|

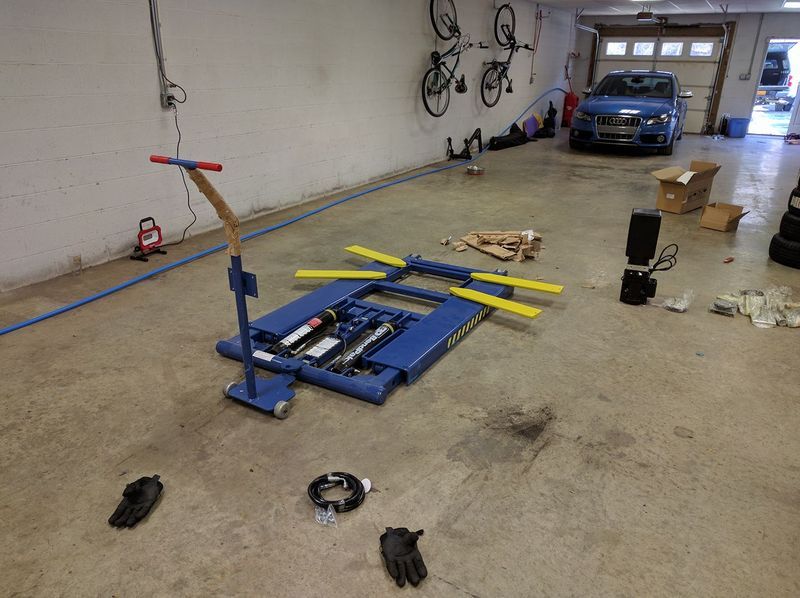

I moved to Asheville, NC from Wasilla, AK about 8 months ago. In AK I had a 3 car attached and 3 car detached garage, so I didn't want to lose that space with a new house. Luckily I was able to find a place with a 2000sq' garage under the house. Moving day  The day the lift arrived  I hate bare walls  Work benches and tool storage area  Can stack 'em in three deep along this wall  I reserve this corner for long term operations  Three wide at the (smaller than I'd like) double doors  Overflow and dually parking outside undercover  In the next year or two, the plan is to move all this nonsense out from under the house and only store runners there. I don't like the idea of potentially burning my house down with project cars. So, the plan is to build a 30x40' shop on slab with 12' ceilings and 2 10x9' doors where the carport thing is.

|

|

|

|

|

| # ¿ May 5, 2024 03:01 |

|

OneOverZero posted:

Nice! Yeah we were lucky as hell to find this place. I'd love to experience an early Neon ACR in the flesh. My first car was a 95 Neon Sport Coupe in black. I would totally buy one if I found one for sale just to hold on to.

|

|

|

|

Are you going to throw a fence or something around that basement window? I feel like I would walk out the door and promptly fall into that hole.

|

|

|

|

slidebite posted:You know it never even crossed my mind. It's a bit of an illusion, it's probably over 6' away from the door and it swings in but it's not an insane idea. I'll probably live with it for a while. If I see it as a genuine risk, I'll figure something out. I've never had a house with Wells before (and my basement has a 9.5' ceiling) so they and any hazards the bring are new to me. Good plan, I've never owned anything like that either. Larrymer posted:How about a grate? Would have been nice when you had the slab poured to put a little lip around it that you could just drop it on. Light gets through and it could lift right off. Yeah I would think like this would be fine

|

|

|

|

I have this Bendpak that I really like. (just for more lift data points)

|

|

|

|

Larrymer posted:Probably raising the car up a little as well to get the lift under it since it's a tiny little MR2. Pretty much all my cars except to X5 and Dually need a little help to get over the thing. Saw it on a Corvette forum, simple little 3" rise rigid box around the lift made of 2x4's and 2x12's. Also, epoxy floors are the best. I was prepared and expected to do it to whatever house we bought down here, but the PO had the floor polished, and I've been trying to keep up the finish. It makes cleaning up oil super easy.

|

|

|

|

NitroSpazzz posted:In the middle of reading through threads on Garage Journal but those that have epoxied floors what did you go with and how did you like it? I'm interested to hear empirical data on different brands of epoxies as well. One of the reasons I didn't pursue them any further, is reading through various forums made it sound like the temp differences I would experience between my garage floor and sticky tires on the Audi/BMW/Starion would result in a lot of lifted epoxy... however realistic that may be.

