|

Miracle of miracles, I actually completed a second project this summer. I originally sketched this out on graph paper while I was bored at work in June, playing with angles and proportions until I came up with a look I liked. When time came to cut the triangles, I pulled out my Incra miter gage and then realized that setting it up in such a way that the pieces would actually fit on the table saw at the right angles was a giant PITA so instead I just used a protractor and straightedge, freehanded it on the bandsaw, then pulled out the Stanley no 5 to shave it to the line. Much simpler. The face is birdseye maple trimmed with sycamore, second layer is birch, and back is sycamore. Basically, "poo poo I had piled around my shop that worked well together." Finally had an excuse to use my router plane to rout out where the mechanism sits so that it's in there firmly and the back is flush with the back of the clock.

|

|

|

|

|

| # ? Jun 6, 2024 17:16 |

|

Nice. Feels a bit art deco.

|

|

|

|

Very clean and stylish

|

|

|

|

How tall is it? Why did you take the picture from such a high angle?

|

|

|

|

Kaiser Schnitzel posted:End grain boards move a ton compared to edge grain, and the more complex it is, the more possibilities for failure. You can get a card scraper, but a good sharp chisel stood upright, or even a single edge razor blade will work in a pinch. Honestly the best option is just sanding it with a DA. Scraping endgrain isnít exactly fun or easy. Tried using one of my chisels. It did an okay job of scraping, but was going to take a good amount of time/effort and probably multiple rounds of sharpening. I think I'll just go pick up some pads for my RO sander.

|

|

|

|

CommonShore posted:How tall is it? Why did you take the picture from such a high angle? It's 18 inches high and 14 inches at its widest point. I took the picture from directly above it as it sits on my workbench, since I haven't decided where to mount it yet. Also still need to get a mounting bracket. But instead, today I got a 16bf slab of rough sawn basswood. I am going to have SO MANY practice carving blanks.

|

|

|

|

Thanks for the advice earlier in this thread. Took a long while but I found the perfect walnut 4/4 slab and they had a ton of maple. Seems like the walnut they had was mostly in the 6-8" width and I was looking for somewhere 10-13". Ended up with 13" but I decided* to cut it down to 10". Handle is probably not going to have the curve I originally wanted due to time and I'm kinda scared of the router now for something that deep. It's like 1.25" wide. Just going to round over the edges.  Link to full: https://i.imgur.com/jokt32Y.jpg *The router decided for me by tearing out massively when the flush trim bit grabbed it. Bondematt fucked around with this message at 06:16 on Aug 22, 2022 |

|

|

|

For end grain boards I use a planer jig for a router. I've also hand planed which is a bit tricky to avoid tear out.

|

|

|

|

I have no idea why that opened up like that. I have one from the same batch I use at my house and have had no issues at all, and I used the shittiest cuts from that batch. My main issue was I had a gap at the purpleheart/maple 45 degree transition because it's a pain to clamp the angle. The 90's all stayed tight. I'm pretty sure that batch was purple heart, cherry, and maple. Everything's glued with Tightbond 2, for the record. When I originally made them I used a random orbital sander, 60 grit stepped up to 440 I think, then finished with mineral oil and beeswax, so you should be able to replicate that if you wanted. Danhenge posted:Just FYI my posts weren't intended as a judgement, hope they didn't come off that way. Not at all. I just have no idea why those joints are failing. AFewBricksShy fucked around with this message at 16:14 on Aug 22, 2022 |

|

|

|

Stultus Maximus posted:It's 18 inches high and 14 inches at its widest point.

|

|

|

|

AFewBricksShy posted:I have no idea why that opened up like that. I have one from the same batch I use at my house and have had no issues at all, and I used the shittiest cuts from that batch. My main issue was I had a gap at the purpleheart/maple 45 degree transition because it's a pain to clamp the angle. The 90's all stayed tight. Just FYI my posts weren't intended as a judgement, hope they didn't come off that way.

