|

That's a nice looking lathe! I wanna get a lathe pretty bad, but currently price restricted. I got a wood drying question. My fiancée wanted to get some log rounds for our wedding next Sept to use as part of a centre piece for the tables. I managed to get some pine logs from a neighbour. They are pretty massive. 2 foot diameter and 1-2 feet long. Freshly cut so the wood is really green and sappy. So my plan is to slice them into half inch rounds now and just stack them to dry with some spacers for 10-11 months, then sand em smooth before the wedding. Does this make sense? Or should I paint the end grain as well, which would be the majority of the piece, to help it dry slower and crack less? If so what kind of paint. Pretty sure my only option here is to hand saw these. So I'm gonna be swole as gently caress after this.

|

|

|

|

|

| # ? May 15, 2024 06:35 |

|

They are called tree cookies http://files.dnr.state.mn.us/education_safety/education/plt/activity_sheets/treeCookie.pdf

|

|

|

|

Tree cookies! I've never heard that before, haha. Works for me. Thanks as usual Wormil!

|

|

|

|

BUGS OF SPRING posted:

Get hold of a chainsaw ffs, and yes coat the end grain surfaces.

|

|

|

|

I have a few questions about tung oil and bambo. I have a grizzly sheet sander at my disposal, with various grits. How fine should I go when prepping the bamboo ply before apply the tung oil? I did a few passes with 400 grit and it's pretty drat smooth/reflective. Hit half of the sample with 2 passes 400 grit + 600 grit on the orbital and it's like glass. And sanding between coats, should I do that with 400 grit by hand? Also, I'm going to be mixing the tung with citrus solvent, apparently that reduces the dying time? Google Butt fucked around with this message at 19:23 on Sep 29, 2015 |

|

|

|

|

Mr. Mambold posted:Get hold of a chainsaw ffs, and yes coat the end grain surfaces. I've debated renting one if the hand sawing becomes too brutal. I'll see how it goes I guess. Thanks

|

|

|

|

You might be set on the sanded surface, but my wife wanted me to cut log rounds for our wedding, so I went out a couple weeks before and cut them about 1.5 to 2 inches thick, and then coated them with water based floor poly right off the saw. Two or three coats built up a nice shine, and she loved them. Plus a couple of our guests asked if they could have them afterwards for their own wedding. So if you can live with the cut marks, you can save a lot of work, and avoid checking entirely.

|

|

|

|

One Legged Ninja posted:You might be set on the sanded surface, but my wife wanted me to cut log rounds for our wedding, so I went out a couple weeks before and cut them about 1.5 to 2 inches thick, and then coated them with water based floor poly right off the saw. Two or three coats built up a nice shine, and she loved them. Plus a couple of our guests asked if they could have them afterwards for their own wedding. Ah that's a good idea too. I'll try one that way and see if she likes it. I bet she will since her theme is sort of a rustic apple tree kind of thing. Thanks! Edit: yeah I cut 1 by hand, gently caress that. Time to rent a chain saw. keep it down up there! fucked around with this message at 15:12 on Sep 30, 2015 |

|

|

|

After a bit of research, I've settled on testing 1 or 2 layers of tung oil + citrus solvent and following up with some sort (wipe on?) satin clear coat. Would it be a pain in the rear end to use wipe on satin poly on a 30x72" piece? Here's what the bamboo looks like (the dark stuff), open to all opinions regarding finishing:

|

|

|

|

|

I used wipe on poly for my computer desk and it was no trouble. Will there be issues if the oil isn't fully cured before you do the poly?

|

|

|

Squibbles posted:I used wipe on poly for my computer desk and it was no trouble. From my research, yes. I ordered some arm-r-seal glossy and satin, gonna try that first. Anyone work with it before?

|

|

|

|

|

Having some trouble planing down hard maple. I'm making a long board deck and did a glue up on some 4/4 pieces, took them for a few passes through the planer to bring them down to a rough thickness, and am noticing some areas where the maple is tearing out / chipping on the face. I've never worked with hard maple before, is this me or the wood? I ran a bunch of red oak and poplar through the same planer last week with no problem. I need to take it down another 16th or so, wondering if I need to do something differently for the next passes.

