|

GEMorris posted:Yep, the sliding dovetail gives enough thickness for staked legs to have full support without additional stretchers. It's all relative. There are a lot of factors which will influence why you would or would not do it, but it's not some stupid thing that an academic came up with. If you work in a shop with big humidity swings, or if your wood isn't dried perfectly, or if you're going to leave your glue up for a while because you can only work every other weekend, you'll be wise to consider it. Sometimes I go a month or more between initial glue up and finishing because "life gets in the way" - when I've alternated, my glueups stay flat. When I haven't, it's quite noticeable and I end up fighting to get the panel flat. the guy who asked the question originally said he just used glue... if you're JUST using glue and sticking legs on the table without an apron, and you live in a climate that sees big humidity swings from season to season, alternating the rings gives you the best chance of long-term success. can you fix it if it goes wonky? sure. but why set yourself up for potential failure? that being said, if your wood is adequately dried and you live in a stable climate, then no, it doesn't really matter. and if your design includes an apron on the table and you know how to properly secure a tabletop to it, then it probably doesn't matter what you do. but to say it's just theory is a bit silly. it's something you should consider doing, based on your circumstances.

|

|

|

|

|

| # ? Jun 7, 2024 15:53 |

|

From a few pages back respirator chat has gotten me concerned about this. Does anyone have any good resources or links or products to buy on this?

|

|

|

|

Aquila posted:From a few pages back respirator chat has gotten me concerned about this. Does anyone have any good resources or links or products to buy on this? Filter wise you want whatever filters the smallest possible particles, as those cause the most harm. As a side bonus the filters for common solvents and such are also cheap as chips.

|

|

|

|

Aquila posted:From a few pages back respirator chat has gotten me concerned about this. Does anyone have any good resources or links or products to buy on this? Amazon. Before that was a thing, I used to go to the automotive paint store because they are serious.

|

|

|

|

I really like the 3M respirator I got. 34 bucks on amazon isn't bad either. Definitely pay attention to the type of filters you put on it and be sure it matches your usual chemicals. I even used to have one of those breaking bad full face ones. Got them when I thought I was going to be working with a chemical that was super reactive to soft tissue. So essentially your eyes would melt away as your lungs dissolve and you suffocate on your own blood  Thankfully I never had to make that stuff

|

|

|

|

I have a fully powered 3m respiration kit that auto body guys use for spraying cars. If you do extensive sanding, especially of walnut, I highly recommend it. Ask me for details about the effects of wood dust overexposure.

|

|

|

|

^^^ I am interested to hear.Aquila posted:From a few pages back respirator chat has gotten me concerned about this. Does anyone have any good resources or links or products to buy on this? I have a 3m respirator... 6503QL. The nice thing about it is that once you get the straps on, it has a quick latch function that allows you to pull it off your face without taking off the straps. Makes it easy to have a conversation, drink coffee, and put it right back. http://www.amazon.com/gp/aw/d/B00IF7RCU6#Ask

|

|

|

|

Deedle posted:Filter wise you want whatever filters the smallest possible particles, as those cause the most harm. Any NIOSH rated mask ('N95,N99,N100,P95,P99,P100') has adequate filtration for hobbyist woodworking wood dust (although going for the higher filtration of 99/100 options certainly won't hurt).

|

|

|

|

This may be a stupid question, but I'm looking for an estimate on how feasible this would be to do. To make a long story short, I don't like any of the bathroom vanity lights I've found, and I stumbled upon this photo on Houzz:  I'm wondering if it would be possible/feasible to frame up a box, probably with framing lumber-- ~6"x"6"x40", face it with either cabinet grade plywood or MDF, and then apply a PSA veneer to the 4 visible faces (front, bottom, and both ends). I'd then cut a few holes in the bottom to install can lights inside, and hang it on the wall, either with a flush bracket or straight into the studs. Is this a bad idea to attempt? I'm not sure how you would handle the veneer at the the corners/edges. From my limited understanding, I don't think you can bend it around a 90 degree corner without cracking it, so you'd have to have 4 sheets of veneer, one for each face, and then try to have the ends overlap ~the thickness of the veneer to hide some of the edges. Any inputs on the what substrate to use for this, how to apply the veneer, etc. would be very helpful. I would need to make two of these, if I decide to go down that route. The second one would be slightly shorter, maybe 30-36" long, to go over another countertop in the bathroom.