|

|

|

|

Gonna cross-post my posts from the "quick questions" thread in here:shut up blegum posted:Not sure if this is the right thread, but not sure where to post it, so... Someone suggested screwing the drywall directly on the rafters. People itt know about wood, so maybe they know if this is a good/bad idea? I'd use the metal railing so the metal can "absorb" the movement of the wood, thus not putting that stress on the drywall. It would be a lot cheaper if just screwing the drywall onto the wooden rafters works too though...

|

|

|

|

shut up blegum posted:Gonna cross-post my posts from the "quick questions" thread in here: You're overthinking this. You don't have to worry about wood movement in framing material vs. drywall. Just screw the drywall directly to it like the pros do. An actual drywall screwgun is a great help here. It sets the screws in just enough to cover with mud (plaster)

|

|

|

|

AFewBricksShy posted:I have no idea why that opened up like that. I have one from the same batch I use at my house and have had no issues at all, and I used the shittiest cuts from that batch. My main issue was I had a gap at the purpleheart/maple 45 degree transition because it's a pain to clamp the angle. The 90's all stayed tight. No worries. It's a beautiful board. I'm just exceedingly lazy because all of my tools are in my shed in the back yard, and I don't have a proper workbench or place to do what is otherwise a seemingly easy task. I always joked that my rule for house shopping was that wherever I live needs n+1 garage spaces, but based on the real estate market that will never work out.

|

|

|

|

I've been (very) slowly working on a media cabinet. I did all the glue ups and dovetailed the joints for the carcass. They were tight but manageable so I moved on to the shelf joinery thinking I'd go back and maybe clean them up if needed. I'm not sure if it was due to a few days of suddenly super high humidity but the next time I tried to dry fit things the top and bottom had cupped enough that the dovetails don't line up anymore. I full admit I wasn't storing the boards super properly while not working on them, but I didn't think it would be this bad. I have them stickered and have a fan on them and am going to give it a bit to see if things straighten out, but otherwise I'm not sure what else to do but cut off all the pins and redo and it'll just be ~1.5 inches shorter.

|

|

|

|

You can usually 'uncup' a board by putting it out in the sunny grass with the convex side towards the sun. Check it every 20 minutes or so-it doesn't take long, especially if the grass is at all wet. Then see if it fits better and go ahead and glue it up if possible-the dovetails will usually hold it flat. You can also clamp stiff battens to each side of the board near the joint to squish it flat and see if that gets you close enough to glue it up.

|

|

|

|

Kaiser Schnitzel posted:You can usually 'uncup' a board by putting it out in the sunny grass with the convex side towards the sun. Check it every 20 minutes or so-it doesn't take long, especially if the grass is at all wet. Then see if it fits better and go ahead and glue it up if possible-the dovetails will usually hold it flat. You can also clamp stiff battens to each side of the board near the joint to squish it flat and see if that gets you close enough to glue it up. Thanks for the suggestion. The bolded was actually my second worry. I wasn't sure if it was more likely that it'd be held in place or the whole thing would crack apart.

|

|

|

|

z0331 posted:Thanks for the suggestion. The bolded was actually my second worry. I wasn't sure if it was more likely that it'd be held in place or the whole thing would crack apart. I had a problem just like this last dovetailed carcass I assembled. Fit rather tightly in a very dry garage in the coldest of winter, then after bringing it into the house, the top and bottom cupped so badly so as to pull the dovetailed joins apart. I probably made a mistake somewhere along the way like going light on glue, but thatís my story.

|

|

|

|

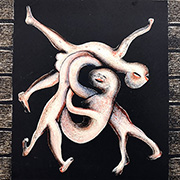

loving with some shapes and dis'n'dat for the big empty wall above my bed.

|

|

|

|

That's pretty wicked... I've got a little scrap end panel growing, I keep gluing a piece on every now and then. That's some inspirational looking work right there.

