|

I am so pleased with how easy that step was! Next coat goes on tomorrow.

|

|

|

|

|

| # ? May 30, 2024 11:46 |

|

Sockington posted:I’m an industrial maintenance guy, so I tend to over-do things than leave it sketchy as a habit. Rounding off the back of the blade a bit with a stone helps a ton too, especially when cutting curves. Basically knock the back two corners off. Helps smooth out the weld too and just makes everything a little happier. Unfortunately the only way I know to do that is holding a stone to the back of the the blade with the saw running which is not for the faint of heart.

|

|

|

|

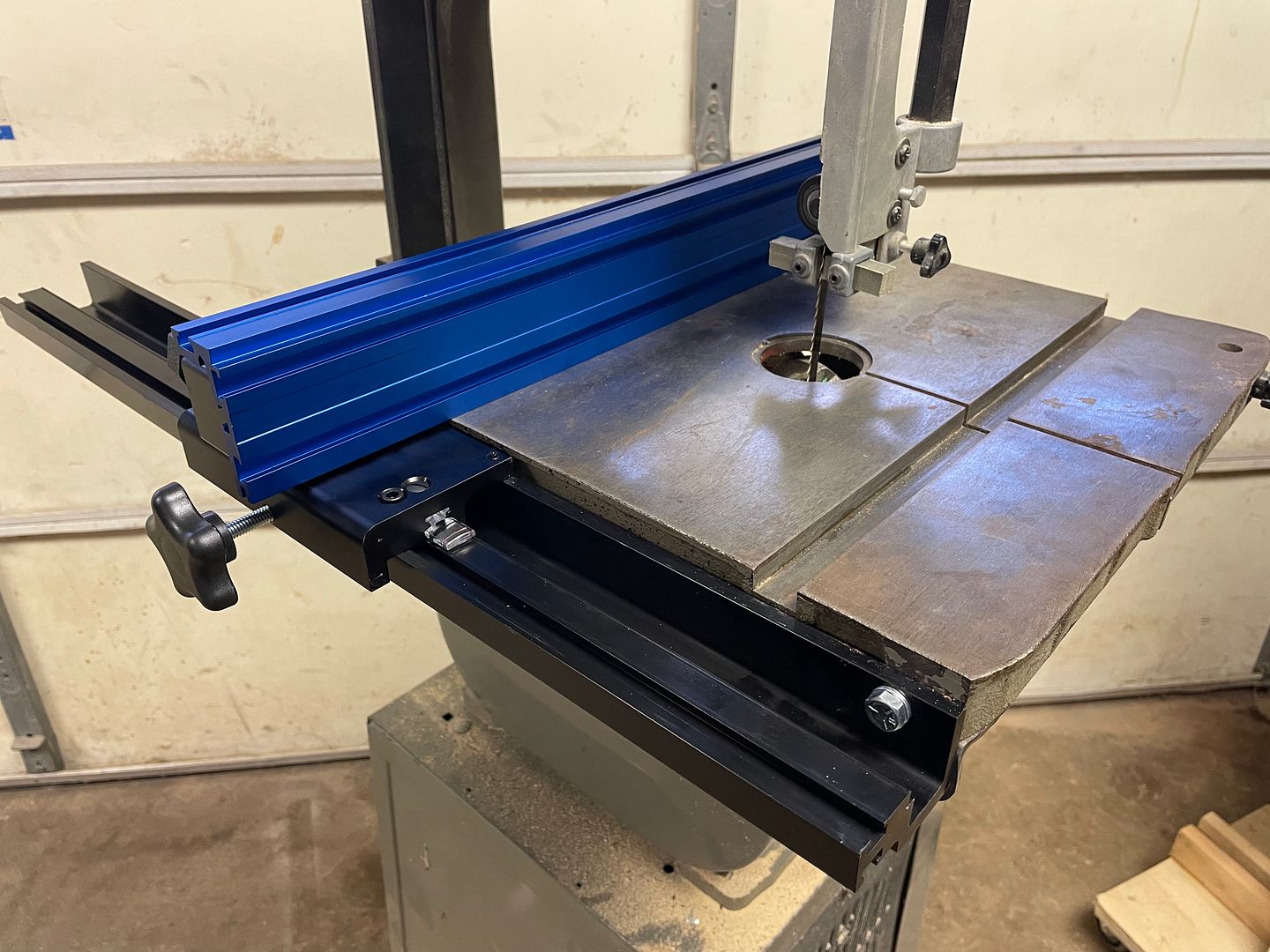

Kaiser Schnitzel posted:If you can adjust that fence, make sure it is parallel to the blade. Run a board into the blade against the fence, turn the saw off. Then see if the blade is centered in the kerf and front/back are parallel to the sides of the kerf. I don’t know why, but every bandsaw blade seems to be a little different and it makes a huge difference if you can get the fence aligned, otherwise it tends to pull the stock away from the fence. I squared the table surface to the blade and then squared the fence to the table as a starting point. The old blades drifted so badly that I didn’t get too picky for my initial run. I washed up the urethane tires as they had dust residue buildup on both. Put on a 1/2” wide fresh blade - old blade picture right.  I’d like to get “The Bow” bandsaw featherboard setup soon but this was okay for now.  Coming down the mountain like Moses with two tablets RELATIVE SUCCESS!  Turns out I ran a pretty un-square chunk of oak through it and didn’t really shoot for a middle cut so much as 1” test run, but was happy with the tracking as a starting point. It has some adjustment to account for drift with the Kreg setup but that’s for another day.

|

|

|

|

I am pulling my hair out trying to adjust my 1950s craftsman 113 table saw using a PALS. I can't seem to get there, I run out of runway to adjust it when the back of the blade is 15-25 thou to the right. I've tried unlocking & moving both trunnions as far as possible to oppose the misalignment, then locking the front in this position and adjusting the rear, no luck. My uneducated senses tell me