|

|

|

|

Aquila posted:From a few pages back respirator chat has gotten me concerned about this. Does anyone have any good resources or links or products to buy on this? Most people that buy one, are happy with the 3M mask. I bought one and it was much more comfortable than I expected. It's still a mask, I'd rather not wear it, but more importantly I'd rather not spend my evening coughing.

|

|

|

|

Tonight I have a 150 liter bag filled with planing shavings and scraps to burn in the forest. It is cathartic.

|

|

|

|

Chips from the lathe make the absolute best fire starter. I keep a tote in my shed for just that reason, it's fantastic.

|

|

|

|

|

Bad Munki posted:Chips from the lathe make the absolute best fire starter. I keep a tote in my shed for just that reason, it's fantastic. Mix it with some dryer lint!

|

|

|

|

Then soak it in gasoline for a while and you can't fail!

|

|

|

|

|

MetaJew posted:This may be a stupid question, but I'm looking for an estimate on how feasible this would be to do. If you're using cabinet grade or paint grade 3/4" plywood, there's no need to frame it out except for back and ceiling nailers- which you definitely want secure. Also, if you're using cabinet grade plywood, it's already veneered. trying to veneer a bathroom lightbox is a huge...erm, waste. imo. Either miter the edges accurately on yon tablesaw, or straight cuts and use 3/4" x3/4" hardwood corners and edges. Obviously, you'd want that hardwood to be the same or similar grain to the plywood. Bonus of using hardwood edging is you can roundover that (avoid routing the inset pins or nails)

|

|

|

|

Free Market Mambo posted:Tonight I have a 150 liter bag filled with planing shavings and scraps to burn in the forest. It is cathartic. I found a way to burn that and various saw dust in my fireplace. Take a big empty metal tin (Ålandsgurkan, highly recommended) and drill a hole in it, 40-50mm or so, and then fit something that is the size of the hole in the can. Finally pack it full with sawdust and stuff, just keep packing it down. Remove the bit from the middle and you have a sort of briquette that will burn really nicely and cleanly, without smoke if you make a small fire under it. This principle: https://www.youtube.com/watch?v=o-S-dMInfQU

|

|

|

|

Mr. Mambold posted:If you're using cabinet grade or paint grade 3/4" plywood, there's no need to frame it out except for back and ceiling nailers- which you definitely want secure. Also, if you're using cabinet grade plywood, it's already veneered. trying to veneer a bathroom lightbox is a huge...erm, waste. imo. Cabinet grade was just a guess. Suppose I use another material, that has a smooth enough surface for veneer: how would you join the corners and veneer it?

|

|

|

|

MetaJew posted:Cabinet grade was just a guess. Suppose I use another material, that has a smooth enough surface for veneer: how would you join the corners and veneer it? I already posted I wouldn't do that

|

|

|

|

Now that I have a real job and free time. I'm getting back into doing some woodworking. Unfortunately, the area I live in is devoid of places to source wood other than Lowes or Home Depot. I'm assuming Lumber 84 would be similar to Lowes/HD? There is a Woodcraft but it's about an hour and a half away. Suggestions for trying to find wood?

|

|

|

|

|

MetaJew posted:Cabinet grade was just a guess. Suppose I use another material, that has a smooth enough surface for veneer: how would you join the corners and veneer it? Smooth enough to veneer is either cabinet grade plywood or properly planed hardwood. Factories veneer all sorts of garbage, but I wouldn't recommend it in a home shop.

