|

Sydney Bottocks posted:Even when things go smoothly, there's still the time it takes to clip items off a sprue, remove mold lines, or wait for glue/putty/etc. to set and dry. And sometimes you can't just leave it to go do something else, because you actually have to hold it in place until it's fully set (and hope you didn't get superglue on your fingers, or plastic cement on the part you're holding). Unless you're buying models for a game that are already preassembled, by and large the time cost for prepping and assembling a plastic/metal/cast resin kit can arguably be longer than cleaning a printed resin mini or model, removing supports, and curing it. Yeah, you can definitely tell when someone hasn't done much with miniatures when they start complaining about wasted time. Ten minutes with some gloves on to clean, cure, and remove supports for a pile of minis beats the hell out of an hour or more spent cutting bits from sprues and cleaning them up just so you can start assembling your models, all the while paying $50+ for the privilege.

|

|

|

|

|

| # ? May 28, 2024 08:05 |

|

I'm about to pop open my .5kg of TPU (96A) i bought on a whim for testing. I fully intend to print tests left and right to figure it all out, but some information seems to be all over the place,and I dont want to waste it and my time unnecessarily. I'm keeping my generic TPU profile pretty much the same, but I am lowering retraction to 3mm. I am using my pretty much stock Ender 3v2, with the only changes being to cooling ducts (not needed here?) and a hotend fix with a capricorn tube segment locked in there. That being said, the stock printer can handle this if i go slow and watch retraction, right? Bed temps I have seen 0 to 80c(!) so I have no idea if i need to actually heat the bed or not, but i am using a PEI sheet for now. I know this is more of a trial and error thing, but will i need to pop it off the printer and into the drybox right away or can this sit out for a bit? What are people's overall experience with this ? My eventual goal is to create some phone / lcd mounts for my car and octoprint setup Roundboy fucked around with this message at 20:28 on Oct 28, 2021 |

|

|

|

I have one TPU that rips PEI off the bed and a different one from the same brand that doesn't stick at all, so have fun figuring that out

|

|

|

|

Definitely don't print TPU on a smooth PEI sheet.

|

|

|

|

I'd really recommend getting some garolite/G10 for printing TPU unless you want to play with adhesives/glues. Or have that rough PEI sheet that Prusa makes as your build plate. It'll still stick like hell if you are too close to the bed, so you'll really want to consider adjusting the Z-offset further away than you normally would for PLA/PETG/Whatever.

|

|

|

|

Ok I jumped the gun and just said 'gently caress it, do it live' and just printed my calibration cube. Bed was off, but still cooling from my last print so it was @33c or so. No glue, and this was pretty drat solid on the plate. temp 238 speed 50m/s retraction was 3mm 25m/s speed   some little zits I can work on, but the corners are sharp, sides are smooth, letters are crisp. and my cheap amazon calipers show 19.8 / 19.9 all around. Honestly not getting all the crazy TPU worry out of this at the moment. But I am gonna try something more signifigant Roundboy fucked around with this message at 21:19 on Oct 28, 2021 |

|

|

|

Roundboy posted:some little zits I can work on, but the corners are sharp, sides are smooth, letters are crisp. and my cheap amazon calipers show 19.8 / 19.9 all around. TPU, printed well, always looks like forbidden candy. that's really crisp for springy poo poo.

|

|

|

|

Nerobro posted:TPU, printed well, always looks like forbidden candy. that's really crisp for springy poo poo. 20% infill and its smooshy like a marshmallow Printing the dice i tried on silk PLA earlier but fell off even with a brim. Im using the PLA gcode of 100% infill and i just turned off the bed and manually set the hotend temp up. 50% done but printing like a champ. The PLA one flew off the mat and ate itself like 5 min in

|

|

|

|

Now try something where stringing will be a factor.

