't bother with aluminum either. But I'll have a forge.

|

|

|

|

Ambrose Burnside posted:Sage advice There might be a zinc alloy that suits what you want to use iron for while being easier to cast. I use a home heating burner just on kerosene, itís cheaper than diesel and gets plenty hot enough. I get my scrap aluminium from the local engineering college and recycling centre, paid for by weight. Rapulum_Dei fucked around with this message at 09:26 on Jan 11, 2020 |

|

|

|

There is no subsitute for cast iron for the things I really want to make, the requirement of cast iron is definite, it's preferred even over steel for scraping purposes and accessories, it just has the right properties and there are no alternatives. Kerosene is more than twice as expensive than diesel here and harder to find. EDIT: I might just make casting dies and take them to a local foundry, if any still exists around here, if it'll be too much effort/money and space (most important) to get an operation like this going. His Divine Shadow fucked around with this message at 10:08 on Jan 11, 2020 |

|

|

|

I did some smelting and casting of aluminium probably 7 or 8 years ago during my bachelor's. All the mechanical engineering students had to do CNC programming, metallurgy, metrology, mill and lathe operation crash courses, and sand casting and some other stuff. I assume it's just as applicable to steel or copper or other materials. Basically we used an induction forge, melted the aluminium, then cast the piece. Normally the various plugs for the moulds were quite basic but we decided to cast the little hand trowel we used to shovel the sand into the mould and did the rest by hand Appropriately, it turned out dogshit as only a couple engineering students could do

|

|

|

|

Old furnace oil burner is a viable heat source - my aluminum foundry is built around one. Also has the advantage of being much more easily refueled midway through and heat output is quite good. I'm seconding everyone else in suggesting to try doing lesser metals first. There's a bunch of learning that should be done with regards to working safely with molten metal. Also don't be thinking of aluminum cans as a source of scrap metal, think in terms of scrap automobile parts. I understand about cast iron as a goal but even good structural aluminum castings aren't the simplest things.

|

|

|

|

I guess I will have to start slow if I do start yeah. But enough about stuff years into the future. Today I finally reassembled and closed up the gear box. Both shafts back together. I had to disassemble the lower shaft again, it was completely impossible to get the three gears in with the lower shaft assembled. So the upper shaft goes first, but try and get as many of the components for the lower shaft in place as well before hand, not a lot of space to work with...  Finally able to start putting components back in place:  Chain drive for the feed gearbox, still need to put in the drive shaft for the Y-axis before putting back the drive belts and pulley.  And the gear box selector is back. This was a difficult operation, trying to fiddle the thing just so, so that it would go into the locating pins (and it's not that light) while not disturing all the forks on the backside that need to mesh against the gears and selection mechanism. Nevermind that the gasket didn't want to stay in place. I had to resort to vaseline to keep it stuck against the gear selector. I probably tried 40 times or so before I got it.... A rubber mallet was required to get the thing to seat properly on the pins. And I had to put the selector in the speed that put the all the selector forks closest to the middle, which I found was 400 rpm.  Once I got this far I decided it's time for a break... Tested changing the speeds and rotating the spindle by hand and all the selector forks seem to have engaged properly. His Divine Shadow fucked around with this message at 16:54 on Jan 11, 2020 |

|

|

|

Rapulum_Dei posted:I use a home heating burner just on kerosene, itís cheaper than diesel and gets plenty hot enough. That's probably because there is no road tax on it. "Red fuel" i.e. home heating fuel will be even cheaper but you may not use enough to make that worthwhile (delivery/storage). I've got a 275 gal tank in the barn, but that's because I'm running it as equipment fuel as well as heating fuel.

