|

Pfft... It's a poor copy of a Gen 2 RX7... Put a V8 in it, no big flashing red lights here!

|

|

|

|

|

| # ? May 22, 2024 17:04 |

|

Yeah, but I really don't want manual steering. I found a place in Brisbane that can do me a kit for $130AUD + GST, so I'll more than likely go that way. aventari posted:You can get a manual rack out of an 83 944. That's the only year the 944 didn't have P/S.

|

|

|

|

aventari posted:You can get a manual rack out of an 83 944. That's the only year the 944 didn't have P/S. Moot since he doesn't want manual steering, but a lot of us are just running depowered power racks. No need to go through all of the ridiculous things people suggest (removing valves, filling with ATF/grease/whatever and looping the lines). Just drive on it. It works fine. Parking sucks, but the rest of the driving is very much improved.

|

|

|

|

Motronic posted:Moot since he doesn't want manual steering, but a lot of us are just running depowered power racks. No need to go through all of the ridiculous things people suggest (removing valves, filling with ATF/grease/whatever and looping the lines). Just drive on it. It works fine. This. Give your 944 a try with the current rack with the fluid lines blocked off. It's not really that much effort for any vehicle under 3000 lbs to steer it with a manual rack. Plus road feel is vastly improved at speed when there's no power assist. That way, if you try it and find out you still hate it, you always have the option to drop coin to reconnect the power pump at a later time, and if you do decide you don't mind manual, you just saved the money you were going to spend on getting your pump system reconfigured for the new engine.

|

|

|

|

I've been daily driving my E30 with the standard steering rack without fluid for drat near 5 years and I still love it! Parking sucks but as long as you're moving (even creeping along) the car steers without much effort. My wife only drives my car when her civic is being worked on and she hates the steering (but she also hates trying to get the car into reverse).

|

|

|

|

At Cars & Coffee yesterday I may have said "El Jes Juan" out loud to several puzzled faces. That is all.

|

|

|

|

HotCanadianChick posted:This. Give your 944 a try with the current rack with the fluid lines blocked off. It's not really that much effort for any vehicle under 3000 lbs to steer it with a manual rack. Plus road feel is vastly improved at speed when there's no power assist. Noooo! Don't block them off  You need to let them free or it won't work (it will bind). It will eventually stop dripping. You need to let them free or it won't work (it will bind). It will eventually stop dripping.But on the rest: hell yeah. It's a better car with a manual rack. The stop power steering is really pretty overpowered to the point of deadening your feel for the road.

|

|

|

|

Isn't the best option to just run some cheap rubber hose from port to port? That way you won't get crud in it.

|

|

|

|

InitialDave posted:Isn't the best option to just run some cheap rubber hose from port to port? That way you won't get crud in it. I suppose you could do that. But what are you trying to save in there? The seals that hold the ATF you'll never put in it again? Mine are zip tied to the rack. For the last 5 years. All is well.

|

|

|

|

Motronic posted:I suppose you could do that. But what are you trying to save in there? The seals that hold the ATF you'll never put in it again? Probably the gears inside that don't like water/dirt  I would probably pump it full of grease and then loop the hoses if I owned one, honestly. Keeps the water and grit out - I know firsthand what happens when some water gets into a power steering pump, it settled down through the hoses into the steering gearbox (regular ol' saginaw style) and a few weeks later the steering felt notchy and grindy, then after a couple months of sitting, it was seized. The pump and box were coming out soon anyways (pump whining, box very loose and leaking from every seal) so I didn't really care, but it would have really sucked if they weren't something I could find in every junkyard in the country for like $50. If you only drive it in fair weather or get lucky it'll be fine, but I try not to rely on things like that.

|

|

|

|

Since I have to get this thing through both an Engineers inspection, as well as a normal Roadworthy inspection by the DOT, I'm going to leave as much of it original as I can, to hopefully simplify the process. I must admit, I am curious as to how it would be to drive with a manual rack ... maybe later on down the track.

