|

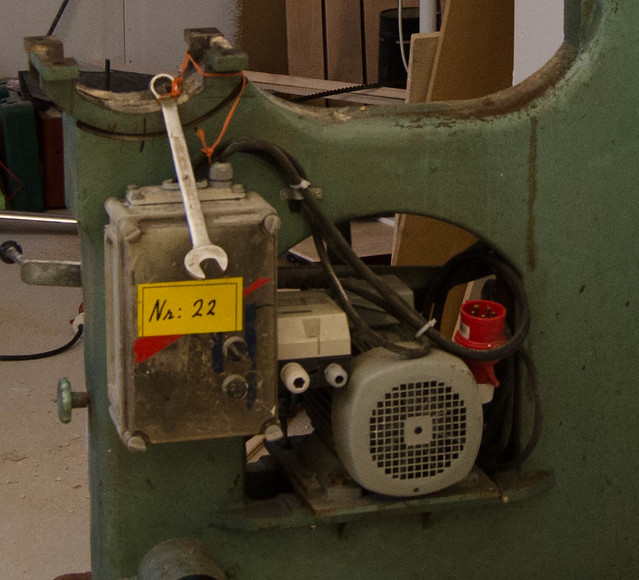

I have a question for any electricians, I'd like an electric brake for my bandsaw and I am contemplating building one myself. The simplest solution seems to be plugging, reversing two phases to change the direction of the motor (this is a 3ph motor and I have real 3ph at home in the walls, no VFD) after shutoff and then reapplying power to brake it. Now I am only after a manual brake, I am happy just pressing a button and doing so until it stops or at least mostly does. Don't need no fancy automatic breaking that turns on automatically and stops when its done. My bandsaws electrical start is a bit strange, it is salvaged from another system I think. There's the motor, a contactor box, and then another panel that has a switch and a button, this bigger panel is used to control the saw:  To start the saw I have to: 1) flip the upper switch 2) press the lower button To stop I turn the switch back and power is cut off and the saw spins down, takes like 10 minutes. You can press the button with the switch in the other way and it will run as long as the button is held down. This feature is not really needed on a bandsaw and probably indicates it came from some other machine after the original motor was swapped out. Now my plan is, what if you put one of these 3-pole 1-0-2 switches between the control box and motor:  You could set it up so that in 1 position it the motor travels one way, and in 2 position it goes the other way. So to break the motor using plugging I'd stop the saw as usual and flip the other switch to two, then I hold down the regular start button and the motor will reverse for as long as I hold it down. That's the general idea anyway, another idea would be to have DC going to two of the phases and use DC injection braking. Not sure what would be better. Atleast with the DC injection you can't accidentally start the saw in reverse. Which is a flaw with my design here and why those commercial solutions cost so much, because they gotta be idiotproof and work in commercial settings. But I am just a hobbyist. Is this a bad idea? Will plugging cause undue stress on my motor to brake those heavy cast iron wheels that also act as flywheels? Will I kill myself? I have wired some 3ph motors before, just fitting them with breakers or a contactor with overload protection and such, never thought out a system like this before. e: my gut feeling is that it's too stressful on the motor, think I a rheostatic brake would be best but I am not sure how to go about that at this point. His Divine Shadow fucked around with this message at 13:21 on Jan 23, 2015 |

|

|

|

|

| # ¿ May 10, 2024 10:33 |

|

Got this motor, really old finnish 1.1kw 3ph motor. I think I would like to use it to build John Heisz' 2x72 belt grinder: The question I got is concerning this cool old breaker that came with it:  It's all metall, even the lever. As such I've been told by some people that it's hazardous, if something goes wrong with the wiring and grounding in particular, then I die. Another person told me if you ground it, and make sure the lever itself is grounded too, it fulfills the electrical code and should this be safe. And I have GFCI breakers for all my circuits so I think that should provide some additional protection. I dunno, I was thinking maybe there's some non-conductive powder coating or similar treatment I could give it to really make it safe, or am I overthinking things? I mean it's really cool I think, would be cool to start the motor with it.

|

|

|

|

Wiring related, but I had an electrician do the job, not gonna mess with this myself. Job was done today, took around two hours to install six 3-phase outlets, one is a combined single/3ph outlet in a corner that was annoyingly lacking any outlets. No more running my larger machines from an extension cord from the junction box.

|

|

|

|

Neutral and ground sharing is normal tho?

|

|

|

|

Ah I missed that

|

|

|

|

Shirley, there must be a simple 110 (or 220) volt switch that just resets back to original position, or just a push button. That way there won't be any wrong or right positions.

|

|

|

|

I bet a lot of those aren't CE marks but the China Export mark which looks basically like the CE mark. Basically something the chinese made to make their products look like they were CE approved despite being nothing of the sort.

|

|

|

|

I bought some panel mount outlets from aliexpress, one schuko and one NEMA and lol, the NEMA one has CE marks on it. No UL marks I can see though.

|

|

|

|

Outdoor usage or indoor? If for outdoor usage then I've had bad experiences with the integrated led and detector lights, 2yr is better than what I usually got. That's why I built my own from a separate motion / dusk detector and an outdoor lamp that takes edison socketed bulbs, the bulb is the most likely failure point so it can just be replaced without tossing the whole thing next time it acts up.

|

|

|

|

|

| # ¿ May 10, 2024 10:33 |

|

TooMuchAbstraction posted:Oh, using the baseboard trim as "conduit" is an idea I hadn't considered! There is a vent in the way, unfortunately. I suppose that I could build more trim around the vent, and route ethernet around it, to keep everything looking nice...that gets to be a lot of work, though. I would probably just run wiring along the exterior of the wall and make it look as neat and tidy as possible. I kinda like the exposied cable look myself, it's what old houses here look like a lot of the time.

|

|

|