|

wormil posted:My favorite Underhill quote is, "Measurement is the enemy of precision." My favorite is his saying "the craftsmanship of risk." He did a great Ted talk about it.

|

|

|

|

|

| # ? May 22, 2024 06:03 |

|

2' it is.

|

|

|

|

Hey woodworkers, I hope someone can answer a question for me. Currently, I'm finishing some drum shells. I started with three coats of aniline dye, then three coats of linseed oil to pull out the grain. It was looking really nice, but I wanted to add a lacquer to give the wood a little added protection, since these things will take a bit of abuse in their life. I went with this spray lacquer here:  One of the shells developed a nasty white haze. I read in a few places that this is due to moisture or temperature change. I did spray these outside, and bring them inside to dry, but the temperature was not much different. As for moisture, the shells were allowed to dry for 24 hrs and rubbing them down with a paper towel beforehand didn't yield any residue. Here's the haze:  This is what the the other shells look like... No haze, quite nice actually.  Anyone know how to treat this? Am I going to have to remove the lacquer and start over? I read in one place that this can just go away over time, but I don't want to continue with the project, drilling the shells and mounting hardware, if I'm just going to have to remove it all and start over. Thanks for the help.

|

|

|

|

JesusDoesVegas posted:Hey woodworkers, I hope someone can answer a question for me. Currently, I'm finishing some drum shells. I started with three coats of aniline dye, then three coats of linseed oil to pull out the grain. It was looking really nice, but I wanted to add a lacquer to give the wood a little added protection, since these things will take a bit of abuse in their life. Non-oil lacquer (nitrocellulose, toluene solvent based, etc) does not play well with oil-based undercoats, although the reverse is quite the opposite. The linseed oil probably did not dry out sufficiently. The cloudiness could be from that or from moisture released by the dye, ftm.

|

|

|

|

There is no longer a MAME thread as far as I can tell, so I hope it's okay that I ask this here. I'm attempting to build a bartop MAME cabinet thing. It's 1/2" MDF all around I have pretty much zero woodworking experience. Here's a picture of the thing I drew up in Sketchup.  Speaking of Sketchup, that is some cool software. Picked up the basics really quickly. Anyway, I'm going to want to add a sheet of plexiglass to the front panel in front of where the monitor goes. Any tips on the best way to do that? Also, I'm going to want a put a backlit marquee thing on the top where the solid front facing board is. Any ideas on the best way to do that, too? I'm a machinist so I have a good grasp on..uh..mechanical concepts, I'm just not sure the best way to go about this. A Proper Uppercut fucked around with this message at 15:57 on Oct 3, 2015 |

|

|

|

On the mame cab, use something like quarter round trim to hold your front glass in place. Years ago I made a mame marquee by sandwiching my print between two pieces of plexi which were screwed in place from the inside, then a light attached behind that.

|

|

|

|

For the plexi use a router/dado stack to cut a bit of an notch at the end of the board that the plexi will go into.. cut the plexi to that size.. so like hole +1/2" on all sides(basically +1 on x and +1 on Y) if you cut a 1/2 inch notch, and glue-epoxy it beind. I'd do the same for the marquee cut a hole.. notch the back, fasten to back with epoxy. Use lung protection with MDF, also do this OUTSIDE! or with dust colleciton equipment.. MDF makes a really dusty awful mess.

|

|

|

|

MDF is terrible stuff. Get the kind with a thin plastic skin and edge veneer it, the generic brand name escapes me atm....

|

|

|

|

wormil posted:On the mame cab, use something like quarter round trim to hold your front glass in place. I like the quarter round trim idea. I can make the radius up the sides a little smaller so that the trim won't stick up over the front. How exactly was the plexi on the marquee secured? Did you just drill holes in the glass? tater_salad posted:For the plexi use a router/dado stack to cut a bit of an notch at the end of the board that the plexi will go into.. cut the plexi to that size.. so like hole +1/2" on all sides(basically +1 on x and +1 on Y) if you cut a 1/2 inch notch, and glue-epoxy it beind. I'm probably misunderstanding you're saying, but I want to have plexi pretty much going across the whole front face of the cabinet where the monitor goes. Wouldn't I have to make a pocket essentially across the whole face of the board for the plexi to fit down into? Also wouldn't you see the adhesive through the glass? Mr. Mambold posted:MDF is terrible stuff. Get the kind with a thin plastic skin and edge veneer it, the generic brand name escapes me atm.... The guy who is helping me with this because I don't have any woodworking tools is supplying some Medex, which is some waterproof MDF or something. Is that what you're referring to? Also, I was planning on putting some t slot molding across the edges.