|

|

|

|

A local dude passed away and had a rather large building filled with casting supplies/equipment. He had founded a local foundry about 40 years ago, sold it once it got big, retired, and it was his "hobby cast iron foundry". Then he died and the estate wanted the building, but none of the poo poo in it. A friend of mine picked it all up for free and filled about 4k sqft of space with molds, tumblers, green sand hoppers, and poo poo I have no idea what it is. (Neither does he) If he ever gets it up and running I'll post some pics. We have a customer that sends us these oddball iron alloys that we grind to ridiculous tolerances. I've toured the casting area and it's pretty cool to see the giant hoppers of raw materials. A ton of chromium here, ton of manganese there, a pile of vanadium behind that thing. Wasn't able to watch an actual pour though.

|

|

|

|

|

Motronic posted:That's probably because there is no road tax on it. "Red fuel" i.e. home heating fuel will be even cheaper but you may not use enough to make that worthwhile (delivery/storage). I've got a 275 gal tank in the barn, but that's because I'm running it as equipment fuel as well as heating fuel. Red/green diesel is easily available as Iím in a farming area but itís still more expensive- not by much but you have to buy different jets for the burner. Waste oil in theory is a good option too but trying to get it an any quantity gets complicated - businesses like mechanics get inspected to ensure theyíre disposing of it legally (which giving it to you to burn definitely isnít) where I live. Rapulum_Dei fucked around with this message at 23:45 on Jan 11, 2020 |

|

|

|

Finished my Stuart Models 10V steam engine last month, and I've been having fun running it on air. https://www.youtube.com/watch?v=uOIbn6lBCtY

|

|

|

|

Rapulum_Dei posted:Red/green diesel is easily available as Iím in a farming area but itís still more expensive- not by much That's strange. I've never heard of that before. K1 kero is always more expensive than red fuel here. Rapulum_Dei posted:but you have to buy different jets for the burner. That's even stranger. I've interchangeably run all three on various things, from oil heaters to engines. Why/for what purpose would it need to be re-jetted?

|

|

|

|

Continuing the reassembly of the Deckel. Drive shaft for the Y-axis is back on.  And the aluminum cover, this protects the pulley belts from getting dirty from the chain drive.  Drive pulley goes on next  Then I pretty much just had to put back the side covers and the controls.    So pretty much back together again now, I refilled the gear box with oil and tested all the speeds and they seem to work. When the vertical head is engage the noise is loud at over 500 rpm, the straight gears meshing in the long reach head really make a lot of noise. I assume this is normal for the long reach head machines. The machine is quiet even at 2000 rpm with only the horizontal arbor. Also I can tell the epoxy paint I used is getting discoloration, blotches that are lighter. Kinda annoying to see... I think epoxy paint might be a good primer, but perhaps this is what happens if you try and use it as a finish paint too, might have been better with polyurethane paint for a finish. But I am not going to bother with that now. Just an FYI.

|

|

|

|

Motronic posted:That's strange. I've never heard of that before. K1 kero is always more expensive than red fuel here. Dunno, viscosity, flame temp or residue maybe. My understanding is it would still work, but in the long term wasnít good. https://www.boilerjuice.com/kerosene-prices/ https://www.boilerjuice.com/red-diesel-prices/ The Deckel is looking class HDS

|

|

|

|

Rapulum_Dei posted:Dunno, viscosity, flame temp or residue maybe. My understanding is it would still work, but in the long term wasn’t good. If it's different fuel types there's likely a requirement for a different flow rate which would be to meet optimal burn conditions to ensure you don't get flashbacks. It's why your MAPP gas torch won't work on a propane cylinder and vise versa

|

|

|

|

McSpergin posted:It's why your MAPP gas torch won't work on a propane cylinder and vise versa Again, what? I feel like everyone is talking about some other types of fuels that are somehow called the same things somewhere else.

|

|

|

|

yeah i've always known and used mapp/propane as interchangeable, this is the first i've heard otherwise

|

|

|

|

Ambrose Burnside posted:yeah i've always known and used mapp/propane as interchangeable, this is the first i've heard otherwise I still have a MAPP torch from when you could actually get real MAPP in the US and it's always also been fine with propane........