|

|

|

|

kastein posted:Probably the gears inside that don't like water/dirt

|

|

|

|

Right....these are things near the realm of the "ridiculous things people suggest" I mentioned earlier. I'm not the only one that is driving around without doing any of that whatsoever for half a decade or more with absolutely no ill effects. And yes, using the car as a daily driver and not just in fair weather. It's just too much fun in the snow to not drive through slop. Of course nothing that was suggested would hurt anything at all (other than blocking off the lines without removing the valving in the rack which would requite removing it first). My point was simply that it's been shown by people who actually own and daily drive these cars to be unnecessary. I think I'm probably one of maybe two people on this forum who has that experience.

|

|

|

|

Motronic posted:I think I'm probably one of maybe two people on this forum who has that experience. Tell me more.

|

|

|

|

West SAAB Story posted:Tell me more. Oh, good....your're both awake and not chasing drug dealers.

|

|

|

|

I can confirm that manual steering on a 944 makes it a bitch to parallel park but is awesome to drive everywhere else. I wish I had more to contribute to the thread.

|

|

|

|

Even power steering on a 944 isn't super light, but yeah, trying to parallel park my dad's old 1983 944 was horrific! I'll be following this thread intently. I'd love to do this with my S2 one day if the engine decided to go to valhalla. Are you going to put 924 Carrera GTS headlight buckets in? Also there is this... https://www.youtube.com/watch?v=3iR2sSHdewE 20v 5cyl Audi block turbocharged.

|

|

|

|

Not much doing at the moment, just waiting on some bits from Summit, which have been backordered; and for more $$$ to play with.

|

|

|

|

Bits are shipped from Summit .... there will be action!

|

|

|

|

Motronic posted:I think I'm probably one of maybe two people on this forum who has that experience.  Pumped to see a LS1 944 get done in here. We have the best people.

|

|

|

|

You've never worked at a lovely garage as a mechanic or known someone who has? You're gonna have to run the wrecker also. That's how it works unless you have a massive AAA or duty tow contract. There's no money to keep a driver holding down a stool in the shop all day to handle one or two calls per shift. And it was a pay upgrade from being a paramedic/firefighter. And fewer biologicals to deal with.

|

|

|

|

Motronic posted:You've never worked at a lovely garage as a mechanic or known someone who has? https://www.youtube.com/watch?v=_EfW9znJYjw

|

|

|

|

This was the response I expected.

|

|

|

|

some texas redneck posted:

Always weird when it comes up. 3k UID and was very active for like 5-6 years (especially after kyle deleted [H] cars) Also haven't been there in a number of years.. it's a shell of what it once was...

