|

Haikeeba! posted:I really like that table. Simple and elegant. What sort of joinery did you use? I've been playing around with some types i don't normally use, like mortice and tenon joins recently, so I'd be interested to know how you did it. The top is built on a piece of 1/4" MDF, since I needed support for the tiles. So the boards that form the tabletop are simply glued to the MDF and each other. The legs are put together with glue and dowel pins. I just used a hand drill for those - in retrospect, I should have built some kind of simple jig, and a drill press would have been handy, but it came out alright. Its sturdy enough that I can sit on it, but I'm not sure it's terribly strong.

|

|

|

|

|

| # ? Apr 20, 2024 13:09 |

|

The project was to make a new monitor stand for my LCD tv/hd monitor. One of the reasons other then the stock stand was junk was to be able to play Ikaruga with the monitor set vertically. A couple days ago I finally found a cheap lcd mount that was on clearance, so the game was on. Heres a before pic.  I forgot to take the camera to the wood shop so all I have are the assembly of the monitor to the stand. Back of stand and the mounting plate.  Mounting the plate on monitor.  I made sure to make room for the cords.  Here it is set up in the little stand I made.  and set vertical for HD Ikaruga awesomeness.  To finish it I will just do a light rubbed on coat of French Lacquer.

|

|

|

|

This was Victoria day long weekend for us filthy Canadians, and I needed a proper forge. So, I bought a big stainless bowl, cut two holes in the sides, mounted a 2 inch pipe in the middle and attached it to a tool stand I built. Then I found a place that sells refractory cement, which is like normal cement, except it doesn't disintegrate at high heat. Here's the little one that I made a couple weeks ago, the original version was pretty lousy, so I cut some slots in the ends and added some cement to improve it. It's much more useful now.  (Click for big.) This is the new model, partially finished. The refractory cement has cured for 2 days and is ready to be heated.   A bathroom exhaust fan makes an acceptable blower, and it heats the steel very quickly.  This is a 10 foot windsock "flagpole" I made out of a 3/4 inch rod, halfway through.  Here's the finished pole, millscale polished off, and freshly painted.  I'm sorry I don't have any pictures of hot iron, it's hard to take a good picture of that by yourself. I was really happy with how these projects turned out, it heats easily, and I can get pretty much any shape/size of steel into it.

|

|

|

|

Ignoramus posted:Im making a box out of a hollow nintendo and an old crappy humidor. I don't suppose you have the guts from the NES still laying around do you? I'd be willing to buy them off you if you'd like to get rid of them...

|

|

|

|

A quick and easy pizza peel. Peels aren't quite as easy to find in stores as stones are, so it's a handy and easy project.

|

|

|

|

disco volante posted:A quick and easy pizza peel. Peels aren't quite as easy to find in stores as stones are, so it's a handy and easy project. Care to explain how you made this? I am looking to build my own outdoor pizza oven some day when the husband and I have a house of our own and I would love to make something like this. Pizza stones are nice and all, but a peel would be fantastic. I am in no way educated about carpentry. Any help would be greatly appreciated.

|

|

|

|

It's a pretty easy project all in all. I used clear spruce battons or burlaps which you can get at any home center or building supply store. They are about 1.25" wide and maybe 3/8" thick. The edges are rounded over slightly, so I used a table saw to snip off 1/8" off each side, leaving me with perfectly squared up edges suited for gluing. Spruce has, I think, the best strength to weight ratio of all the common woods. That said, a nice piece of maple would be so much sturdier and nicer looking for a project like this, but I used what I had around, and it should work fine, though it's a little soft compared to a nice hardwood. Anyhow, regardless of what type of wood you go with, what follows is the most important part to get right. You need to arrange your strips until they form the rough shape of your future peel. Use a jointer, table saw or hand plane (whatever you have) to get the edges good and square. You don't want to see any gaps between the pieces. Use pipe or bar clamps to apply end to end pressure, making sure you also apply weight from above to prevent the board from cupping up as it adjusts to the lateral pressure. I used cinder blocks for this step, but if you happen to have high quality bar clamps, you may not need to bother since they tend to apply nice, even pressure parallel with the work. I didn't take many pictures of the construction process, but here's an annotated illustration of the board before it was glued and clamped.  After gluing I used the same method to fix a reinforcing piece on the tongue of the peel. Shaping can be accomplished a number of ways depending on what tools you have available. I used a jigsaw to cut out a template, and the used a router with a trim bit to trace along the pattern. This ensures that your work will be symmetrical, since you only cut out one half of the pattern, and then flip it to cut the other side. Then sand the whole thing good and flat. If you were careful during glue up, you shouldn't need to do much to level the surface. This may either make no sense, or it may be completely obvious. The project invokes some fairly standard woodworking tools and techniques, so you may find just by looking at it carefully you can guess what I did.

