|

BattleMaster posted:If I'm building a battery powered device is there any need for filtering on the battery power? I found a paper that examined battery noise and found that essentially 100% of the noise from batteries is from Johnson-Nyquist noise in the equivalent series resistance, which makes me think that it's stable and clean enough that there's no need for any filtering. Just power your device with Weston cells

|

|

|

|

|

| # ? May 31, 2024 18:56 |

|

ANIME AKBAR posted:So at work I'm diving into some FPGA poo poo for the first time in ten years, which is cool. But I'm working with VHDL for the first time and holy crap I can't believe how strongly typed this language is. The state of HDL languages totally sucks. In verilog you can use case and if inside a begin/end but not outside which makes no particular sense. And it’s super loose about many other things in a bad way. The software world generates new languages all the time but in hardware we’re stuck with crap from the 80’s invented before synthesizers.

|

|

|

|

ANIME AKBAR posted:So at work I'm diving into some FPGA poo poo for the first time in ten years, which is cool. But I'm working with VHDL for the first time and holy crap I can't believe how strongly typed this language is. Why would you add a boolean to an integer? That's a you problem, not the language.

|

|

|

|

asdf32 posted:The state of HDL languages totally sucks. In verilog you can use case and if inside a begin/end but not outside which makes no particular sense. And it’s super loose about many other things in a bad way. Have you looked at Chisel? I haven't touched it at all, but I know people that have produced cool FPGA stuff with it.

|

|

|

|

Give Verilog a try, I think it's a little easier to learn than VHDL e: fixed phone post massacre taqueso fucked around with this message at 00:31 on Jan 1, 2020 |

|

|

|

insta posted:Why would you add a boolean to an integer? That's a you problem, not the language. That might not be a great example. Here's one: If you require a diagram like this printed up on your desk, your language has issues

|

|

|

|

I retract my troll.

|

|

|

insta posted:Why would you add a boolean to an integer? That's a you problem, not the language. Basically I want to increment a number if a condition is true. IMO this shouldn't require an if statement, or any type casting (if the number is just an integer). ante posted:That might not be a great example. Here's one: And having an integer type in addition to signed and unsigned types, all of which require explicit typecasting to work together, is loving bonkers. ANIME AKBAR fucked around with this message at 00:29 on Jan 1, 2020 |

|

|

|

|

ANIME AKBAR posted:Basically I want to increment a number if a condition is true. IMO this shouldn't require an if statement, or any type casting (if the number is just an integer). I do hope you have a good understanding of the underlying synthesized hardware since that’s what really makes or breaks a design (language syntax is trivial to google). Signed vs unsigned for example is something I want explicit control over (since it consumes a bit). Which tools are you writing in and what for? Xilinx Vivado has a credible C compiler and many other useful high level blocks. Stabby McDamage posted:Have you looked at Chisel? I haven't touched it at all, but I know people that have produced cool FPGA stuff with it. Looks neat. What’s it supported in so far?

|

|

|

|

asdf32 posted:I do hope you have a good understanding of the underlying synthesized hardware since that’s what really makes or breaks a design (language syntax is trivial to google). Signed vs unsigned for example is something I want explicit control over (since it consumes a bit). I know nothing about FPGA programming, but I'm also curious what would integer represent that's not already handled by a signed type?

|

|

|

|

Stabby McDamage posted:Have you looked at Chisel? I haven't touched it at all, but I know people that have produced cool FPGA stuff with it. Why the hell is it based on scala of all things e: Oh it's a front-end to another thing that actually does the leg work, so you can use other frontends for it including Python apparently, okay. Shame Boy fucked around with this message at 02:02 on Jan 1, 2020 |

|

|

asdf32 posted:I do hope you have a good understanding of the underlying synthesized hardware since that’s what really makes or breaks a design (language syntax is trivial to google). Signed vs unsigned for example is something I want explicit control over (since it consumes a bit). Sure, in other situations things might get weird. Like if you add signed variables with different lengths, you will get weird results if you just feed them into a normal hardware adder. But translating that sort of trap scenario into working logic is what a good compiler/synthesizer would do. Categorically disallowing any mixing of types, and forcing the user to explicitly typecast everything, is just loving lazy. Like it's fine if VHDL exists, but it blows me away that people still write it all the time. peepsalot posted:I know nothing about FPGA programming, but I'm also curious what would integer represent that's not already handled by a signed type? signed and unsigned must be declared along with the number of bits they use. integers are declared with a range of values they are allowed to have. For some reason, someone decided that would be a useful thing. Oh but if you want to access an element of a vector, the index variable has to be an integer! Because gently caress you, that's why!? ANIME AKBAR fucked around with this message at 03:13 on Jan 1, 2020 |

|

|

|

|

VHDL is very much not terse, I think having to cast everything falls under that umbrella. But yeah HDLs are a dumpster fire.