|

|

|

|

Having tried to apply veneer over a large area myself, it's a pain in the rear end and doesn't really save you any money anyway. Just buy pre-veneered products and save yourself a ton of trouble.

|

|

|

|

MetaJew posted:Cabinet grade was just a guess. Suppose I use another material, that has a smooth enough surface for veneer: how would you join the corners and veneer it? My suggestion is find the materials first, preferably a cabinet grade ply with a veneer you want already. If you still want to veneer it, then find your veneer and study up a bit on how to apply it. The corners are nothing special, just butt joints, but the veneer is so thin it looks fine. Applying veneer to something that small and boxy shouldn't be too difficult but I have never applied wood veneer like that so I defer to the more experienced guys who say it is a PITA. My podcast question got lost in the hubbub, anyone listen to anything other than FWW, Woodtalk, or 360 WW?

|

|

|

|

wormil posted:My suggestion is find the materials first, preferably a cabinet grade ply with a veneer you want already. If you still want to veneer it, then find your veneer and study up a bit on how to apply it. The corners are nothing special, just butt joints, but the veneer is so thin it looks fine. Applying veneer to something that small and boxy shouldn't be too difficult but I have never applied wood veneer like that so I defer to the more experienced guys who say it is a PITA. Thanks. I hadn't considered that I could get a cabinet ply with walnut, since all I've seen locally are oak and ash veneers. I'll have to figure that part out.

|

|

|

|

I'm so goddamn excited, I'm disappointed that I have to go to Mexico on vacation in a week.

|

|

|

|

Bring it with you. I'm sure the hotel/resort will have some wooden furniture that could use a good flattening.

|

|

|

|

MetaJew posted:Thanks. I hadn't considered that I could get a cabinet ply with walnut, since all I've seen locally are oak and ash veneers. I'll have to figure that part out. I have made a few projects with veneered hardwood and... it's fine. People who go on about the thin-ness of the veneer and how much it sucks have usually just bought into the old-timers' critique of the stuff, because it's admittedly thinner than it used to be. But it has its place. As long as you aren't sanding aggressively, it'll definitely suit your needs. It's not being closely inspected if it's high above the sink in a bathroom. You can get by with G1S cabinet plywood, which is "good one side". In terms of techniques, I would say that your best bet is to buy some and try it out for yourself... see how good of a corner you can make using different strategies. Because it's veneered, a mitred corner will instantly look lovely if you bang into it... it'll also look lovely if you don't manage tearout when you're cutting - so score your cutlines and use a sharp blade in your saw. I prefer to edge-band my veneered ply with 1/8" strips of wood, and then use butt joints (with a dowelmax). So long as you're picking edgebanding with a tone that matches the ply, only nitpicky woodworkers will call attention to the joint. If you're fixated on veneering it, the typical approach would be (1) build the case, (2) veneer the sides, then trim flush, (3) veneer the top/bottom, then trim flush. How you trim flush is up to you - most common is a router with a flush trim bit, but you could also use a block plane or get a little laminate trimmer.

|

|

|

|

Guitarchitect posted:I have made a few projects with veneered hardwood and... it's fine. People who go on about the thin-ness of the veneer and how much it sucks have usually just bought into the old-timers' critique of the stuff, because it's admittedly thinner than it used to be. But it has its place. As long as you aren't sanding aggressively, it'll definitely suit your needs. It's not being closely inspected if it's high above the sink in a bathroom. You can get by with G1S cabinet plywood, which is "good one side". Thanks, this was helpful. Like I said, veneering was just my first idea because I haven't seen a cabinet grade plywood with the veneer I like, locally (big box store) but I also haven't looked very hard. Ordering a roll of veneer sounds like it would be easier to do than ordering a 4x8 sheet of plywood, but I can appreciate that applying the veneer can be challenging, to say the least. If anyone has advice on where to source 2GS or 1GS ply in central Texas, I'd appreciate the guidance. I'm sure it can be located based on how booming the real estate and luxury home market is, here.