|

|

|

|

This is my desktop computer case. The only hardware I've upgraded in 3 years is the video card, but I've been modding the case. First, here is the tower in normal operation and in "super-bright" mode. The four front LEDs were keeping me awake, so I wired a switch to turn them off. I also added a couple 12v fluorescent lights for the inside, which are easily bright enough to read by. In retrospect, they're overkill.  Here, you can see the light switch for the lights, and... INTERNAL SPEAKERS! I had a crappy pair of desk speakers lying around and decided to take them apart and integrate them into my case. The black toggle adjacent to the light switch controls whether the computer's audio goes to internal or external speakers.  Here's the board for the speakers' amps and such. Volume, treble, bass knobs which I don't touch anymore. The board is wrapped in an old antistatic bag (conductivity barrier), and placed inside the metal enclosure from a broken CD drive. The light/audio switches are directly in front of this.  And here's the power supply for the speakers -- it's a 12v transformer screwed directly to the computer power supply, with wires soldered to the 120vac points inside.

|

|

|

|

I had some scraps laying around (actually a lot of them) and made a little gift box. and lined it with some felt over posterboard:

|

|

|

|

tempo502 posted:Here's a couple custom electronics projects that basically worked, but didn't end up being usable: I'm sure I've told you this before, but you sure have a knack for making things more complicated than they need to be.

|

|

|

|

eddiewalker posted:I'm sure I've told you this before, but you sure have a knack for making things more complicated than they need to be. touche.

|

|

|

|

My shop has been without a router table for far too long - store bought millwork is way too expensive, and the wood will never match the rest of my project. So I bought this one a while ago, and finally built a suitable home for it this weekend. A really basic stand/cabinet outfit made mostly of 3/4" MDF. Joints between panels were dadoed for added stability. I made standard frame/panel doors for aesthetic reasons. I made space inside for these plastic drawers that had recently been made vacant after I cleaned out my room and got rid of the old computer parts that they had once contained.  I might put it on casters; my workshop is so small I can expect to be moving it a lot. funny song about politics fucked around with this message at 01:40 on May 29, 2008 |

|

|

|

Nice job on that router table/cabinet Disco, very professional looking. I wish I had your skill level. I improved my forge over the weekend, drilled some holes so I could secure a lid on it, and mounted the blower fan on a rod underneath the firepot. It's much more convienient to use now that I don't have to line up some workstands as a table to put the blower on.  I'm working on some tongs from ridiculously huge stock as practice (because, man, do I need it). Forge still heats nicely. Shows better at night, too.

|

|

|

|

I'm thinking about making a solar powered cooling thing for my car. I got the idea after seeing the aptera and reading about how the solar panels on the roof provide power to the climate control which makes it run slowly all day instead of blasting it only while driving. I couldn't find an actual a/c unit small enough for my needs, but I did some digging and I "think" I've figured out what I could do. I found a single bottle wine cooler that chills bottles down to 24 degrees. I was thinking of rigging up a fan system to blow into one half of the container and have it come out the other half. I would also have a fan to pipe hot air out of the car. Right now this is all ideas and doodles, so I thought I'd get some feedback on what people with more experience thought before I actually went and bought anything.

|

|

|

|

What you want are talking about are peltier coolers, which is what's in that single bottle wine cooler- remember nothing can magically generate cold; so while one side of the cooler gets cold the other side gets hot, hence either the hot side must be vented outside the vehicle, or it must actually be outside the vehicle, if you put a peltier inside a vehicle without venting or proper placement it will have a net heat gain, and actually make the inside of the car warmer. Peltiers are a good low cost solution to get an electrical cooling effect, but they will require some engineering to get right; it might work better if you combined a peltier with a water cooling system of some kid to displace the majority of the heat outside the vehicle.

