|

wesleywillis posted:I know very little about table saws except they hunger for human flesh. You'd sacrifice a lot of cut quality going that route.

|

|

|

|

|

| # ? May 24, 2024 17:54 |

|

Elviscat posted:You'd sacrifice a lot of cut quality going that route. Could that be remedied with a finer tooth (and probably more expensive) blade?

|

|

|

|

I feel like if you went slow enough to actually affect the amount of flesh you'd lose, it would go so slow you would have a very hard time not losing grip on the wood since the blade will be running at like, walking speed. I just treat them with respect at this point and assume I'm going to lose anything I put within 6 inches of the blade if it's in the plane of death.

|

|

|

|

I'm getting a table saw tomorrow. It an old 2hp Boice-Crane 10" left tilt saw. It is going to go into my basement so I will need a base for it so I can move it around. Is there a consensus on the best value mobile base for tools like this?

|

|

|

|

I have some of these Iíve been meaning to install on an old cabinet saw. Seem like a good choice. https://youtu.be/5aCMIsfmiVk

|

|

|

|

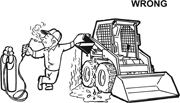

Thats a fantastic tutorial - I used to make zero clearance inserts for tools at the shop I'd moonlight at - we also had a cnc router so it was super easy to just draw it and cut one. never thought about making a splitter like that but that's drat cool - I wonder if you could use an piece of aluminum rather than the wood for a bit more of a strong surface - hmmm I'll be thinking about this I've been using table saws like this one pretty much my whole life, as a matter of fact, this very saw may have been my grandfathers, but there's no substantiating that - this belonged to a friends dad who passed away in 2015, he was an avid junk hunter and garage sale'r - He lived just a block from my grandparents house, and after my grandfather passed in 97, my grandmother took it in her own hands to decimate his garage and sell off all his tools - I begged my mom not to let this happen, but I was just a kid and I really had no say in it. My friend remembers his dad getting this saw in the same time period so it very well may have been my grandfathers - there is obviously no way to prove it but stranger things have happened between our families - our kids are now the 4th generation of friendship. slidebite posted:I sell all that poo poo to some clients. The Jason is OK, fenner and Gates are probably the best... but for table saw I can't imagine it's a problem either way. The whole thing is in "as is, set up condition 50 years ago - I have quite a bit of cleanup to do on the thing, one of my OCD things is that the tables on these old craftsmans are as close as I can get them to being true flat - I spent a long time getting my bandsaw pretty good and I assume this will probably be a long process - its a shame because I don't have room for it indoors, only in my outdoor shop thats covered from the elements, but open air on a slab. I'd get a regular v belt, but this one is cooked, stretched and coming apart so I don't think I'd get an accurate measurement from the remaining - the link belts have always intrigued me and I'd love to give them a try. the sheaves are very nice - this thing hasn't had a lot of use, its problems come from lack of cleaning rather than wear I haven't really torn in to this thing yet as wood projects are pretty low on my priority list, however I can see myself getting this up and going before the end of the year. EDIT: just doing some poking around for vintage craftsmans with mods came across this interesting piece:  Seems legit... I must say, I'm really impressed with all the recommendations regarding safety and these old tools - I've been so accustomed to being so cautious with these machines that upgrading them with some simple safety features has literally never entered my mind. another dangerous tool that I own is this beast:  mine is a 1954 DeWalt Power Shop radial arm saw, if those last 3 words dont strike fear in to you, then just take a look at this lovely brochure on the operation of this incredible tool  Super portable at only 130 lbs!  but the absolute best... is this  yes they advise you walking a 4x8 sheet in to a blade spinning directly at gut level... so, i did the wise thing:  but believe it or not, I actually like using the old dewalt too. LobsterboyX fucked around with this message at 06:00 on Feb 10, 2021 |

|

|

|

Commodore_64 posted:I have some of these Iíve been meaning to install on an old cabinet saw. Seem like a good choice. https://youtu.be/5aCMIsfmiVk Going to need to watch this later, kickback is a terrifying thing for me, itís like you donít know when or if itís gonna happen. I have a good fence, a nice 60tooth blade and good plywood it will still happen

|

|

|

|

OH NO, OH JESUS gently caress NO! Pushing towards the saw too, so if the plywood breaks or you stumble you go straight into the machine.

