|

My toilet is basically a corexy printer. I can even do multiple filaments too

|

|

|

|

|

| # ? May 28, 2024 23:31 |

|

w00tmonger posted:If you think about it we 3d print on the toilet every day https://www.thingiverse.com/thing:1918916

|

|

|

|

Roundboy posted:My toilet is basically a corexy printer. I can even do multiple filaments too So people with IBS just need to calibrate their e-steps and their flow rate? I am so mad my doctor never told me this.

|

|

|

|

InternetJunky posted:It's fine in the vat as long as you want to leave it (I've left it 6+ months before). Stupid_Sexy_Flander posted:Not dumb at all. You can leave it in the vat as long as it's covered, or you can strain it and pop it back in the bottle. Either one should be fine. Some people (like me) are lazy and just stir it up before Ithey print, others worry about a leak developing somehow and ruining their machine, and pop the resin back in the bottle. Just depends on how smelly the resin is I guess, and how paranoid you are about the vat leaking. Awesome! Thank you both. I have the included test print going now. We will see how it goes.

|

|

|

|

I'm thinking about buying a replacement steel nozzle or a couple brass ones to have on hand when the time comes. I've read recently people were saying to get the hardened nozzle and be done with replacing them forever, but I was looking into it and it looks like the steel nozzles have different thermal characteristics from the brass ones and require changes to the slicer settings and print speed? Just wondering how much tinkering would be required if I switch nozzle types. Also I'm looking at getting a silicon sock. Would that help with things? I've had oozing latch on and ruin some things on the first layer if I'm not careful to avoid it. Also I'm planning on learning how to print PETG and I hear that the sock could help a lot with that. How well does the sock work in practice? Should I get the E3D ones? All the reviews universally claim that the socks are always loose.

|

|

|

|

E3D socks are fine for me. We're at the point where you can pretty definitely say there's no reason to buy any nozzles except CHTs or tungsten carbide (for abrasives) anymore I think, though I haven't used a CHT yet. Need a copper block to seal the carbide nozzles on the V6.

|

|

|

|

do the more expensive nozzles clog less? I'm not gonna spend $20 on one if I'm just going to get unlucky and throw it away

|

|

|

|

Ghostnuke posted:do the more expensive nozzles clog less? I'm not gonna spend $20 on one if I'm just going to get unlucky and throw it away are you clogging often? You shouldn't be getting clogs much.... It might be worth investigating that before trying to swap parts to make it better.

|

|

|

|

Cory Parsnipson posted:I'm thinking about buying a replacement steel nozzle or a couple brass ones to have on hand when the time comes. I've read recently people were saying to get the hardened nozzle and be done with replacing them forever, but I was looking into it and it looks like the steel nozzles have different thermal characteristics from the brass ones and require changes to the slicer settings and print speed? Just wondering how much tinkering would be required if I switch nozzle types. If you're willing to pay a premium, tungsten carbide nozzles have the thermal conductivity of brass with greater hardness than hardened steel.

|

|

|

|

The NozzleX, which is steel, has similar enough thermal performance to a stock E3D one that I haven't had to change any PrusaSlicer material settings for basic stuff like PLA, PETG, ABS. For nylons and composites and whatnot I will always run a few test prints to dial in the temperature myself anyway so idk. The seriousness of the thermal difference is really overblown in my opinion. It may become an issue if you are trying to print extremely fast, but at the normal feedrates in the default presets, it's fine.

|

|

|

|

Ghostnuke posted:do the more expensive nozzles clog less? I'm not gonna spend $20 on one if I'm just going to get unlucky and throw it away What are you clogging on, filled filaments?