|

|

|

|

That's what I was thinking. I already had a plan to vent the hot air outside, but I like the idea of water cooling. I might be able to rig up a cpu water cooler to the peltier system and install the exhaust...under the car or something. Two tubes of fluid would be much easier to route to the outside of a car than a large vent. Thanks for the ideas!

|

|

|

|

Peantoo posted:That's what I was thinking. I already had a plan to vent the hot air outside, but I like the idea of water cooling. I might be able to rig up a cpu water cooler to the peltier system and install the exhaust...under the car or something. Two tubes of fluid would be much easier to route to the outside of a car than a large vent. Thanks for the ideas! Based on a 5 minute analysis I think you'll have quite a bit of trouble cooling a car like that. Full sunlight delivers around 1000 watts / meter ^2 and your car has a square meter or two of surface area exposed to the sun. So if you want to keep the car's temp. equal to the outside temp. your cooling system is going to have to move at least a kilowatt. Those wine coolers work at lower power because they're removing energy from an insulated box so the conduction of heat back in is small. If you have [thermal energy out] > [thermal energy in] and [thermal energy in] is small, the inside of the box cools and it takes little power to do so. A car is very far from an insulated box and getting [thermal out] > [thermal in] will take significantly more power. A simpler solution would be a solar powered fan that vents the hot air to the outside .

|

|

|

|

This is true. The sun will deposit a colossal amount heat in your car and actively removing it would require a gigantic cooling system. You can consider, just as shorthand, the fact that your car's built in air conditioning compressor, being sufficient to cool the car down, requires a notable amount of energy to operate (enough that it makes an appreciable difference in fuel economy). It's unlikely that you'll be able to muster that much solar power, and no matter what means you use to actively remove heat (be it evaporative, thermoelectric, etc.) you'll be facing similar energy demands. My dream system would be to somehow run your car's existing blower off of solar energy, thus keeping air moving through it. You could, at best, get the inside temperature of your car equal with the outside temperature, but that's much better than the greenhouse temperatures cars can reach with no air movement.

|

|

|

|

EigenKet posted:Based on a 5 minute analysis I think you'll have quite a bit of trouble cooling a car like that. Like this?

|

|

|

|

poeticoddity posted:Like this? Exactly, except buying an already made one is no fun.

|

|

|

|

poeticoddity posted:Like this? My friend's mom was looking at buying one of those, specifically a solar powered one that would fit in your window if you cracked it a bit. . .. I suggested she just crack her windows an inch and call it a day, convection will take care of the rest.

|

|

|

|

Hadlock posted:I suggested she just crack her windows an inch and call it a day, convection will take care of the rest. That's also no fun. and lets bugs / rain in.

|

|

|

|

I have one of those already and that's kind of where I got the idea. It also came from the fact that what I'm suggesting is what the Aptera does. I was just trying to figure out a way to take their idea, home build it, and install it on my car. I guess they must do something different...

|

|

|

|

disco volante posted:This is true. The sun will deposit a colossal amount heat in your car and actively removing it would require a gigantic cooling system. You can consider, just as shorthand, the fact that your car's built in air conditioning compressor, being sufficient to cool the car down, requires a notable amount of energy to operate (enough that it makes an appreciable difference in fuel economy). It's unlikely that you'll be able to muster that much solar power, and no matter what means you use to actively remove heat (be it evaporative, thermoelectric, etc.) you'll be facing similar energy demands. What if I just put one of those reflector thingers in my windshield and tinted the others a lot? Then the solar panel on the roof would absorb/reflect a lot. That would heavily reduce the heat getting in, wouldn't it?

|

|

|

|

Peantoo posted:What if I just put one of those reflector thingers in my windshield and tinted the others a lot? Then the solar panel on the roof would absorb/reflect a lot. That would heavily reduce the heat getting in, wouldn't it? Actually by nature of what they are solar panels do an excellent job of absorbing light (and therefore creating heat), but a 3cm gap between panel and roof would prevent that from transferring through.

|

|

|

|

So possibly 3 cm of insulation perhaps? Damnit, I am going to do whatever I can to make this idea work in some way.

