|

The store I went to has quite a very large variety of wood. Pretty much all the ones I know of and many I've never heard of. Crosscut hardwoods for anyone around Seattle/wherever else they are. I sanded the end grain down to 220 grit and took some more pics after cleaning off the dust   It's not super important I know what it is, I'm using some small pieces of it on some furniture for my home. I'd just like to know for curiosity's sake and for if people ask me about it. E: I wouldn't say it smells like much of anything but I'm not that great at identifying wood by scent outside of like cedar or something extremely obvious PokeJoe fucked around with this message at 02:11 on May 19, 2023 |

|

|

|

|

|

| # ? May 31, 2024 02:45 |

|

I've been to the Seattle Crosscut quite a bit and their selection is enormous and goes well beyond local species. They appear to have both Spanish cedar and a few varieties of mahogany. Here's there general rough cut selection: http://www.crosscuthardwoods.com/species.html

|

|

|

|

im beginning to think this question is nearly impossible to answer unless we have a resident woodologist

|

|

|

|

|

PokeJoe posted:im beginning to think this question is nearly impossible to answer unless we have a resident woodologist Take it back to the store and walk around until you find the matching one?

|

|

|

|

PokeJoe posted:The store I went to has quite a very large variety of wood. Pretty much all the ones I know of and many I've never heard of. Crosscut hardwoods for anyone around Seattle/wherever else they are. e: meranti is usually quite soft and will dent easily with your thumbnail, african mahogany will probably be about as hard or slightly softer than walnut. e2: if you hand plane the edge is there any tearout like from interlocked grain? or on the face? thats much more likely on african mahogany than on meranti, which does not usually have interlocked grain. The website also says they only stock dark red meranti, which that doesn't really look like. It looks more like light meranti, but the whole naming of meranit/shorea is a giant mess and you never really know what someone is going to call the flavor of meranti they are selling. Kaiser Schnitzel fucked around with this message at 02:43 on May 19, 2023 |

|

|

oXDemosthenesXo posted:Take it back to the store and walk around until you find the matching one? Not sure it's worth that much effort for me to solve this mystery  . I bought it like 8? months ago and it's been in my scrap pile waiting for a use ever since. . I bought it like 8? months ago and it's been in my scrap pile waiting for a use ever since.

|

|

|

|

|

My guess would be meranti, also sold as Philippine mahogany (which is an enormous stretch), Shorea spp., the face and endgrain & shavings are a ringer for it at least.

|

|

|

|

Kaiser Schnitzel posted:It's African Mahogany. Maaaaaybe phillipine mahogany/meranti, but the face grain looks more like african mahogany to me. I disagree with african mahogany (Khaya), which "features an endgrain that is, for the most part, absent of any discernible annual or seasonal growth rings." https://www.wood-database.com/wood-articles/mahogany-mixups-the-lowdown/ PokeJoe's wood has clear growth rings. e. the endgrain samples on http://hobbithouseinc.com/personal/woodpics/meranti,%20white.htm and http://hobbithouseinc.com/personal/woodpics/meranti.htm etc. for meranti are all diffuse, densely porous, e2. the more I look at PokeJoe's endgrain, the less sure I am about the pores being clustered near the ring boundaries, so maybe this is. "Black Cherry" (Prunus serotina) seems like another candidate. I previously said willow but I'm editing that out too. Leperflesh fucked around with this message at 02:58 on May 19, 2023 |

|

|

|

Epitope posted:We had a 2000 psi hydrogen tank rusted to the point of leaking. Mildly alarmed, we asked the vendor to address the issue. They came and looked, said eh it's just a small leak, we'll come back in a few days. That is hosed. It does somewhat depend on where the leak is, but if it is on the neck or body of the tank, then it could definitely be a sign of complete structural weakness. Particularly with H2, which can cause steel embrittlement. Even small cracks can cause catastrophic failure and complete delamination of the tank. Definitely something that could and has caused serious injury and death. Not to mention that a) even a small leak would cause the H2 to leak out within a small period, b) H2 leaks can autoignite. For air compressors, generally the tank is rated for a very large number of cycles (and being under pressure for long periods). Moisture leading to rust would be main risk that I could see. Yes lower pressure, but even small tanks at 150psi have a very large amount of stored energy and could cause serious damage if it lets go at a bad time. But I'm less familiar with these.

