|

Slugworth posted:OK, I officially give up on math. I need help. I'm building a chicken coop/run, and I absolutely cannot figure out the angles for the roof. Realistically you should probably just lay them out on the lawn, but the math is a 56.3° cut and a 33.7° cut. The two cut angles should add up* to 90° since the ends will be perpendicular to each other. The steep cut would go at the ridge - each rafter rises up 3 feet and runs over 2 feet to the center. To have the board make a 56.3° angle on that top plate you would be cutting at 90-56.3=33.7. 67.4° at the top means each is 33.7° (=67.4 / 2), which means the actual cut is 56.3° (possibly too steep for a normal miter saw) * in geometry terms you are technically subtracting, 33.7 left - 57.3 right is a difference of 90 degrees.

|

|

|

|

|

| # ? Apr 30, 2024 08:33 |

|

The tricky part is that however you cut it, you want one edge as long as possible and one edge as tall as possible. Another way to put it is that the points should both be on one edge.

|

|

|

|

If you are building that out of 2x4 home depot grade lumber, good luck getting pieces that are straight and stay straight enough to hold that perfect angle. You realistically are not going to cut lumber to within a tenth of a degree unless it's perfectly dry extremely stable hardwood or an engineered product, and even then, you'll need very precise marking and a very precise way of cutting and the wood has to be extremely straight grain and fully dried/seasoned so it stays true. Or to put it another way, if you get within a degree, nails or screws will do the rest. Don't sweat a small gap. It's a chicken coop.

|

|

|

|

Leperflesh posted:If you are building that out of 2x4 home depot grade lumber, good luck getting pieces that are straight and stay straight enough to hold that perfect angle. You realistically are not going to cut lumber to within a tenth of a degree unless it's perfectly dry extremely stable hardwood or an engineered product, and even then, you'll need very precise marking and a very precise way of cutting and the wood has to be extremely straight grain and fully dried/seasoned so it stays true. Current internal debate is whether I use an acute angle jig for my miter saw or the miter gauge on my tablesaw. I don't really like either option. I'm never building a roof again.

|

|

|

|

I think your approaching this wrong. You can do it all with no math, just layout. On the ground set a 48 long board. Find the center and place another board perpendicular, mark your desired height. Lay a third board diagonally across so that the outside edge interests the end of your 48 and that same edge intersects the center line on the vertical. Mark the lines (vertical line matching your center line, horizontal line matching the top of your 48). Cut the lines using a standard circular saw, that's your template. Make a second and match them to verify. Edit: with regards to your last point, since we are talking about 2x4 and the length of the cut is very short and it is rough framing, id suggest just using a circular saw and free handing the cut against a pencil line. emocrat fucked around with this message at 12:18 on Apr 8, 2024 |

|

|

|

emocrat posted:I think your approaching this wrong. You can do it all with no math, just layout.

|

|

|

|

Probably late in the process, but I think this is why a lot of small structures like coops and sheds have roofs with a single slope, rather than peaked (gabled?) because it's a lot easier to just build the front wall somewhat higher and lay flat boards across.

|

|

|

|

old-school carpenters didn't sit around doing much trigonometry, because you lay out in such a way as to just draw lines against surfaces and cut to those lines in a broader sense: get a pair of dividers, learn how to use them, and you'll find yourself actually measuring less, and just making things proportional more, which is an easier way to live

|

|

|

|

emocrat posted:I think your approaching this wrong. You can do it all with no math, just layout. I call this Tom Silva math

|

|

|

|

Leperflesh posted:old-school carpenters didn't sit around doing much trigonometry, because you lay out in such a way as to just draw lines against surfaces and cut to those lines I almost made a snarky post about this. It might not seem like “doing much trigonometry” but simply knowing about the existence of, say, 3:4:5 and 5:12:13 right triangles makes the process of designing a gable pretty trivial. E: basically, “when am I gonna use this high school math in real life?” suddenly gets answered when you’re posting about online calculators telling you to cut with tenth of a degree precision.

|

|

|

|

The point was that they weren't actually doing the hard math of calculating sines/cosines and measuring out angles. They put the responsibility of that work onto technology, just like we do, except their technology was "a stick" and ours is "a ridiculously powerful computer"...and the stick is better.

|

|

|

|

TooMuchAbstraction posted:The point was that they weren't actually doing the hard math of calculating sines/cosines and measuring out angles. They put the responsibility of that work onto technology, just like we do, except their technology was "a stick" and ours is "a ridiculously powerful computer"...and the stick is better. Computer says "assume perfectly straight and correctly dimensioned lumber". Stick says "cut on this pencil line to make these two line up"

|

|

|

|

TooMuchAbstraction posted:The point was that they weren't actually doing the hard math of calculating sines/cosines and measuring out angles. They put the responsibility of that work onto technology, just like we do, except their technology was "a stick" and ours is "a ridiculously powerful computer"...and the stick is better. So you're saying we should avoid... Too much abstraction?