|

|

|

|

Stultus Maximus posted:Miracle of miracles, I actually completed a second project this summer.

|

|

|

|

z0331 posted:Thanks for the suggestion. The bolded was actually my second worry. I wasn't sure if it was more likely that it'd be held in place or the whole thing would crack apart. There's not usually a tremendous amount of force behind cupping unless you're really soaking the board all the time, in which case you'll need to stop peeing on your media center. Humidity will let it expand/contract unevenly if it's let free to do so, but it's the same humidity on all sides of the board and the difference in expansion/absorbency between the two sides won't be enough to tear the whole thing apart if the joints are otherwise sound. If you're really worried about it start using quartersawn wood. A Wizard of Goatse fucked around with this message at 22:56 on Aug 26, 2022 |

|

|

|

Wallet posted:loving with some shapes and dis'n'dat for the big empty wall above my bed. These are all cool, but I absolutely love the twisty thing on the left. It's so, so good.

|

|

|

|

Wallet posted:loving with some shapes and dis'n'dat for the big empty wall above my bed. You make so much cooler stuff out of scrap than I do out of big fancy boards and I love it

|

|

|

|

Not much fine woodworking here but it did give me a chance to use the pantorouter for some mortise and tenon work.

|

|

|

|

I just want to reiterate that your pantorouter is really loving cool.

|

|

|

|

I've become obsessed with Matthias's website and videos lately and I'm thinking about buying some plans from him and making something - maybe the jointer or slot mortiser

|

|

|

|

CommonShore posted:I've become obsessed with Matthias's website and videos lately and I'm thinking about buying some plans from him and making something - maybe the jointer or slot mortiser His stuff can be really useful. I bought his bigprint program a couple years ago for easily resizing some patterns i hand drew.

|

|

|

|

I've built his box joint jig and while it was a bit of a pain to make it was well worth not having to deal with dado blades anymore. Turns out I mostly used them for box joints. I've also bought plans for his big bandsaw, but haven't made it yet. It's a project I want to take on but it's hard to justify fitting a 2nd bandsaw into the small shop.

|

|

|

|

CommonShore posted:I've become obsessed with Matthias's website and videos lately and I'm thinking about buying some plans from him and making something - maybe the jointer or slot mortiser Do it! All his machines are great, and moreso are a blast to actually build. If you're not already a metric person, get a nice MM rule and a good (short) metric tape. The box joint jig is excellent, as well as the router lift and multilap tenon jig. I built a slot mortiser that's inspired by his too and it's wonderful. e: and the sanders. Both strip sanders are great. I built one that's somewhere in-between the two in terms of design. Great for nice safe sanding on small parts (because my edge sander is scary, and disc sanders are jerks), or using the slack belt for rounding things.

|

|

|

|

I built his jointer (more or less) would recommend. Cnc carving is too much fun. Think it was another goon in the thread that inspired this.

|

|

|

|

I may build the jointer! Know what's extremely frustrating, though? Having the wheel on your honing guide seize up. Now I'm down a honing guide and I need to lap a few stones. That's what i get for sharpening a plane iron while on the phone.

|

|

|

|

I have a little Ryobi random orbital sander I got to replace an awful one from Harbor Freight. I got one with a plug on it since I don't need it to be portable, and for the most part I'm happy with it. The one thing that drives me wild is that the plug end doesn't seem to fit an outlet correctly; it's so loose that if you put any tension on the cord it just slides right out. I feel like there has to be an easy fix but I have no idea what it is. Anyone got any bright ideas? (It's been too long to return it, which is what I should have done.) I didn't have enough work space to actually see all four of the pieces together until I had it on the wall and all together they felt a bit too much like a clean box to me so I made a couple modifications to the twisty boy and added a few little friends to break up the overall shape. I think I might need one more on the top right to wrap it up.  Hypnolobster posted:These are all cool, but I absolutely love the twisty thing on the left. It's so, so good. What I'm saying is I'm not sure I would recommend it. The main thick twisty mahogany bit was a peach, though. More than enough surface area that you could just make one and slap it on a wall.