|

|

|

|

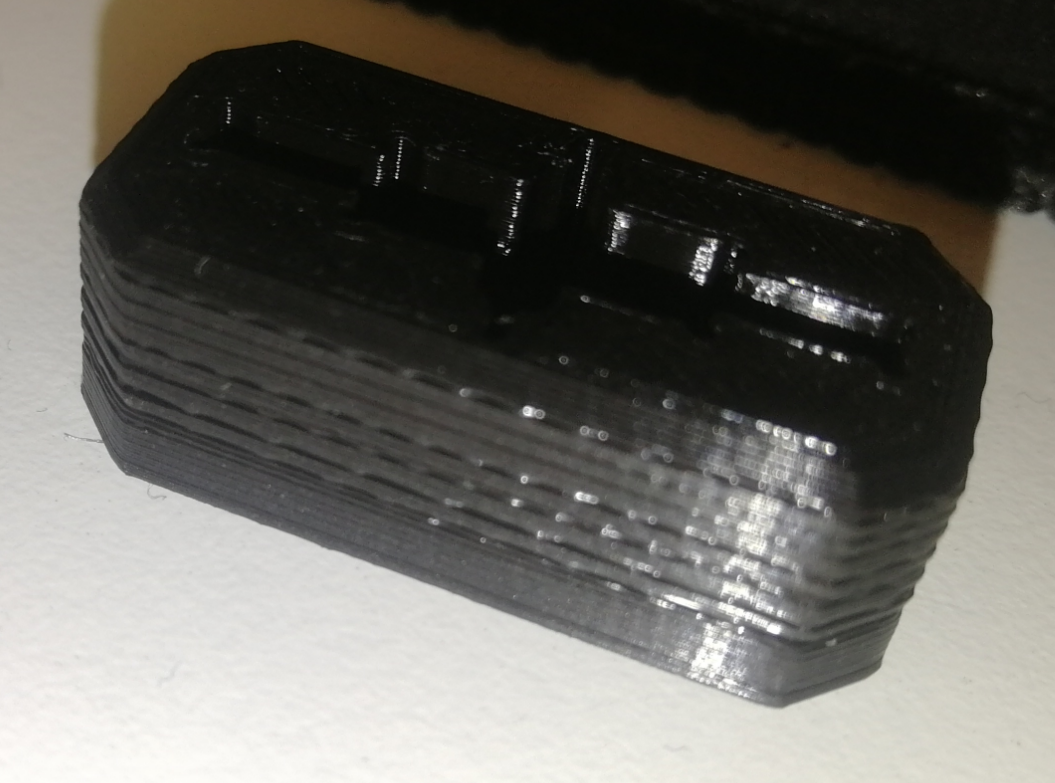

I had not so much clogging issues as other filament issues during a failed print that caused me to have ti dissasemble the hotend, and the thermstor broke, so i could not easily heat the nozzle to clean it out. When i have 30 just sitting here its easy to swap it, and worry about heating it up with another method outside if the printer later. And yes, i have the $20 nozzle now this thing is why i got the heat gun out to make sure everything is kosher so it stays on the printer

|

|

|

|

Wang Commander posted:E3D socks are fine for me. We're at the point where you can pretty definitely say there's no reason to buy any nozzles except CHTs or tungsten carbide (for abrasives) anymore I think, though I haven't used a CHT yet. Need a copper block to seal the carbide nozzles on the V6. Wow, those CHT nozzles look fancy. TerminalSaint posted:If you're willing to pay a premium, tungsten carbide nozzles have the thermal conductivity of brass with greater hardness than hardened steel.  dang, that's too expensive for me though I appreciate that it lets you have your cake and eat it too. I don't think I'm going to print anything abrasive for the foreseeable future dang, that's too expensive for me though I appreciate that it lets you have your cake and eat it too. I don't think I'm going to print anything abrasive for the foreseeable futureSagebrush posted:The NozzleX, which is steel, has similar enough thermal performance to a stock E3D one that I haven't had to change any PrusaSlicer material settings for basic stuff like PLA, PETG, ABS. For nylons and composites and whatnot I will always run a few test prints to dial in the temperature myself anyway so idk. The seriousness of the thermal difference is really overblown in my opinion. It may become an issue if you are trying to print extremely fast, but at the normal feedrates in the default presets, it's fine. Well that sounds good. I like that it sounds like a drop in replacement. Although a 0.4mm e3d brass nozzle is just 5 bux...  That's something to think about, thanks for the input, folks! Cory Parsnipson fucked around with this message at 04:44 on Dec 3, 2021 |

|

|

|

Oh, I'm not having clogging problems. It happened once ever, I was just wondering

|

|

|

|

Never had a clog in a NozzleX.

|

|

|

|

Oh wait I got another question. Does the "polyphobic" coating on the nozzle x mean you don't need to put a sock over it?

|

|

|

|

SEKCobra posted:Well yeah, the nozzle was in service for a while and I just figured it would be easier than clearing a clog (my simple attempts beforehand failed). I don't really have a good way to dry it ATM, but all my Amazon rolls so far worked completely fine, so I am confused as to why this one is acting up so much. Dried the filament in the oven overnight, using a food thermometer  No change, so I decided to tear down and clean out the hotend, there definitely was some gunk in places it shouldn't be. Messed around a bit trying to get the z offset dialed in, hopefully i did it right, because I don't remember which of the options was the right one (home offset, mbl z height...) I'll report back after the print if cleaning it out fixed anything.

|

|

|

|

SEKCobra posted:Dried the filament in the oven overnight, using a food thermometer What type of filament is this? Also I assume that that outer face is supposed to be flat - if so it looks like whatever the problem is, it's both regular and covering multiple layers which screams slicing or other software problem rather than an issue with the filament to me - have you tried printing it with known-good filament?

|

|

|

|

Cory Parsnipson posted:Oh wait I got another question. Does the "polyphobic" coating on the nozzle x mean you don't need to put a sock over it? The socks are for the heater block, not the nozzle (though the nozzle does benefit).

|

|

|

|

SEKCobra posted:No change

|

|

|

|

RabbitWizard posted:I wonder about those parts in the layers where it seems like filament is missing. Are you printing too fast? And/or is your extruder gear grinding over the filament? Yeah I thought underextrusion as well. New testprint came out good again, so I guess it must really have been some significant problem inside the hotend. The filament was printing decently before, so I kinda couldn't believe the sudden drastic change in quality.