|

|

|

|

ANIME AKBAR posted:Sure it's cool to define the exact size of variables in hardware. But is there any difference between adding two unsigned and two std_logic_vectors of the same length? So why shouldn't one be allowed to add an unsigned to a std_logic_vector? I definitely disagree on typing in general. If there are easy casts between types its not much of a burden and helps prevent confusion and mistakes in many cases. Typing also has huge benefits in the IDE in terms of auto-complete and realtime syntax highlighting. It's sad watching a python IDE try as hard as it can. If it has 'seen' what type a variable is then it can autocomplete that objects methods when you add a '.'. But often it has no way to know. That's a huge letdown from say C# in visual studio. Likewise typescript is a big improvement over javascript entirely because of its static typing. Really I'm surprised one of the two major FPGA companies (or the ASIC world) hasn't created its own language to address these problems and differentiate from competitors. Xilinx Vivado is actually a reasonably modern IDE at this point (syntax highlighting etc) but is lacking a modern language.

|

|

|

|

I moved into a new house with 6 bookshelves. I’d like to use them next to an electronics bench and store my various components, spare parts and in progress projects. Currently I use about 4 of the crappy waist height white plastic roll around bins. I especially have hundreds of various cables I’d like to store better. What’s your fav small parts and project storage that’d work with a bookshelf?

|

|

|

|

I, too, would like to know this. I converted an in law suite to a workshop and have the same storage.

|

|

|

|

I always thought the toilet paper tube method of storing cables to be very clever. Doesn't work too well horizontally though. I'd just go to the hardware store and get a couple plastic containers. See which size fits your shelves best, then buy a dozen and return the rest. edit: and get some flat boxes with adjustable dividers for the really small stuff, like fishing tackle trays. kid sinister fucked around with this message at 08:41 on Jan 2, 2020 |

|

|

|

Lets make a Quantum Computer! https://media.ccc.de/v/36c3-10808-build_you_own_quantum_computer_home_-_99_of_discount_-_hacker_style#t=958

|

|

|

|

kid sinister posted:I always thought the toilet paper tube method of storing cables to be very clever. Doesn't work too well horizontally though. My problem with the plastic containers is appearance. They look fine in a garage but this is somewhere I spend hours per day making lovely posts, so I want it to look nice. I just moved in to this new house this week and had fam for the holidays so pardon the irony of this looking bad but...I went to Ikea:  Those grey boxes are $6 and the wood ones are $20. For the wood: I have a stain that matches the bookshelf pretty well so I think I might stain the wood one to match(ish) then paint or stain the boxes a dark color and add stainless finials. For the grey: I'm using the boxes for different cable types, for example heres my audio/video cable box. I added a $5 Ikea insert to the box.   So my cable box cost me $11 and the grey doesn't match the wood great but its a huge improvement on my previous terrible boxes so I'll take it. Ikea also has this which, if you're not trying to fill book cases, is probably a better option. Just combine with some plastic boxes and it'll still look nice.

CarForumPoster fucked around with this message at 14:49 on Jan 2, 2020 |

|

|

|

CarForumPoster posted:Ikea also has this which, if you're not trying to fill book cases, is probably a better option. Just combine with some plastic boxes and it'll still look nice. I use something more similar to this from the Container Store. Their Elfa shelves have freestanding half-height and full-height drawer units that use modular trays that slide in on a track. I use 1u tall trays subdivided as needed for small bits and cables, 2u trays for projects, larger modules or components and tools, 3u trays for power tools and large cables or bulky items. Great thing is that you can pull the whole tray out and take it to the table where you are working, then put it back when you are done.