|

|

|

|

I'm itching to build that makergear micro printer. But add a heated bed. I shouldn't. I just want a portable printer. Roundboy posted:20% infill and its smooshy like a marshmallow instead of 100%, try.. like.. 98% or 95%. Also, double check that extrusion rate. "anything to give room for extrusion errors" makes life a whole lot easier. I'm having alittle bit of trouble following though. Did you turn the bed off while printing PLA? withak posted:Now try something where stringing will be a factor.

|

|

|

|

Nerobro posted:I'm itching to build that makergear micro printer. But add a heated bed. Sorry my original settings for dice were based on pla. 100% infill, 205/60 temp, brim for adhesion because the model was printing balanced on a corner as to make the dice fair I didn't realize for you, I just used the printer menu to set the bed from 60-->0 and the hotend to 238. My wife is a little disappointed it's not smooshy, so I can redo it with some space inside

|

|

|

|

I printed a benchy on the Longer LK1 today and it seems OK, although the flavor of Marlin they put on there seems to have a problem with M1/M0 gcodes, I found that out trying to use my leveling script which causes the controller to crash. Also, being on stock cura profile is strange, especially because they default to a raft. Will have to really tune this in later.

|

|

|

|

withak posted:Now try something where stringing will be a factor. Nerobro posted:

Challenge accepted! Benchy is on the way, but I always wanted one of these squishy   Sure the stringing from the head to tail is there, but it cleans up easy and i haven't even started to tweak it yet. I wonder if i can up the retraction to 5 from 3 to solve it even more. The lines are clean otherwise, and the 'flex' is still there so the parts are still l captured, but this really does shine in a rigid plastic. The issues i used to have in other filaments was the tail section being so small it would need extra adhesion or it would lift off and fail. Not here, this PEI sheet is pretty drat nice with the texture for this. I wonder how the glass sheet would work

|

|

|

|

I've recently noticed that my printer appears to be dropping "oil" spots on my PEI sheet: Closeup:  The dripping areas seems to correspond with being underneath the front of my extruder under the diagonal fan-ish area, and it doesn't seem to be melted filament. It's got the consistency of really thin oil. And it smudges like wet marker when I run my finger over it. I can only find one page where some guy had leaking bearings, but it's not really similar to what I'm seeing on mine. Nothing on my printer looks oily or dripping (and none of my rods are over-lubed either). What the heck is happening?

|

|

|

|

Fan is dying. Cheap ones use oil bushings.

|

|

|

|

insta posted:Fan is dying. Cheap ones use oil bushings. Oh, that's a relief. I guess it won't be too much trouble to get a replacement. How long do they usually last? I've had this printer for less than a year.

|

|

|

|

About a year  Get a double-ball replacement instead. Get a double-ball replacement instead.

|

|

|

|

Paradoxish posted:Yeah, you can definitely tell when someone hasn't done much with miniatures when they start complaining about wasted time. Ten minutes with some gloves on to clean, cure, and remove supports for a pile of minis beats the hell out of an hour or more spent cutting bits from sprues and cleaning them up just so you can start assembling your models, all the while paying $50+ for the privilege. Last week I was assembling a 1/56 Tiger tank from the Bolt Action range, and I can't tell you how many times I cursed because it turned out that some part I was holding accidentally had some plastic cement on it and I left a nice big finger- or thumbprint on it that had to be cleaned up.

|

|

|

|

Welp, after being trapped in customs for 4 days, the box containing the resin showed up today. The giant loving box containing the mega is apparently "in transit" still. So, the box that could have been sent immediately with no problem is out there somewhere, but the box with the resin that needed paperwork because I might be importing a bioweapon made it here today. Hooray! $500 well spent on shipping!  gently caress I hate FedEx

|

|

|

|

Saw someone printed a skeleton in white TPU on a black shirt, so now I own a roll of white TPU

|

|

|

|

Yeah, rclifeon did printing on t-shirts a few years ago (I doubt he was the first but it was the first I saw it). Prusa just did a video about setting it up on their machines to make iron-ons or direct printing as well (they also looked at longevity with washing, flexible TPU seems to stay on). This was RCLifeOn's second video on the subject: https://www.youtube.com/watch?v=YUW8G4vXZfg Recent Prusa video: https://www.youtube.com/watch?v=9IHftw8cmd8 Pretty neat, I could see making some one offs in TPU.