|

|

|

|

A Proper Uppercut posted:I like the quarter round trim idea. I can make the radius up the sides a little smaller so that the trim won't stick up over the front. Thinking back I'm not 100% how I made the marquee, it was in the early 2000's. You could cut or route a groove for the marquee glass but you will need a slight design change: The front panel (marquee) above your speaker ports should be inset between top and speaker board. Hopefully that makes sense. You could simplify and use quarter round for the marquee, makes it easy. I wouldn't use epoxy , especially for the marquee because someday you might want to change the poster. I've worked with real arcade cabinets and they were built chintzy from cheap particle board so I'm sure any solution you use will be as good if not better.

|

|

|

|

A Proper Uppercut posted:I like the quarter round trim idea. I can make the radius up the sides a little smaller so that the trim won't stick up over the front. Melamine. Not sure if it's the same.

|

|

|

|

Melamine refers to the plastic veneered part. I've only ever seen it used with particle board as the core.

|

|

|

|

dyne posted:Melamine refers to the plastic veneered part. I've only ever seen it used with particle board as the core. http://www.builddirect.com/Melamine-Sheets-Results.aspx

|

|

|

|

Also keep in mind that most wood glue (pva I think, I'm not a chemist) doesn't stick to melamine and the likes. So where Elmer's would be fine if it was just a wood joint, you'll either need to strip the melamine off and glue mdf to mdf, or use dowels or screws to reinforce joints.

|

|

|

|

So apparently my late grandfather in law had one of these in the basement / workshop. And now it's on the way to my garage workshop. Should I keep it inside since I live where there is winter?  Anything I should know about checking it and setup? I figure first trial will be to run some lovely pine or poplar through it before I run anything of value through it.

|

|

|

|

Deedle posted:Also keep in mind that most wood glue (pva I think, I'm not a chemist) doesn't stick to melamine and the likes. So where Elmer's would be fine if it was just a wood joint, you'll either need to strip the melamine off and glue mdf to mdf, or use dowels or screws to reinforce joints. Titebond makes a specific melamine glue, I assume other brands do as well.

|

|

|

|

tater_salad posted:So apparently my late grandfather in law had one of these in the basement / workshop. And now it's on the way to my garage workshop. I've got that one. Gotten plenty of mileage for what it set me back. He took the infeed table off, lotta guys do that. You might take an air chuck and blow it out, including the brushes. Take a look at them while you have them out. Before you plug it in, crank it up and take a look at the knives for nicks. Or just run your finger along one, they will generally all have a nick(s) in the same location. (There's a trick for that) Flip it on, listen how it sounds. It'll only take like a 1/16 at an average pass depending on width and hardness of the lumber. Calibrate the red pointer for accuracy. When you're actually using it, feed in with the back end tilted upward to avoid a snipe going in, and raise the outgoing board gently also to avoid same on the end.

|

|

|

|

Does anyone here have any tips for buying/acquiring green wood?

|

|

|

|

Make friends with a local arborist and get him/her to hook you up. Most of the decent ones have a lot full of freshly-cut logs somewhere, just waiting for some chainsaw loving.

|

|

|

|

Just had a literal windfall and now have about 100 kg of green Norway maple I just debarked and am about to seal the endgrain of. We'll see how big of a mess of shop drying i make. Maple for days, which is super rare this far north. Divine Shadow, I have more than I know what to do with, and I'm happy to hook a bror up if you want any.

