|

You can make charge pumps in different ratios than 2:1. Voltage multipliers might be one approach. http://en.wikipedia.org/wiki/Voltage_multiplier What are you actually trying to do? Depending on the application you might be able to use a lower voltage, as well. For example, if you're amplifying a signal to a single-ended output, but a differential signal would work just as well, you can halve the supply voltage needed by bi-amping. With +/-15V supplies you already have a 30V swing, so you only need to double it to get 60V p-p. If your output is an AC signal of sufficiently high frequency you could consider an output transformer with normal opamps, although that won't suit DC or some loads. Two opamps running on +/-15V supplies driving a 2:1 output transformer would give you 60Vp-p without having to convert your supply voltages at all.

|

|

|

|

|

| # ? Jun 11, 2024 22:23 |

asdf32 posted:But with very high frequency much small input filters can give you that low ripple. So it seems like high frequencies are going to be a necessity to bring the filter sizes down.

|

|

|

|

|

Base Emitter posted:You can make charge pumps in different ratios than 2:1. Voltage multipliers might be one approach. http://en.wikipedia.org/wiki/Voltage_multiplier I'm specifically trying to amplify an AC signal. I have a waveform generator that feeds a PGA to control amplitude, then feeds that output to a high voltage op amp. ~250 Hz is the lowest frequency I will use, but I will be using a square wave until 10-20 kHz when I switch to a sine wave. ~2-300 kHz is the highest frequency I should need to use, and I'm ok with losing some amplitude at these higher frequencies due to GBW. I should probably specify that I will not be sweeping the frequency. It will be static for a given experiment. As I mentioned earlier, higher voltage = better sensitivity, so I'd really like it as high as feasibly possible. At least 100 Vpp would be good.

|

|

|

|

ANIME AKBAR posted:High frequency PWM can't do anything about the 120Hz ripple inherent to a single phase DC/AC converter. That frequency isn't allowed to change, so the energy ripple always has to be dealt with by using energy storage. Yeah fair enough. I had to double check their specs to convince myself that they really meant that. But you're right. Definitely significant energy storage within the inverter.

|

|

|

|

Slanderer posted:kaptop tape for fixing the lifted traces--it's non-conductive and works at higher temperatures Ooooooh, that stuff looks neat. I tried electrical tape already with my lifted traces and the glue failed on the first sunny day outside. Thanks for the copper tape idea too. I shouldn't have too many problems with that pad I tore. It was for an gauge illumination bulb, in parallel with 4 others on nice, fat buses. Plus, this flex board is 26 years old, so that should give you an idea of how wide the pathways are. poo poo, now that I think about it, I had to fix the flex board connector on a Nintendo DS touchscreen that I broke 6-7 years back. You're right, it's not fun, scraping off coatings to solder on 30 gauge wire...

|

|

|

|

Stealth Like posted:

Are you one of the MIT grad students at my work today?

|

|

|

|

ante posted:Are you one of the MIT grad students at my work today? How cute. https://www.youtube.com/watch?v=8hwLHdBTQ7s 2 kV from 9 V batteries.

|

|

|

|

Regarding the weak pull-ups on Microchip PIC I/O pins, according to the datasheets (of several models) it seems as though it's some kind of current source rather than a pull-up resistor. Even so, if I set the pin to input and enable the pull-up, it will read as a 1 if left floating and a 0 if tied to ground, right? Specifically, I want to connect a row of DIP switches between I/O pins and ground so I can read it and set the I2C slave address on a bunch of identical units but I don't want to have to use pull-up resistors if I can avoid it. I hate to ask a newbie question about micros I've used for years but I've actually never used the internal pullups before.

|

|

|

|

Stealth Like posted:I'm specifically trying to amplify an AC signal. I have a waveform generator that feeds a PGA to control amplitude, then feeds that output to a high voltage op amp. ~250 Hz is the lowest frequency I will use, but I will be using a square wave until 10-20 kHz when I switch to a sine wave. ~2-300 kHz is the highest frequency I should need to use, and I'm ok with losing some amplitude at these higher frequencies due to GBW. I should probably specify that I will not be sweeping the frequency. It will be static for a given experiment. You might find it easier to build a push-pull stage from discretes and use an opamp to control that, similar to a ~100W class AB power amplifier but without the power. For a step-up it sounds like you might get good results from using a 10:1 transformer and a sine-wave driver (low noise, half wave rectifiers will give dual outputs from one winding). A straight boost converter for 15V -> 100V is very feasible if you have large inductors on hand, LTSpice has proven pretty good at simulating those circuits. Check the LT1070 design manual if you want to design a switcher, it's good stuff. Hookup will be different for negative output boost, but the datasheet often has an example of how you could do it.

