|

BoostCreep posted:You assume all of these stages happened. Wasn't this "vice president of engineering" the guy whose job it was was to smack the lift mechanism of the door with a hammer, and if it didn't fall apart it passed inspection? I seem to remember seeing that on a tv show about Malcolm Bricklin years ago.

|

|

|

|

|

| # ? May 3, 2024 03:04 |

|

BoostCreep posted:Also I need to sell this goddamn transmission! I'll trade you a set of wheels and tires

|

|

|

|

New header got here. That was fast. Hopefully I'll have time this weekend to check the fit.

|

|

|

|

The new header fits perfect. I gained about 2 inches and the outlet is exactly where it needs to be.   On to the motor mounts... Practice welds.  Not as good as the practice ones:  This is using flux core MIG, since it's 1/4 plate. Tracing!  Cutting!  Drilling!  Bolting!  Welding!  You can see the weird angle I had to create to make these things match the slanted stock engine mount horns.  More weird angles. The plate on the left and the bushing both had to be at specific angles for the geometry to work. Pain in the rear end.  Driver side mount with tack welds for fitment. I ran out of wire before I could finish the welds. I'm going to add two triangular braces under the bushing on the left side there for reinforcement.  So I'm still learning how to weld (this is actually the first thing I've welded apart from my fuel floater arm a few pages (months) back), and I'm using a 120v Hobart MIG welder, drill, and angle grinder to make these mounts. My plan is to overbuild and reinforce the hell out of them so I can get the car running and driving, then later on I'll most likely take them out and either make new ones with better tools (and more practice!) or have better ones made by people who know what they are doing. I just have to have the engine bolted in so I can move on with other areas of the project.

|

|

|

|

BoostCreep posted:

I hate to be that fuckin' guy but this part is doomed for a couple reasons. -Incomplete fusion: You will never ever ever get enough heat into that 1/4" with a 120v, the physics just isn't on your side. The dissimilar thicknesses aren't helping this either and I'd wager the bushing has been hardened to some degree. -Excessive welds: Filler metal is stronger than the base metal, the more filler, the more brittle the weld. Also the repeated heating and cooling can harden the area around the weld, which further reduces ductility. As far as the welds themselves they look better than my first fluxcore! Are you pushing or dragging the torch? I didn't read the directions at first so I was pushing like normal mig and my poo poo was a mess. Troll CL for a 240v mig with a gas bottle, you'll never look back. This project owns because I love weird goonybird cars and I'd hate to see you hoisted by your own petard

|

|

|

|

dubzee posted:I hate to be that fuckin' guy but this part is doomed for a couple reasons. Thanks for the input. I figured this is what I'd hear. For now I just need the mounts to hold the engine in place so I can get to the rest of the car. I'll have to find another way to have them made I suppose before I actually drive it. The problem is I don't have power in my garage. I have to use a plug adapter on the light bulb socket to use a drill, and to get a grounded 120v outlet I have to borrow my neighbor's power with a 100ft extension cord. This is not an ideal place to wrench on a car, let alone fabricate parts. I was dragging the torch, by the way. If nothing else, at least I've made a template so I can take these to be remade somewhere better I guess. BoostCreep fucked around with this message at 18:06 on Aug 4, 2014 |

|

|

|

I could be way off here but it also seems like the frame side will really, really benefit from a gusset or something to help tie that bushing and plate together other than a single weld. But yes, at least you've got templates and progress. Even if it's not the step you wanted to take, it's still a step forward, unlike the circles I keep running in on my brakes!

|

|

|

|

BoostCreep posted:Thanks for the input. I figured this is what I'd hear. For now I just need the mounts to hold the engine in place so I can get to the rest of the car. I'll have to find another way to have them made I suppose before I actually drive it. The problem is I don't have power in my garage. I have to use a plug adapter on the light bulb socket to use a drill, and to get a grounded 120v outlet I have to borrow my neighbor's power with a 100ft extension cord. This is not an ideal place to wrench on a car, let alone fabricate parts. My god man. No power? Can we start a "Get BoostCreep an electrician to come wire his garage" kickstarter going or something?

|

|

|

|

Our friendly neighborhood moderator is on the right track... was thinking about your mount this morning and did a dirty sketch of the frame side: Yeah it looks nothing like what you have but you get the idea. Get some 1/8" and fiddle around with some designs. It's cheap, easier to work and weld and beefy enough to get the motor mounted at least. Also if you haven't already, put .035" wire + tips on your welder.

|

|

|

|

dubzee posted:Are you pushing or dragging the torch? I didn't read the directions at first so I was pushing like normal mig and my poo poo was a mess. BoostCreep posted:I was dragging the torch, by the way. I'm entirely surprised that a manual would tell you to drag a flux core weld. You need to get heat into the weld for the flux to boil out, otherwise you'll get inclusions in the weld. Anyways, for 1/4" plate, bevel your welds (but leave a flat, called a "land"), use .035" wire like suggested, and turn your welder all the way up, then adjust the speed until you get a nice sizzle. The bad thing is as soon as you get it set right, you're probably going to melt the crap out of that bushing. Can you press them out, weld on the shells, then press them back in?

