|

Yooper posted:Get good with a quality micrometer and you'll feel dips and bulges on a shaft in the .00005 range. It'll be beyond what your mic can read, but you'll feel the tight spots-loose spots. Then to verify stick it into a laser mic, and whammo, there it is. Blacksmithing/Metalworking: You'll feel dips and bulges on a shaft in the .00005 range.

|

|

|

|

|

| # ? May 23, 2024 15:54 |

|

ArtistCeleste posted:Pagan, why are you watering your anvil? Hot anvils are usually a good thing. And drat, that's a lot of hand hammering. For the 2nd stage of forming the blank (hizikuri), you keep the anvil wet because it blasts off the scale. When the water is trapped between the hot anvil and the hot iron, the steam has enough force to detach the scale, and it doesn't really cool things off that much. I need to get more in the habit of filming as I work. It still feels unnatural and like I'm having to stop every five minutes, but if I don't keep at it I'll never get better. I enjoy hand forging. I bought some new stock today, and I decided to go with 1" square 1095, instead of blanks that are 2" x 1/2" x 12, because I like that part the most. Grinding sucks. Stock removal knife making focuses on the least fun part, so I would much rather hammer it into shape. I also have many more options for shapes and bevels. Since I'm not trying to make a living (one day....) I can indulge that side. I'm also able to do finish grinding mostly by hand. It took about two hours of filing to get the full size tanto ready for heat treat. It broke (which is why I decided to try buying new steel instead of using scrap, at least while I'm still learning) but the other knives I've made, I use a belt grinder to get to about 200 and then I use hand stones for the rest. ArtistCeleste posted:I learned a lot from a class with Brian and Ed Brazeal. ... they really are obsessed with the efficiency of both those things. They taper on the edge of the anvil because it works as an aggressive fuller. (I still prefer a round hammer on the horn.) I've watched a lot of Alec Steele, and even paid for his intro class. He teaches a lot of the same techniques as Brian Brazeal (that name pops up a lot) and that's why I am in the habit of tapering on the edge of the anvil. It's interesting to meet smiths who've learned the other way. Ambrose Burnside posted:Now that I'm making chips at school I'm honestly kind of surprised how good the ol' mk 1 eyeball is. like, if I zero and center-drill and then jog the machine around and line the drill back up by eye without the DRO, I can consistently land within about +/- 5 thou. That's the kind of precision I got cranky about not always meeting when doing repousse stuff. Guess I overestimated how small a unit a thousandth actually is. I was thinking about this. I wonder how accurate the eyes and hands are? I'd love to do a double blind experiment, have things that are off by varying degrees, and have random people sort them by straightness. Or feel the surface of something and see what's the difference between a surface imperfection someone can see vs something they can feel. Imagine having to sort a series of ball bearings, in the dark, sorted by the final grit they were sanded or polished with. Sure, everyone can feel the difference between 80 and 200, but how many can tell the difference between 800 and 1000, etc. If I had REAL funding, there'd also be a demographic segment to see if craftspeople and artisans, or people who do "precision labor" are better. I imagine it's a skill that improves with practice, but how accurate is it?

|

|

|

|

I really want a metal vise now after having needed one but all I got are wood vises mounted inside where I don't wanna do any grinding. But all you can buy are expensive cast iron vises and the used market is looking dried up. So I'm leaning towards John Heisz's metal vise, has anyone here made it? Looks like a solid design from what I can tell. I have a acme thread and nut left over too, all I need is the tubing.

|

|

|

|

Pagan, I love that idea with the double blind testing. That would be fascinating. Alec Steele learned from Brian starting at age 13. Everything I have seen him post, tool making or decorative, looks just like Brian's work. Brian has a large YouTube channel, which I have not watched. He said he is putting his whole curriculum up there. I did learn a lot from him. But I don't think he is the end all be all of blacksmithing . He started almost every demo by saying, "I am the best ever in the world at this, there is no one in the world who does it faster and better than me." Despite this proclamation, I still prefer Mark Aspery's overall style, which is possibly derived from the Hartford School.