|

|

|

|

Elviscat posted:OH NO, OH JESUS gently caress NO! Pushing towards the saw too, so if the plywood breaks or you stumble you go straight into the machine. my thought was trying to juggle the two sides if you managed to somehow make it across the gauntlet of death and fumbling right in to that blade. I'd known about these awesome machines for a long time, one came up on a facebook group along with a few other tools for basically free - I'm completely obsessed with the finish on these dewalts is this awesome chartreuse green with black and gray speckles - I started collecting the cool print materials on these, as well as some attachments, including a reciprocating saw head that fits on the motor, and I picked up this brochure at a flea market and my jaw hit the loving floor when I saw this photo - there are some other gems in there too, but this one was the worst

|

|

|

|

My former roomate had one of those DeWalts actually, we had to make a guard and stuff for it, it's a good tool as long as you keep your fingats away. I never once thought to flip it into a murderpanelsaw though.

|

|

|

|

LobsterboyX posted:but the absolute best... is this As soon as I saw the old DeWalt, I was going to post that picture, but you beat me to it. Legendary danger with that tool. I've talked about my new DeWalt table saw here before, I think. Modern table saws are so much more usable than old tools. More rpms, much better fences, much safer (the riving knife itself is worth the purchase). I recognize the attachment to the old tools, but they were really just stepping stones to modern production. I just gave my ~30 year old Craftsman table saw away after I saw the new one's capabilities. Now yours is a generation+ older yet, so it's earned its place.

|

|

|

|

LobsterboyX posted:

I love stuff like that. I like reading through old Popular Mechanics and looking through the ads and old car reviews.

|

|

|

|

LobsterboyX posted:I'd get a regular v belt, but this one is cooked, stretched and coming apart so I don't think I'd get an accurate measurement from the remaining - the link belts have always intrigued me and I'd love to give them a try. the sheaves are very nice - this thing hasn't had a lot of use, its problems come from lack of cleaning rather than wear (d+D)1.57+2c Where: d - small sheave dia D - big sheave dia c= sheave centre-centre distance. If you use sheave OD, typically go down an inch as most* V-belts are measured by inside, not outside. FYI, you may have figured out that 1.57=half of pi. That assumes belt wrap is around half the pulley and it works close enough for ratios up to around 3:1, after that there is another formula to include more significant wrap. Obviously, if you want to use the link belting, fill your boots, but it's not "cheap" and you may be able to get a V-belt off the shelf at home depot or something. You may want to consider going to an industrial wholesaler for the link belting (or V-belt) assuming they sell to the walk-ins. You may be able to buy it by the foot.

|

|

|

|

You can get basically any kind of industrial v-belt at Napa, and probably any other parts store, too.

|

|

|

|

I use the microjig splitter kit with a zero clearance insert. The inserts are pretty easy to make with plywood/phenolic. Make a couple of different ones to account for blade height, if you are worried about the distance between the blade and the splitter (and I was)

|

|

|

|

Big Dick Cheney posted:I use the microjig splitter kit with a zero clearance insert. The inserts are pretty easy to make with plywood/phenolic. Make a couple of different ones to account for blade height, if you are worried about the distance between the blade and the splitter (and I was) They looked pretty easy to install, just a few holes to drill in the blade insert, comes with a jig. Do you have to drill the phenolic inserts twice or something?

|

|

|

|

Commodore_64 posted:They looked pretty easy to install, just a few holes to drill in the blade insert, comes with a jig. Do you have to drill the phenolic inserts twice or something? It comes with a drill bit that is good enough to drill phenolic.

