|

HOORAY! I haven't been in the DIY forum in a while, and just ran across this thread today. Fun! I'm mostly an oxy-acetylene guy, specializing primarily in small scale sheet metal welding, producing the fun stuff you see in the welded figurines thread in SA-Mart. That started out with me trying to figure out what to do with a bunch of extra automotive sheet metal I had sitting around. In the case of the figurines with the oxy-acet torch, laying down beads is out of the question. You just melt the sheet together using coat-hanger wire as filler, and voila! It's probably akin to melting plastic together, really. I also bang around on a couple of arc welders; I've got a little 100 amp AC welder, and a 295/195 amp AC/DC welder. I've got a TIG kit for it as well, plus a high-frequency attachment, but I haven't gotten around to buying an argon tank yet. I really haven't decided if I want to try my hand at TIG at all, or if I'll sell the kit instead. TIG consumables are pricy, aren't they? How quickly does one typically go through them? And how much gas is generally used in TIG? I suppose if I had a TIG setup, I'd weld different things... but at the moment, since I'm just making figurines, I can't really see an immediate need for TIG. But who knows... I've got a Datsun 510 that I need to fab up some parts for, so maybe having one around will be handy.

|

|

|

|

|

| # ¿ May 4, 2024 09:32 |

|

Slung Blade posted:If you enjoy oxy/acetylene welding, you'll probably enjoy TIG welding, they're quite similar, except with TIG, you don't have to gently caress around with balancing the 2 gas pressures. The TIG electrodes last quite a long time, they're somewhat pricy, but considering they're not actually going into the weld, they hold up pretty well from what I've seen. With the small scale welding that I do, the balancing of the gasses is actually not an issue. If you do it long enough, you can almost do it by ear, since the change in pressure creates a different sound. As for rods... ha. I'm using coat-hanger wire.

|

|

|

|

Slung Blade posted:I hate to triple post (god dammit you guys post some project images, I don't care if they're not done < Wow - I had no idea what it was you were making. That's fantastic! Now, I'm in the insurance business, and I do know that having secured bars over a window poses a life-safety risk, on account of people being unable to flee through the window in the event of a fire. If your friend has fire insurance of any kind, and the insurance company does a periodic inspection, they may hear about it. Just giving you a heads up. Not sure if there's any kind of quick-release mechanism on there...

|

|

|

|

Slung Blade posted:The basement is unfinished and will remain so, it's his gym area. There's another window on the other side about 15 feet away that has no security bar that's better suited to escape, as the fence is farther away from it, and it's closer to the gate to get out of the yard. Yeah - if there's another escape route, that should be fine.

|

|

|

|

I've been hunting around on craigslist for an anvil, since I'm interested in doing some more hammer work, but I've been balking at the $150 to $400 price tag I've seen on them. However, I happened to swing by a garage sale today, and the guy was selling his late father-in-law's old metal working tools. And I found this: It's not a big anvil (just 25lbs and 19" long, made from a railroad tie), but as I'm only really working with automotive-sized sheet metal, nails and coat-hangers, this thing is perfect. Total price: $6. And that included the hammer. Woo hoo.

|

|

|

|

This is a true story: I'm going to build a forge this winter. Half to add to my metal-working inventory, and half to keep warm while staying outside, because outside is more fun than inside.

|

|

|

|

Now that I've got a little anvil, I'm thinking about building a forge. I have an old oversized woodstove that I picked up for free that included woodstove firebricks. Any words of advice or caution regarding converting it into a forge? Also, does anybody know what it typically costs to have a machine shop mill down the surface of a 19-inch section of railroad track? I'd like the surface to be smooth, but if it's going to cost me $100 to do it, I'd just as soon save up and buy a proper anvil.

|

|

|

|

My woodstove, hopefully to become my forge. Or maybe raw material for a forge...

|

|

|

|

Slung Blade posted:Hmm, it's awfully large inside. Yeah, after I opened it up, I remembered how big it is. A couple of years back, I cut my christmas tree in half and stuffed the entire thing inside. Maybe cutting it up and welding together a smaller chamber (and making better use of the firebricks; I just now realized that the floor and ceiling are lined with the bricks, but not the walls) would be a better option.

|

|

|

|

dv6speed posted:Is that steel or cast iron? Cast iron IS weldable, but unless your a pro, you probably don't want to attempt it. Even pro's have a hard time with cast iron. Oh, it's not cast iron. It's plate-steel. In fact, the previous owner actually built the woodstove by welding it up. The doors might be cast iron, but the body isn't.

|

|

|

|

Slung Blade posted:I didn't weld anything yesterday, or today. I was still frustrated. But I did do a little forging. Ah, looks fun. Sucks about the glass. Do you have neighbors? I live in a neighborhood, and I'm concerned that the ringing of the anvil is going to cause some trouble.

|

|

|

|

Regarding making a forge... I've seen some open-top forges and some enclosed forges. Any thoughts to the pros/cons of either? My initial assumption is that an enclosed forge will be more efficient, since it'll keep the heat contained a bit better -- you'll use less fuel, whether it's coal or propane. Thoughts? I ran across this link: http://cr4.globalspec.com/blogentry/6502/DIY-Blacksmith-Forge It seems like a pretty good design for the open-top forge, but again... all I can think about is the loss of heat. Is that not an issue?