|

|

|

|

McSpergin posted:If it's different fuel types there's likely a requirement for a different flow rate which would be to meet optimal burn conditions to ensure you don't get flashbacks. It's why your MAPP gas torch won't work on a propane cylinder and vise versa ... yes that comparison would make a lot of sense if, say, kerosene and diesel had different air fuel requirements. They basically don't. Whatever though. Different refinery structures - diesel is cheaper around me (central US)

|

|

|

|

His Divine Shadow posted:Continuing the reassembly of the Deckel. Drive shaft for the Y-axis is back on. I'm excited to see this thing make chips. Your rebuild would be worthy of it's own thread. Thanks for sharing it here.

|

|

|

|

Thanks, chip making is a bit off yet though as that noise I was talking about wasn't just the spur gears but as I was told by another FP2 owner, indicated the bevel gear meshing in the vertical spindle head needs tuning. I had the vertical head off and checked and it did reduce the noise. So I'll be doing that next, bluing up and checking how it fits and I guess adjusting as needed. I have a manual that shows how to read the bluing pattern and how to adjust. I'm fitting a new one shot oiler lubing system as well. Want to get everything really tuned in. I also need to spend some time tuning the double gib setup on the X-axis table, it's a bit finnicky and in later models they went to just a one gib setup.

|

|

|

|

Motronic posted:Again, what? When I use my propane blowtorch head, it sucks balls when used with the "MAPP" gas they sell (it is slow and doesn't seem to mix right and ends up not as hot, but when I use the MAPP one, it blasts out hot and fast. No idea about the propane with the MAPP head, it may have just been a different brand issue to keep loyalty with the replaceable cylinders. Idk then, if they're fairly similar then I've no clue tbh

|

|

|

|

Wasn't sure which of the DIY threads to ask in: Are there any goon-recommended resources for learning fusion 360?

|

|

|

|

Tres Burritos posted:Wasn't sure which of the DIY threads to ask in: Its worth just starting with it, especially if you've used any other CAD program before. Hopefully someone else can chime in with a better answer if you've already tried that.

|

|

|

|

Tres Burritos posted:Wasn't sure which of the DIY threads to ask in: This series of videos got me started: https://www.youtube.com/watch?v=A5bc9c3S12g

|

|

|

Tres Burritos posted:Wasn't sure which of the DIY threads to ask in: I liked the NYCCNC dudes videos. https://www.youtube.com/watch?v=user?saunixcomp?videos I've been working with the sheet metal side of 360 lately and I've been really impressed at some of the cool stuff you can do. Titan Gilroy had some decent videos too if you don't mind his style. Though he's now been sponsored by Mastercam so I quit paying attention to his new stuff.

|

|

|

|

|

Pick up some out-of-date AutoCAD and inventor textbooks from amazon or ebay for like $5, ignore the text and sketch/model the practice exercises until all the snaps and constraints are instinct. AutoCAD Tutor for Engineering Graphics older than 2012 and Madsen's Engineering Drawing and Design 3rd or 4th edition are good for this, and again, very cheap for older versions Parameterize everything you can so you can just change dimensions in one place instead of having to root around through your model. shame on an IGA fucked around with this message at 19:01 on Jan 19, 2020 |

|

|

|

Yeah I agree with that except do not buy any AutoCAD stuff.

|

|

|

|

I really need to learn to set up parameters for stuff in Solidworks. Anyway.

|

|

|

|

|

| # ? May 25, 2024 13:33 |

|

Tres Burritos posted:Wasn't sure which of the DIY threads to ask in: +1 for ny cnc videos. A lot of them got dated suddenly when they updated their UI. Buttons are still there, but moved. Also a lot of work arounds for weird issues aren't needed anymore. If you're wanting to use it for modeling and cnc machining I can help. I don't use it for sim, sheet metal, 3d printing, or design though.

|

|

|