|

|

|

|

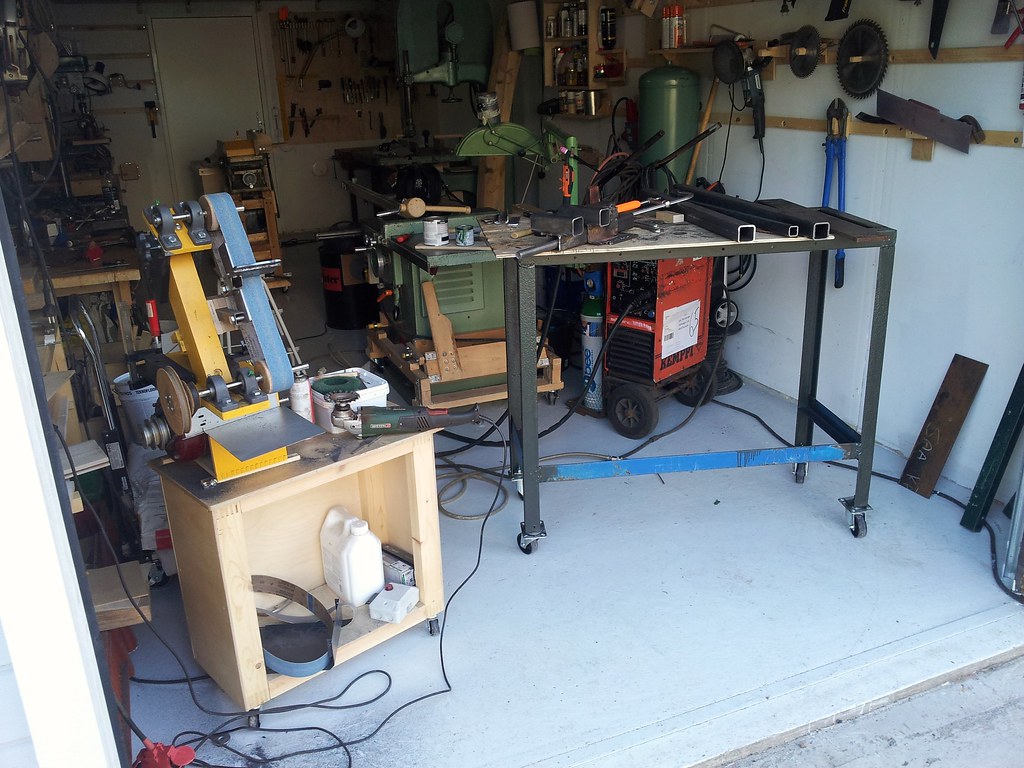

OK got a piece of plate for my welding table top, just need to go pick it up. 6mm thick, 80x130cm or 1/4" thick and 2.6 by 4.2 feet. A bit on the thin side but I think I'll be fine, just need to add some support in the top frame to prevent sagging.

|

|

|

|

For a single anecdotal datapoint, I once picked up a glass jar, noticed it felt weird, and discovered .080" of runout when I put the calipers on it.

|

|

|

|

How do you tell the difference between TCMT 31.52 and 21.52 inserts? Googling the question just mystifies the poo poo out of me. I got a 1/2" shank 5 piece no-name set of indexable lathe tooling a year ago and I've finally started to wear through the garbage carbide that came with them and I don't know which ones I need. I think I need 31.52 but I'd like to know before I waste $30 bucks + shipping.

|

|

|

|

Pimblor posted:How do you tell the difference between TCMT 31.52 and 21.52 inserts? Googling the question just mystifies the poo poo out of me. I got a 1/2" shank 5 piece no-name set of indexable lathe tooling a year ago and I've finally started to wear through the garbage carbide that came with them and I don't know which ones I need. I think I need 31.52 but I'd like to know before I waste $30 bucks + shipping. The first number is inscribed circle in 1/8ths of an inch, second is thickness in 1/16ths, third is tip radius in 1/64ths. So a 31.52 has a .375" inscribed circle, is .094" thick, and .031 nose radius. gently caress ISO in it's stupid god damned face. e: Find a metalworking supplier in your area or call MSC and ask for a local rep. There are usually sales where if you buy a box or two of inserts they'll throw in a holder. oxbrain fucked around with this message at 01:45 on Sep 30, 2016 |

|

|

|

Anybody got any particularly good videos for grinding lathe bits? I gotta do one but I couldnt see the instructor's demo (20 people tryna watch a 3/8" bit of steel being ground) and the written instructions are bad.