|

|

|

|

BattleMaster posted:Regarding the weak pull-ups on Microchip PIC I/O pins, according to the datasheets (of several models) it seems as though it's some kind of current source rather than a pull-up resistor. Even so, if I set the pin to input and enable the pull-up, it will read as a 1 if left floating and a 0 if tied to ground, right? Heh - I had the same thought of using them for DIP switches, except it was a Microchip IO expander attached to a PIC (MCP23008). I ended up using an external RPACK, mostly because I want to minimize the number of board spins and that was the most risk averse thing. Effectively, they describe it as a 100kOhm resistor, which is really very, very weak (uA of current). I think for a DIP switch application is fine -- as you said, you can have an input with a PU enabled as well, and it should read 1 when the switch is open, and 0 when you close the switch and connect to GND. I have run into problems in the past with the IO structures of other devices and using weak internal PUs/PDs -- devices that implement bus-hold circuitry (like TI logic products with a 'H' designator) can overpower or otherwise render those pulls insufficient due to the cross-coupled inverter (IIRC) they use to implement said hold logic. In this case, since it's just switches, I think you are fine with the internal pullups.

|

|

|

|

longview posted:You might find it easier to build a push-pull stage from discretes and use an opamp to control that, similar to a ~100W class AB power amplifier but without the power. Or maybe use an off-the-shelf part to get the voltage higher than desired, then regulate it back down? Like an EL wire driver or something? Either way, audio amplifiers (the LM3886 specifically, and ones like it) have a very wide voltage range and are generally pretty good at low power. edit: I'm not sure what voltages you have available, but might the best solution be a voltage divider from 110V on the happy side of an isolation transformer?

|

|

|

|

movax posted:Heh - I had the same thought of using them for DIP switches, except it was a Microchip IO expander attached to a PIC (MCP23008). I ended up using an external RPACK, mostly because I want to minimize the number of board spins and that was the most risk averse thing. Groovy; they really meant it when they said it was a "weak" pull up. In any case I'm glad it's an option because I'm planning on making 16 of these things - each micro is meant as a single element in a 4 by 4 array of sensors - so keeping the parts count down will save me a whole bunch of time and money. As it is each board is just going to be a micro, DIP switch package, and some pin headers because Microchip is great about packing in tons of peripherals. I'm also going to use them in a different project for couple of input pins that are connected to a header so that they won't read spurious values when nothing is connected. This time I'm being miserly on parts and board space because I have a design for a Geiger counter that fits in the palm of one's hand and I don't want to ruin that with more parts. Edit: Hahahaha TI wants me to fill out a fuckin' export form just to download software for this Launchpad eval board BattleMaster fucked around with this message at 14:55 on Jul 30, 2014 |

|

|

|

Is this a good place to ask FPGA advice as well, or is there another thread? I am using Spartan 6 XC6SLX9 with a main clock of 50MHz. I have an input signal on a pin which is essentially a clock that operates between 14-16kHz. This is generated by externally connected devices. I would like to output a 6MHz clock on another pin, that is phase locked to the 15kHz input clock. I can easily generate a 6MHz clock through CoreGen, that has (manual) dynamic phase shift support, but I don't really see any obvious way to lock the phase to another input clock. Is this supported, and if so, what's the preferred way of doing it? I can't really generate a 6MHz clock from the 15kHz clock directly, since this clock frequency will vary depending on externally connected devices. Other ideas for generating a 6MHz pulse locked to the ~15kHz input would also be cool.

|

|

|

|

Buffis posted:Is this a good place to ask FPGA advice as well, or is there another thread? There's a Verilog thread in CoC but it doesn't see crazy amounts of activity. Can you run the 6MHz clock through a rising-edge triggered D Flip-Flop with the enable governed by the 15kHz clock?

|

|

|

|

Well I found a solution for my power needs. Pico and EMCO both sell dual output DC/DC supplies that do anywhere from +/- 50 V to 6 kV. They're expensive at $100-130 but it's worth it for me.

|

|

|

|

movax posted:There's a Verilog thread in CoC but it doesn't see crazy amounts of activity. Uh, if the enable is connected to the 15kHz clock, i dont see how I would get 6MHz pulses during the time that clock is low. I still want 6Mhz then, just phase aligned with the 15kHz pulses

|

|

|

|

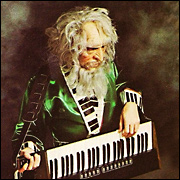

SoundMonkey posted:Or maybe use an off-the-shelf part to get the voltage higher than desired, then regulate it back down? Like an EL wire driver or something? I was leafing through my stack of application notes at work, and found this in Linear AN-18:  It's rated for about 10mA, but only 12 kHz FPBW If the intended output frequency is in the audio band and distortion isn't critical I'd suggest using a low power audio amplifier IC and a step up transformer, a commercial 110V step down transformer would probably work well at <400 Hz. Some tube audio transformers even include an aux winding for feedback from the output.