|

|

|

|

If you guys want to store longer cables (20'+) find somebody who 3D prints. I have so many empty cable spools and no real use for them outside of the garbage or burning for heat (not marked, can't recycle).

|

|

|

|

While we're talking about storage, I think this thread originally recommended me the AideTek BOX-ALL containers for SMD things and they've been a loving lifesaver. They're a little pricey but absolutely worth it if like me you have a bunch of SMD stuff on tape in bags that you currently have no idea what to do with. I got a bunch of different ones with different size containers for different things and now all my tens of thousands of SMD things fit in a stack of these boxes like a foot and a half high. They're a bit of a pain in the rear end to label properly (I got rid of the labels they came with because they suck and printed up my own with some sticker paper) but so loving worth it. Now I just need to figure out what to do with my big box of through-hole stuff...

|

|

|

|

Shame Boy posted:While we're talking about storage, I think this thread originally recommended me the AideTek BOX-ALL containers for SMD things and they've been a loving lifesaver. They're a little pricey but absolutely worth it if like me you have a bunch of SMD stuff on tape in bags that you currently have no idea what to do with. I got a bunch of different ones with different size containers for different things and now all my tens of thousands of SMD things fit in a stack of these boxes like a foot and a half high. They're a bit of a pain in the rear end to label properly (I got rid of the labels they came with because they suck and printed up my own with some sticker paper) but so loving worth it. Ditto on the through hole. I have one of those flip-top divider boxes, but the components wiggle under the little removable dividers and get mixed up. That, and when the top is open, I'm terrified that it will get knocked over and I'll be stuck reading colored stripes til I go blind. The little drawers are a bit better, but still vulnerable to getting knocked over. Something with separate boxes per thing would probably be best. Any ideas, folks?

|

|

|

|

To store all my through hole stuff, I got my box, and I chucked it right in the trash, where it belongs

|

|

|

|

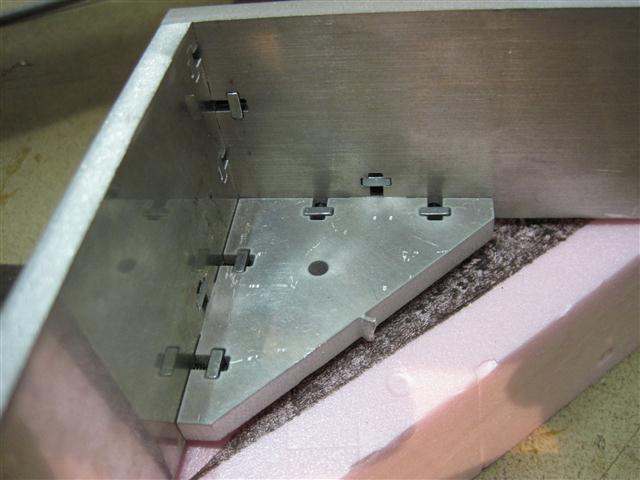

IRT bench/shelf storage solutions, i love designing laser-cut storage units to fit my exact needs. You don't have a laser cutter, probably, but having a commercial shop cut a Bespoke Storage System for you from 1/8" - 1/4" plywood as a single job still ought to be cheaper than buying commercial equivalents new. Once you have a design workflow and have figured out what values you need to get close-fitting finger/tab-style joints from your given machine, it's surprisingly painless. i have this parametric laser-cut finger-jointed box plugin for inkscape i downloaded ages ago that's great for throwing together open-topped boxes, multi-compartment grid-divider boxes/drawers with lots of little compartments, and combinations thereof (you can more or less replicate commercial multi-drawer organizer units to spec by designing the organizer shell, and then designing the part bins to suit). You don't need to worry about the design at all, it makes sure everything lines up and should produce decently-mating finger joints right off the bat. Assembly is quick and easy, you only need a little bit of glue for the joints. Google around for the plugin, idk where I found it. If you do your own design I'm a huge fan of captive nut joinery, you cut recesses for square nuts into one part and aligning clearance holes for screws in the mating part, and then add some loose-fitting slot-tab pairs to aligh the parts:   it makes for knock-down designs that can store perfectly flatpack-flat and eliminates the need for close-fitting finger joints, the only toleranced/fiddly part of the whole design. You also don't have to stick to plywood, transparent acrylic drawers/drawer faceplates let you see the drawer contents much better than commercial organizer drawers tend to permit. Captive nut joinery tends to be easiest for acrylic because the joinery is unforgiving There are lots of good grabcad designs out there too if you want to keep your life simple; they tend to be much slicker/more thoughtfully-laid out than commercial options to boot. They're usually organizers for modelmakers and non-electrical hobbyists, though, so customizing them is usually called for. e: so this is a little less off-topic, all the above also applies to custom enclosures, which scientists have recently learned are really just highly sophisticated boxes Ambrose Burnside fucked around with this message at 23:09 on Jan 2, 2020 |