|

|

|

|

Took some more pics of the finger taker 5000    its just really.. dirty, its been outdoors for a long time - if I get some time I'm going to give it a real good cleaning and see where we can start.

|

|

|

|

I need some crow foot wrenches. I need them to be as slim as possible. I'm looking for some line wrench (flarenut) style. The regular open end style are too fat to fit in the places I need them to go. I've seen set of 12 pointers that *look* like they would do the job I want them to do, and even in the sizes that I would need, but it was EIGHT HUNDRED DOLLARS!. These are for Hydraulic fittings and sizes are about 3/4" up to 1 1/4" roughly. I'm not opposed to buying individual wrenches, but I'd rather pick up a set, even if I have a bit of overlap, or some small ones that only get used once or twice. What the hotness in the crowfoot wrench world?

|

|

|

|

Cheap HF crowfoots and a belt sander is my recommendation. If the fittings are as thin as I think they are, the flares won't matter. That recommendation goes towards any line wrenches you can get for throwaway prices.

|

|

|

|

um excuse me posted:Cheap HF crowfoots and a belt sander is my recommendation. If the fittings are as thin as I think they are, the flares won't matter. That recommendation goes towards any line wrenches you can get for throwaway prices. Thanks for the suggestion but Uhhhhhhh.......... what? They're too thick in the dimension of the red line, not of the black line.  I'm hoping to find a decent set of something like this:

wesleywillis fucked around with this message at 02:02 on Feb 12, 2021 |

|

|

|

Check out Husky 45009 https://www.walmart.ca/en/ip/45009-WRENCH-CROWFOOT-SAE-11PCS-SET-ASSORTED-SIZES/PRD28HF413J7OTI e: there seems to be 5 of these sets in existence, all at a hobby shop in Ontario. Powershift fucked around with this message at 02:19 on Feb 12, 2021 |

|

|

|

You could still try it, but you might run into strength issues, especially for fittings that big. My only recommendation is to check eBay - tools like that ($800 crowsfoot) are the opposite of disposable, and you might be able to pick up a used set or at least the sizes you need for a lot less.

|

|

|

|

wesleywillis posted:Thanks for the suggestion but Uhhhhhhh.......... what? Oh I totally thought you mean black. You're gonna pay some money for red. You got a welder? You could probably make something similar with a socket and an old wrench. um excuse me fucked around with this message at 02:33 on Feb 12, 2021 |

|

|

|

E: ^^^^^^ I do. though I proved myself awful at overhead welding the other day  but I could maybe macgyver something up, only problem is sockets that large come at a premium at my place of work. Bigger sockets (1"+) and also 3/4" sockets/wrenches are my work's version of everyone else's 10mm sockets. but I could maybe macgyver something up, only problem is sockets that large come at a premium at my place of work. Bigger sockets (1"+) and also 3/4" sockets/wrenches are my work's version of everyone else's 10mm sockets.Powershift posted:Check out Husky 45009 Holy fuckin poo poo. I just ordered that (because of your link, thanks). There does happen to be a Sayal Electronics next city over from me though. Probably could have just went there, but for the fuckin lockdown poo poo. gently caress it. The closest Wally world is close enough I can practically spit on it from where I live. And if the bars were open, it would be only a short detour to take a piss on it on my way home from the local pub. E again: with my luck, the size that I particularly need right this moment, will be the 1 1/8" which isn't in this set... wesleywillis fucked around with this message at 02:40 on Feb 12, 2021 |

|

|

|

It's not, just 1" and 1"-1/4" still, $20 beats $800

|

|

|

|

Is there a laser cutter in your city? A design like that would be trivial to cut from, say, 8 or 12mm plate with a half inch drive square in it. You could probably get a whole set out of a square foot of plate. If I was still working at the laser cutter manufacturing company I was at for a few years I'd design a set and get a co-worker to cut them for a case of beer. Hell, he'd probably have cut two sets and just given me one for doing the design

|

|

|

|

E: drat! I love AI goons just for this reason! ^^^^Powershift posted:It's not, just 1" and 1"-1/4" Definitely. In fairness, the 800 dollar set had sizes up to 2" which..... is a bit bigger than I'd need.