|

|

|

|

This might be an overly broad question but I haven't had much look googling it. I have a microcontroller (but the same question goes for an FPGA) and it is on an evaluation board (launchpad). Once I have my code all working and tested, how do I go about mounting this IC on a custom PCB? I want to fabricate my own PCB, but I have no idea how/what to connect the pin traces to. I look in the datasheet at the pinout for both the FPGA (spartan 3e on a basys2 board) or the microcontroller (TM4C1294NCPDT on the Tiva C Series TM4C1294 Connected LaunchPad), but it doesn't really provide me with any information beyond what all the pins are for. This might be enough information but I'm not sure how to translate it into a functional PCB. Obviously I know what to do with obvious pins like Vcc or ground, but I'm not sure where to put the coupling/decouping capacitors or whatever else I need to "bias" (I know this is not the correct term, but it conveys the idea I am trying to get across) the IC. I have experience USING these devices through courses, but no experience whatsoever trying to mount the individual chips on my own boards.

|

|

|

|

IratelyBlank posted:This might be an overly broad question but I haven't had much look googling it. I have a microcontroller (but the same question goes for an FPGA) and it is on an evaluation board (launchpad). Once I have my code all working and tested, how do I go about mounting this IC on a custom PCB? I want to fabricate my own PCB, but I have no idea how/what to connect the pin traces to. It's a totally legitimate question! Usually this (and tons of really useful stuff never taught in school) is available in app(lication) notes. For instance, there is a table of app notes which apply to the TM4C12x on TI's "Technical Documents" page. The one you're looking for is called the "System Design Guidelines" and it walks you through exactly how to layout a board for this chip while avoiding common pitfalls. The information in app notes is not necessarily device-specific and by reading them you'll learn best practices that apply to almost every micro/FPGA/etc. You'll soon learn that some companies produce amazing app notes (TI is an example, as is Analog Devices) while others' are really lacking.

|

|

|

|

Buffis posted:Uh, if the enable is connected to the 15kHz clock, i dont see how I would get 6MHz pulses during the time that clock is low. I still want 6Mhz then, just phase aligned with the 15kHz pulses I don't entirely follow. You just want 6 million pulses per second and you want those pulses aligned to another 15kHz clock? Given that the frequencies aren't multiples of one another you'll obviously have a varying period on the 6MHz clock. So you can take the known 50Mhz clock (it's accurate right?), use it to generate an internal 6 (exact will be hard, but you can get reasonably close by counting ~9 50Mhz clocks). Then rebuffer that internal 6MHz with a flip-flob clocked to the 14-16MHz.

|

|

|

|

ANIME AKBAR posted:High frequency PWM can't do anything about the 120Hz ripple inherent to a single phase DC/AC converter. That frequency isn't allowed to change, so the energy ripple always has to be dealt with by using energy storage. I'm not an EE by any stretch, but I was thinking about this. Instead of PWM, couldn't you have a high-speed DAC drive a MOSFET for each side of the waveform? Then you wouldn't have the sharp square-wave effects to dampen later. I was thinking the high-speed microcontroller could adaptively "learn" the input/output curve of the MOSFET using a PID controller against the output voltage. Again, I'm not an EE, so I'm just duct-taping together the concepts I do know.

|

|

|

|

Does anyone know much about EDM/electro-discharge machining? It's basically sending a pulse through an electrode to erode away part of a metal workpiece. I hope to do burn PCBs with it. I've done a poo poo ton of research lately, and while there are some impressive garage CNC builds, the electronics are all really really basic. Usually consisting of a 555 pulse generator and some lightbulbs pretending to be power resistors. There isn't a whole lot published on design considerations (it's all very proprietary), but I think I want these parameters: 30-80VDC. Max 4A. Frequency 20kHz-100kHz. Rise/fall times of less than 20ns. Here's what I think is right:  (I marked it up a little after leaving behind my Altium license at work) The important switching stuff can (and should) be controlled by PIC so I have flexibility in tweaking settings. I've got a transformer that should give me about 80VDC after rectifying. Any suggestions? Better schematic ideas? The idea is to measure voltage with an ADC, and switch the "charge" MOSFET to get around whatever voltage I want to try. I haven't done any inductance calculations, so the values posted may not work. Also may need a series resistor, I'm not sure. I wouldn't mind having 4 amps at lower voltage, too, but there's no easy way to do that. edit: this is kind of a clever way of choosing resistance. The capacitor box is unnecessary with proper control, though. ante fucked around with this message at 07:00 on Jul 31, 2014 |