|

|

|

|

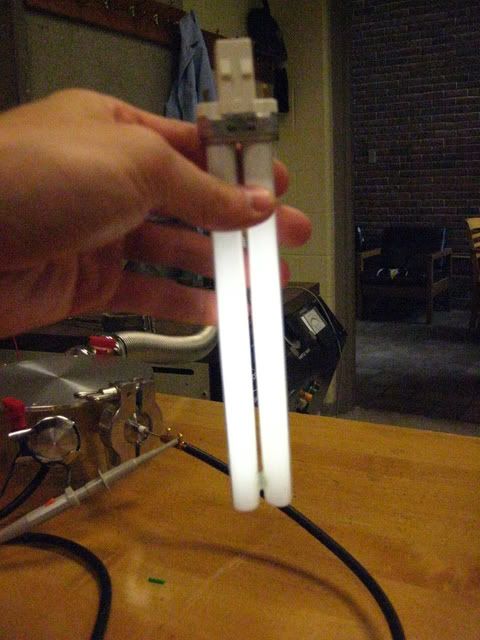

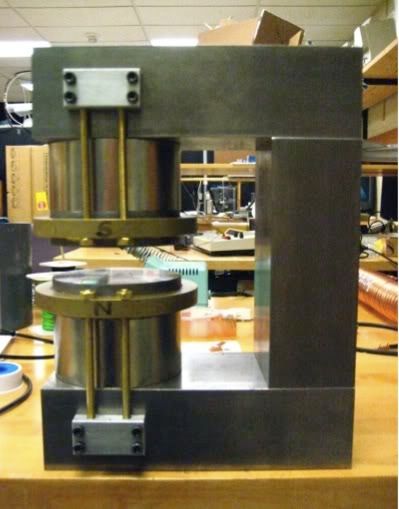

My senior capstone project (physics major) was to build a permanent magnet cyclotron. Here's a few pictures.

|

|

|

|

What does that do? Did you do the machining yourself?

|

|

|

|

Squier posted:My senior capstone project (physics major) was to build a permanent magnet cyclotron. Here's a few pictures. sweet, what energy do you get? Can you get x-rays? gamma? I have a physics project I'm working on. It's for biophysics, so no accelerator, but we do have lasers. pew pew! I'm building an intensity autocorrelator to measure the shape of our pulse. http://en.wikipedia.org/wiki/Optical_autocorrelation RealKyleH posted:What does that do? Did you do the machining yourself? it's a particle accelerator (a small one) http://en.wikipedia.org/wiki/Cyclotron EigenKet fucked around with this message at 07:50 on Jun 13, 2008 |

|

|

|

Last summer I built a TV stand by laminating strips of plywood end to end. The pieces were stacked vertically, with a large concrete top on which the television sat. The inside was hollow and virtually unusable (what with having a tv and a block of concrete on top). I brought it home this summer and set about refinishing it and making it better looking a more practical. It is now a much lighter color, the concrete top is gone, the edges have been rounded over, the inside smoothed over and painted flat black (for that 'all consuming black hole' look) and the box sits on its side for a better flowing look. I just finished painting the inside the other day, so here it is:

|

|

|

|

disco volante posted:Last summer I built a TV stand by laminating strips of plywood end to end. The pieces were stacked vertically, with a large concrete top on which the television sat. The inside was hollow and virtually unusable (what with having a tv and a block of concrete on top). I brought it home this summer and set about refinishing it and making it better looking a more practical. It is now a much lighter color, the concrete top is gone, the edges have been rounded over, the inside smoothed over and painted flat black (for that 'all consuming black hole' look) and the box sits on its side for a better flowing look. I just finished painting the inside the other day, so here it is: Thats awesome to. I have been wanting to do a coffee table with a stacked plywood top for a long time, but I need to get a table saw first to make the cuts. I think a lot of people go a long way to cover up the the signs that something is plywood, but I think it it looks awesome.