that either something is taking up all the play in the front, or the arbor twists too much when I put the motor on and tension the belt. Has anyone dealt with this? E: I finally found it. I had locked the tilt mechanism at 90 while I was making my adjustments, which was pulling the front trunnion towards the left of the saw and taking up all the slack on that side. I tilted the saw slightly, loosened the bolts on the front trunnion,moved it all the way to the right, and locked it in that spot. The rear trunnion now has adequate range to move the alignment around both sides of the zero mark. HolHorsejob fucked around with this message at 04:30 on Sep 4, 2023 |

|

|

|

Just catching up on last month's Fine Woodworking and, uh, why didn't anyone post this??!

|

|

|

|

Been a while since I've had access to space to work. Never been particularly good at this stuff but I've enjoyed it and now that I have my own house and a floor I'm basically turning into a workspace, it feels good and I'm hoping to get better. This is the result of my first month settling into the new space, a nice little plant table.   Turned out significantly worse than I'd planned but significantly better than I'd expected so I'm gonna call it a win. Mostly this was an opportunity to get repeatedly frustrated by tools and other things I needed having gone missing or broken over the years and getting them replaced, as well as figuring out some ideas on how I want the workshop set up and organized. I still consider myself very much a beginner at this point, so to keep things simple my next project is going to be doing some bits and pieces for the cat structures I plan on littering the walls of the house with and then its on to my next big project - building a bed frame of some sort. No idea what sort of bed frame I'm going to build yet, and am open to ideas. Since I'm building it myself I can do whatever I want, no matter how commercially unviable or functionally unwise! Loft bed? Fold out bed? Hammock bed? Bed suspended by chains? No idea what I'll settle on, yet. Right now I'm leaning towards some sort of basic loft bed though.

|

|

|

|

Woodworking for Mere Mortals did a pretty good series of videos on Catification projects that might give you some ideas.