|

|

|

|

^^^ Yep, that's how my teacher said to do it too, "slag you drag". I was going to mention bevels and lands but then thought about all the grinding over the last few semesters and aaaaaaaaaaa. More heat less grinding

|

|

|

|

Agreed, if there's slag, you drag. That's how I learned. And I agree those welds are doomed to failure. They look about like my first fluxcore welds back in '09, honestly. Hell, tack it up how you want it put together and mail it to me and I'll blow some boogers on it, it might not be quite as pretty as UF's welding but it'll be reasonably nice looking and will NOT break. I even have my 230A Snapon MIG welder working now, so you won't have to clean flux off. Here's what a couple years of practice does, that's 100 amps, .035 fluxcore on 1/4" wall tube and 3/16" spring perch stock:

|

|

|

|

I went and bought .035 flux core wire and tried to finish up the other mount tonight. The power situation is so bad at my garage that the welder on the 4/50 setting blew the fuse in my neighbor's house. So no more welding for me here. I did at least get two half-assed welds on the mount, which let me install both motor mounts and remove the jack from under the engine for the first time. I just don't have enough power here to make these welds work. I couldn't even get a proper puddle. These will work for now until I can take them somewhere else to get properly welded. I have no pictures because my phone died, but the engine and transmission is sitting on the new mounts and everything is fitting perfectly. The engine is level, both headers fit, the new alternator bracket fits with an inch to spare before it touches the side of the engine bay, etc. The only thing I didn't test is the hood clearance, but I think I have room to spare there. The new Camaro water pump fits perfectly with the LS2 intake as well. All I need to do is cut a little bracket out of the remaining 1/4" sheet to make the transmission bolt to the crossmember and the engine is finally in its proper place. Next I need to plumb the fuel lines and get my wiring harness figured out. So much to do...

|

|

|

|

Are you using an extension cord for the welder? If it is too small it will cause a high amperage draw that can pop breakers. A 140a 110v welder draws like 10amps I thought? What are most circuits wired for? It should be enough unless you're running a cheap extension cord or have other big draws on the same circuit (like an air compressor).

|

|

|

|

mafoose posted:A 140a 110v welder draws like 10amps I thought? If you're talking about a 140A output welder, they generally draw 20-30A at peak, or thereabouts. I wouldn't use them on anything less than a 30A circuit.

|

|

|

|

Bumping to keep this out of the archives. Work on this project slows down over the warm (blistering) socal summers, and I always get the bug to work on it this time of year. I'll probably start pulling apart the wiring harness slowly so I can get it ready for standalone duty. Then I'll just need to find a place to remove the VATS from the ECU and engine wiring harness should mostly be taken care of. Hopefully I'll have some actual progress posting in the coming weeks.

|

|

|

|

BoostCreep posted:Bumping to keep this out of the archives. Work on this project slows down over the warm (blistering) socal summers, and I always get the bug to work on it this time of year. I'll probably start pulling apart the wiring harness slowly so I can get it ready for standalone duty. Then I'll just need to find a place to remove the VATS from the ECU and engine wiring harness should mostly be taken care of. I'm ready for some winter reading

|

|

|

|

I realized it's been a while since I've posted a picture, so here's one I took the other day with the F-Body water pump installed to clear the throttle body. I'm starting to hate the LSBRACKETS.COM writing on the accessory bracket. I'm going to have to think of a way to cover that up without making it look like hell. I've been on an anti-logo kick lately (It's not like LSBRACKETS is paying me to have their logo on my engine), so seeing it there in every photo is really annoying. Please excuse the clutter on the fenders and windshield.  I tend to get busy and forget about the Brick for months at a time, and also forget how much work/progress has been done so far. I also tend to build stupid mental roadblocks for myself which isn't helping. For example, I've mounted the surge tank where I want it to go, but for some reason I can't bring myself to get under the car and plumb the lines. Motivation problems I guess? I'm having the same issue with the transmission mount. In typical Bricklin fashion, the crossmember for the transmission mount is not symmetrical, so the transmission sticks half off the side of the mounting flange for the AMC transmission. I need to mock up a solution, but it keeps falling into a "deal with it later" category and not dealt with. Maybe I just need to focus on tackling other issues and come back to that stuff later.

|

|

|

|

BoostCreep posted:Maybe I just need to focus on tackling other issues and come back to that stuff later. Its because you aren't wearing your car-thinkin' cap! I guess you could always just dope up the lsbrackets bit that was cut out and then give it a tasteful cover with Rustoleum BBQ Black.

|

|

|

|

Viggen posted:I guess you could always just dope up the lsbrackets bit that was cut out and then give it a tasteful cover with Rustoleum BBQ Black. Yeah, I think that's going to be your only option. Epoxy / bondo / something as a filler, then paint. Or carbon-fiber vinyl  I know that feeling all too well. Just remember that there's never such thing as a "done" project car.

|

|

|

|

You'll hate the stupid logos less from the drivers seat. Get the turd running first.