|

|

|

|

NitroSpazzz posted:Sticky tires and lifting is a big concern of mine but Dad hasn't had any issues with fairly sticky tires (Dunlop Star Spec ZII) lifting even in the heat of WI summer after a hard drive. But WI summer is a lot different than TN summer. From what I read people's concerns were with the air conditioned garages versus the 115 degree + tires disbonding the epoxy from the floor. When I read that it made enough sense for me to want to do a lot more research. In Alaska I saw a lot of formerly nice epoxy floors that were just missing the coating where the tires rode.

|

|

|

|

FatCow posted:Would peel and stick linoleum tile be a terrible idea? I'm not sure what does it, but whenever I see linoleum or vinyl tiles in a workspace, they seem to curl over time. Maybe hot cold cycles, or too much weight, or some sort of solvent reaction?

|

|

|

|

slidebite posted:Not sure if this is the best place to ask, but any recommendations for getting an oil stain out of concrete? My movers truck had an oil leak and didn't notice it until after they left and it dripped on the new, unsealed in any way driveway. Am I screwed? I heard someone say dumping copious amounts of solvent (IE: Gas) works, but I don't think dumping a massive amount of gas on it is a great idea. I had an unsealed concrete garage in Alaska, and spent a winter rebuilding/swapping 302's into gen 2 ford vans, and wrecked the floor in the process. Before I sold the house I used a bunch of this: https://www.walmart.com/ip/Purple-P...7&wl13=&veh=sem and some stiff bristle brushes and water and it made the floor look new again.

|

|

|

|

slidebite posted:How difficult is it to install a garage door opener? My builder didn't bother putting one on the pull-thru of the 3rd bay, but he did completely wire/rough everything in before he buttoned up the walls. So I've got cables for the photo-eyes, a cable for the wall switch with everything ending up on the ceiling near a power outlet. I wasn't going to bother but there are some sales on right now so I'm thinking of it. It sounds like most of the stuff is in place for it. I've replaced one before and it was pretty straightforward. Do you have the allstrut or whatever in place to hang it on and the channel needed for the opener chain/belt? If not that might take some work, but not insurmountable by any means.

|

|

|

|

slidebite posted:Nah, none of the mounting stuff/hardware is there, just the cables for controls/eyes and power. I assume these door kits come with all that stuff for mounting though? I think the kits just come with the center channel (in addition to the motor, remotes, sensors, etc). So you'd need to find a joist in the ceiling to mount the unistrut to to make a hanger for the motor and end of the center channel. Also, IIRC there needs to be a decent header board above the garage door to mount the door-side of the center channel to as well. edit: http://www.homedepot.com/p/Direct-D..._-204154626-_-N

|

|

|

|

tangy yet delightful posted:I need to figure out what swing gate with solar powered setup to buy now that I will be driving in and out of my back yard the wooden manual gate is no bueno. I have a gate like this on my driveway: https://www.lowes.com/pd/Tarter-Com...2hoChBMQAvD_BwE It's mounted to a 6x6 and there's another 6x6 on the other side. I have this installed, but never use it because driveway (and mostly ups/fedex/usps parcels are nicer on my porch): https://www.amazon.com/Mighty-Mule-...te+opener&psc=1 This combo seems to work well, the gate is really light (comparatively) and the opener never seems bogged down or anything.

|

|

|

|

Mat_Drinks posted:There is a lot of stuff I'm willing to do and have done myself, but garage door installation is one of the few I will always pay someone to do. I've heard way too many horror stories about people setting the preload on the spring incorrectly and breaking an arm or just straight up screwing something up. garage door opener =/= garage door installation. I have done a garage door spring once, and I will never again for the reasons you mentioned.