|

|

|

|

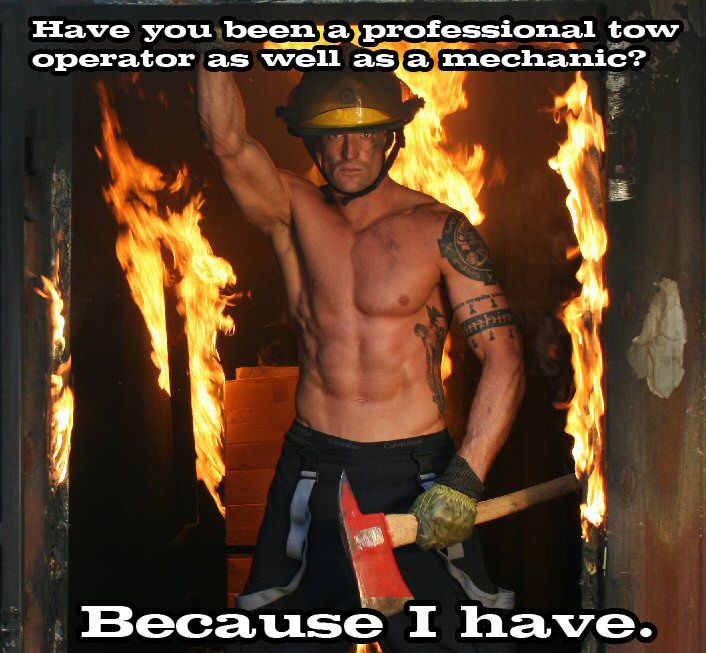

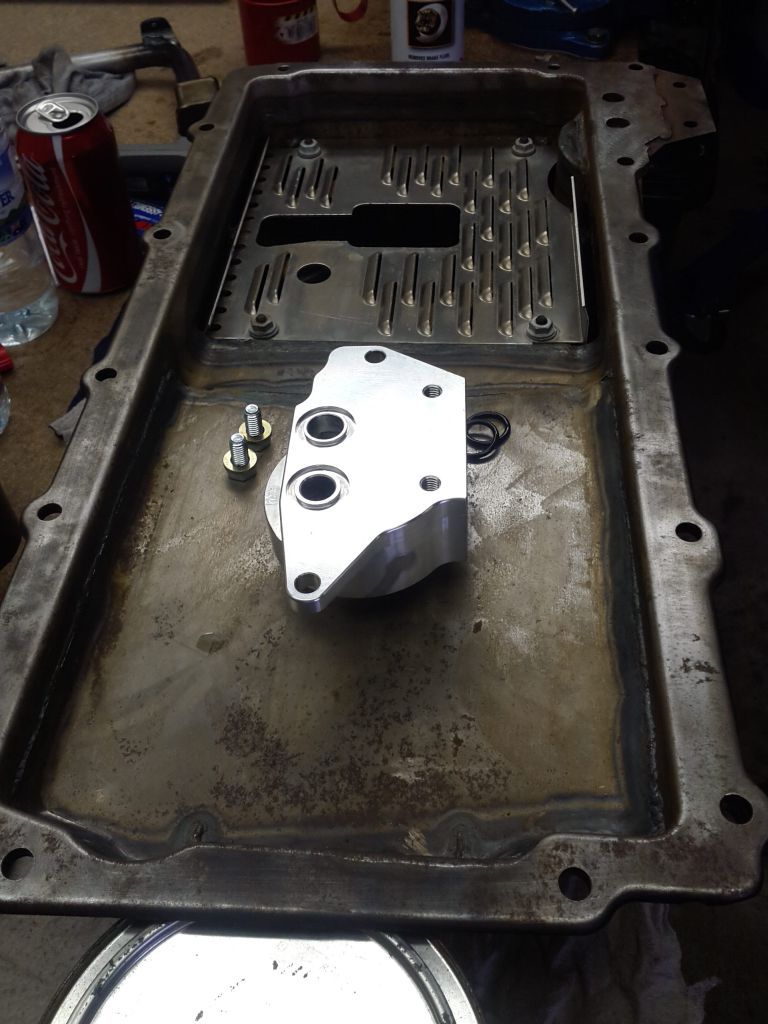

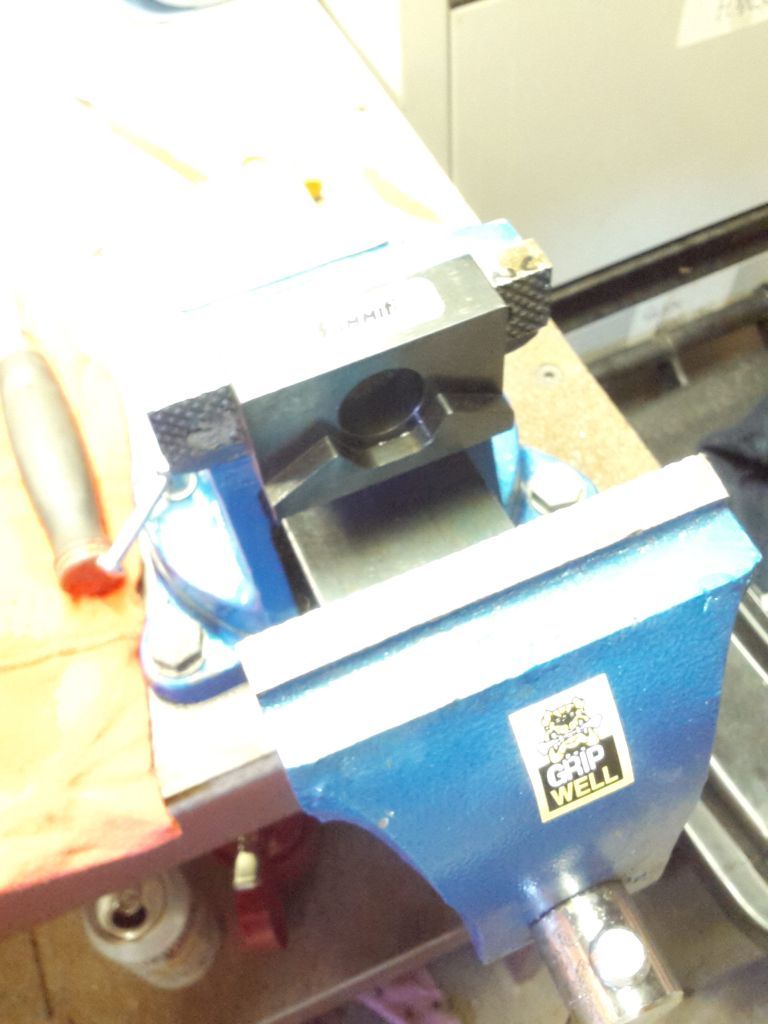

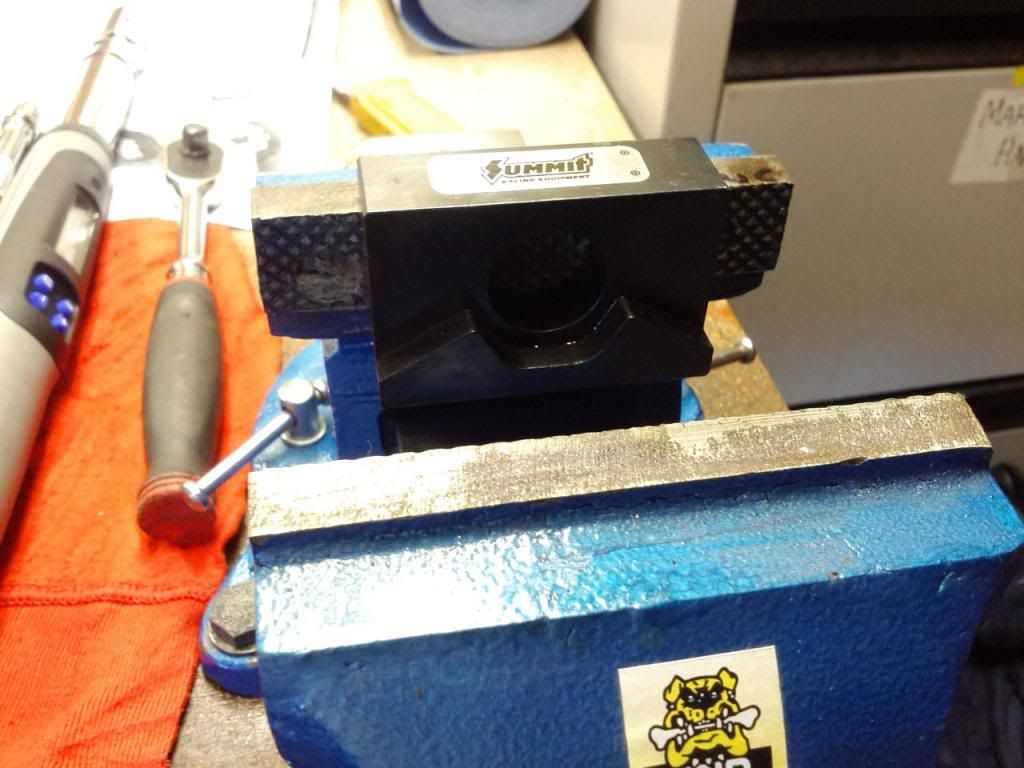

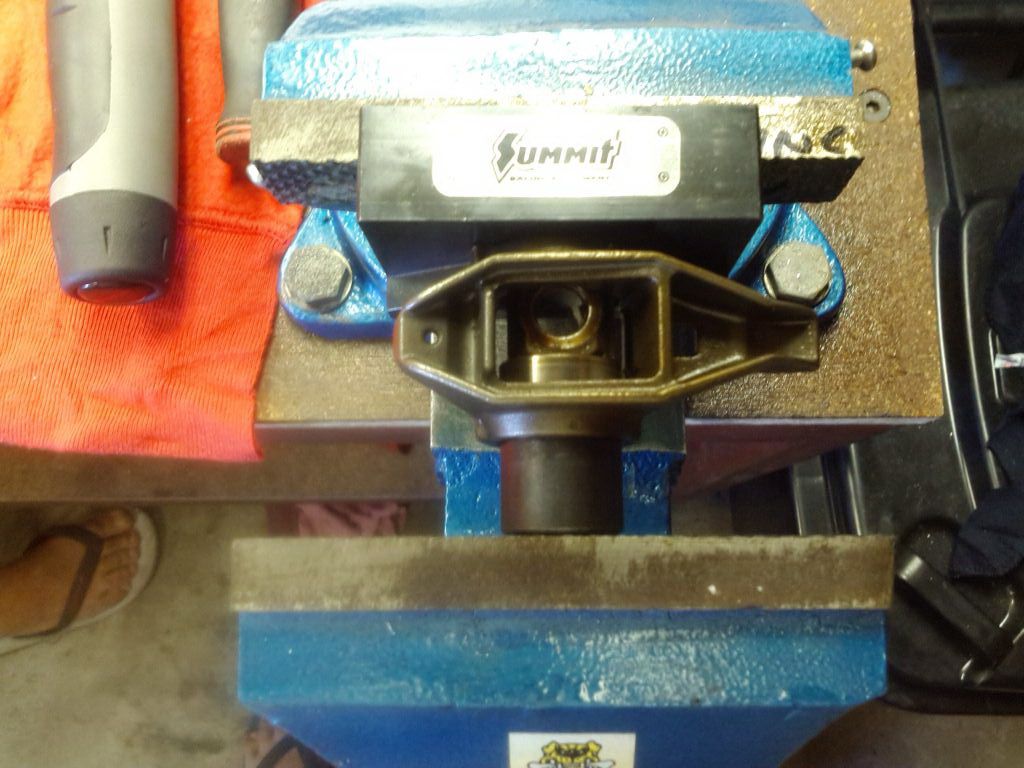

Hokay, I finally got some poo poo done! Got the double row timing chain and cogs in, as well as the trickflow timing chain damper. Also got the oil pump lubed up, and on the motor.  Next was clearancing the timing cover, on account of the double row timing chain, and Mellings HV Oil pump. Next was to bead blast, paint, and install the seal on the timing cover. Modified for clearance:  Painted, Seal installed and on the motor:  Next was the Rear Main Seal. Didn't really catch any pics of this, but its pretty boring anyways. Rear cover removed:  Not a very good pic, but here, the valley cover is on:  Here's the sump that came with the conversion kit. It was loving filthy inside with metal shavings, and also has a nice warp across the rails. This is gonna be a big gently caress around, but more on that later. Pictured also with the Oil filter housing adapter thingy. The louvered baffle plate also had to be clearenced for the pickup to fit, due to the timing chain and oil pump combo.   Water pump on. This was another gently caress around, as I got it into my head that I wanted to run pretty black -20 AN fittings and hoses for the radiator. I managed to crack the water pump pressing the -20 fitting in, and had to get a bead of weld run up it. Hopefully it wont leak.  