|

|

|

|

Taking one of those goofy T-shirts that look like a Playstation controller is on it and printing TPU buttons and sticks onto the controller would be an entirely too involved project for a laugh at Halloween parties, but still may be worth it if you have the time to do it.

|

|

|

|

Roundboy posted:Ok I jumped the gun and just said 'gently caress it, do it live' and just printed my calibration cube. I usually let the bed preheat for a few minutes at 60 or whatever, because even if the thermistor is at 60, the far corner probably isn't.

|

|

|

|

Yay the mega 8k showed up finally! Not gonna lie man, this thing is like LOL XBOX IZ HUJ levels of "gently caress that's big". It's still in the shipping box but it's about 2 inches shorter than my chest freezer.

|

|

|

|

Cory Parsnipson posted:I guess it won't be too much trouble... Sweet jesus, replacing the part cooling fan takes 16 steps and I have to take apart the extruder, move the pinda sensor, undo the cable bundle, and gently caress with the wiring. And I literally just got my bed z level adjust perfect five days ago  I'm gonna pick up these: https://www.amazon.com/gp/product/B07W82CQRM/ref=ox_sc_act_title_1?smid=A2C8XBVC2XSV8U&psc=1, which claim to have ball bearings in them. On the bright side, it looks like the extruder fan is a noctua and from what I'm reading, it has some weird proprietary system that is like a ball bearing, so at least I don't have to replace that one. e. Actually, could be either fan, really...  I think the noctua failing is less likely, but I should try and figure out where it's coming from. I think the noctua failing is less likely, but I should try and figure out where it's coming from.ee. maybe i'll pickup this one instead just to be safe...