|

|

|

|

Only like a hundred more than a traditional one too, not bad. https://www.amazon.com/LiftMaster-8...ft+mount+opener

|

|

|

|

I currently have a ~ 2000sq' under-house garage that I use as my primary shop and daily driver storage. As I'm getting more into welding and metal fabrication, my wife and I are questioning the safety (more like acknowledging the distinct lack of safety) of doing that under the house and decided it's time to build an outbuilding to be my shop/garage/project area. She also wants some climate controlled space for her emerging hobbies as well, so this will end up benefiting both of us. The current garage looks like this, and houses our daily drivers, my tool room area, all my machine tools, my lift, and a couple project cars.  Currently outside, there's one of these three-stall barn-port things. I store the dually and overflow project cars out there currently. It's sitting on a gravel pad and is ~ 35'w x 26'd.  The prevailing plan is to dismantle the barn-port and move it/reassemble it into our lower pasture where it will serve as an actual barn and put a new building in its current location. We plan on having chickens and goats in the not-to-distant future. I'll build a wood rear wall and a wood front wall with a barn door on it down there when I fence the pastures in. We also have a 20'x40' RV barn that I keep the toy hauler in (orange circle) and I'll probably store the dually down there next to the camper.  So, on the spot that the barn-port is being moved from we'll have someone come in and pour a slab and erect a metal building. The one we like the most right now is a 30'w x 40'l x 12'h with two 10x7 doors and two windows and one man door. The company we looked at is offering that on a concrete pad for $11,450. I need to talk to them about pad thickness and such because I plan to put a 2-post lift in on one side, and leave the other side open for a mobile gantry crane and my current scissor lift. This is what the building looks like, but I want more neutral colors, probably brown like my current ones.  I'm going to extend the gravel driveway over to it, and that will be about $1,000 in crushed granite gravel for a 30'x55' area with 3" bedding sand and 3" or gravel on top of that. The bonus is I'm cutting into all the mowable grass we have, which is approximately 3 acres worth right now.  We don't plan to plumb the building for water because of the (lack of) proximity to our well and septic tank. But I want to run 200A electrical at a minimum to it. I haven't talked to the electric coop yet about how that needs to be done. We have underground power on my property, and I'm, not sure if they can make another run from one of the existing utility boxes in the yard, or what.

|

|

|

|

Slung Blade posted:They'll probably have to run it from the house panel if that's where the transformer feeds to. Not a huge deal for a competent contractor. Sadly, we're in the land of no natural gas. I might do heating oil if heavy heating becomes a necessity, our house is electric/heat pump only with a wood stove for backup. Between A/C in the summer and heat in the winter our electric bill is pretty static, for whatever that's worth. The metal building company is running a special on "buy a building with insulation, get a heater or an A/C unit for free". Will have to think about that one, but probably heat since I can open doors and use fans in the summer. The only potential issue I see with the house panel is a) it's full. They'd have to wire a secondary panel with feeds to output to the garage. And b) the current input to the house and meter goes under my concrete parking apron, and I don't want to dig it up to run back out the the garage. I'm not against having a second meter on the new building if that's what it comes down to.

|

|

|

|

angryrobots posted:If it isn't, may have to dig all the way from the road, unless you're lucky and the existing service happens to be in pipe. I'm fairly in the dark (har har) about what is actually going on with my power. There's above ground electrical wires on my road, but for my property and the ones above me, it dives off the pole here (blue) and comes up through my property and there's a utility box here and here (red). My power meter is between my current garage doors here (orange).  The utility box halfway down the driveway doesn't hum and is this:  The utility box near the house hums, and therefore I assume is the transformer, and is this:  And the power meter is here, and the line going to it can be seen disappearing into the slab:

Garage2Roadtrip fucked around with this message at 17:11 on Oct 12, 2017 |

|

|

|

angryrobots posted:The small box that doesn't hum is a high voltage junction cabinet. The second one is the transformer, yes. 15 kva. Awesome, thanks for the info! Looks like I'll be in good shape if those kind of numbers hold up around here.

|

|

|

|

dreesemonkey posted:Is liquid propane available where you live? I'd probably go with that over heating oil if available. So, when I lived in Alaska I had radiant slab heating in my house, which had a 3 car underneath garage, and the outside 3-car had in-slab heating as well. It was all hydronic baseboard boiler-style heating, the house boiler had a circuit for the home in floor, and a waterheater was used in the outside garage. It was great for when the temps dipped below freezing. Here, just west of Asheville, NC, it doesn't get nearly that cold, and it doesn't get that cold for very long. I think I'd rather forgo the extra cost of the radiant in-floor for just a plain ol' electric garage heater. If I need to take the edge off, I can always use those radiant propane things, which I still have a few of from my time in AK. Here's some data I pulled from weather underground for the last 12 months here:

|

|

|

|

MonkeyNutZ posted:Super interested to see how your shop comes together, that'd be a killer deal for if/when I buy property here. I received quotes ranging from 12k-17k with concrete for that size shop. The negative reviews I saw for the companies on the cheaper end of the spectrum deal exclusively with the assembly of the structure, not the materials, pad, etc. I feel like if we're on this part of this forum, we have the ability to identify deficiencies and correct them with something as simple as galvanized square stock, sheet metal siding, and tek screws. If all pads are equal (a lot of these guys outsource concrete work), and I level the pad myself, I don't mind saving $5,000 to have to spend a few hours going over the building to make sure it doesn't fall in on me. Also, someone mentioned it earlier, but these are just fully boxed-in carports for all intents and purposes (albeit with some additional bracing and insulation etc). I'm keeping an eye on the load values they claim for the roof, but even that isn't a huge deal with the amount of roof pitch and lack of snow we get here.

|

|

|

|

A bigger concern is heat/humidity in the summer. My current thinking is to get a few fans and just keep some airflow in there. Luckily half of the building will be pretty well shaded from the treeline adjacent to it.

|

|

|

|

That camo WORKS

|

|

|

|

Fermented Tinal posted:Worst part is he spent all day telling me how he's worn that shirt for three days because it's cotton and feels great... Lol, gotta smell natural for seer season tho...

|

|

|

|

Rhyno posted:You said you don't plan to run water to the shop, have you thought about a rain reclamation system? My friend's dad just has his gutters running to a collection barrel which then runs to a tank inside. He doesn't drink it but has it plumbed to a faucet so he can wash oil and whatnot off before going inside the house. I think he just uses iodine tablets to treat the water in the tank. I've definitely thought of it, especially after seeing how much water comes off the roof of these building when it rains. It would be nice to have gravity fed gray water for handwashing. I didn't want to dig another septic, so maybe just a vertical french drain pit for outflow? Nice thing is that biblical levels of rain seem to go on either side of where a 30x45 would be. Although if I throw in a driveway to it, I'm thinking I'm going to have to elevate, ditch, culvert, etc to keep it from washing all the gravel down into the field.

|

|

|

|

In the shop chat: Bought a welder last week after much procrastination. Threw down a couple of practice beads and got to work.   Hit up the steel yard and bought some supplies.   First project was throwing together a stand for my bench grinder.    Then got to work on my welding table.         Came out pretty level.  Then started messing around with tacking scrap together for 'art'.  And had a successful time with the world's cheapest plasma torch.  Today I'm picking up more steel to build the lower braces and shelf on the table, as well as supplies for future projects.

|

|

|

|

Slung Blade posted:drat, nicely done. Table looks perfect for garage projects. I ended up mounting my vise on one of those H-D Husky brand adjustable height tables.  drat a new sheet of expanded steel is purrrty.  Larrymer posted:Wait for the noise... Indeed!  And thanks for the kind words!

|

|

|

|

Finished off the welding table this afternoon. Put 2x2x3/16" angle bracing around the lower parts of the legs.  Then cut and fitted a piece of 1/4" expanded steel sheet to sit on the angle iron.   I'm forgoing a welding cart for the time being, and using this as a one-piece-fits-all table/cart.  Now I guess it's time to throw together an engine run stand for the 1UZ and fab up the motor and trans mounts in the Starion.

|

|

|

|

boxen posted:For a second I thought you welded the casters directly to the table and was thinking that'd hurt you down the line, but then I realized what you actually did. Looks good. I'm confused as to what the brake-slack-adjuster is/does? I'm going to make a stationary stand (insomuch as for the engine, I'll put casters on it too for wheeling around the garage). I have an engine stand/rotisserie thing that spins for building engines, but I don't see any reason to need to spin an engine while running or wiring it. I'm going to use one of the extra front subframes for the Starions I have laying around and bolt that to plates with a bunch of holes on either side of the frame so I can use other subframes for other engines in the future. I also plan to make it higher than most run-in stands I've seen so I can access the oil pan etc.

|

|

|

|

|

| # ¿ May 5, 2024 03:01 |

|

boxen posted:Oh, a run-in stand. I thought you meant one for assembly/disassembly of engines. That's neat. I've always just used a jack handle and man-handled it to the various detents.

|

|

|