|

|

|

Stabby McDamage posted:I'm not an EE by any stretch, but I was thinking about this. You can't drive the MOSFET in the linear region without massive losses. The idea is to switch the MOSFET as quickly as possible because both on and off are lossless (ideally) states but in between burns a lot of heat. asdf32 fucked around with this message at 18:05 on Jul 31, 2014 |

|

|

|

asdf32 posted:You can't drive the MOSFET in the linear region without massive losses. The idea is to switch the MOSFET as quickly as possible because both on and off are lossless (ideally) states but in between burns a lot of heat. Ah, thanks. Is there such a thing as a semiconductor that can allow through partial analog voltage (i.e. not PWM'd) without burning off the excess as heat? I suspect the answer is "no, because physics", but I'm not sure.

|

|

|

|

Stabby McDamage posted:Ah, thanks. Is there such a thing as a semiconductor that can allow through partial analog voltage (i.e. not PWM'd) without burning off the excess as heat? Well, the issue isn't that you can't use a mosfet in it's linear region---you totally can. However, a lot of mosfets are designed as to be used as switches, and consequently they don't have a great linear behavior. There are still a lot of great linear amplifiers that can be made with mosfets--googling "mosfet amplifier" will provide you with a bunch of material on how to design one. However, for audio amplifiers, mosfets often get used as "class d amplifiers", where they are used as high speed power switches, and then the output signal is filtered to get the desired output. They are more efficient (I think), but not suitable for everything.

|

|

|

|

Whats a good soldering iron that can be used to move a resistor on a motherboard? I need to move a 0 ohm resistor or make a new connection in order to use a 6 core processor on the board.  Would a conductive pen work here after removing resistor at 538? I'm out warranty on the board so it'll cost $50 to ship the board back to EVGA to have it done. Want to use a Xeon x5650 on this board (EVGA X58 SLI).

|

|

|

|

Stabby McDamage posted:Ah, thanks. Is there such a thing as a semiconductor that can allow through partial analog voltage (i.e. not PWM'd) without burning off the excess as heat? Right it's ohms law. Voltage * Current = Power (heat). So if this inverter is taking in 400V and you're driving the mosftet such that you get 200V out that's a 200V drop. Even an amp is 200 watts. You just can't leave it in this state. This is why on (0V) and off (0A) are essentially lossless states. Linear components approximate resistors and there is always heat dissipation in proportion to the current. Linear regulators are exactly the same. The exception is reactive components - inductors and capacitors. Inductors and capacitors ideally will never dissipate any energy, and will store energy that's provided to them.

|

|

|

|

KennyLoggins posted:Whats a good soldering iron that can be used to move a resistor on a motherboard? My guess is those are EIA 0402 at the smallest; you can easily do that with your average Weller WESD50 or similar with a relatively fine tip. Those are just strapping resistors, so I would expect the pads to be thermally relieved, meaning you should not need to use a larger tip iron. If your local makerspace is fortunate enough to have a Hakko or Metcal with the tweezer attachment, this gets even easier. Not too bad with a single tip though, you can just blob a small amount of solder intentionally to bridge and heat both sides equally. If you do that, you'll need a replacement resistor most likely; are they 10K or 0R jumpers? You can order like 100 0R jumpers for a few bucks from Digi-Key.

|

|

|

|

Is there an easy way / tool to invert the polarity of Gerber layers? Apparently OSH Park is maker-centric enough that they want internal layers/planes as positives

|

|

|

|

movax posted:My guess is those are EIA 0402 at the smallest; you can easily do that with your average Weller WESD50 or similar with a relatively fine tip. Those are just strapping resistors, so I would expect the pads to be thermally relieved, meaning you should not need to use a larger tip iron. I have no idea what resistor it is. I saw a thread on the EVGA support forums and some people said they moved the resistor or just used solder to make the new connection at 539. Given I don't have a soldering iron or any experience and would like to do it on the cheap I figured just removing the resistor and using a conductive pen would suffice.

|

|

|

|

KennyLoggins posted:I have no idea what resistor it is. I saw a thread on the EVGA support forums and some people said they moved the resistor or just used solder to make the new connection at 539. Given I don't have a soldering iron or any experience and would like to do it on the cheap I figured just removing the resistor and using a conductive pen would suffice. In this context, you can pretend "0 ohm resistor" means a wire or just a solder bridge. You're breaking the connection between one set of pads and making a new one between a different set.