|

|

|

So what you're saying is, I now have an economic reason to buy a shaper origin?

|

|

|

|

ehhh, captive-nut joints are elegant and good-looking if you can cut sharp-cornered designs with essentially no min corner radius, so they're v popular with laser cutter / abrasive waterjet assemblies. they make less sense on a router/mill because you need to predrill clearance holes at the nut slot corners or else use undersized cutters and add in (ugly + hard to conceal) relief pockets that the cutter can handle. you can def still do em, but the relief-sized cutter for an M4 nut slot (sized for 1/4" sheet) is gonna be tiny and idk how well small tooling works with handheld CNC router approaches. that said, if you're looking for an excuse to buy a CNC machine tool, this works as well as anything through-cut panel joinery and fastening is its own weird little world where the cleverest approaches tend to leverage the unique features of the tooling, like zero-radius inner corners with the laser. you can do some surprisingly sophisticated joinery with just the panel material itself, for ex snap-lock slotted joints that assemble by hand but create a permanent join that you usually need to destroy to undo:  there's a decent survey here, if you're looking for more excuses https://makezine.com/2012/04/13/cnc-panel-joinery-notebook/ Ambrose Burnside fucked around with this message at 01:29 on Jan 3, 2020 |

|

|

|

How to Make Your Everything Really Really Fast is an excellent jumpstart to the mechanical world for computer dorks, too. I think it's an Instructable now.

|

|

|

|

ante posted:How to Make Your Everything Really Really Fast is an excellent jumpstart to the mechanical world for computer dorks, too. I think it's an Instructable now. I hadn't run into this til now, but yeah, i'm bookmarking it because yeah it's great: https://www.instructables.com/id/How-to-Build-your-Everything-Really-Really-Fast/ esp like the General Lessons & Themes as a primer for people doing sth like this for the first time, it really does hit the critical half-dozen design considerations that ought to produce workable designs from the start

|

|

|

|

OK, so jukebox project is going well, composite video overscan on RPi is a huge pain in the rear end. I need to get the woodworking done and maybe build some speakers. Thanks for the advice on those! Back to that 5" monochrome display, I'm thinking of doing a "real" Pip Boy for a cosplayer friend, Is there any safe way to protect the wearer from the flyback transformer without a reliable ground? Capacitor bank with light bulbs to discharge them? "Power Failure" Neon tube? Anything like that sound plausible?Unperson_47 posted:I've tried this but with homemade "solder paste" made of powdered graphite mixed with various glues, epoxies, and even acrylic paint. If you add enough graphite, the resistance is actually really low and you can paint circuits on paper and such. I applied the glue with a syringe and it hardened in the grooves. It worked but was messy as hell. What a dumb goose chase project that was. Learning Electronics: It was even more of a mess

|

|

|

|

The title this thread should have is the one where someone said their time tunnel (?) wasn't working on their oscilloscope or something like that. edit: found it: Bad Munki posted:There's something wrong with your time tunnel The Something Awful Forums > DIY > There's something wrong with your time tunnel in the Learning Electronics MEGATHREAD I don't even know if a time tunnel is real. Unperson_47 fucked around with this message at 17:36 on Jan 3, 2020 |

|

|

|

GWBBQ posted:OK, so jukebox project is going well, composite video overscan on RPi is a huge pain in the rear end. I need to get the woodworking done and maybe build some speakers. Thanks for the advice on those! Back to that 5" monochrome display, I'm thinking of doing a "real" Pip Boy for a cosplayer friend, Is there any safe way to protect the wearer from the flyback transformer without a reliable ground? Capacitor bank with light bulbs to discharge them? "Power Failure" Neon tube? Anything like that sound plausible? Why doesn't it have a reliable ground? Can you just pot the entire thing? Also I'm not trying to be an rear end in a top hat but you probably don't want to be making kilovolt-containing wearable devices for other people if you're not entirely sure how to not kill them...