Cory Parsnipson fucked around with this message at 23:01 on Oct 29, 2021 |

|

|

|

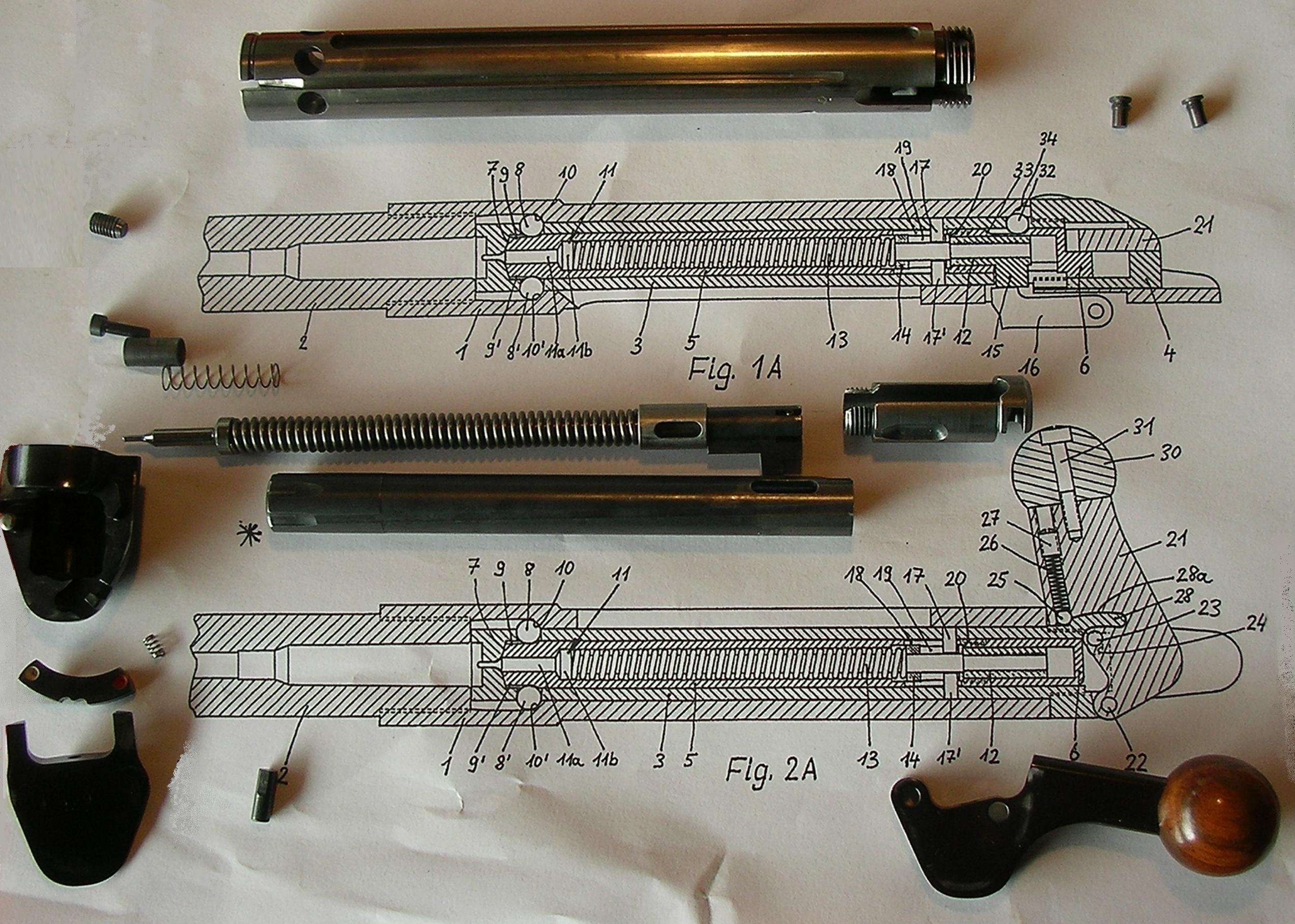

crosspost from CADthread; i designed an overengineered speedloader for my stupid pirate-rear end paintball gun and goddamn if the printed prototypes aren't coming together perfectly on the first try Ambrose Burnside posted:i wanna post this somewhere b/c it's a weird and fun CAD project that’s coming together unusually-well and doesn’t really fit in any one DIY thread, so hey:

|

|

|

|

That's loving awesome

|

|

|

|

gently caress man I kinda wanna buy one of those guns so I can print that loader. Awesome work!

|

|

|

|

Ambrose Burnside posted:crosspost from CADthread; i designed an overengineered speedloader for my stupid pirate-rear end paintball gun and goddamn if the printed prototypes aren't coming together perfectly on the first try Nicely done. Crossing two of my hobbies :-) ..... I won't get started on the magfed folk. *giggles*

|

|

|

|

If I want to hop back into FDM printing, but don't ever want to have to "tinker" with the drat thing then my best bet is a Prusa I3, correct? If I buy one, run into a problem, post about it, and hear back "oh, first thing you needed to do was replace the stock part with this..." I'm going to commit murder. This will be my fourth attempt at FDM printing if I decide to buy.

|

|

|

|

InternetJunky posted:If I want to hop back into FDM printing, but don't ever want to have to "tinker" with the drat thing then my best bet is a Prusa I3, correct? If I buy one, run into a problem, post about it, and hear back "oh, first thing you needed to do was replace the stock part with this..." I'm going to commit murder. Yes. Buy Prusa.

|

|

|

|

InternetJunky posted:If I want to hop back into FDM printing, but don't ever want to have to "tinker" with the drat thing then my best bet is a Prusa I3, correct? If I buy one, run into a problem, post about it, and hear back "oh, first thing you needed to do was replace the stock part with this..." I'm going to commit murder. I've been running mine nearly 24/7 since getting it a month and a half ago. I've upgraded no parts. An example of what I've been printing recently, these building floors are roughly 10 - 25 hours each, most on the higher end.  The problems I've had so far:

I've been very happy with it so far.