|

|

|

|

Leperflesh posted:I disagree with african mahogany (Khaya), which "features an endgrain that is, for the most part, absent of any discernible annual or seasonal growth rings." https://www.wood-database.com/wood-articles/mahogany-mixups-the-lowdown/  There's like half a dozen species that all get sold as 'african mahogany' and some seems to have them and some doesn't. I've bought african mahogany both with and without them. IME the wood that has them is a bit denser than the wood without them, which tends to be real soft. Just Winging It posted:Philippine mahogany (which is an enormous stretch), Shorea spp., E: Leperflesh posted:

Kaiser Schnitzel fucked around with this message at 03:15 on May 19, 2023 |

|

|

|

Is finished wood any easier to identify?

|

|

|

|

|

PokeJoe posted:Is finished wood any easier to identify? No. If you wet your wood and post pics though, that'll definitely help us all get off this tangent

|

|

|

|

Yeah my confidence drains away as I look at more endgrain pics. If PokeJoe sanded to 1000 grit, washed it, and then took perfect photos that showed the rays, any parenchyma visible, and a scale, we might nail it but right now Kaiser is probably more likely to be right than I am but neither of us can really be sure.

|

|

|

|

Can we DNA test the wood?

|

|

|

|

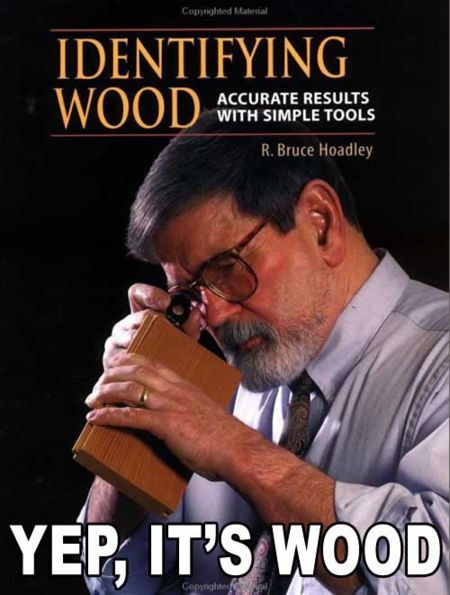

The moral of this story is that wood identification is hard, even for experts with PhDs in wood science. If you want to learn more about it, this is the bible: https://www.amazon.com/Identifying-Wood-Accurate-Results-Simple/dp/0942391047 I'm gonna post so many pics of african mahogany tomorrow that you'll all have to believe me e2: actually just look at this he has a good variety of the many flavors of african mahogany/khaya http://hobbithouseinc.com/personal/woodpics/mahogany,%20african.htm e: FISHMANPET posted:Can we DNA test the wood? Kaiser Schnitzel fucked around with this message at 03:19 on May 19, 2023 |

|

|

|

Kaiser Schnitzel posted:The moral of this story is that wood identification is hard, even for experts with PhDs in wood science. If you want to learn more about it, this is the bible: I was hoping this book would come up, mostly because well before I was into any sort of serious woodworking I saw the cover with a caption "yup. that's wood"

|

|

|

|

more falafel please posted:I was hoping this book would come up, mostly because well before I was into any sort of serious woodworking I saw the cover with a caption "yup. that's wood" Itís the perfect cover because 1) itís a perfect illustration of the topic of the book and 2) itís the perfect shitpost

|

|

|

|

dupersaurus posted:Itís the perfect cover because

|

|

|

|

more falafel please posted:I was hoping this book would come up, mostly because well before I was into any sort of serious woodworking I saw the cover with a caption "yup. that's wood" Someone in byob photoshopped it to say ĎIdentifying Weedí and replaced the block of wood with a bong and I canít find the picture but it was real good. E: found it biosterous posted:

Kaiser Schnitzel fucked around with this message at 13:09 on May 19, 2023 |

|

|

|

PokeJoe posted:Can any wood experts give me a clue on what wood this is? I got it from an offcuts bin. The one on the RIGHT. The shavings are also from the same board. It looks like an Asian hardwood that a lot of imported dining sets are made of. My folks had one years ago and I was intrigued trying to figure it out. It does resemble lauan (philippine mahogany) but it was definitely harder and denser (and a lot lighter, like blonde) than the stuff I was exposed to in construction.

|

|

|

|

We all know that wood will change color as it ages, but this is somewhat nuts. I got some mulberry because hey why not. It started as 5/4 and I resawed it in half. Here's what the outside vs the inside looks like. The outside has been aging for god knows how long, the inside is fresh cut.  Also of note, mulberry is a small tree so I have about 7 inches of heartwood out of a 9 inch wide board, the rest is sapwood which is practically white.

|

|

|

|

My Monticello stacking bookcase has been stacked for the first time, I assembled the base last night as a near final step. Still a few more things to take care of like finish the top half and base; and then a couple uprights to attach all the stacks together at the back. I feel like I've been working on this forever.

|

|

|

|

Stultus Maximus posted:We all know that wood will change color as it ages, but this is somewhat nuts. Thatís cool. Mulberry is really pretty. I had to copy some old early Louisiana beds a few years ago and the originals were mulberry and they had that really pretty warm brown color. I couldnít source mulberry commercially obviously so I wound up faking it with walnut and that worked okay. Ash with a dark stain might wave worked better as the grain structure is a little more like mulberryís. I wonder if it darkens on UV exposure like cherry? Or if itís an oxidation thing like most woods? If you want it change fast, lye is a strong oxidizer. Iíve used it before on different woods and it works fast and dramatically. Iirc it reacts with the tannins which are mostly in the heartwood. Obviously be careful etc. but itís readily available at most hardware stores and isnít as nasty as potassium bichromate or permanganate.

|

|

|

|

Kaiser Schnitzel posted:Thatís cool. Mulberry is really pretty. I had to copy some old early Louisiana beds a few years ago and the originals were mulberry and they had that really pretty warm brown color. I couldnít source mulberry commercially obviously so I wound up faking it with walnut and that worked okay. Ash with a dark stain might wave worked better as the grain structure is a little more like mulberryís. I'm going to leave it in the sun for a week to see if that does anything. Also I'm a high school chemistry teacher so I have all the dichromate, permanganate, KOH, NaOH, and whatever else you can think of that anyone could wish for. Hell, I might just experiment with all of them and whatever other oxidizers I have on hand like perchlorate or 30% hydrogen peroxide. Stultus Maximus fucked around with this message at 22:50 on May 19, 2023 |

|

|

|

Stultus Maximus posted:I'm going to leave it in the sun for a week to see if that does anything. As a Ďkilling time at the end of the yearí project you should give your students a bunch of wood and all the chemicals and see what they can come up with and then please report back in this thread. Using chemical reactions to change the color of wood is neat and fun and practical. Potassium permanganate is really wild because it starts out neon purple but turns everything brown

|

|

|

|

There's one you can do, ammonium chloride I think? Where after you paint it onto the wood, if you hit it with a heat gun, it'll scorch. It's a little tricky to do with precision, otherwise I'd use it to sign my work.

|

|

|

|

Stultus Maximus posted:We all know that wood will change color as it ages, but this is somewhat nuts. The ones around here get pretty big, but mine in the back yard branched out pretty low. Had a chance earlier in the week to get some curb wood from a 40+ year old one down the street that became a tornado statistic, but didn't even know it had been destroyed until I walked dogg past there. Nothing but a ground level stump.