|

|

|

|

BoostCreep posted:Maybe I just need to focus on tackling other issues and come back to that stuff later. When I get it that point on a project, I usually try to make myself go take care of the "easy" things. If I knock out a couple of those (tidy a bit of wiring, find a bolt, adjust some angle,) I'll often find myself tackling something I was dreading, just because it was next to what I was working on anyhow. I trick myself into doing the work, and it didn't even cost me half an apple or a dead rat with a string to swing it with.

|

|

|

|

jhcain posted:When I get it that point on a project, I usually try to make myself go take care of the "easy" things. If I knock out a couple of those (tidy a bit of wiring, find a bolt, adjust some angle,) I'll often find myself tackling something I was dreading, just because it was next to what I was working on anyhow. I trick myself into doing the work, and it didn't even cost me half an apple or a dead rat with a string to swing it with. A second technique is to run other aspects of your life into the ground, so that dealing with the car represents procrastination from dealing with that stuff.

|

|

|

|

Just thought I'd check in and let y'all know that I took a 5 hour cruise through all 21 pages of this thread. I'm glad people like BoostCreep exist for us to vicariously experience the careful polishing of this Brick of poo poo to a sparkle. Amazing thread, terrible car, but a gem nonetheless.

|

|

|

|

Yeah bondo and paint would be the correct solution if you can't weld and grind it. I do have some orange vinyl and black vinyl but not sure how that would hold up with under hood temps.

|

|

|

|

You could TIG it up and face mill the whole thing again but it will probably warp and/or look different at that spot.

|

|

|

|

InitialDave posted:A second technique is to run other aspects of your life into the ground, so that dealing with the car represents procrastination from dealing with that stuff. How I took a project from purchase to 90% complete in 6 months, right there. for the LSBRACKETS.COM thing, just mount something on top of it? even just a little bracket to hold up a hose or wiring harness could be cleverly fabricated to obscure the logo.

|

|

|

|

Don't think I've seen this posted: https://www.youtube.com/watch?v=x2ERt0R8T1c It's been stuck in my head since I first discovered Bricklin many years ago. And it starts replaying whenever I open this thread. The closer you get to done, the closer you get to outdoing the company

|

|

|

|

|

I just realized there was something I completely forgot in the engine mount welding discussion. Electrode polarity. MIG and fluxcore use opposite polarities, your welds will come out like poo poo with the wrong one. Fluxcore you should be running DCEN, MIG is DCEP. I knew this academicaly, but completely forgot it the first time I ran fluxcore through my MIG, and the welds came out horribly because of it

|

|

|

|

But once you do it with gas it is so much cleaner and easier it's hard to go back.

|

|

|

|

There is no problem JB Weld can't solve.

|

|

|

|

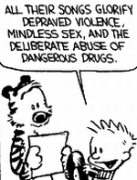

I'm single again as of last week, which was my birthday week, my team is not in the superbowl, and this just showed up: I know what I'm doing this weekend. BoostCreep fucked around with this message at 11:00 on Jan 30, 2015 |

|

|

|

BoostCreep posted:I'm single again as of last week, which was my birthday week, my team is not in the superbowl, and this just showed up: Are you secretly 13 Inch?

|

|

|

|

I kind of want to see a Bricklin/Civic fusion now...

|

|

|

|

Humbug Scoolbus posted:I kind of want to see a Bricklin/Civic fusion now... Gull-wing doors on the Civic would be baller as gently caress.

|

|

|

|

I'm not sure if you saw this snap, but here is some inspiration. http://phoenix.craigslist.org/cph/cto/4831144071.html

|

|

|

|

Holdbrooks posted:I'm not sure if you saw this snap, but here is some inspiration. I did see that snap. At least I can still say I'll be the first LS powered original framed/bodied Bricklin. Maybe. Not that it really matters, I just want to get it started and moving. Still have a lot left to do, but at least all the wiring is here and ready to go. Hopefully I can sell the stock truck wiring harness, PCM, and intake/exhaust manifolds to offset the cost of the PSI harness and PCM a bit. I went with their $200 PCM which already has VATS removed, plus tuned for my application. Once I get the harness installed and fuel hooked up I could technically start the engine which is exciting, and possibly a good motivation tool to move on this project faster. Things left to do, in no order: code:I have an evil bug planted in the back of my mind that I'm squashing on a daily basis knowing I have a forged 2.3L 4G63 in a Talon that likely won't see street use again and a Magnum T56 sitting around. SQUASH SQUASH SQUASH. BoostCreep fucked around with this message at 01:33 on Jan 31, 2015 |

|

|

|

Reacon posted:Are you secretly 13 Inch? No, the Seahawks ARE in the Superbowl

|

|

|

|

BoostCreep posted:I'm single again as of last week, which was my birthday week, my team is not in the superbowl, and this just showed up: Sit in the corner and cry, with a bottle of Makers Mark in one hand, and a pistol in the other?

|

|

|

|

|

| # ? May 3, 2024 03:04 |

|

MrYenko posted:Sit in the corner and cry, with a bottle of Makers Mark in one hand, and a pistol in the other? No, you're confusing BoostCreep with me.

|

|

|