|

Sagebrush posted:there is a physical meter. it's a relic now that the meter is defined by the speed of light, but the metric system was invented well before the speed of light was measured with any accuracy. the meter prototype is a platinum-iridium bar and, as with the prototype kilograms, there was one central standard in paris and many copies in national laboratories around the world. What about a physical foot?

|

|

|

|

|

| # ? May 29, 2024 06:21 |

|

|

|

|

|

The physical foot is based on Henry VIII; it's one inch for each of his wives

|

|

|

|

wesleywillis posted:What if you 3d printed a CNC machine and then used it to make 3d printers? Oh yes a 3 C and D machine

|

|

|

|

No one is going to 3d print countertops. It will always be easier to cut a block of stone.

|

|

|

|

Unlike Disney or Nintendo, C and D machines

|

|

|

|

poo poo POST MALONE posted:Print til you can't print til you can't print no more. Gonna make you work till you bleed

|

|

|

|

sigher posted:God drat, so would the same thing apply to say a car if you were going full bore and just happened to lift it off the ground so the tires aren't touching the ground anymore? I guess if you drove the thing off a cliff would be the only case for this, but just asking. Yeah, you can hear that happen in pretty much any Rally video where the car tops a hill and gets totally airborne. Methinks the the ECU would probably govern the absolute top end, though. I know that on Class 8 diesels (that haven't had their ECU flashed) they have an absolute top end that basically saves the engine. On a boat? I have absolutely no idea.

|

|

|

|

OzyMandrill posted:Nah, the two will merge. 3D printed base and a c&c finish from the same machine. Honestly, I doubt this will gain much traction at the professional (metal) manufacturing level, which is my background. I can't speak to plastic FDM printers or anything. It's not that the concept is impossible or anything: you can buy these machines right now! They're... finicky, to say the least, but they do work. It's that the requirements of the two sides of the machine are extremely different. If you're building a milling machine, there are three requirements that are really expensive: it needs to be stiff, it needs to be accurate, and it needs to be fast. Stiff means big castings and linear guides. Accurate means ground ballscrews, thermal management, maybe even glass scales for really high precision work. Fast means big motors and a really, really good control system. A metal 3d printer doesn't need any of that. The forces are low, the accuracy is (depending on the exact process) usually more on the order of 0.1 to 0.25 mm at best, and the traversal speeds are relatively low. If you're building a metal 3d printer, the expensive bit is basically the deposition and fusion system itself, whether that's powder bed, cold-spray, MIG, etc. All of that stuff provides zero benefit to a milling machine. So if you build a machine to do both, you're spending a ton of money on expensive components that are only getting used half the time, since it can only do one process at a time. When it's working as a printer, the milling machine stuff is wasted, while when it's milling, all the printing equipment is sitting idle. That's super inefficient. Then you have to look at the drawbacks of combining them: thermal management is a nightmare so you probably have to let the part sit for a while before you start machining, you've got to account for parts warping as they're printed, and there's a whole ton of extra safety and control hoops you have to jump through to get it working. It's just inefficient. Much easier and more productive to just buy two machines and put them next to each other. The two processes are complimentary, but the real way forward IMO is in palletization: have a printer that can automatically transfer the parts to a mill or lathe to finish them.

|

|

|

|

Karia posted:Honestly, I doubt this will gain much traction at the professional (metal) manufacturing level, which is my background. I can't speak to plastic FDM printers or anything. It's not that the concept is impossible or anything: you can buy these machines right now! They're... finicky, to say the least, but they do work. It's that the requirements of the two sides of the machine are extremely different. If you're building a milling machine, there are three requirements that are really expensive: it needs to be stiff, it needs to be accurate, and it needs to be fast. Stiff means big castings and linear guides. Accurate means ground ballscrews, thermal management, maybe even glass scales for really high precision work. Fast means big motors and a really, really good control system. This. I work in low-force applications where in theory it would be perfect to do metal sintering to make our 3d parts. I've done it a few times through the machine shop, but in practice, it's so niche that we're better off with plastic (for use in water/saline issues), and the porosity of the metal is a problem. It also doesn't scale well for manufacturing, so if even your R&D prototype fixture making folks don't use it frequently, then there aren't a whole lot of people who will. Now SLA printers that print out of resin? Those things are fantastic and I have printed literally thousands of parts for use in various fixtures over the years. What you can do with those machines is phenomenal, and they have really good water/saline resistance if you use the right resin. Not only that, but multimaterial printing lets you embed parts in each other and do some really cool stuff.

|

|

|

|

Could your problems be solved with better FDM plastics?

|

|

|

|

the future will arrive when I can 3D print a taco

|

|

|

|

FuturePastNow posted:the future will arrive when I can 3D print a taco You can get a tortilla out of a pod, so we're getting there.