Knock sensors installed, you can also see the weld on the water pump:  Next up was the Comp Cams trunion upgrade for the rockers. This was surprisingly easy to do, with the Summit Tool. So, here is half the tool; it has a Mandrel for pressing (the shiny bit middle right), an end cap for pressing out the old trunion and bearings (the dark coloured cap, middle bottom), the washer is for pressing in the second new bearing, and the round spacer is for lining up the first bearing to be pressed in. It's pretty simple in practice.  Here's the other half of the tool. It has magnets, so it sticks to the vice, and basically just holds things in the right place.   Pressing out the old bearings and trunion. The black cap presses around the edge of the bearing, and the trunion presses out the other bearing.  Pressed out:   Here is the first new bearing to go in. The black cap goes over one end of the Mandrel, the bearing goes writing side (outside) to the stop on the mandrel, and the spacer on the end locates the new bearing squarely in the rocker arm.  New bearing going in:  And home:  Comp cams recommends a 5-10 thou fit, so it takes a bit of playing around to work out how far to press them in. Here is the new trunion slid in. The new, second bearing, is located by the new trunion, which is held square to the rocker arm by the washer.  Pressing in:  Circlips on the trunion, and its good to go!  One side done:  Rocker Covers painted, and gaskets installed:  So, thats all I have pics for at the moment. I did manage to install the harmonic balancer, and confirm true running of the belt by reinstalling the accessories. More to come in the next few days!

|

|

|

|

Just to prove I'm not dead under a Porsche, here's a bit of an update. Here's where we were at:  Today's aim was to test fit the engine for the first time, to make sure the thing is actually gonna fit, and to check out exhaust clearances. First job was to get the car onto jackstands at the front, and not 20L drums. CHECK. Next job was to remove the transaxle, so the torque tube ca be slid back, to make the engine easier to get in from the top. CHECK. So, CV Joints removed, to be reconditioned:  Transaxle out, this fucker is not fun to balance on a jack:  A shot from the rear of the car, showing where the transaxle came out of. The black rod in the bellhousing is the shifter rod, and the cast aluminium bracket above it is the pissy standard transaxle mount; I have a new billet mount to fix that.  Setting the engine up to drop it in:  Empty engine bay:  Crossmember bolted in, with the partially stripped PS rack in:  On the way in:  Getting close:  IN!  Its a pretty goddam tight fit, to the firewall, and for the exhausts. This is the passenger side (for a RHD car):  And this, is the problem side:  There's not a whole lot of room in the first place, and this side has the steering shaft, as well as the starter motor, which isn't in there yet. I can see this negating being able to run any sort of standard cast iron manifold, like I wanted for easy registration purposes. I can see me buying a set of the ICengineworks legos in my future .... Plenty of clearance at the front:  This however is troubling. The kit comes with spacers to drop the crossmember, they are not installed here.  Hopefully they create sufficient clearance for the hood. Next is to play with the spacers and test fit the hood, then to sort out the oil pump pickup tube fouling the sump. Til next time!

|

|

|

|

Good progress. Don't forget to take a picture of yourself in the engine bay for posterity

|

|

|

|

Opensourcepirate posted:I can confirm that manual steering on a 944 makes it a bitch to parallel park but is awesome to drive everywhere else. I wish I had more to contribute to the thread. It wasn't that bad! Falken posted:Even power steering on a 944 isn't super light, but yeah, trying to parallel park my dad's old 1983 944 was horrific! I had a depowered 14:1 rack in a Neon on summer tires with a small steering wheel. Now THAT was hard to parallel park.