|

|

|

|

InternetJunky posted:If I want to hop back into FDM printing, but don't ever want to have to "tinker" with the drat thing then my best bet is a Prusa I3, correct? If I buy one, run into a problem, post about it, and hear back "oh, first thing you needed to do was replace the stock part with this..." I'm going to commit murder. Almost. Being a little pedantic, the current main offering from Prusa Research is the Mk3. It's an excellent printer, as is their mini. I comment because its actual name is the Original Prusa i3 Mk3S+. If you just look for a prusa i3, you'll still find many from random vendors, dating from the days that Prusa wasn't a company but someone's (Josef Prusa) named variant of a reprap design. The quality of these i3s will vary between good and very poor.

|

|

|

|

I've been obsessed with articulated finger extensions, so I'v spent the entire day for the most part printing various gears and other parts with very small 1.5-2mm holes for joining them together. Most of my little tabs kept breaking off , and i notice my normally nice printing is now going....funky. Aside from a couple spools of PETG, pretty much all of my PLA spools are really Silk PLA because i wanted pretty metallic colors, so my normal go to of the metaling silver was just giving me so much grief. Brands are all over because i was buying what was showing up on amazon for a good price and color choices. Getting a lot of globbing and poor layers, and some just outright missing portions of layers. Found a spool of unopened hatchbox PLA i must have bought as a 'standard' and the printing is night and day, everything is working like it should be. I guess i'm going to relegate the pretty colors to kids toys and get a supply of proper PLA for the stuff i need to work. I was even considering using my glow in the dark spool of PLA+ just because it prints so solid as a default go to.

|

|

|

|

I've noticed a bump up in extrusion issues since buying one of the cubes of $9/kg filament from gst3d a while back. It's ultimately tolerable but there's a clear difference in quality and consistency that makes the hatchbox stuff worth still buying for SOME things

|

|

|

|

|

I have WAY to much fillament to burn through on garbage stuff before I bother with buying more, but I am disappointed in all the shiny metallic i have so far (except for this rainbow) and I think i am just going to stick with a big name pla or even PLA plus in primary colors

|

|

|

|

Chainclaw posted:Stringing with some PLA. I'm mostly working around this by sticking to PLA that strings less, and avoiding models that are especially problematic. Consider investing in a cheap food dehydrator or a dedicated filament dryer, although they're essentially the exact same thing. Dry all your filament, even the brand new stuff. Almost every issue I've had with stringing and probably a huge portion of the issues I've had in general came back to lovely, wet filament. Even PLA. Even brand new PLA from extremely reputable companies in vacuum-sealed bags. I'm at the point where I won't start printing anything for a paying client unless I know I've dried the filament relatively recently, even though my house is at a constant 40-45% humidity. On the other hand, I find that most of the dirt-cheap filament I buy works pretty flawlessly if I throw it in my dehydrator first. edit- I'm currently printing some stuff for myself with an old roll of filament I had lying around that I didn't dry and it's stringing like crazy. It's hilarious because I've hardly seen a single string on any part that I've printed in months and my printers are going pretty much 24/7.

|

|

|

|

I recently bought a pack of big sealed plastic tubs to hold my filament, just with the silica packs sitting in it. The longer term plan is to print holders and feeders out of it, but how long do you leave a spool out on the holder before it's 'burned' and needs to be dried?

|

|

|

|

Roundboy posted:I recently bought a pack of big sealed plastic tubs to hold my filament, just with the silica packs sitting in it. The longer term plan is to print holders and feeders out of it, but how long do you leave a spool out on the holder before it's 'burned' and needs to be dried? It depends on your environment and the type of filament. PLA should actually take a long time under normal conditions, like definitely weeks or months. Nylon you might as well feed directly from a dryer box because it'll turn to poo poo in no time flat.

|

|

|

|

|

| # ? May 28, 2024 08:05 |

|

Yeah markforged printers come with a modified Pelican Case for holding their nylon spools, and it has a feeder tube from the box to the printer. With enough inactivity, even that lets some moisture in. Once we let the printer sit inactive for like a month or two. Even after the purge line it starts with, the first dozen layers were a little weird from the filament having some wetness to it.

|

|

|