|

|

|

|

Slung Blade posted:Gas forges should always be enclosed regardless of location, since usually the gas burner is coming in from the top of the forge itself, I can't say I've ever seen a burner that works from the bottom. Oh, interesting. I always assumed (since I haven't looked very closely) that a gas forge *did* work from the bottom, and looked just like a solid-fuel burner, minus the solid fuel. I looked around and found these two, which are enclosed: http://www.zoellerforge.com/squareforge.html http://www.zoellerforge.com/miniforge.html So what's the benefit of gas fuel verses solid fuel?

|

|

|

|

Well, I thought about spending a bunch of time building up a forge, but I found one on craigslist for $100, and I'm picking it up tonight. I'll take some pictures when I get it home, if it's still light out.

|

|

|

|

FORGE! Craigslist for $100. The hand-crank blower is in perfect condition, too. Fun.

|

|

|

|

Dongsmith posted:Nice find! A hand-crank blower is a great thing to have, and next on my list after a post vice. It's got that rack on it. Do the coals/charcoal go on top of the rack, or under it?

|

|

|

|

Looks like I found a good use for the firebricks in that old fireplace:  Would forming a full box out of the firebricks (walls, lid, and one opening) be an even better arrangement? I imagine that containing all the heat would make things hotter...

|

|

|

|

Also, where does one get charcoal for their forge? I just threw on some quick-light BBQ briquettes, just to see what would happen... haha.

|

|

|

|

Walmart. That should work. Thanks. As for the workpiece... I wasn't really working it. I was just taking a picture. haha... I did get it red-hot, though, and then took some plyers and bent it, and then used it to move my briquettes around. I guess I made my first tool.

|

|

|

|

Some work on the metal workshop: I'm a big fan of the step-by-step photos, since they tell a good story. Here's the starting place for my metal workshop, with a bunch of lumber sitting there. The welding table is on the left, and the forge is there on the right. Until this picture, the welding table was on my covered deck, but I felt that the fire hazard right up next to my house wasn't a very good idea.  Here you can see that the work space is right there next to my chicken coop. Hope they don't mind the noise.  Next day, got some framing done. The main walls are 6-feet tall, and the taller sections are 8-feet tall. I have a taller section in there because I know that an overhead swing of my hammer will require a taller-than-6-feet ceiling. ... I noticed that it was awfully tall next to that fence. I asked my neighbor if it was going to be an eyesore, and he said he wouldn't mind. But then he said that he wasn't sure what his wife was going to think, so I decided to prevent a neighborly marriage crisis and move the frame. A dolly and a wife sure come in handy.  Here's the frame with some 4-foot walls next to my garden shed. I'm actually going to take over the garden shed (where else am I going to store my coal/charcoal?) and connect the walls somehow.  Here's the new welding spot. It's a little close to the doors on the shed (they swing out to open), but once the exterior walls are done, I'm not sure I'm even going to have doors on the shed. We'll see.  And here's the forge. Woo hoo.  Trusses up on the short-side of the workshop. Roof should go up in the next few days. And then I'm going to put up some aluminum screen over all the openings to keep cinders/ash from getting out. As for the interior, I'm probably going to use some thin sheet metal and cover all the exposed wood so there's little chance of everything going up in flames. Also, over the high part, I'm going to have a fully open roof. Well, screened, anyway. The shop has a dirt floor, so I don't mind rain getting in, and I'd like as much way as possible for the smoke to get out. jovial_cynic fucked around with this message at 04:11 on Sep 9, 2008 |

|

|

|

Finally got around to making a how-to video of my welded figurine process: http://www.youtube.com/watch?v=4PjCzy0zHWI

|

|

|

|

dv6speed posted:Great stuff! I Just skimmed through it and will watch it in greater detail when I get home today. I have a small video camera that was just given to me a couple weeks ago. I should try it out sometime soon. Oh, I know all about using a torch striker. I actually mention in the video how stupid it is to use a lighter to start a torch.

|

|

|

|

kapalama posted:I was talking to a welder dude the other day and he said that basically O/A or Torch welding is a dying art, not being taught in the tech schools anymore. Well, "torch" is kind of ambiguous - TIG welding using a "torch," too. O/A (oxy/acetylene) welding is the most specific, although I hear some people refer to it as "gas welding." I don't know about it being a "dying" art, though. jovial_cynic fucked around with this message at 18:08 on Sep 12, 2008 |

|

|

|

dv6speed posted:jovial_cynic, I just used windows movie maker.

|

|

|

|

Slung Blade posted:I have returned from my vacation. The blacksmith on duty at Fort Steele was just a summer student who started learning 3 months ago. She was good, but she didn't really know much more than me. Though she did have experience with forge welding and such. Maybe easier to get a hold of... but much more expensive, as long as I can keep getting the hangers for free. Not a lot of people are just off-loading welding rods.