|

|

|

|

Ambrose Burnside posted:Anybody got any particularly good videos for grinding lathe bits? I gotta do one but I couldnt see the instructor's demo (20 people tryna watch a 3/8" bit of steel being ground) and the written instructions are bad. This video got me going for lathe bits. He also has a good one for Fly Cutter and (I think) threading tools, as well. Skip to about 7:30 or so if you're not interested in the reasons for why everything is being done. https://www.youtube.com/watch?v=bvJhRtRR7rk

|

|

|

|

oxbrain posted:The first number is inscribed circle in 1/8ths of an inch, second is thickness in 1/16ths, third is tip radius in 1/64ths. So a 31.52 has a .375" inscribed circle, is .094" thick, and .031 nose radius. That's even worse than anvils being marked in English 100wt http://www.anvilfire.com/article.php?bodyName=/FAQs/anvil-6.htm quote:Typically the hundreds weight markings are seperated by dots but not always. These figures were stamped into the finished anvil and are often not very deep. The first figure to the left is hundred weights which equal 112 pounds. The next figure is quarter hundred weights which equal 28 pounds and the last number is whole pounds. The three are added together for the total weight. Examples:

|

|

|

|

These guys have been solid suppliers for my employer as cutting tools go. Mitsubishi Carbide has been running a bunch of sales trying to break in to the market, ask about them. http://www.cmtindustrial.com/

|

|

|

|

Delivery McGee posted:A partial success! In that this is the first time I've ever beaten on red-hot steel with a hammer, and it mostly worked. I'd like to make the flattened bit more round than long, but otherwise the concept is proven. Honestly that looks like chromeplate not galvy. Still bad for you, just in a "lol cancer" sort of way (if you managed to inhale any) not a zinc fume fever way. IIRC the layers under a chrome plating will be a copper plate over a nickel plate, but I may be wrong about that, I have zero actual training in metalplating and only picked up a little researching it myself. sharkytm posted:Grind your ground point... You want fresh, clean metal where the clamp makes contact. Agreed. FWIW, the Harbor Freight cast bronze/brass ground clamp is great, I put one on all my welders eventually.

|

|

|

|

Iirc, abom79 did a good video on hand grinding HSS toolbits on his YouTube channel. Actually if you don't watch him, go do so- he's really good at actually explaining what he's doing and he's drat good at what he does too. Watching him index in a piece in a 4 jaw chuck to half a thou of run out in under 30 seconds is like watching a wizard at work!

|

|

|

|

Halligan142 has a couple videos for lathe tool bit grinding where he has a large wooden model that is helpful to see in describing the various angles. https://www.youtube.com/watch?v=nHEf6YL6sFI https://www.youtube.com/watch?v=sFnTXgXMbrQ

|

|

|

|

Bought 3 meters of 2x2 thickwalled rectangular tubing, also a meter of some smaller stuff, time to weld a vise.

|

|

|

|

The guy with the giant wood lathe bit is what got me over the hump. I'd suggest making one or two out of key stock first: You'll see if the bevels are going the right way, see your results a hell of a lot faster, and it's cheap. If you get your tool rest to a decent angle you can use it for all three facets. Something else that helped me wrap my head around the geometry was thinking about how I would hold a knife to cut something really soft in a lathe, and then make that except a really fat knife with like 70-80° double bevel.

|

|

|

|

AbsentMindedWelder posted:6013 was a rod developed by a masochist with the express purpose of making weldor's experience using it a living hell. The only thing I remember about 6013 is that it runs on AC pretty well, so it does have it's uses.