|

|

|

|

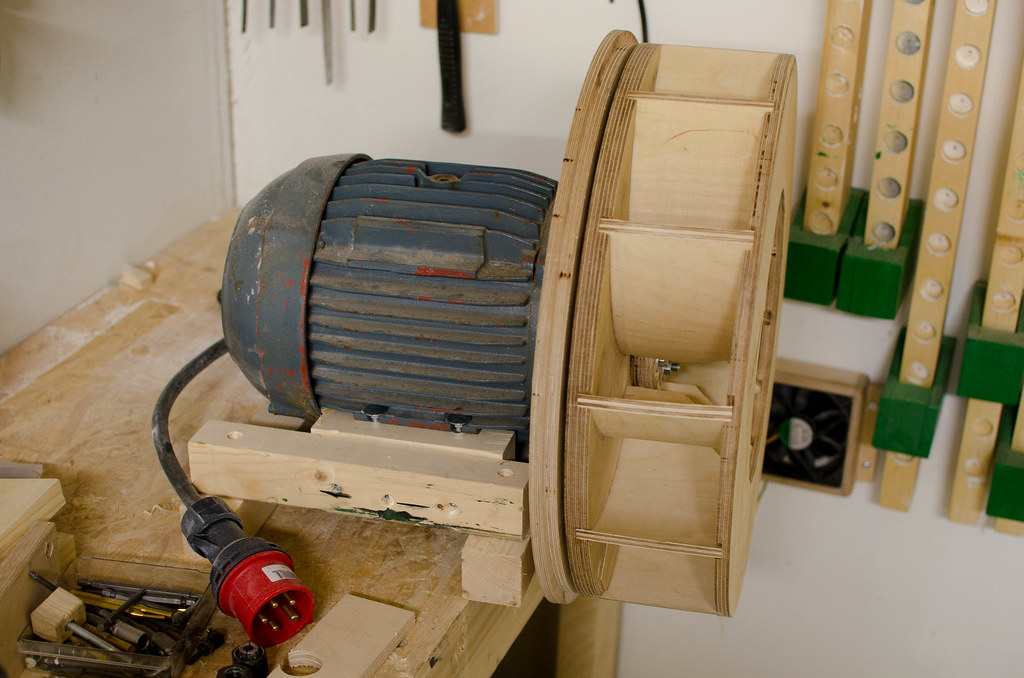

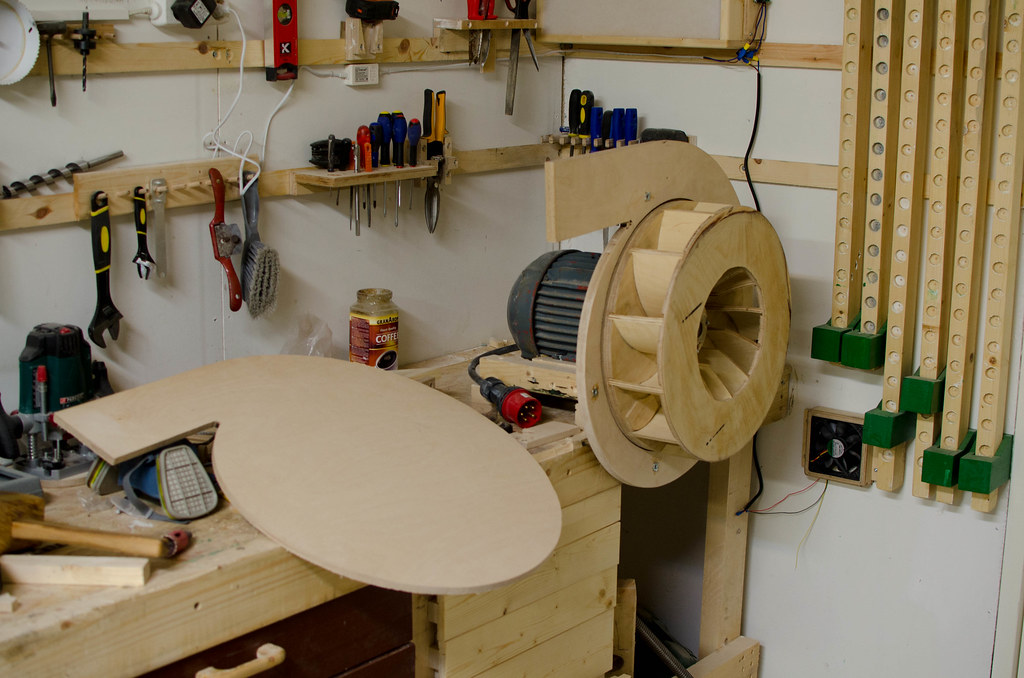

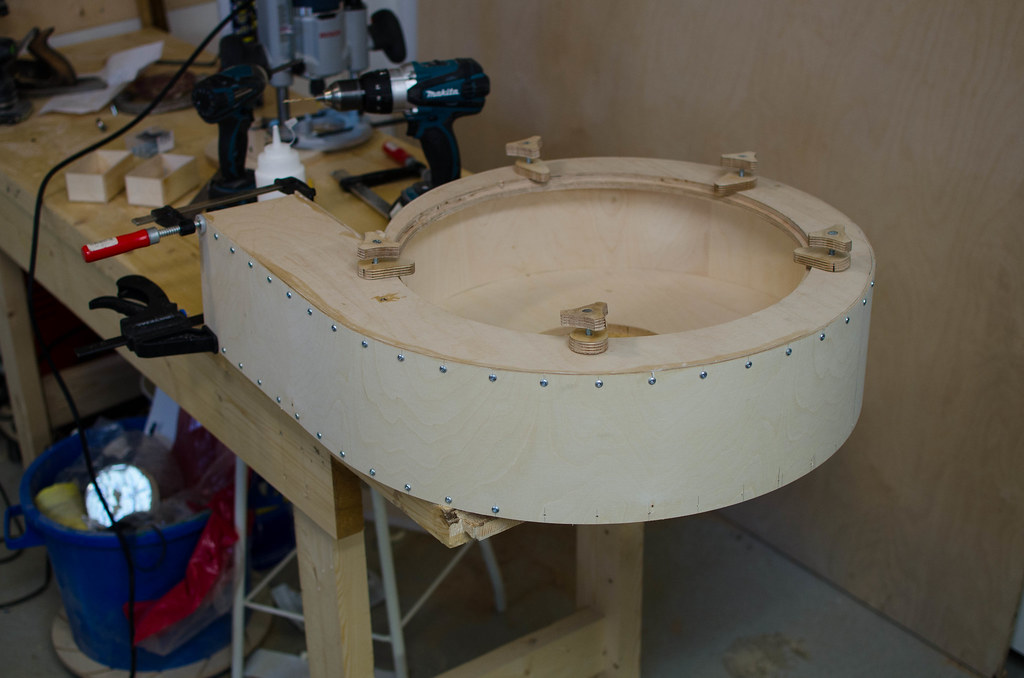

Not sure what you can do with Norway maple, but I lack the ability to transport wood since I only own a yaris anyway. In other news my dust collector project advanced a bit. Finally got the top and bottom of the impeller housing done:  And I made a router compass jig for my new router, it works great, used it so much for this project so far, here I am cutting a hole for the impeller:  Had to hand tune the final size a bit, as the impeller needs to fit through this hole, a spokeshave made it easy:  Backing plate for the impeller mounted, note the rabbet, fits into the part shown above, which has a corresponding rabbet.  Like this:  Started assembling the impeller housing  Ran out of screws!

|

|

|

|

Looks nice! Are those the plans from Mathias Wandel? I've been following a build of his plans here (by Marius Hornberger): https://www.youtube.com/playlist?list=PLBfiYOoCeIJtmTF9VeCkfZAMJmmTyM9NP. I like his use of transparent materials.

|

|

|

|

I used his plans for the impeller, which I've modified a lot. I've taken about as much building notes from Marius Hornbergers DC building videos too. The way the impeller housing is attached for instance.

|

|

|

|

Got my bamboo top all sanded and ready to go. I've seen a lot of conflicting information in regard to the application technique of arm-r-seal, some say overlapping circular motions, some say straight with the grain passes. Does it even matter?

|

|

|

|

|

So we all know the number of clamps you need is n+1, where n is the number you currently possess. I broke 2 clamps today, how many replacements should I buy?

|

|

|

|

3 at a minimum.

|

|

|

|

Cakefool posted:So we all know the number of clamps you need is n+1, where n is the number you currently possess. I broke 2 clamps today, how many replacements should I buy? Sears sells a set of 30 but your local store may not stock it.