|

|

|

|

Kaiser Schnitzel posted:As a Ďkilling time at the end of the yearí project you should give your students a bunch of wood and all the chemicals and see what they can come up with and then please report back in this thread. Using chemical reactions to change the color of wood is neat and fun and practical. Potassium permanganate is really wild because it starts out neon purple but turns everything brown Yeah, the permanganate ion reduces to manganese dioxide. Which is a great catalyst for decomposition of hydrogen peroxide, but it is really hard to clean off of things.

|

|

|

|

I made a thing! Since moving to a new place that has some garage space, I've been thinking about trying some woodworking. So I decided to try making a simple lidded box for my wife's birthday. I really loved Meow Meow Meows old boxes and marquetry, so with their old tutorial post and some followup advice (thankyou so much!!), I went with marquetry design for the lid. Definitely bit of more than i could chew, since I've never done any woodworking/hand craft work apart from a month in early highschool tech class and have very limited tools available. A ryoba pull saw, a couple of chisels, a collapsible workbench thing, a drill/drive set, a hand fret saw, and an old mitre saw that in retrospect I should have spent more time setting up. Thankful I started it months before, since I only finished it with 1 day to spare but pretty happy with the way it turned out. Dado for the lid, grooves for the splines, rebate for the base were all cut with ryoba and cleaned up with chisels. Mitres were cut with the mitre saw. Hinge mortises were cut with chisels. Wood is a S4S board of Tasmanian Myrtle, splines are Huon Pine thick veneer that I think was originally for drawer fronts, lid and base were just plywood since I didn't have enough myrtle left. Design is of our cat, came out a bit derpy but so is the cat so thats fine.    Many mistakes made, and many lessons for next time. - Worst mistake was during glueup of the marquetry. After about half an hour i had a bad thought that I had glued it backwards, so I went to check and then realised instead I hadn't used a sheet of wax paper between the panel and the clamping board. It had already started drying so ended up having to rip/chisel it off the clamping board, breaking a bunch of the marquetry. Thankfully managed to mostly patch it up and it isn't too noticeable. - Keeping the correct angle while doing the dual bevel cutting is difficult. Accidently had it in wrong orientation a few times, and it matters how much backing tape you have on the back. - I need to find some proper, non 3 holed veneer tape somewhere in Australia (somehow very difficult). The 3 hole stuff I can find worked reasonably well, but left some circle imprints on the backing wood that I missed while sanding. - The oak burl ended up a bit muddy I think. But unsure what I would have used instead - I probably should have tried cleaning up the cut marks around the splines with some sawdust and glue. - I need to work out how to properly sand out glue marks on side corners, without just going directly against the grain. Pretty keen to get some more tools, and keep going. My space is kind of limited, so will probably be a followup post asking for advice once I have exact space and budget nailed down.

|

|

|

|

Had to break out the ol board stretcher. Baltic birch is too expensive to just scrap a gently caress up.

|

|

|

|

Hey woodworking thread! I've had you bookmarked for a long time but am seriously behind and I need some help/opinions. I have this table and 4 chairs that's about 20 years old. It's made of Teak wood. It's been my/our primary kitchen table for that whole time and while it's not perfect, it's held up really well. What hasn't held up as well is the chairs. One in particular seems to be coming apart so much that we no longer use it. I wasn't going to attempt anything myself because I figured it would require a rebuild of certain pieces and I have no tools or woodworking experience. However, I watch Project Farm and his episode on wood glue got me thinking. I had no idea how strong wood glue is and how much it's used in legit woodworking. I always saw glue as a temporary fix but realized that's dumb now. Could these effectively be repaired with some Titebond Ultimate and a clamp while it sets? Chair1, the worst one:  Chair2, which we can still use but now I think we shouldn't until Its fixed:  Is this a complete fools errand or not? I guess the important question is: Will I make future proper repairs harder or impossible by attempting to glue these back now? Do I have anything to lose by trying? Thanks so much!

|

|

|

|

Glue is fine to fix those. I'd recommend unscrewing/seperating any removable parts nearby and completely separating the joint. That way you can glue it up properly. Or at least open it up a bit before you glue it if it's still fixed in place by the other joins. Don't just smear it on the exposed part and push it back in if you can avoid it