|

|

|

|

I've got a stereo receiver (JVC RX 318) that's got fucky audio in both left channels. I'm suspecting a bad cap, but beyond that i have no idea what to look at; the board is some multilayer thing and i can't travel circuits to see where the traces from the speaker plugs go to. Is there a trusted repository of service manuals somewhere out there?

|

|

|

|

Fender Anarchist posted:I've got a stereo receiver (JVC RX 318) that's got fucky audio in both left channels. I'm suspecting a bad cap, but beyond that i have no idea what to look at; the board is some multilayer thing and i can't travel circuits to see where the traces from the speaker plugs go to. Is there a trusted repository of service manuals somewhere out there? Google with different search term combos and filetype:pdf e.g. "JVC RX 318 filetype:pdf" You may not find the right one, but you may find sites that you can manually look at that are a repository of such things.

|

|

|

|

CarForumPoster posted:My problem with the plastic containers is appearance. They look fine in a garage but this is somewhere I spend hours per day making lovely posts, so I want it to look nice. if they are the ones we use here (ikea Alex) we don't bother with wheels and use them to support the tables.

|

|

|

|

Fender Anarchist posted:Is there a trusted repository of service manuals somewhere out there? There's BAMA, but that's for even older stuff than your JVC. I found the service manual available for purchase: https://www.analogalley.com/osccart/product_info.php?products_id=1085 It also hints that your receiver is similar to the 316 and 317. According to here, the 318 is only a few parts off the 317. Here's the service manual for both the 316 and 317: https://elektrotanya.com/jvc_rx-316bk_rx-317tn_am-fm_rceiver.pdf/download.html

|

|

|

|

Hey electronics thread. I'd like to post a public service announcement. Yesterday I was almost electrocuted to death. I was modifying an ATX power supply to be a bench power supply with binding posts like I've done several times before. I had just tested it, I turned off the soft power switch, but forgot it was still plugged in with the case open. I didn't follow my usual double-check procedure when working with AC. I picked the box up with both hands to turn it over, and it arced across one hand as well as between my hands -- through my heart. My hands convulsed and I physically couldn't drop it. It was absolutely terrifying. I let out a scream as loud and as intense as anything I've ever heard. After a beat, I realized I needed to run away from the outlet til the cable yanked, so I did. When I got out of the room, the box was ripped from my hands and I fell to the floor. It took me a while to become coherent again. I realized I was bleeding from one hand where the sheet metal had cut through, and my other hand had several patches white as paper -- the areas where my flesh was cooked. I dressed the wounds and went to the ER. They checked my heart and did a urine screen for deep tissue damage -- all came up okay. The burns and cut are starting to heal now, but if I'd held the box differently or if I took another second to run away, I could be dead right now. This was "just" 110VAC, and despite this story, I do actually know what I'm doing. The danger is that experience breeds complacency. Double and triple check your high voltage sources. Be systematic and habitual about it. Install a GFCI in lab areas. Hopefully this post prevents at least someone else from being as dumb as I was. Oh, and the worst part? The loving power supply broke from the fall.

|

|

|

|

Scary poo poo. Sorry to hear about the supply. I was working alone today with 350VDC in some big capacitors and an alligator clip popped off and vaporized a test lead in a split second. Scared the crap out of me, but no harm done. Stay safe out there.

|

|

|

|

One of the checks I always do: Before I physically interact with a mains powered device, I check I can directly see the complete mains cable and plug, unplugged, at all times, and i look at it every time. If it's not clear which mains lead is which, I rearrange my workspace so it is. This won't protect me from big scary caps though, only making sure it's not connected, so I just don't go near those.

|

|

|

|

|

| # ? May 31, 2024 18:56 |

|

The rule I put in place is easy to follow. If I'm working on anything plugged into a wall, one hand is placed physically behind my back. Luckily, or unluckily depending on how you look at it, I know from experience that I don't lose motor control in similar situations.

|

|

|