|

|

|

|

Can anyone point towards a good guide to setting up a stanley #4 plane ? I got one and sharpened it a bit, had it working, then put it back together after more sharpening. But now instead of a shaving nothing happens no matter how far the blade sticks out . It just glides along the wood. I'm not sure if I have it set up incorrectly or I somehow curved the bevel too much. I've never used planes before and I have a #5 that was pre-sharpened and just kind of works.

|

|

|

|

Sointenly posted:Having some trouble planing down hard maple. I'm making a long board deck and did a glue up on some 4/4 pieces, took them for a few passes through the planer to bring them down to a rough thickness, and am noticing some areas where the maple is tearing out / chipping on the face. I've never worked with hard maple before, is this me or the wood? I ran a bunch of red oak and poplar through the same planer last week with no problem. I've only worked with hard maple a couple of times, and I have found it tears out like crazy. With both my power planer and with hand planes.

|

|

|

|

Sylink posted:Can anyone point towards a good guide to setting up a stanley #4 plane ? https://paulsellers.com/2015/07/setting-your-plane-after-sharpening/ https://www.youtube.com/watch?v=gE4yVgdVW7s

|

|

|

|

Sointenly posted:Having some trouble planing down hard maple. I'm making a long board deck and did a glue up on some 4/4 pieces, took them for a few passes through the planer to bring them down to a rough thickness, and am noticing some areas where the maple is tearing out / chipping on the face. I've never worked with hard maple before, is this me or the wood? I ran a bunch of red oak and poplar through the same planer last week with no problem. It's rock maple, it's notorious for having a couple of grain reverses in a single board. If you can find someone with a wide belt sander, that's about the only surefire way I know. Soft Southern maple is a bit more forgiving, but even so...

|

|

|

|

Sylink posted:Can anyone point towards a good guide to setting up a stanley #4 plane ? There are a few details on the set up to know about but your experience sounds like what I dealt with early on. I was freehand sharpening and getting the bevel wrong. The heel? of the bevel was lower than the cutting edge when mounted in the plane so it just rode across the surface on the rounded part. You can try to adjust your technique until you get it right or pick up a cheap honing guide.

|

|

|

|

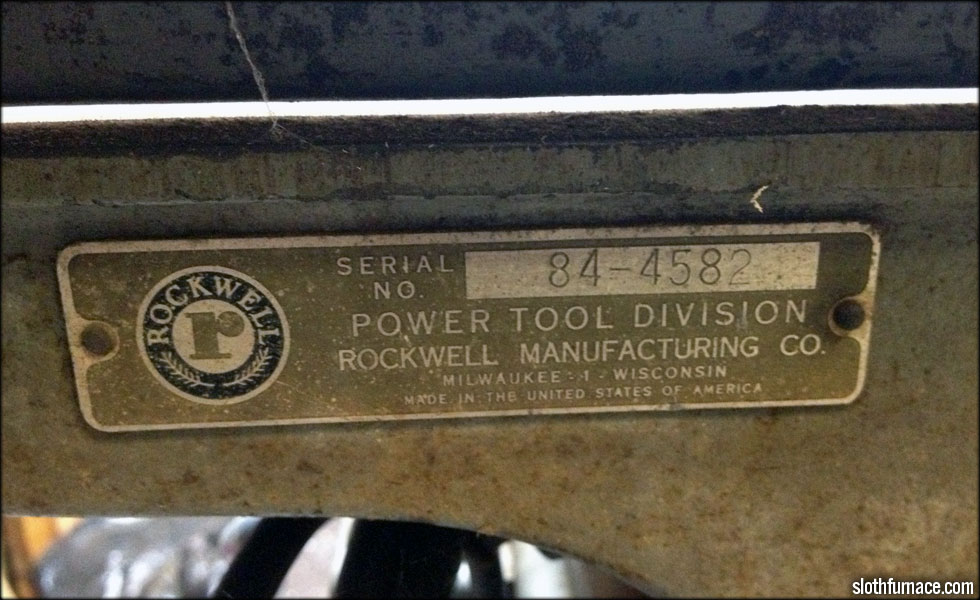

Listed my Powr-Kraft 9" bandsaw today on Craigslist and within 30 minutes it was sold. I was a little surprised it went so fast.  But now I have space in my shop for a new project. Awhile back I saw this and this ...   So earlier tonight I bought this:  Hopefully an interesting project for the winter.