|

|

|

|

I finally finished my 2 foot long tongs after loving around with them for days. I also cut some 2 x 3/4" bar stock and started work on a tenon maker.  I'll be cutting this in half, lining the troughs up, and welding a small spring so it opens like a V. Then I can heat up square material and form it down into a uniform round shape that I can use to hold large objects together without welding them.  An iron tenon is kind of like a rivet, except instead of going through 2 plates, it goes through one. I couldn't find any decent images of iron tenons, but it's like this:  Except it will be round, and when I attach them I will heat it up and flatten the tip on the other side. The worst part is, when I was making the tongs, I tried to punch the hole for rivet but I guess I was too slow. The punch softened up and the tip spread out inside the neck of the tong. Tried to drill it out from the other side, but of course, the high carbon steel of the punch made my drill bit drift and miss it (also ruined the bit

|

|

|

|

Like Slung Blade, I'm into blacksmithing. Unlike him, I don't have my own forge yet. The handle and bolster are still works in progress, and the blade still needs more polishing, but here's my very first knife!

|

|

|

|

Third Murderer posted:Like Slung Blade, I'm into blacksmithing. Man, that knife is awesome, great work. What kind of steel is it? 1095? gently caress, I wish there was a centre like that Peter's valley near me. Knifemaking, advanced blacksmithing, loving damascus classes by Don Fogg? Holy poo poo man, you lucky bastard. Take more courses so we can restart the blacksmithing megathread

|

|

|

|

Slung Blade posted:

"1084," which apparently can mean just about anything - it's not actually manufactued to that specification, and anything labeled as such varies in actual carbon content. It is high carbon steel, I know that much. I wanted to try something with that Damascus billet I made last year, but I didn't have the time. Also I screwed up my first two attempts at forging a knife and wasn't feeling confident enough to risk my nice material! I might try to find some spare time later this summer for that. Slung Blade posted:gently caress, I wish there was a centre like that Peter's valley near me. Knifemaking, advanced blacksmithing, loving damascus classes by Don Fogg? Holy poo poo man, you lucky bastard. I'm already registered for two more classes this summer, one of which is Don Fogg's class.

|

|

|

|

I still want to try making damascus, but I don't know if I can get my charcoal forge hot enough. Maybe if I make a pile of fuel 2 feet high and get an 80 cfm blower... Still, I have a few parts I need to make a gas forge, I'll get around to it eventually. Please post pictures when you get done with your other courses, I'd love to see them.

|

|

|

|

Third Murderer posted:"1084," which apparently can mean just about anything - it's not actually manufactued to that specification, and anything labeled as such varies in actual carbon content. It is high carbon steel, I know that much. If it is 1080 steel (I couldn't find anything about 1084) its probably at 30+ Rockwell depending on how you quenched it. Very hard. If you know the approx temps and whether it was water cooled, oil cooled, etc you can look up its properties at http://www.matweb.com/. You might find that you could buy some tool steel from your local material drops retailer and get a harder knife that may have more desirable properties. (Plus I think its just fun to compare them.)

|

|

|

|

Slung Blade posted:Please post pictures when you get done with your other courses, I'd love to see them. You bet! RealKyleH posted:If it is 1080 steel (I couldn't find anything about 1084) its probably at 30+ Rockwell depending on how you quenched it. Very hard. If you know the approx temps and whether it was water cooled, oil cooled, etc you can look up its properties at http://www.matweb.com/. I'm not a chemist or a metallurgist or anything like that, so Rockwell numbers don't really mean much to me to be honest. There was a brief explanation of how the steel transforms from pearlite to austerite to martensite, leaving it brittle, and then the tempering toughens (or softens, depending on how hot you get it) the material. I took notes, but I'd be lying if I claimed to really understand the chemistry behind it.

|

|

|

|

30 Rockwell C is pretty fuckin' hard. It is about as hard as a forged steel crankshaft in a race car. (Depending on a lot of variables including whether you measure at the surface or measure in the center) For comparison's sake a HSS drill bit would be about 60 Rockwell C. They have several Rockwell scales, (A-E if I remember correctly.) If you found metallurgy interesting its really not hard to understand form a "how it works" perspective. I couldn't do the math or anything but just reading quite a bit I know the hardness, machineability and properties of the more common materials.

|

|

|

|

|

| # ? Apr 20, 2024 13:09 |

|

Projects? Many. Here's a link to a description of the latest one, a flop. http://monocerosfour.livejournal.com/3793.html Yeah, I actually tried this at home. For fun. An austere and laborious sort of fun. EDIT: Error of first attempt almost fifteen percent (low). Error of second attempt -1.1%. I'm getting there. monoceros4 fucked around with this message at 07:36 on Jun 20, 2008 |

|

|

the Mods, they knew!

the Mods, they knew!