|

|

|

|

calandryll posted:Now that I have a real job and free time. I'm getting back into doing some woodworking. Unfortunately, the area I live in is devoid of places to source wood other than Lowes or Home Depot. I'm assuming Lumber 84 would be similar to Lowes/HD? There is a Woodcraft but it's about an hour and a half away. Suggestions for trying to find wood? It depends on what you're planning on making specifically, if you have a particular project in mind you'll need to be more specific. If you're just looking for just general wood to have around in case you feel like makin' sumpin, you can score wood from basically anywhere. Your first bet is looking for a local sawmill - try the yellow pages, looking around on craigslist, and if there's Amish in your area they always have one or more, you just have to find it. If you turn wood on a lathe I've had great luck just buying firewood pieces and rounding them with a hatchet before spinning them. Try getting hold of a tree service and seeing about scoring some wood. It'll be green logs, so of course that's only any use for some stuff- if you want to make mahogany cabinetry this route is obviously worthless. I've gotten wood out of curbside trash, good stuff too. Of course it's mostly, you know, trash, so you have to know what you want. I guess the real question is what kind of wood do you want? What are you going to make? If you want to build tiny exquisite boxes out of exotic hardwoods, just buy online. If you want to make hand-hewn log benches, just find some logs. If you want plywood, Lowe's etc will usually do. Lathe wood I just use firewood chunks. Lots of folks out in the country have wood sitting around, make them an offer. People on craigslist have portable sawmills, find one of them. Of course, most pallets are hardwood- usually white oak.

|

|

|

Uncle Enzo posted:Your first bet is looking for a local sawmill - try the yellow pages, looking around on craigslist, and if there's Amish in your area they always have one or more, you just have to find it. There are a ton of Amish here, didn't think about them. Unfortunately, craigslist for DE can be definitely hit or miss. As for what I want to make, probably going to start off doing some boxes and then into other stuff once I get back into it. I'll probably just bit the bullet and hit up Woodcraft one of these weekends.

|

|

|

|

|

MetaJew posted:If anyone has advice on where to source 2GS or 1GS ply in central Texas, I'd appreciate the guidance. I'm sure it can be located based on how booming the real estate and luxury home market is, here. Name your city? If you look up Hardwood lumber suppliers, they typically carry plywood as well. Mills as well, but I don't know what your mill situation is like in Texas. Fair warning, if they're anything like the wood shops here in Ontario they're never (or barely) open on weekends. Mine are only open Saturday mornings. It makes sense when you consider that 99% of their business is trades+tradespeople, but gently caress is it ever annoying.

|

|

|

|

Guitarchitect posted:Name your city? I'm in Austin, and yeah I couldn't go to the HVAC or trim/builder supply stores in town because they were only open M-F 9-5, and they were across town from my office.

|

|

|

|

calandryll posted:There are a ton of Amish here, didn't think about them. Unfortunately, craigslist for DE can be definitely hit or miss. As for what I want to make, probably going to start off doing some boxes and then into other stuff once I get back into it. I'll probably just bit the bullet and hit up Woodcraft one of these weekends. Go for a drive around Amish country, the sawmill is the long low crummy-looking shed with piles of sawdust and stickered wood stacked around it. Can't miss it.

|

|

|

|

If you're lucky the owner may ask you to impregnate a relation, roll with it and you will be blessed with the clearest of lumber.