|

|

|

|

nonentity posted:Hey guys, I need a Nixie clock. Bad.

|

|

|

|

Posted this in r/woodworking about applying arm-r-seal to my large bamboo plywood desk top. Does that seem like sound advice?

|

|

|

|

|

The Nova G3 I ordered from Amazon that was such an amazing deal (2 sets of jaws + insert) came without an insert. It was an open box deal so they can't replace it. Question is, do I keep it and order a $20 insert, puts my total at $152. Or buy the SC3 (rebranded G3) at Highland for $163 shipped with 3 sets of jaws + insert?

|

|

|

|

Got some vintage tools the other day. A stanley 80, bevel gauge, a drawknife and a disston crosscut saw. They need a bit of clean up, but will make pretty good user tools. Here's some progress on my bookshelf. I just finished the tusks for the through tenons tonight, they just need a bit of sanding.   Different thicknesses for the tusks to match the different thickness tenons.

|

|

|

|

ChaoticSeven posted:I need a Nixie clock. Bad. Yes, you do. They are awesome.

|

|

|

|

wormil posted:The Nova G3 I ordered from Amazon that was such an amazing deal (2 sets of jaws + insert) came without an insert. It was an open box deal so they can't replace it. Can't go wrong with either, the way I see it.

|

|

|

|

Google Butt posted:Posted this in r/woodworking about applying arm-r-seal to my large bamboo plywood desk top. Does that seem like sound advice? I think that guy's nuts building with what, 6 coats gloss and then satin on top of that? but I've never used that product. And I know some folks are hell-bent on that kind of thing. He doesn't realize apparently if he wants a satin coat, he can just buff the last gloss coat down with a high grit, wherever he chooses to stop. Or he can just apply 2 or 3 satin coats and realize it's as sealed as it will ever get....at least with all other oil and lacquer based finishes I've used. It's a varnish basically, so you don't wipe off, unless it's got a stain built in, you wipe stain products off. And you apply with the grain. Most of what he recommends is basically sound. There is such a thing as OCD overkill, I do know that much.

|

|

|

Mr. Mambold posted:I think that guy's nuts building with what, 6 coats gloss and then satin on top of that? but I've never used that product. And I know some folks are hell-bent on that kind of thing. Apparently Arm-R-Seal kinda sucks for buffing out finishes. I agree with you that guy is pretty extreme, I'm going to try doing 3 coats of satin on a scrap piece. I have both gloss and satin at this point, so I might do another test with 2 coats glossy and 1 coat sating just for fun. Coating the bottom is going to be annoying no matter what, this thing is heavy as gently caress.

|

|

|

|

|

Mr. Mambold posted:Can't go wrong with either, the way I see it. Amazon gave me credit to buy the missing insert so all is good. So I got a G3 with 2 sets of jaws + insert for $132 shipped, I can live with that deal.

|

|

|

|

I've been lurking on this thread for a while, drooling over the awesome poo poo you're all doing. Some questions came to mind: How did you begin woodworking? What resources have you found most useful? I've never picked up a tool in my life, but I'm fascinated and have begun to plan a few projects. I live in a slum so I'm able to find wood pretty easily and I've got enough now to try to repurpose it into a kitchen island for the house. I'm a bit overwhelmed by the process.

|

|

|

|

Cannon_Fodder posted:How did you begin woodworking? 1) Needed poo poo made of wood, or wood was the only thing to hand to make poo poo from, made some lovely wood things, made a lot of mistakes, learned from them. Now make slightly less lovely wood things. 2) Youtube / Roy Underhill for learnins, farmers/antiques/flea markets for tools. Seriously, Roy's books are some great first-principles poo poo. I have this one. http://www.amazon.co.uk/Woodwrights-Shop-Practical-Traditional-Woodcraft/dp/0807840823/