|

|

|

|

In the past 20 minutes I came into a few feet of Ash logs. What should I do with it? I have absolutely no experience carving and I guess ash is a pretty hard wood, but hey here I am.

|

|

|

|

The only thing I know that Ash is wonderful for is a hurley, but I don't think that'll be right up your alley. It is, however, right up my alley because my present one is fiberglass.

|

|

|

|

I am not a book posted:In the past 20 minutes I came into a few feet of Ash logs. What should I do with it? I have absolutely no experience carving and I guess ash is a pretty hard wood, but hey here I am. How does the idea of carving electric guitar bodies sound to you?

|

|

|

|

Mr. Mambold posted:Non-oil lacquer (nitrocellulose, toluene solvent based, etc) does not play well with oil-based undercoats, although the reverse is quite the opposite. The linseed oil probably did not dry out sufficiently. The cloudiness could be from that or from moisture released by the dye, ftm. Looks like you were right. The cloudiness cleared up after drying a day or two. So I suppose it was nothing to worry about. They're looking sexy again.

|

|

|

|

Bit of a long shot, but I figured I'd give it a try anyhow. I have a Kobra hollowing system I need to sell. It's borderline unused, just a few discolored spots from hollowing a couple green walnut vessels. I don't have the time to use this thing like it should be used. If you've heard of the Kobra you probably know it's got a waiting list over a year long at this point and the guys who make it don't even advertise it because of that, I believe. They're still actively making them though, and I ordered a replacement 45 degree tool holder from them a few months ago to replace one I lost in the shavings under the lathe and threw out. It's built like a loving tank. I have the 3/4 tool steel boring bar, three different angled tool holders and the laser. I'm looking for $580 shipped. That's half of my cost plus about half of what it would cost to ship it. Just thought I'd mention it because I know a few of you have gotten into turning. I'm not sure any of you have gotten THAT into turning though.

|

|

|

|

This thread seems to be the appropriate place for this. i have the desire to stain some birch with a nice blue.. pretty middle of the road darkness wise, that lets me see the blue but also allow the grain to pop through, similar to this Aside from that particular dye, i have plans to finish it with a protective coat of some semi loss finish (poly,shellac?) and in researching ways to get my color, with rit dye, mixing ,etc i'm getting very confused on what my options are. i understand keeping oil and water based stuff apart... but is it feasable to: apply a wood conditioner -->apply a black water based stain --> sand lightly to remove most --> apply blue tain layer after layer for color --> finish with xxx coat sanding / cleaning with tack cloth in between for the above. I guess I'm really asking is the better path mixing my own color with rit dye + some clear stain vs getting the color itself from an existing stain? My biggest thing to avoid is making everything a dark blue mess with no highlights. Youtube is showing me guitar refinishing that gets very close, but they are all over the place using leather dye, etc .. what does that give me over say 'island mist' minwax water based dye ? or some oil based dyable ? Roundboy fucked around with this message at 03:20 on Oct 6, 2015 |

|

|

|

Hubis posted:How does the idea of carving electric guitar bodies sound to you?

|

|

|

|

Re: the load of Norway maple in my shop. Not entirely sure what I'll do with it, I understand it's good for turning and carving. It will take a while to dry (at least a year) , but I have some green wood projects and classes I can use some for in the meantime. I got ahold of it after it had been bucked into smaller logs, so it was easily carried in my car. There's some nice spalting, so once it's dry I will probably make some small furniture from it.

|

|

|

|

Roundboy posted:This thread seems to be the appropriate place for this. Look at analine dye, you can get really vivid colors while still allowing the grain to come through nicely. Not blue, but here is an example of a piece I saw earlier this year that highlights the grain quite nicely-

|

|

|

|

Dyami over at the Penultimate Woodshop finished a chair in blue using transtint dye. You might get some tips from his writeup

|

|

|

|

Took a short video of testing my impeller with the housing mounted: https://www.youtube.com/watch?v=JrW-fWd8g-Y

|

|

|

|

His Divine Shadow posted:Took a short video of testing my impeller with the housing mounted: That is terrifying.

|

|

|

|

|

| # ? May 22, 2024 06:03 |

|

I'm sorry it appears you accidentally manufactured an air raid siren.

|

|

|