|

|

|

|

Hello. Two hopefully small questions. 1 - I bought a house with shelves in the "workshop room". These shelves are installed against the studs but there's no drywall on that side of the room so there's a 3.5" gap between the shelf and the wall and things keep falling into the gap. Is there an easy way to shove something like cardboard in the gap so that things stop falling? Or should I get like thin wood and screw it into the shelf to cover the gap? I feel like the real way would be to unscrew the shelves and cut grooves for the studs and then re-screw but that feels like a full day I don't want to deal with. Other drywall --------------------------- | gap | gap | gap | <--- studs -------------------------- | shelf ................| |..........................| |..........................| --------------------------- 2 - I am going to blow in insulation in my roof but understand I need baffles. I have four 20-foot lengths to baffle. That's like $400-$500 to get like 100 of those plastic things from home depot. Is there a simpler way or can I find a giant roll of landscape paper or something to just roll across the space? Or are those plastic things the way to go? Thanks

|

|

|

|

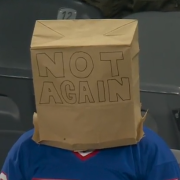

Took all of yalls advice and just winged the coop roof, I think it came out pretty drat well.

|

|

|

|

I was such a baby about doing roof math when I built my lean-to that I did a single slanted roof and used these: Single 4-in x 6-in 18-Gauge G90 Galvanized Variable Pitch Connector https://www.lowes.com/pd/Simpson-Strong-Tie-VPA-Galvanized-Variable-Pitch-Connector-for-2-1-2-in-Joist/5001528347

|

|

|

|

Slugworth posted:Took all of yalls advice and just winged the coop roof, I think it came out pretty drat well. Literally what I was thinking while reading that discussion. I made a template for both my coop and shed roof. They still came out slightly wavy, because as previously mentioned, straight wood ain't. You can't tell at all once the sheathing and shingles go on.

|

|

|

|

The Dave posted:Single 4-in x 6-in 18-Gauge G90 Galvanized Variable Pitch Connector https://www.lowes.com/pd/Simpson-Strong-Tie-VPA-Galvanized-Variable-Pitch-Connector-for-2-1-2-in-Joist/5001528347 TIL that wood comes in "nominal" and "actual" sizes. I had no idea, but I'm still learnin' the American Way.

|

|

|

Vim Fuego posted:So you're saying we should avoid... Too much abstraction?

|

|

|

|

|

How interchangeable are the hoses linking a handheld shower head to its mount? I have a Moen Quattro with a broken rubber tube inside the hose. It comes off with no trouble but I'm hoping I can replace the hose with something cheaper than the $85 the company wants for it, since that's nearly what I paid for the whole unit originally. The part number is 210007SRN, but I'm not too set on having the color and finish match. We're going to replace it with a different shower head for the master bath and put it in the guest bathroom. My wife never really liked this one in action anyway.

|

|

|

|

SouthShoreSamurai posted:Literally what I was thinking while reading that discussion. When I built my garage, I had no plan or drawings for the roof joists. Once my loft kneewalls were done, I got them as plumb, square & parallel as I could. To size up the joists, I threw up a 2x4 at the centerline front & back, measured up where the peak would be (code-limited to 20' above grade) and drew a string from front to back at that height (accounting for the joist chord of 7-3/4") & anchored it. You can see the rear board still up, now stabilizing the rear-most joist 'truss'. Then I measured from the 'peak' (string) down to my top plate, left & right. Using those as a guide for peak to rest I laid out a jig, using the front & side kneewalls. Built a test unit & set it up. Satisfied it was near where it had to be, just banged out a dozen or so home-made trusses.   Still had to shim & adjust. I had checked the wall measurements multiple times but still had to cinch a few in, even sister a couple, to get a good touch on all of them with a chalk line. e: I struck the angles by overlapping the joists, then cut then with a circular saw, fitted, and secured the peak with plywood scrap. Used a jigsaw to cut the birds-mouths. e2: this was almost 20-years ago PainterofCrap fucked around with this message at 03:50 on Apr 10, 2024 |

|

|

|

Lemniscate Blue posted:How interchangeable are the hoses linking a handheld shower head to its mount? I have a Moen Quattro with a broken rubber tube inside the hose. It comes off with no trouble but I'm hoping I can replace the hose with something cheaper than the $85 the company wants for it, since that's nearly what I paid for the whole unit originally. Followup in case anyone ever searches the thread for a similar issue: According to the plumbing aisle guy at the hardware store they're completely interchangeable and standardized, so I'll just get a cheap replacement hose.

|

|

|

|

Probably a dumb question, but what's the best way to get a small amount of silicone? I just need to redo a very small patch of our tub, and I don't want to open up a full 10oz tube of it when I don't have any other similar projects for a while. If that's my only option, I'll do it -- it's not like it's expensive -- it just seems wasteful.

|

|

|

|

If you stick a big nail or screw into the tip of the tube, it'll keep for a little while, at least a month.

|

|

|

|

TooMuchAbstraction posted:If you stick a big nail or screw into the tip of the tube, it'll keep for a little while, at least a month. I find it helps to put it in a baggie and squeeze out as much air as possible, but even so it doesn't last more than a few months before getting too thick to use.