|

|

|

|

GlyphGryph posted:Turned out significantly worse than I'd planned but significantly better than I'd expected so I'm gonna call it a win. Words to live by. I had my first good go at resawing a bunch of beams I had kicking around since last winter.  Made some useable lumber out of them and cutout the worst bits. Most of it cut 1.5-2” thick. The beam chunks were thrown in for free when picking up some other stuff for my shop table and weren’t really usable as-is so she’s a win for this.  Having used the bandsaw properly for a few hours, it’s very clear why people say resawing on a table saw sucks. It does. I did it for my daughter’s desk and had some awkwardly close moments.

|

|

|

|

Kaiser Schnitzel posted:Just catching up on last month's Fine Woodworking and, uh, why didn't anyone post this??! Like, on a scale of 1 to that spider man comic?

|

|

|

|

I should post some things I've been working on. Bookcase for a friend of mine, in progress. All maple, and I'm REALLY happy with how well the joints were cut. This is just the dry fit, but everything snugs up really well and the dados for the braces are snug and clean... it's just coming together so well. Lots to do still, sanding, edge profile, make it nice and pretty.  A little cherry plant holder I made a while back.

|

|

|

|

Kaiser Schnitzel posted:Just catching up on last month's Fine Woodworking and, uh, why didn't anyone post this??! well I did have to spend an afternoon this weekend hosing everything down with antifungal spray A Wizard of Goatse fucked around with this message at 17:00 on Sep 5, 2023 |

|

|

|

El Spamo posted:A little cherry plant holder I made a while back. The book case is looking sharp too, but I really like this plant holder. Are the drip trays being hidden for the photograph or how did you deal with the holes in the bottom of the pots?

|

|

|

|

Kaiser Schnitzel posted:Just catching up on last month's Fine Woodworking and, uh, why didn't anyone post this??! Because FWW isn't really worth subscribing to for the occasional interesting article? Anything noteworthy in the article beyond the usual sensitizing suspects, general danger of particulates, and certain exotics containing fucknasty crap?

|

|

|

|

Just Winging It posted:Because FWW isn't really worth subscribing to for the occasional interesting article? Anything noteworthy in the article beyond the usual sensitizing suspects, general danger of particulates, and certain exotics containing fucknasty crap? How Toxic is Your Woodworking Magazine?

|

|

|

|

Just Winging It posted:Because FWW isn't really worth subscribing to for the occasional interesting article? quote:Anything noteworthy in the article beyond the usual sensitizing suspects, general danger of particulates, and certain exotics containing fucknasty crap?

|

|

|

|

El Spamo posted:I should post some things I've been working on. I'm in the process of buying a house and wanna get back into woodworking and bookcases are on my list. This is changing the design in my head!

|

|

|

|

I'm looking to order some food safe wood to be shipped to me for whittling kitchen tools such as spoons. Does anyone have a favorite store for ordering such things? I live on the road and have only an ax to split wood so I need to take that into consideration.

|

|

|

|

Kaiser Schnitzel posted:The treasure of FWW is the FWW Unlimited subscription which is access to their website and most importantly all their archives. The search is pretty decent and they also have a bunch of video lessons etc. You get a free print subscription with it I guess so they can keep their circulation numbers up to woo advertisers. Figured as much. Guess I'll look into that Unlimited stuff at some point, because their back-archive sounds like an interesting place to check out.

|

|

|

|

Just Winging It posted:Figured as much. Guess I'll look into that Unlimited stuff at some point, because their back-archive sounds like an interesting place to check out.