|

|

|

|

Personally, I'm a traditional hand-tool purist/weirdo (no power tools, period), so that's what most of my links are geared toward. I'm probably one of the least-experienced in here, but I started around November last year, I think? Personally, I've found Paul Sellers to be an invaluable source of information, as far as resources go (there's some stuff on his Youtube page but the Masterclasses subscription has been phenomenal; I wholeheartedly recommend it). There's also Shannon Rogers; I got one of his courses as a Black Friday promotion late last year. Haven't gone through it yet in detail but it looks really informative! He also has the Renaissance Woodworker site and submits videos very frequently. Early on I also came across Wood and Shop late last year, but I think it drowns you in stuff early on. "If you wanna start woodworking basics, you need these twenty tools. Please get the best ones." I mean, I get it that you don't want to scrimp, but I just don't like how it approaches this topic for newbies. For more videos and general info, Popular Woodworking has **TONS** of videos, as well as the vast majority of Woodwright's Shop. Seriously, if you're thinking of getting a DVD based on something tool-related, check this site; it might already be on there. There's some sorta partnership thing, I think, and they put them on here pretty fast. I bought a Moravian Workbench set of videos and found the same thing on here (albeit in one ginormous video) a month or so later. Edit: I'd also encourage regularly scouring Woodworking on Reddit

Geop fucked around with this message at 16:36 on Oct 2, 2015 |

|

|

|

|

I watched a fair bit of the wood whisperer when I was starting out. His end grain chopping block video is near mandatory if you are making one.

|

|

|

|

|

Badass. Looks like a wealth of info. So far my education has been this: Try to dovetail. Fail miserably. Look up youtube. Try again.

|

|

|

|

My HS had an amazing woodshop and offered lots of classes. I took every class and tried to take them twice but the school wouldn't allow it. The great thing about classes are they answer questions you don't know to ask. I will 2nd or 3rd or whatever the recommendation to watch Roy Underhill. It's not just techniques I learn from but a way of thinking.

|

|

|

|

wormil posted:My HS had an amazing woodshop and offered lots of classes. I took every class and tried to take them twice but the school wouldn't allow it. The great thing about classes are they answer questions you don't know to ask. I will 2nd or 3rd or whatever the recommendation to watch Roy Underhill. It's not just techniques I learn from but a way of thinking. I've been watching woodworking shows including The Woodwright's Shop and The New Yankee Workshop (when it was still airing) for about 25 years or so--since I was 5 or 6 (I was a weird kid). I used to prefer Norm with all his ludicrously expensive toys, but for the past decade or so, I've really come around to preferring to use hand tools wherever practical and Roy is just so fun to watch in addition to being really knowledgeable about the history of woodworking and the various methods and tools used through different time periods. He's also an excellent showman. I especially love episodes of The Woodwright's Shop when he has Chris Schwarz as a guest. The campaign furniture series of episodes was on this past week and the banter between the two is great.

|

|

|

|

My favorite Underhill quote is, "Measurement is the enemy of precision."

|

|

|

|

Ugh decisions, I've got an 8x4 sheet of plywood in front of me for a workbench top, I was going to do it 2' wide but now I'm thinking 3'. I might compromise at 2'6".Cannon_Fodder posted:Try again. The most important step that people seem to omit.

|

|

|

|

All my workbench tops are 2' wide, simply because I can slice a 8x4 sheet down the middle and glue em together for a nice sturdy top. I'll admit I've found a bit wider could be nicer though.

|

|

|

|

Cakefool posted:The most important step that people seem to omit. I'm building a scrap pile of wood for ~projects~ and have identified a few simple ones. Example: I trash-picked a table and I'm hoping to take another (fairly thick) wooden surface, and add a shelf to the table, then resurface and stain it. Add casters, add hooks, and I've got a working kitchen island. Wish me luck.

|

|

|

|

Cakefool posted:Ugh decisions, I've got an 8x4 sheet of plywood in front of me for a workbench top, I was going to do it 2' wide but now I'm thinking 3'. I might compromise at 2'6". Stick with 2'. I had wider ones and over time grew to hate them. Most workbenches are 18-24".

|

|

|

|

|

| # ? May 15, 2024 06:35 |

|

wormil posted:Stick with 2'. I had wider ones and over time grew to hate them. Most workbenches are 18-24". I make mine 22" because you can't get a full 4' off of most "4 foot" stock (blade kerf, shrinkage, imprecision) so just building in 2" of slack lets me get it ~PeRfEcT~

|

|

|