|

|

|

|

FuturePastNow posted:the future will arrive when I can 3D print a taco https://www.youtube.com/watch?v=b_-aS2nJXo8&t=21s

|

|

|

|

CNC machining won't be fully replaced by 3D printing until you can print in literally any material and also when the printers can hold sub-1/10000" resolution in every axis. Even then there are still precision grinding machines that work down to the micron scale. 3D printing will replace CNC machining (and already is in many cases) for a lot of cheap and cheerful jobs like plastic fixtures and light alloy parts, though Sagebrush fucked around with this message at 19:28 on Nov 26, 2020 |

|

|

|

Hey sorry to chime in while being so far behind on the thread again, but I'm in a rare posting mood. I was asked earlier about safety tales from my time on a cruise ship. There's only one real point in time that jumped out at me, apart from a constant baseline of problems that I'll talk about later. The one thing that stood out to me was one time, just after we had tied up in Barbados, we were having divers down to have a look at our bow and stern thrusters. Similar to these https://upload.wikimedia.org/wikipedia/commons/1/12/2012_09_03_Innovation_3-Querstrahler_im-Bug_2kk_DSCI0786.JPG. We were mysteriously losing oil from the seal header tanks for all 4 of our thrusters, and that costs money. Also, something about it making the corporate overlords potentially in violation of their probation. No biggie. We have a standard checklist for divers, specifying the LO/TO to be done. I'm the watchkeeper on duty in the machinery spaces, so I get running around doing the isolations. There is one LO/TO which isn't located in the machinery spaces. It's the impressed current cathodic protection system. Pump electrons into the hull so that the steel isn't giving up its own is the idea. Probably best to turn off the juice before we give the dive master the A-OK right? That's the duty electro-technical officer's job. I called him up, and told him what the deal was. After an appropriate interval, he shows up in the control room and signs off the checklist to say the system has been isolated by him. I do all the other isolations, sign the appropriate boxes, and remember that this individual is the laziest sack of poo poo I've ever had to work near. I call the bridge and ask them to check the indicator panel, and sure enough, it's all still live. Of course there was zero consequence for falsifying a safety checklist. This was, thankfully, not the norm. Most everyone I worked directly with or for actually cared about doing things properly, planning out what you're doing, and making sure people don't get hurt. It was a strange cultural juxtaposition to a big blind spot I'm going to talk about in a bit. The pervasive issues plaguing the ship I worked on were likely reflective of the majority of the cruise industry. No budget for doing things the right way, or for spare parts. In some aspects the cruise industry is waaaay behind the times (you could largely use melanin levels as an inverse proxy for rank), but in others, they are at the bleeding edge of innovation (penny pinching, tax avoidance, exploitation of a global labour pool). The only way you are going to get the company to do anything is by making them believe they will profit from it in a timeframe they like. Making something a legal requirement, court orders, fines, etc. don't work. ref:https://www.cruiselawnews.com/2020/10/articles/pollution/federal-court-lets-carnival-corporation-off-the-hook-again/ Another pervasive safety issue, which was likely fairly unique to the culture of the particular line I worked for, was the super permissive drinking culture. There was the policy, what everyone said, and what everyone either did themselves, or kept their mouths shut about. Only the first 2 were largely in alignment. Whenever the policy of "Two units of alcohol" was mentioned, it was accompanied by an index finger tapping the side of the speaker's nose. Any time a party, or "pour out" was held in the wardroom, it would be decorated, and the only thing that was the same, regardless of the theme of the party was that the clock would have something taped over it. That way, the boss isn't going to see you in a picture of a party that he can place a date on, and get a time from the picture. No sir, I was not drinking in the 5 hours before watch. I only had 2 units. Truth being, most people would not open more than 2 drinks at once. All the booze we bought from the company would be tallied up and you'd get your bar chit on payday. Department heads would hand them out. Everyone's boss had a printout of what they had ordered from the bar. One very charismatic engineer, who everyone loved because he was such a schmoozer, and had been with the company since before he was old enough to drive had a real serious problem. Everyone just kept their mouths shut about it. Nobody wanted to be the person who "stitched up" this guy. It would be the fault of whoever said something for this guy losing his job, or having to go to rehab, not the fault of the company gladly selling him a 24pack of Becks every single day for 4 consecutive months, not the fault of everyone who knew and said nothing, not the fault of the guy himself, and certainly not the fault of a terrible addiction. This one guy was just the most extreme example. Nearly everyone drank far too much. If you were among the one or two people who didn't drink, or were very light drinkers, you were largely distrusted. But nobody was ever drunk. They only had 2 units. No, I'm not liquored, just tired. I learned a lot about being reserved while drinking, and not attracting attention. Saw some real heavy duty functional alcoholism. Completely messes with your perspective too. When everyone around you is carrying on, nobody seems to ever suffer consequences that can't be alleviated with a little hair of the dog, and you've got real far gone cases still apparently holding down employment in front of you, it's really easy to look at yourself and conclude that you're not drinking too much, you're nowhere near 24 beers a day, you don't go to your cabin at coffee break to down a couple beers. It's fine.... I am forever grateful I escaped when I did, and went into a job where it is a requirement to be 100% dry and sober 24hrs a day while on shift.