|

|

|

|

huhu posted:I'm looking to order some food safe wood to be shipped to me for whittling kitchen tools such as spoons. Does anyone have a favorite store for ordering such things? I live on the road and have only an ax to split wood so I need to take that into consideration. https://www.bellforestproducts.com/ has everything but you'll be paying for it. https://ocoochhardwoods.com/ have the best prices you're likely to get online but they're still only worthwhile for stuff like surfaced thin stock when you don't have the means to make it yourself. Wood is extremely not worth shipping unless it's something very niche you cannot possibly get locally. If you have access to firewood to use that axe on and no requirements beyond "food safe" just use that? Green is even better for whittling, go in the woods and grab a branch VVV there's like a million bookcase plans online. If you have access to a table saw you can make a heirloom -grade one in your sleep, if all you have is a hand saw, drill, and some 2x4s you can make something ugly but indestructible to fit whatever size you like; make a box that's open on one side and add sub-boxes. Your biggest concern is going to be preventing racking (push on the side and watch your nice square box become a rhombus), which you can most easily accomplish by adding a solid back to the bookcase A Wizard of Goatse fucked around with this message at 19:20 on Sep 5, 2023 |

|

|

|

Ultra Newbie question: about how difficult is it to make a stable, solid bookshelf? I'm thinking 3 shelves, each one about as tall as your standard TTRPG game manual(so pretty tall for a book), and an unknown width. I'm moving soon, and I'm using the same bookshelf I've had since I was a small child which is just getting a little too small for my big ol collection of books I haven't read lol. I'm not asking about finishing it (lacquer, glaze, wood finish etc) but the actual carpentry itself. My father has some very rudimentary hobbyist skills with wood and I think we have plenty of tools but I don't even know where to start with picking wood that would be good for the project, or what goes into building a bookshelf(like schematics or something). Are there tried and true designs to follow available on the internet? what nails should be used? or does anyone have any all encompassing guides to follow?

|

|

|

|

huhu posted:I'm looking to order some food safe wood to be shipped to me for whittling kitchen tools such as spoons. Does anyone have a favorite store for ordering such things? I live on the road and have only an ax to split wood so I need to take that into consideration. When making cutting boards for food contact, the advice is to avoid certain woods like walnut that may be a bit toxic, and then a bunch of woods that are open-pored and tend to expand and contract too much. But for like spoons, even that isn't a big issue. You can go into any big box (or otherwise) hardware store and buy any of the domestic hardwoods other than walnut and they're fine, and you can also use most of the typical hardwood firewoods too. For common American domestic hardwoods, pick and use freely any of these (stolen from https://www.hardwoodinfo.com/specifying-professionals/species-guide/) ALDER ASH ASPEN BASSWOOD <-- probably too soft to make a durable spoon but might be the best possible wood for learning carving with BIRCH CHERRY COTTONWOOD <-- can leave a fuzzy surface, I've never worked with it? ELM GUM HACKBERRY HARD MAPLE HICKORY & PECAN PACIFIC COAST MAPLE POPLAR RED OAK SOFT MAPLE SYCAMORE WHITE OAK This isn't a comprehensive list, like it's missing almond for example which is commonly sold as firewood in california (the almond orchards "retire" the trees when they get old enough for production to drop off) and there are probably countless species of hardwood not commonly found as lumber that you could still pick up a stick of and whittle into a spoon. Avoid exotic/imported hardwoods: many of these may be suitable, but many are not, and you'd need to look each one up and there may not be good information. Also they're generally more expensive anyway. I'd also avoid the softwoods, by which we mean the evergreen trees like pine, because they are sappy and aromatic woods that may impart unpleasant flavors. There are probably some softwoods that would be OK but I don't know them.

|

|

|

|

Is there a source on the walnut toxicity thing? I see conflicting details on it everywhere I look My daily cutting board is all walnut and now I'm going to die

|

|

|

|

As far as I know, nobody's like, proven that the juglone in walnut is toxic enough to actually be an issue with a little food contact. It is definitely bioactive, though. It's more concentrated in the fruit, bark, and roots, so the amount you'll get from a walnut cutting board made of the heartwood is probably really small? I see it recommended against here and there when discussing food-safe wood so I'm following suit. I do not personally think your walnut cutting board will hurt you, but I would not sell them to the public myself.