|

|

|

|

Wallet posted:I have a little Ryobi random orbital sander I got to replace an awful one from Harbor Freight. I got one with a plug on it since I don't need it to be portable, and for the most part I'm happy with it. The one thing that drives me wild is that the plug end doesn't seem to fit an outlet correctly; it's so loose that if you put any tension on the cord it just slides right out. I feel like there has to be an easy fix but I have no idea what it is. Anyone got any bright ideas? (It's been too long to return it, which is what I should have done.) It's not the easiest solution (the easiest solution I can think of would be to cut off the end and wire on a better plug, and also make sure your outlets are new enough) but, as I've mentioned elsewhere, but for almost all of my tools, I cut the cord off, all but 3-4" of it. Then I put an L5-20P locking plug on the end of it so I can plug it into one of the bunch of L5-20R cables in my shop (normal 3-prong end at the wall) instead of dragging cords around, especially ones that come with cheaper tools. I started this with my Skil router (the one that doesn't go in my router table) but now my Bosch sander, extremely cheapo jigsaw, are all set up this way. One of those L5-20R cables is zip-tied to a vacuum hose and plugged into a vac relay (with a bunch of adapters hanging in a bag off the side of the workbench), so I can plug any tool in to power and vac without really thinking about it. tracecomplete fucked around with this message at 20:10 on Aug 28, 2022 |

|

|

|

CommonShore posted:I may build the jointer! Should have put it on plane mode.

|

|

|

|

Wallet posted:I have a little Ryobi random orbital sander I got to replace an awful one from Harbor Freight. I got one with a plug on it since I don't need it to be portable, and for the most part I'm happy with it. The one thing that drives me wild is that the plug end doesn't seem to fit an outlet correctly; it's so loose that if you put any tension on the cord it just slides right out. I feel like there has to be an easy fix but I have no idea what it is. Anyone got any bright ideas? (It's been too long to return it, which is what I should have done.) You could try pinching the prongs toward each other. Works for me. Also try a different wall outlet, the loose one might be worn out.

|

|

|

|

Any thoughts about this bandsaw? Is there some reason it's so cheap? https://easternshore.craigslist.org/tls/d/hurlock-delta-bandsaw/7527081569.html

|

|

|

|

Danhenge posted:Any thoughts about this bandsaw? Is there some reason it's so cheap? It's old. The guides and rollers probably need some touchup and the wheels may or may not need alignment Tire condition can't be seen in the picture. Looks like it was painted fairly recently which really provides no benefit except to to jack up the price or hide issues. Price for it isn't really good or bad depending on the actual condition. It going to lack all modern amenities like dust collection hookup, a lever to take tension off the tires when not using it, and it's not fully enclosed. I'd take a look at it as long as it isn't too far out of your way. Guy has other bandsaws in his shop in the picture too so maybe he'll have something else interesting while you are there.

|

|

|

|

It's cheap cause there's like a million of those Delta-Rockwell 14" saws gathering dust in garages and everyone who wants one has one. Old shop equipment tends to be cheap as hell but unlike grandpa's equally worthless radial arm saw or rusty shaper the bandsaws aren't really lacking any important modern features. Personally I'd hold out for one with the riser block kit or at least where the motor is enclosed but as a class that's about what they cost, they're extremely okay starter bandsaws, and they're an unbeatable deal for what you get.

A Wizard of Goatse fucked around with this message at 05:57 on Aug 29, 2022 |

|

|

|

|

| # ? Jun 6, 2024 17:16 |

|

Wallet posted:loving with some shapes and dis'n'dat for the big empty wall above my bed. I love this. As a total novice how would someone even go about designing something like it? Just draw and color some shapes on paper? Declare YOLO and just wing it entirely?

|

|

|