PokeJoe fucked around with this message at 17:34 on May 20, 2023 |

|

|

|

|

PokeJoe posted:Glue is fine to fix those. I'd recommend unscrewing/seperating any removable parts nearby and completely separating the joint. That way you can glue it up properly. Or at least open it up a bit before you glue it if it's still fixed in place by the other joins. Don't just smear it on the exposed part and push it back in if you can avoid it cool, thanks for the quick reply. I was going to try and disassemble it some like you said but I can't find ANY screws on it other than the ones in that "diagonal cross-member"(??) type thing front and center in the photo. I see how the joins work, and assume they're just glued together. it's hard to see but one of the protrusions(?) on chair1 has actually broken indicating that the glue into the slot(?) was literally stronger than the wood in that part. Can anyone tell me the name of the parts of joins like this so I don't sound so dumb talking about it? like I'm assuming the diagonal cross-member things are a tongue-in-groove arrangement? But I have no idea what to call the main thing coming apart in chair2. Oh and just to say it, I did read the last like 10 pages of the thread to try and not sound so dumb... so many words I had to look up. and so many cool things done by goons!

|

|

|

If the only screws are for the rear end board you probably got a mortice and tenon situation going on for the rest of it, or maybe dowels. It's almost certainly just glued in the first place. Post a better pic of the broken parts, the other pics make it look like the tenon is just slipping out

|

|

|

|

|

namlosh posted:Hey woodworking thread! I've had you bookmarked for a long time but am seriously behind and I need some help/opinions. I'd recommend epoxy instead of wood glue. It will do much better on that small glue surface and will bond better to the end grain. Yes, it will make future repairs harder and if you take them somewhere to be repaired they will curse your name.

|

|

|

|

Yoooo

|

|

|

|

namlosh posted:Hey woodworking thread! I've had you bookmarked for a long time but am seriously behind and I need some help/opinions. Kaiser Schnitzel posted:I'd recommend epoxy instead of wood glue. It will do much better on that small glue surface and will bond better to the end grain. I'm neither here nor there on using epoxy over glue, since the original (maybe hide glue?) lasted 20 some years. But I'd def recommend cleaning up the original glue surfaces the best you can with medium grit, say #150? sandpaper.

|

|

|

|

Sticko posted:I made a thing! Hell yeah! That's a rad box.

|

|

|

|

PokeJoe posted:If the only screws are for the rear end board you probably got a mortice and tenon situation going on for the rest of it, or maybe dowels. It's almost certainly just glued in the first place. Post a better pic of the broken parts, the other pics make it look like the tenon is just slipping out After looking: yes, the screws only hold the rear end board to those cross members. The pic is awesome, thanks. I think you're right that part of the join is mortise and tenon and as you can see from the pics below, the tenon(?mortise?) broke  Kaiser Schnitzel posted:I'd recommend epoxy instead of wood glue. It will do much better on that small glue surface and will bond better to the end grain. Thanks! My first instinct was to use JB Weld... but I bought some wood glue for this so might as well try it, lol. I want the option to take them somewhere and not look like a total scrub if need be. Mr. Mambold posted:I'm neither here nor there on using epoxy over glue, since the original (maybe hide glue?) lasted 20 some years. But I'd def recommend cleaning up the original glue surfaces the best you can with medium grit, say #150? sandpaper. Awesome! I do have some sandpaper I can use to clean it up first. Someone asked for better pics, so I GENTLY pulled the join a little further apart and get a couple. Now that I'm seeing them I should have added more light. These are all from the WORST join on the worst chair    If these pics change anything let me know.

|

|

|

|

|

| # ? May 31, 2024 02:45 |

|

Wood glue will be fine. JB Weld won't do great unless there's a substantial gap in there you're trying to fill and even then it's just kind of a hack job

A Wizard of Goatse fucked around with this message at 22:35 on May 20, 2023 |

|

|