|

|

|

|

Leperflesh posted:When making cutting boards for food contact, the advice is to avoid certain woods like walnut that may be a bit toxic, and then a bunch of woods that are open-pored and tend to expand and contract too much. But for like spoons, even that isn't a big issue. You can go into any big box (or otherwise) hardware store and buy any of the domestic hardwoods other than walnut and they're fine, and you can also use most of the typical hardwood firewoods too. Your list was otherwise really good. Walnut is fine for cutting boards though. You need to ingest the dust of walnut for it to be a concern. I wouldn't use it for a spoon though for exactly the reason that spoons will break down under heat of cooking. If you want to make a walnut butter knife you're going to be just fine though. Juglone doesn't leach in any concerning quantity for human contact just from touching things. It is bad for you while sanding, and the dust is toxic to breath and can cause a reaction on skin contact too. Cured walnut wood that's already been worked and oiled/finished won't have this issue though unless you're chewing on it. My favorites are birch or poplar because they grow fast, relatively straight, and are easy to work with your hands. They also grow fast enough where no one's going to be annoyed if you take a branch or two from a forest. Unless you have horses, but then you already know. They just keel over from three fields away if a walnut leaf falls.

|

|

|

|

I've used a big walnut serving spoon to stir my pots and dish up for like five years and it's neither broken nor poisoned anyone, that's usually accomplished by my cooking. It does tend to get, like, fuzzy under sufficient application of heat and water but you just scrub it and it cleans up fine, wood does poorly in the dishwasher generally. Can't find any record anywhere of someone coming down with a case of walnut poisoning but just to be on the safe side I'd eat no more than five pounds of hulls in a sitting

A Wizard of Goatse fucked around with this message at 20:11 on Sep 5, 2023 |

|

|

|

Woodworking: Gathering of the Juglone

|

|

|

|

Pretty much the tl;dr on most wood in terms of food contact is 'yes, probably some of the extractives are in theory carcinogenic or otherwise toxic' but you'll probably get more exposure to Bad Things from smoking a pack of cigarettes or breathing 2023 city air for a week than you will from a lifetime of using a teak or walnut or bubinga or w/e cutting board. That article definitely seemed like dumb 'OMG TOXINS?!?!' facebook fearmongering to me. Woodworkers SHOULD be worried about wood dust, but the risk from finished wood projects is pretty negligible. e: to be clear there is some nasty stuff in wood and maybe don't boil a pot full of cumaru wood chips for days and drink the resulting liquid and die of homemade warfarin overdose or something. Kaiser Schnitzel fucked around with this message at 20:37 on Sep 5, 2023 |

|

|

|

A Wizard of Goatse posted:I've used a big walnut serving spoon to stir my pots and dish up for like five years and it's neither broken nor poisoned anyone, that's usually accomplished by my cooking. It does tend to get, like, fuzzy under sufficient application of heat and water but you just scrub it and it cleans up fine, wood does poorly in the dishwasher generally. Can't find any record anywhere of someone coming down with a case of walnut poisoning but just to be on the safe side I'd eat no more than five pounds of hulls in a sitting Yeah, if you want to be super on the safe side it's that fuzzy stuff that can fall off into your cooking. I'm not so worried about it myself, but if you already have a sensitivity to it I suppose it might. Much more precautionary about the dust to the point where proper PPE and dust collection is super important. E: the article was written by the State of California Prop 65 in AI form.

|

|

|

|

imo before eating off it you should just seal in all the bad scary walnut juice with a traditional, all-natural urushi lacquer

|

|

|

|

Basically there's what I'd do myself, and then a big gap, and then there's what I'd feel comfortable recommending to a newbie in a recommendation thread. For me personally I'd put an accent strip of walnut into a cutting board design for my own use without a problem. When I tell other people what to do I err on the side of being certain that I'm not recommending something potentially harmful. Anyway honestly there's no special reason to use walnut to make a spoon. Sure it's a pretty wood but there's loads of pretty woods that aren't walnut.