|

|

|

|

dv6speed posted:Our teacher told us "A weldor who says they have never failed an x-ray has either never had his welds x-rayed, or is a liar." Ah, cool! I can't wait until I have some time to try forging some stuff. I was at an estate auction today, and there was an anvil and a bunch of blacksmith tools, but I got to the auction with my three young kids and my wife, and the auction didn't start showing the good tools until HOURS into it. The kids were getting very bored.. so we ended up leaving before they showed them. Boo. I'm looking forward to getting through all of my welded-figurine orders so I can have a few hours at the forge to see what comes out. Fun fun.

|

|

|

|

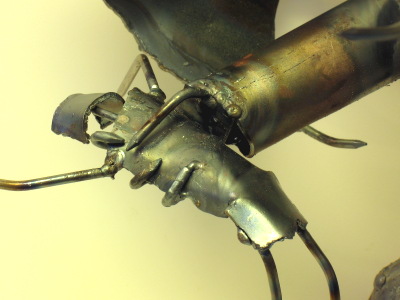

I got a bunch of work done this weekend, too. Namely, finishing up my latest large cthulhu figurine:    My welded figurine queue is getting clearer, so I think there might be some forging going on at my place in the near future...

|

|

|

|

Slung Blade posted:Holy poo poo the quality of your figurines just gets better and better. Nice stuff man. Thanks! Yeah - I've looked back at some of my older stuff, and I've come a long way. This one turned out pretty nicely, I think. Nindoze made it during one of his "I'll make you an animated avatar" threads last year, but I didn't get around to actually using it (and then paying him for it) until recently, when he reminded me that he still had it. I love it.

|

|

|

|

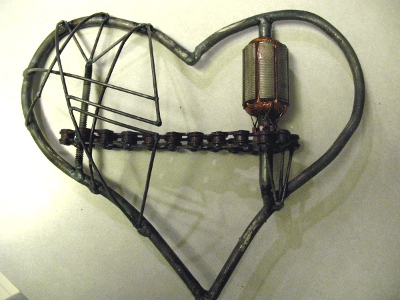

Some fun with oxy/acetylene:   I typically just use sheet metal, nails, and hanger wire for my stuff, but I've had some recent commissions for larger pieces, so I've included the use of 1/4" steel rod. I've currently buying the rod from Home Depot, so it's costing me more than I'd like, but I think I'll stop by the metal supply shop and pick some up to have a bunch on hand. And yes - that's a motor armature. No, it doesn't do anything except look pretty.

|

|

|

|

Slung Blade posted:I like it, the copper stands out nicely against the iron. Shelf. I welded on a base this morning. However, I showed it off to some women at work who swooned over it, and they asked if I could make a set of them that could hang. So... I may end up making some that do.

|

|

|

|

Papercraft meets metalcraft. bacteriophage:    I actually made this from a papercraft template I found in the papercraft thread.

|

|

|

|

Slung Blade - very cool. Also, that's quite an anvil. Did you guys happen to see this sword making video on youtube? http://www.youtube.com/watch?v=62iHEaE8uzI Very cool.

|

|

|

|

I thought I'd experiment a bit and see about making a stand for a figurine or two at the upcoming craft-show at my work:  I think it's kind of cute.

|

|

|

|

Slung Blade posted:You could probably get your work into a local art show too Jovial. It's pretty awesome stuff. Thanks! I'll have my stuff at an artisan fair next month, and it'll be the first time I'll have my stuff physically on display for the public. We'll see how that goes.

|

|

|

|

Made some non-commissioned art. Unless somebody buys it from me in the next two weeks, I'll have this on display at a local artisan fair, along with the rest of my stuff: Tree of Life:

|

|

|

|

Slung Blade posted:Are you going to make a tree of death out of wire to sit next to it? That might be kinda neat. Oh. That is a good idea. Roses look great, by the way.

|

|

|

|

I got my smithy/metal-workshop mostly finished. It was actually finished a while ago, but I never took the final pictures. And now the entire roof is up, and much of the outside is painted. I haven't gotten all the windows screened up yet, and I still need to line the interior with sheet metal to keep it from burning down if any rogue sparks get away from my work.  Here's a shot of my welding area, viewed from the entrance of the smithy. My welding "table" is actually three chunks of 4" square tubing that are pressed against each other (I'll weld the tubes together eventually) on top of some cinder blocks.  Here's a shot of the welding work space from behind my welding chair. I plan to do some reconfiguring of the space eventually, but everything seems to work well at the moment. All of my tools are within reach, and I'm protected against the elements. It's a fine workspace.

|

|

|

|

dv6speed posted:jovial_cynic, Does open air count? The walls are only 4' high, and then it's wide open with screen. The roof is open on the sides as well, allowing any rising smoke to escape. And that entrance doesn't currently have a door, but when it does, it'll just be a screen door.

|

|

|

|

dv6speed posted:A fire extinguisher would be a fantastic idea too. Oh, I have one there.

|

|

|

|

|

| # ¿ May 4, 2024 09:32 |

|

Slung Blade posted:We need more pictures in this thread from someone other than me. OK! Three recent figurines I'm particularly proud of: Three Wishes:  Cuddly Alien:  Going Up:

|

|

|

> ) but I took the cage over and installed it.

> ) but I took the cage over and installed it.