|

|

|

|

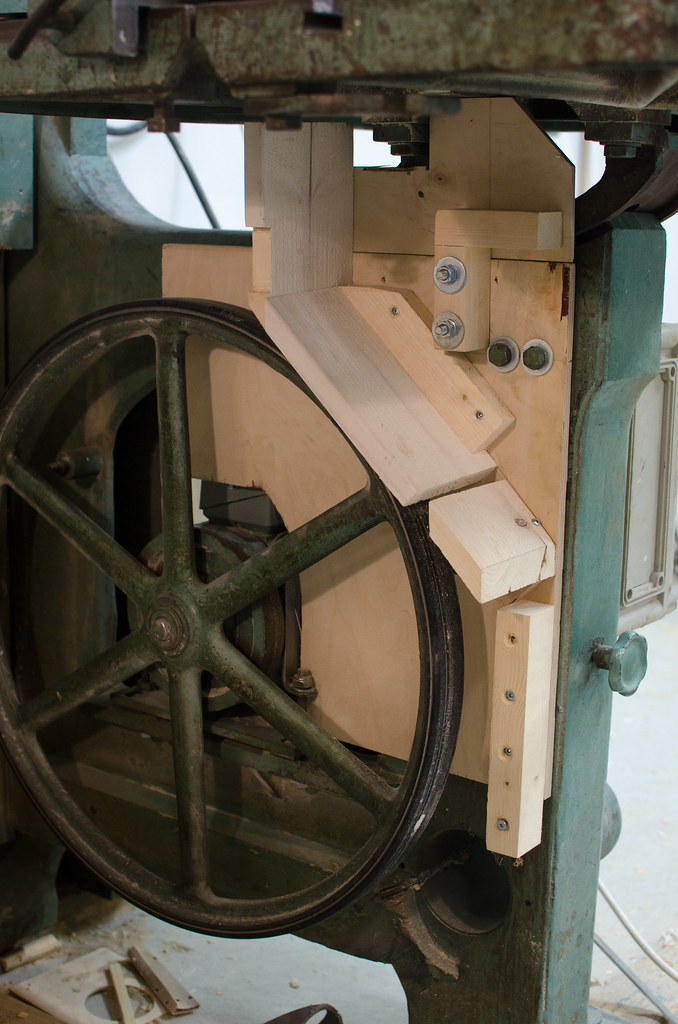

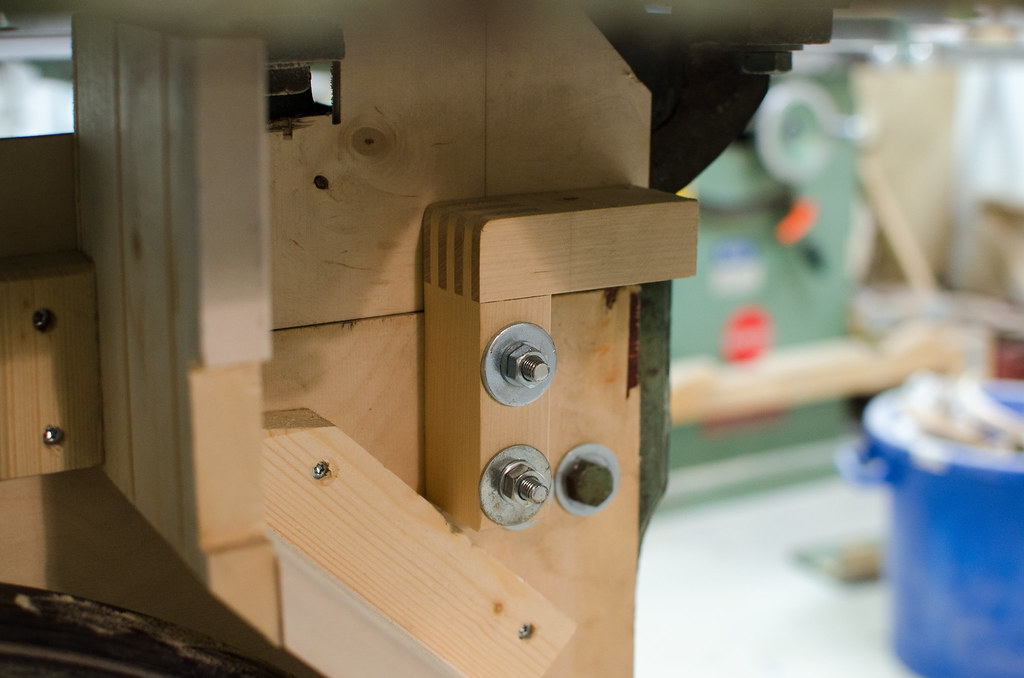

Rebuilt the lower blades guides for my bandsaw. These are the old ones, extremely simple, no thrust bearing, situated very far down under the table: Tracking hasn't been the best due to this. These are the new guides, made from scrap pieces of hardwood, oak side guides and a thrust bearing, I am very frugal with my hardwood so I've glued smaller pieces together to make a bigger whole:  The thrust bearing doesn't really have any adjustment, it's adjusted with the side bearings as one unit. But it doesn't really need any, for now. I'll have to see how it acts with other types of blades in the future. But I only have the one 1/2" blade.  In redoing the guides I am also redoing the dust collection system and closing in the underside of the table. The old system was simple and effective, but couldn't be used with the table tilted and also interfered with having the guides higher up. The spokes on the wheels act as fans which throw dust around, so enclosing the dust from the table like this solves a big problem with the original design. Where the two green bolts are, that's where the old guides sat.  The L-shaped piece of wood is the new mount for the guides, the box-joint jig is really handy for making super sturdy joins, box joints are the strongest join there is, stronger than dovetails:  A lag bolt fits into the slot on the guide body, see the slot in the back of the guides in the picture above,   Blade installed:  I believe if I wanted to, I could modify this design to use bearings as side guides, by mounting the bearings on cams that I would lock down instead of the oak blocks. But I think wooden blocks given good enough wood, are just as good as bearing guides. The difference in tracking is very noticeable to me. The saw cuts straighter and more accurately than before. I might remake them in metal sometime in the future. But wood seems to work well enough for now. Work on enclosing the whole thing continues still. I'll paint the exterior green later to match the saw better.