|

|

|

|

Work continues at a slow pace .... nothing major achieved due to lack of funding (thanks to my beautiful 6 month old).

|

|

|

|

XtaC posted:Work continues at a slow pace .... nothing major achieved due to lack of funding (thanks to my beautiful 6 month old). I know AI has an aging demographic but I find myself increasingly of this mindset, seeing all the slow-moving projects these days.  So long as you're happy though, and don't let it die, I'll sit on the edge of my seat for updates.

|

|

|

|

Stuff is definitely happening, just a bit (read: a lot) slower than I'd like. This would be fixed if my missus would agree to me heading out to the mines for work >:[ My mate Pete's coming round today, and we will look at fitting the spiggot bearing, so I can bolt up the Torque Tube and Transaxle, to see if that changes the way the motor is sitting on its mounts. Will also test fit the bonnet, hopefully .....

|

|

|

|

Yes. You're making me miss my old 944 that I dreamed of dropping a v8 into. I actually want to drop one into my miata now that I have a new WRX to DD, once I get my poo poo together and buy a house. Nice work so far, beautiful car.

|

|

|

|

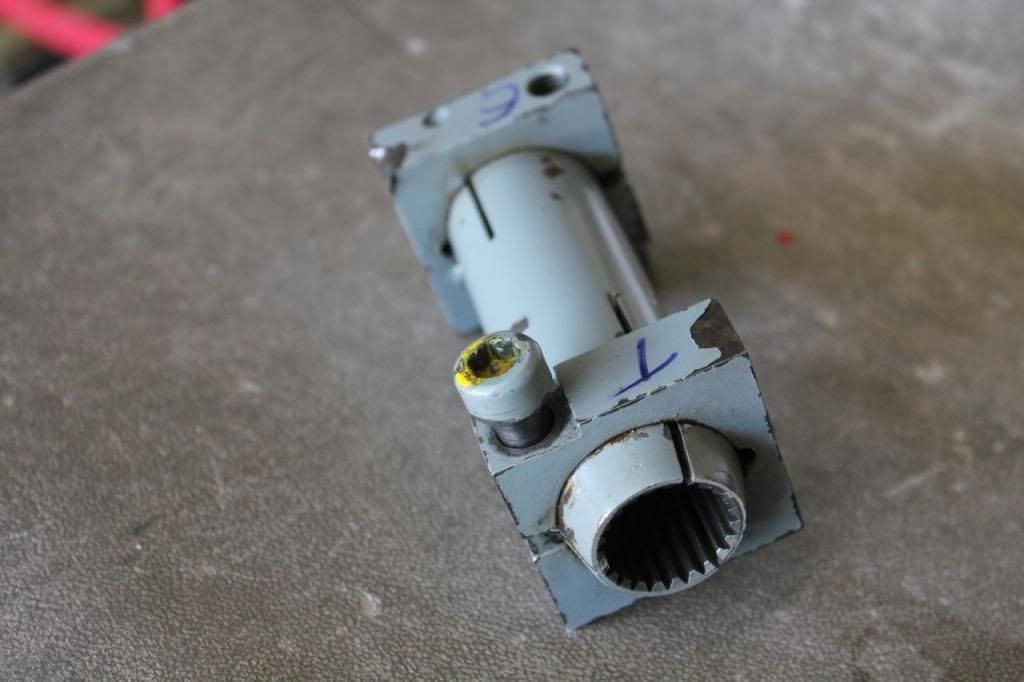

Time for an update! I've had a couple of half day sessions working on this fucker over the last month or so.... The first job was to fit up the Lindsey Racing semi-solid billet transaxle mount. This was a part I was pretty keen to fit ... I'd noticed a few time that the car would squirm around a bit funny at times, and with the standard mount you could wiggle the transaxle side to side, when the car was up off the ground.   The next biggest headache turned out to be the spiggot (pilot) bearing. The spacing/offset is obviously different between the Porch 4 banger and the LS1. TPC provide a handy bearing carrier/adapter to get it into the correct position.  Its just a piece of round bar bored out to accept the bearing, and spacing it towards the rear of the car. Problem was, when we fitted it to the engine, and attempted to bolt the Torque Tube to the bellhousing, the splines of the input shaft of the TT were hard up against the inside of the bearing, while still leaving a 12/13mm gap between the TT mounting face and the bellhousing adapter. I've read of a few people having issues with this, and decided to have a mate make another one up for me, but 12mm shorter. This would have worked out well, if the drawing for the part was a bit more accurate! Turns out, the adapter I had made was a tight fit in the hole, but was not captive; insufficient crush fit. My mates coming round this arvo to actually measure the back of the crank, so we can get it right this time. Bellhousing with adapter temp fitted.  Splines on the input side of the TT, prior to cleanup.  Cleaned:  You will probably notice the munged up splines on the shaft. They look worse than they are, and wont be an issue for use. The damage was more than likely due to part of this dirty little fucker, that I found floating around down the TT housing.  