|

|

|

|

Jhet posted:The book case is looking sharp too, but I really like this plant holder. Are the drip trays being hidden for the photograph or how did you deal with the holes in the bottom of the pots? Plant plants that are ok without drainage holes in their pots. So spider plants (pictured), succulents, air plants, etc. Between their tolerance and terra cotta pots being just a little bit porous they do well. Otherwise you can put the little drip trays underneath and tack them down with some blue tak or hot glue or something.

|

|

|

|

LurchinTard posted:Ultra Newbie question: I would expect that most plans you find online are going to be for fancier designs that require more tools. But the basics of a shelf are simple enough. The simplest I can think of would be to use plywood (1/2" thick or thicker) to build a box with 4 sides and a back, then put plywood shelves inside it and screw through the sides/back to hold the shelves up. You could do that with a circular saw and a drill (and a straightedge, square, measuring tape, pencil, drill bits, and a driver for the screws). The back is important, because it provides a lot of resistance against racking, where the entire shelf tilts sideways. The back doesn't have to be anywhere near as thick as the rest, though; you could do it at 1/4" thick and it'd be more than strong enough. That saves on weight and cost. You can also do solid wood if you want. The main challenge there will be finding boards that are wide enough for your shelves. That said, I built this bookshelf out of (if I recall correctly, 1x10) hardware store pine, which should be readily available:  It required more tools than the plywood plan I described above, because I cut slots into the sides for the boards to fit into, and also put a subtle taper on the shelves themselves. You can do the slots with a table saw or (as I did) a router, and the taper is completely optional, it's just for aesthetics really. Or you could do screws as with the plywood above. The back is multiple pine boards placed side-by-side.

|

|

|

|

Appreciate the advice friend. Admittedly I'd want it to be out of solid wood just for the aesthetic factor.

|

|

|

|

Jhet posted:Unless you have horses, but then you already know. They just keel over from three fields away if a walnut leaf falls. To be fair, a horse will freak out and have a heart attack if they see a weird looking cloud.

|

|

|

|

Why didn't I get a ryoba sooner? WHY!?

|

|

|

|

LurchinTard posted:Appreciate the advice friend. Admittedly I'd want it to be out of solid wood just for the aesthetic factor. Solid wood shelves are biting off more than you can probably chew- it's more advanced than newbie stage because of qualities of movement, cupping, etc. Hardwood veneered 3/4" plywood, you can edge-band and never have to worry. Or better, use hardwood stiles & rails on it for more structural support. I did dozens that way trimming homes- hell, maybe a few hundred, idk, and you can get fancy with it. And not just tract homes. Plywood is stable. This is a big deal. I also always backed it with 1/4" material of the same veneer, whether free-standing or not. Again, for structural stability.

|

|

|

|

My neighbor just gave me this out of nowhere. Wouldn't even accept cash after I told him it was a sought after item.

|

|

|

|

My father-in-law has no use for this so he'll be bringing it with him next time he visits in May, to complete my planer/table saw/jointer holy trinity  It's obviously super old, with a (home made?) wooden stand that also holds the motor, connected to the actual machine with a belt. Couldn't find any identifying marks beyond it being "Delta" and that FJ 304 marking on the back, but I wasn't looking too hard either.

|

|

|

|

|

| # ? May 30, 2024 11:46 |

|

Mr. Mambold posted:Solid wood shelves are biting off more than you can probably chew- it's more advanced than newbie stage because of qualities of movement, cupping, etc. Hardwood veneered 3/4" plywood, you can edge-band and never have to worry. Or better, use hardwood stiles & rails on it for more structural support. I did dozens that way trimming homes- hell, maybe a few hundred, idk, and you can get fancy with it. And not just tract homes. Plywood is stable. This is a big deal. I also always backed it with 1/4" material of the same veneer, whether free-standing or not. Again, for structural stability. This sounds relevant to me since I'd like to build a basic entertainment console/record cabinet like this guy: https://wilburdavisstudios.com/shop/recordcredenza/ How would you deal with cupping of hardwood? Do you need a planer to get it flat? I am just getting into this and have some hand tools, like small planer & chisels but as far as power stuff I only have a table & miter saw.

|

|

|