|

|

|

|

Home Depot or any other hardware store should have these 3 oz little guys of silicon around https://www.homedepot.com/p/POLYMERSHAPES-100-Silicone-2-8-oz-Clear-Caulk-and-Sealant-for-Plastic-Sheets-GE-57/202038072

|

|

|

|

I have a 2019 LG Dishwasher that just started not fully opening to the floor. It goes down to about 80 degrees then there's resistance. It will go down to its full 90 degree extent if you push down on the door heavy, but springs back to the 80 degree mark without heavy force (e.g. the lower basket doesn't do it). I thought this was related to recently seeing a piece of gasket on the bottom, but I can't tell it's there. Anything obvious I should check? I thought maybe a piece of gasket where it tore was preventing opening but I don't see anything.

|

|

|

|

Hed posted:I have a 2019 LG Dishwasher that just started not fully opening to the floor. It goes down to about 80 degrees then there's resistance. It will go down to its full 90 degree extent if you push down on the door heavy, but springs back to the 80 degree mark without heavy force (e.g. the lower basket doesn't do it). I'd start with appliancepartspros.com (or your favoriote exploded diagram lookup), put in your model number (should be on the door or the door jamb on the tub) and get the parts diagrams. That's gonna help you figure out what the parts of the mechanism you can't see look like and what might be jammed or perhaps what spring is broken. I don't know LGs so I don't know if there's something common, but that's how I'd start.

|

|

|

|

Got some wood delivered for joists and they came warped, chipped and moldy. ] ]Thanks, Lowe's!

|

|

|

|

You're lucky. They normally charge extra for pre-aged wood.

|

|

|

|

I need to remove some very dense and old juniper bushes that are 4-5' in diameter. I have a cordless electric hedge trimmer but it can only manage the green parts and anything thicker it gets bogged down. Is there something between a hedge trimmer and a chainsaw I can use or would a beefier hedge trimmer do the job? A chainsaw feels like it would be like using a circular saw to cut cardboard but it will probably work pretty well.

|

|

|

|

You want a lopper: They're basically overgrown gardening shears, with big blades and extra long handles to give you the leverage to easily cut through branches. You can cut through a 1" thick branch pretty easily with them, and 2" if you work at it a bit and the wood is green.

|

|

|

|

or a Sawzall, as the name says yes, "reciprocating saw" doesn't, I know I've used it for getting rid of some roots in that size range

|

|

|

|

Rule of thumb for loppers is to cut nothing bigger than your thumb.

|

|

|

|

And yet I've easily chomped through inch thick limbs with mine and it's lasted 14 years now. Just like, don't add pipes to the handles to add mechanical advantage to push it way beyond what it can do. You'll break it. gbut posted:or a Sawzall, as the name says Roots are held still by the dirt. A 1" limb is going to vibrate like heck and be a huge pain in the rear end to try to cut with a sawzall. Not that it's impossible, just... ew, rather use a hand saw or something. Speaking of. A greenwod bow saw like this is cheap and works great on limbs too thick to get through with your loppers. Takes a few seconds.

|

|

|

|

gbut posted:or a Sawzall, as the name says Seconding reciprocating saw, with appropriate blade.

|

|

|

|

There's pruning blades for reciprocating saws like this: https://www.amazon.com/9-Inch-Pruning-Reciprocating-Sawzall-Blades/dp/B072WM881G/ Downside is that they vibrate a lot but they work pretty well if you already have a sawzall or equivalent. There's also cheap chinese mini chainsaws. These are great little tools, usually work well, but you have to be really careful with them. I got one like this a couple of years ago after folks in the aliexpress thread were buying them. https://www.amazon.com/Chainsaw-Cordless-Electric-Handheld-Portable/dp/B0981Q8KBJ There are more expensive ones made by the big tool companies now, but the cheap ones work decently. Mine's only crapped out after sawing for a while if the battery gets lot or if it gets too hot. It's still working.

|

|

|

|

kid sinister posted:Seconding reciprocating saw, with appropriate blade. A year ago I would have agreed, but the Ryobi shill (said with love and admiration) in the tool thread convinced me to buy a Ryobi pole saw that came with a baby battery chain saw too and I love it so much for things like this. It's much easier to use than a recip saw for this type of thing.

|

|

|

|

Motronic posted:A year ago I would have agreed, but the Ryobi shill (said with love and admiration) in the tool thread convinced me to buy a Ryobi pole saw that came with a baby battery chain saw too and I love it so much for things like this. It's much easier to use than a recip saw for this type of thing. Whispering to myself: be strong, be strong, be strong…

|

|

|

|

|

| # ? Apr 30, 2024 08:33 |

|

Motronic posted:A year ago I would have agreed, but the Ryobi shill (said with love and admiration) in the tool thread convinced me to buy a Ryobi pole saw that came with a baby battery chain saw too and I love it so much for things like this. It's much easier to use than a recip saw for this type of thing. I also have the 18v ryobi pole battery chainsaw thing, and it's great. I have tried to use it on things that are near the ground and it is awkward to do that though. Also I haven't tried it on small stuff like <1".

|

|

|