|

|

|

|

boxen posted:edit 3: God I hate pipe threads. All this poo poo and it's STILL a pain in the rear end to get them to seal. Just let me use straight threads with loving o ring somewhere. Thread sealing is the rankest bullshit. Face‐seal everything.

|

|

|

|

wesleywillis posted:E: ^^^^^^ Don't be too excited, I've used that style of crows foot and I loving despise them, they have absolutely no strength, and will bend and slip at the smallest forces. Hopefully the torque values for what you're doing are smaller than what I do. I'd grind a regular crows foot down on the red dimension if I had to. Platystemon posted:Thread sealing is the rankest bullshit. Hey, don't diss on our old friend the radial seal.

|

|

|

|

Williams, who makes the snap-on wrenches, makes them too. When I turn my work computer on tomorrow I can tell you how much $$, but I imagine this website is "close" https://www.industrial-tools.ca/store/9981706/williams-38-drive-crowfoot-wrench-set-8-pc

|

|

|

|

Thanks goons, I think the worst case scenario is, I'll tighten till they slip, and deal with it when they possibly loosen off again and start leaking. These are Hydraulic fittings that go through a metal plate via bulkhead fittings, and they're really close together. I think there are maybe two of 6 fittings that can be tightened without having to remove most of the adjacent fittings. Which is probably par for the course, but even the outside fittings I can't get poo poo on to, including a pair of channel lock pliers. I figure if I had some 12 pointers, I'd be able to turn a tiny bit at a time and "reset", turn a bit more etc... the flat style ones, I'd have to turn them 60 degrees which ain't happening. Hopefully this works, I don't think they need to be super mega tight.

|

|

|

|

You can buy the 1 1/8 solo if you want - Williams SCF36. That way you can try it out without blowing $200 for the set.

|

|

|

|

Thank. I might have to. In the meantime I bought the thirty dollar husky set that powershift linked. Hopefully that fitting is 1 or 1 1/4"

|

|

|

|

This Stanley rotor ratchet came up on kk.org/cooltools today: https://www.amazon.com/Stanley-Hand-Tools-89-961-Rotator/dp/B00HNMZ3G4 It's got a feature where you can twist the handle and it'll screw or unscrew socket that's attached. It's kinda mindblowing. I really need to up my ratchet wrench game.

|

|

|

|

That one looks like a better setup than the no-name equivalent I have - mine has a relatively skinny handle so you can't generate much torque when using the twist action.

|

|

|

|

Huh, I have them in my system at work. gently caress it, I'm ordering a 1/4 and 3/8.

|

|

|

|

why do they insist on bright color plastic handles? based on looks alone that looks like a lovely tool, but a very cool concept, however I seem to recall seeing a very old version of this with a nice knurled handle at a tool swapmeet - in other news - I feel like I made an adult decision today, I need a nice set of snap ring pliers, instead of going to buy another set of HF ones (the previous ones I've had from them last exactly 1 job before they bend and become launched in to the can) I did some looking and bought the channel lock ones with the replaceable tips.

|

|

|

|

LobsterboyX posted:why do they insist on bright color plastic handles? Pretty much what I expect of most Stanley tools.

|

|

|

|

|

| # ? May 24, 2024 17:54 |

|

Give me all the bright colored handles. I lose things throughout the job in front of my face and drop everything through the engine bay onto a slope where it hides behind a tire. Or I decide after 10 times of hooking the tape to my toolbag this time I'll just leave it on the ground. I'm the guy with the playskool looking tool bag on purpose.

|

|

|

EVERYWHERE

EVERYWHERE

C-Bangin' it

C-Bangin' it