|

|

|

|

Sagebrush posted:CNC machining won't be fully replaced by 3D printing FWIW I started this derail by trolling the dynamics I published in the area of micromachining, using spindles >75k rpm where machine dynamics matter. I was straight trollin by calling it c and c machining and saying it�ll be replaced by 3d printing because it obvs won�t that�s a very dumb thing dumb people think.

|

|

|

|

Wow, neat. I loved micro machines when I was a kid.

|

|

|

|

All this art school talk reminds me of the girl in art class who misunderstood her teacher when they were doing molds of their hands. Instead of putting her hands in the clay she put her hands directly in the plaster of paris. Horrific poo poo. https://www.mirror.co.uk/news/uk-news/art-class-girl-loses-eight-424409

|

|

|

|

Just catching up with the thread, but I've been doing a lot of baby wearing lately, and holy loving poo poo is that a bad idea. First, babies can't lift their own heads for the first several months, so carriers have to have head support or the baby's head can tilt down, constricting their airway and causing them to suffocate. That thing has no head support. Second, you need to support their legs properly in a "frog" position or you risk loving up their hip joints. That baby is just scrunched down in there. Third, babies wriggle, and you need to ensure they can't wriggle their way out of the carrier and onto the floor. That giant gap on the side would be perfect for that.

|

|

|

|

Stupid man makes stupid decision, news at 11?

|

|

|

|

B33rChiller posted:After an appropriate interval, he shows up in the control room and signs off the checklist to say the system has been isolated by him. I do all the other isolations, sign the appropriate boxes, and remember that this individual is the laziest sack of poo poo I've ever had to work near. I call the bridge and ask them to check the indicator panel, and sure enough, it's all still live. Of course there was zero consequence for falsifying a safety checklist. If the divers were contractors you probably could have just let the DM know, and that line would have a real hard time finding divers in the future. gently caress that guy forever and ever. Thanks for the peek into

|

|

|

|

https://www.youtube.com/watch?v=bBDxqCHxT_8

|

|

|

|

|

|

|

|

That's a good way to accidentally touch the blades on the ground and have it splintering all over the place

|

|

|

|

I don't speak Russian, but I understood "good helper" and "friend".

|

|

|

|

loving with tires that big is a good way to get blown up

|

|

|

|

Diggus Bickus posted:loving with tires that big is a good way to get blown up It's a solid piece of rubber. No air. e:

Ornamental Dingbat fucked around with this message at 01:45 on Nov 27, 2020 |

|

|

|

xtal posted:The physical foot is based on Henry VIII; it's one inch for each of his wives Divide by the Archbishop of Canterbury to get wives per miter.

|

|

|

|

Buttchocks posted:Divide by the Archbishop of Canterbury to get wives per miter. What's an emote that hits that halfway point between anger and applause

|

|

|

|

WarpedNaba posted:What's an emote that hits that halfway point between anger and applause

|

|

|

|

Here's a video of a guy almost losing fingers while demonstrating how not to use a table saw: https://www.youtube.com/watch?v=u7sRrC2Jpp4

|

|

|

|

Ornamental Dingbat posted:It's a solid piece of rubber. No air. Serious question: how can you tell? Looks like it has an airing assembly to me. I'd stay away not knowing any better personally.

|

|

|

|

It looks like a `Nemesis fucked around with this message at 06:21 on Nov 27, 2020 |

|

|

|

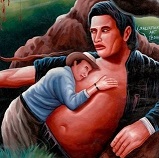

Good job Androcles!

|

|

|

|

It's rare catching them grooming each other like that in the wild.

|

|

|

|

https://www.youtube.com/watch?v=IIQu1e8DGUw i already hate angle grinders but jesus loving christ i will never voluntarily use one of those wood carving chainsaw tooth disk attachments for angle grinders.

|

|

|

|

https://va.media.tumblr.com/tumblr_qke6jfvvKi1yri6y0.mp4

|

|

|

|

|

| # ? May 29, 2024 06:21 |

|

the little launch at the end

|

|

|

Yes, it's like a lava lamp.

Yes, it's like a lava lamp.