Its part of a guide tube for the Porsche throw-out bearing. Thats been through a clutch job too ...... The coupler for the TT to transaxle.  Pete giving the inside of the Trans a quick cleanout.  Dirty Trans.  Transaxle going back in, after bolting up the TT.  You can't see it very well in that pic, but the TT has a corresponding bellhousing deal on the Trans end. Here's the TT all bolted up. The adapter is sitting in the back of the crank. The nose of the TT input shaft sits nicely where the spiggot bearing will be. This thing came with a plastic looking throw-out bearing .... is the plastic something to be concerned about? Is there a better alternative?  \ \And finally, the real test .... does the bonnet fit?????   Holy gently caress it does! But only by a dickteenth ....  Thats the top of the TB with the bonnet closed ... lucky the engine mounts wont have much movement in them. And thats as far as I managed to get. Next up, I'll pull the engine to get the sump to fit right, and then the pedals, I guess.

|

|

|

|

I think the GM hydraulic throwout is plastic too? Could be wrong, but either way good to see some progress. And that's some really loving tight clearance on that intake, goddamn.

|

|

|

|

IOwnCalculus posted:I think the GM hydraulic throwout is plastic too? Could be wrong, but either way good to see some progress. Yeah, I think I'll be shaving the TB down a bit .... I'm just stoked that it actually fit!

|

|

|

|

This project is not dead, just had its metabolism slowed! So at this point, the next thing to do is make an Oil Pickup tube, as the one with the kit did not fit in any useful way. What are people's opinions; I'm leery of having welds in a pickup tube like this, but I don't see me making it any other way?

|

|

|

|

As another owner of a slow moving AI project, I am enjoying every update to this thread.

|

|

|

|

I see nothing wrong with welded pickups as long as they're done right. Back purging is pretty much a must to prevent carbide precipitation on the back side if it's stainless. Hell I would even do it on mild steel for a better more consistent root pass. A nice bevel on both sides of the tube definitely helps.

|

|

|

|

Glad to see this project is slowly moving along. My project is in a similar position where I spend one weekend make up for all the lost time and then it sits again for weeks. Its going to interesting to see how you handle the starter/steering rack/header issue. I thought it was insanely tight as is w/ a normal LHD car.

|

|

|

|

|

| # ? May 22, 2024 17:04 |

|

shoopeach posted:Glad to see this project is slowly moving along. My project is in a similar position where I spend one weekend make up for all the lost time and then it sits again for weeks. I'm pretty sure I'm going to run the Drivers side exhaust (side with starter and steering shaft), forward, around the front of the engine, and out the Passenger side. I genuinely can't see another way of doing it, and getting a reasonable diameter pipe in there, and not dumping huge amounts of heat into the starter motor.

|

|

|