|

|

|

|

TasogareNoKagi posted:In this context, you can pretend "0 ohm resistor" means a wire or just a solder bridge. You're breaking the connection between one set of pads and making a new one between a different set. Basically it's a jumper, except they figure few enough people will use the feature that it doesn't justify the cost of actually just using a pair of jumpers.

|

|

|

|

Thanks for the input. http://www.amazon.com/Elenco-Electronics-ST-12-Soldering-Tool/dp/B0002LLWZY/ref=pd_tcs_subst_hi_1?ie=UTF8&refRID=0A5R9862HRNV8CYNSN1P http://www.amazon.com/Weller-SP40NKUS-Watt-Soldering-Black/dp/B00B3SG7F0/ref=pd_tcs_subst_hi_2?ie=UTF8&refRID=034CXKBTBXR7F9CPBQWQ Which would be better suited for what I'm looking to do?

|

|

|

|

With a cheap soldering iron, your best bet is to use a small chisel tip to heat both leads of the resistor at the same time, from the side of the resistor. I'd go for the weller, just because it's a well known brand (and apparently comes with a small chisel tip).

|

|

|

|

|

meatpotato posted:It's a totally legitimate question! Usually this (and tons of really useful stuff never taught in school) is available in app(lication) notes. For instance, there is a table of app notes which apply to the TM4C12x on TI's "Technical Documents" page. The one you're looking for is called the "System Design Guidelines" and it walks you through exactly how to layout a board for this chip while avoiding common pitfalls. The information in app notes is not necessarily device-specific and by reading them you'll learn best practices that apply to almost every micro/FPGA/etc. You'll soon learn that some companies produce amazing app notes (TI is an example, as is Analog Devices) while others' are really lacking. Another way to do it is to

|

|

|

|

I think this is the right place to post this question. I'm using LabVIEW to control a set of stepper motors through an Arduino with LIFA. I would like for the stepper motors to have a smooth custom velocity profile. The subVI I'm using (Stepper Write.vi, I think this is a standard one), only gives a trapezoidal velocity profile. When I try to feed a new velocity value to the subVI, the motor stops, then enters a new trapezoidal profile. This makes coordinating motion between two motors difficult or impossible. Is there any way to use Stepper Write to get a smooth profile? Is there some other way to approach this? I'm looking into LINX but I don't really know anything about it and also I am pretty lovely at LabVIEW.

|

|

|

|

So I finally got my first PCBs shipped (technically second but the first company Fusion PCB was crap boards so I re-ordered through Sunstone). Got most of the parts soldered on and plugged it in hesitantly waiting for it to explode in my face. All looks good! Power LED came right up and nothing seems to be overheating. I realized though that the reset LED is stuck on when the reset button is not being pushed cause I'm dumb and forget that its ~RESET on the Atmel chip I'm using.

|

|

|

|

|

Popete posted:So I finally got my first PCBs shipped (technically second but the first company Fusion PCB was crap boards so I re-ordered through Sunstone). Got most of the parts soldered on and plugged it in hesitantly waiting for it to explode in my face. All looks good! Power LED came right up and nothing seems to be overheating. I realized though that the reset LED is stuck on when the reset button is not being pushed cause I'm dumb and forget that its ~RESET on the Atmel chip I'm using. That's not a mistake at all, you just have a "Not Resetting" indicator now!

|

|

|

|

Alfred P. Pseudonym posted:I think this is the right place to post this question. I'll assume you're comfortable with LabVIEW, but if you're comfortable with the Ardunio code, you might want to consider writing a basic serial out sub-VI for whatever minimum parameters you need and having the Arduino do the rest. The Arduino will handle the delays you'll need far better than LabVIEW will. I don't know how hard it is to deal with basic serial-over-USB in LabVIEW, since my professors had us using DB-25 and DB-9

|

|

|

|

|

| # ? Jun 11, 2024 22:23 |

|

Popete posted:So I finally got my first PCBs shipped (technically second but the first company Fusion PCB was crap boards so I re-ordered through Sunstone). Got most of the parts soldered on and plugged it in hesitantly waiting for it to explode in my face. All looks good! Power LED came right up and nothing seems to be overheating. I realized though that the reset LED is stuck on when the reset button is not being pushed cause I'm dumb and forget that its ~RESET on the Atmel chip I'm using. Curious, what kind of price were you looking at? I know there are shitloads of variables of course but still

|

|

|