|

|

|

|

I made a cherry and mahogany gift box for my wife's uncle who is letting us stay at his place for our upcoming vacation.  Continuous grain wraps around the box.  And the gift, used wood shavings instead of bubble wrap or packing peanuts.

|

|

|

|

wormil posted:My podcast question got lost in the hubbub, anyone listen to anything other than FWW, Woodtalk, or 360 WW? I hadn't even thought about podcasts for woodworking... will have to check out 360WW. FWIW I subscribe to Frank Howarth, William Ng, and Rob Bois on youtube EDIT: oh yah, Rob Cosman, Paul Sellers, and Mathias Wandel Guitarchitect fucked around with this message at 02:35 on Feb 1, 2016 |

|

|

|

Meow Meow Meow posted:I made a cherry and mahogany gift box for my wife's uncle who is letting us stay at his place for our upcoming vacation. This is very cool and a neat gift, I'm sure he'll love it

|

|

|

|

Guitarchitect posted:I hadn't even thought about podcasts for woodworking... will have to check out 360WW. Rob Bois whenever available.

|

|

|

|

Bringing back resperator talk, I went full hog and got one of these: http://www.amazon.com/gp/product/B007JZ1M10 because it serves as a "one tool does everything" for face protection during turning, eye protection during everything and dust protection. It also makes me resist the urge to just toss on some glasses and do a quick couple cuts because how much dust is there really? For what should be a one time expense it made sense to me. Added bonus, random dust doesn't get in my eyes anymore making me stop what I'm doing for 2-5 minutes trying to blink it out.

Anubis fucked around with this message at 04:26 on Feb 1, 2016 |

|

|

|

|

| # ? Jun 7, 2024 15:53 |

|

Anubis posted:. Added bonus, random dust doesn't get in my eyes anymore making me stop what I'm doing for 2-5 minutes trying to blink it out.

|

|

|