|

|

|

|

Cory Parsnipson posted:Oh wait I got another question. Does the "polyphobic" coating on the nozzle x mean you don't need to put a sock over it? No. The sock is about hot end temperature stability and protecting the rest of the printer from a 250c block of metal. The "collcting poo poo on it" is a byproduct.

|

|

|

|

ImplicitAssembler posted:Never had a clog in a NozzleX. This by far does not mean a NozzleX can't clog, just you haven't clogged one.  In general, expensive nozzles are better quality and will put up with more abuse, brass or not. They will be more consistent nozzle to nozzle, requiring less calibration after swapping. If you are willing to spend an hour recalibrating to save a $4 difference in brass, you do you i guess

|

|

|

|

Right? I've had a clog in a Nozzle X. It was due to lovely filament.

|

|

|

|

I've had a clog in a nozzle x, but also, buy a nozzle x or other high quality nozzle. It's not worth saving  and cheaping out on arguably the most critical component in the extrusion. and cheaping out on arguably the most critical component in the extrusion.e: except ruby, don't buy a ruby nozzle.

|

|

|

|

I thought I was pretty solid going forward with a marlin board (and basically using octoprint / klipper) but i am really starting to like the look of the reprap firmware, but the Duet board is $$$ Has anyone used both? I like the config look and web browser of reprap, but is klipper the 'go to' for print quality and speed and configuration ?

|

|

|

|

Hypnolobster posted:I've had a clog in a nozzle x, but also, buy a nozzle x or other high quality nozzle. It's not worth saving I'm just using the E3D branded brass ones so far

|

|

|

|

Ghostnuke posted:I'm just using the E3D branded brass ones so far Also totally fine, assuming you're using normal filaments in normal hobbyist quantities. It's the 10 pack of 0.4mm with a weird name on Amazon for $8 that are the real problem.

|

|

|

|

Here's a wearable generator so you can charge your phone while you're jerkin it https://thangs.com/repeatedfailure/Jerk-Juice-Wearable-Kinetic-Energy-Generator-for-HalloWearables-33553

|

|

|

|

Might make a decent web shooter for a homemade spidey costume.

|

|

|

|

Well, I've figured out this weeks theme: I calibrated E-Steps, it can't be an extrusion issue. [Narrator: It was an extrusion issue.]

|

|

|

|

90% of what I print are structural parts Why did I wait until now to pop a 0.8 nozzle in this bad boy This fuckin rules I’m doing a big series of prints that were 11 hours and now they’re 6 This is great

|

|

|

|

w00tmonger posted:Here's a wearable generator so you can charge your phone while you're jerkin it Give it a crystal that glows when charging and

|

|

|

|

Roundboy posted:I thought I was pretty solid going forward with a marlin board (and basically using octoprint / klipper) but i am really starting to like the look of the reprap firmware, but the Duet board is $$$ https://github.com/Stephan3/dwc2-for-klipper Get the UI, have the joy of klipper's performance and ease of config. Spend the difference on an Octopus with good drivers, or a nicer hotend. If you want to use a PanelDue, https://www.youtube.com/watch?v=G7yqrAaUMPw, Nero 3D has you covered, although I personally much prefer KlipperScreen.

|

|

|

|

Sockser posted:90% of what I print are structural parts hell yeah! I stick with 0.6 because I don't feel like going full volcano, but even then everytime I need to swap back to .4 for something it seems like my printer is crippled

|

|

|

|

cephalopods posted:hell yeah! Prusa doesn't offffficially support 0.8mm nozzles for the MMU so after this project I'll probably back down to a 0.6 for normal printing

|

|

|

|

Sockser posted:90% of what I print are structural parts I feel you, and it's one of the reasons I decided to go for a second printer, however I'm not sure if I wouldn't prefer to have two printers with (almost) the same setup to jump between.

|

|

|

|

That might be a really interesting use for the tool-changing printers - swapping between nozzle sizes as you go from finely-detailed outer walls to structural inner walls and infill, although I guess the time spent changing ends and priming probably make it counterproductive on anything but the hugest prints.

|

|

|

|

3D Printing Nerd just published a video recorded at Formnext, where some company has a huge 3D printer that does gel deposition with in-place UV curing. And due to that they appear to be able to print entirely supportless (within reason I guess, so long it's no impossible geometry kind of stuff). I'm wondering if there's a middle-ground possible for FDM, having an easy/quick to melt filament that is UV curable, so that you can force it to harden at temperature. I mean, it'll make it harder on the printer, since everything needs to be UV proof, but still.

|

|

|

|

|

| # ? May 28, 2024 23:31 |

|

Combat Pretzel posted:3D Printing Nerd just published a video recorded at Formnext, where some company has a huge 3D printer that does gel deposition with in-place UV curing. And due to that they appear to be able to print entirely supportless (within reason I guess, so long it's no impossible geometry kind of stuff). Well those 3D pens allow that pretty much just by relying on the filament cooling enough to be self-supporting as long as the operator goes slowly enough - I'm sure with good-enough quality control of the filament and appropriately-slow printing you could do the same.

|

|

|