|

|

|

|

Felt I had a slight breakthrough in my self-learning TIG experience. Turned up the amps and boy everything got much easier. I really need to get that LCD display fixed so I know what I am running at for sure. I was making beads on a 3.2mm or 1/8" piece of square tubing and not until I upped to setting 5 (assumed to be 150A) did it really start work. I've never really run the TIG torch over setting 4 which I guesstimate is 120A since max current is 300A and it has 10 numbers to indicate min-max. Did it really require me to goto 150A just for 3.2mm? I stick weld that on 90-110A easily. I need to upgrade my torch since it's only rated for 130A, also clumsy and annoying. I think I should build a water cooler. EDIT: Just realized, maybe I need to go down a size on electrodes for the lower amps, I only got 3/32nds (2% lanth), I should buy some smaller ones. His Divine Shadow fucked around with this message at 18:41 on Oct 2, 2016 |

|

|

|

My makerspace has both TIG and MIG welders for use after taking the appropriate classes. Most of the projects that I'm thinking about doing would be sheet metal up to 1/4" plate at the thickest, mostly steel. Am I correct in thinking that MIG would be the class to take first?

|

|

|

|

Absolutely. Mig is just useful utilitarian welding, and a great launchpad to more complex stuff later.

|

|

|

|

I feel slightly robbed that my intro to welding cc class two years ago was strictly stick and oxy

|

|

|

|

shame on an IGA posted:I feel slightly robbed that my intro to welding cc class two years ago was strictly stick and oxy If you're proficient at either/both of those, mig won't give you any trouble. It's pretty easy.

|

|

|

|

shame on an IGA posted:I feel slightly robbed that my intro to welding cc class two years ago was strictly stick and oxy Negative, you were blessed. Most people don't go out of their way to learn stick, they pretty much have to be forced to do it properly, and afterwards you are left with a valuable skill. I understand the makerspace will make you take a class before using their poo poo, and that's fine, but realistically speaking to Learn MIG you spend some time on Jody's website and youtube channel and you'll learn everything you need to know about MIG. The bigger challenge is having the correct equipment and consumables. knowing what these are, and setting the machine up properly for a given job.

|

|

|

|

AbsentMindedWelder posted:Negative, you were blessed. Most people don't go out of their way to learn stick, they pretty much have to be forced to do it properly, and afterwards you are left with a valuable skill. I've been watching Jody's channel for a while, just out of interest, but I'll definitely check back over a bunch of his MIG videos before the class. All of the equipment at the maker space is new, shiny Lincoln-Electric stuff (including movable fume extractors), so I'm surprised that there's no stick welders. I guess whoever the Lincoln rep was in touch with was wowed with the big ticket items and didn't buy what I'd always assumed was the basic type of welder.

|

|

|

|

Most likely whatever TIG welder the shop has will also do Stick if anyone really wants to. They are both constant current power supplies. That said, a makerspace would not be full of professional weldors, so I'm not surprised there is not a dedicated stick welder.

|

|

|

|

My phone's working again so a snap of my metalworking stuff. Still need to grind off the blue paint from the stretchers so I can paint it to match, on wednesday I should get the plate for the top. I basically roll everything outside for metalwork to spare the welder and woodworking stuff from excess grinding dust. I plan to get some plastic sheet I can shape into a kind of cover for the front and rear of the welder.

|

|

|

|

I thought this thread would appreciate this as well artist Jeff Parke https://www.instagram.com/j.parke/ Looks like engraved silver, with gold inlay and black enamel coating

|

|

|

kastein posted:Honestly that looks like chromeplate not galvy. Still bad for you, just in a "lol cancer" sort of way (if you managed to inhale any) not a zinc fume fever way. IIRC the layers under a chrome plating will be a copper plate over a nickel plate, but I may be wrong about that, I have zero actual training in metalplating and only picked up a little researching it myself. Can you expand on this a bit for me please. I was thinking of annealing a galvanised nut and grinding it down to a ring, but if thats going to be bad, I will go grab a stainless nut.

|

|

|

|

|

NPR Journalizard posted:Can you expand on this a bit for me please. I was thinking of annealing a galvanised nut and grinding it down to a ring, but if thats going to be bad, I will go grab a stainless nut. https://en.wikipedia.org/wiki/Metal_fume_fever

|

|

|

|

Get stainless steel nuts then. Roger.

|

|

|

|

|

The galvanized debate comes up every so often. FACT: the poo poo's bad for you, even lethal under some circumstances FACT: If you have an alternative available to you, you should absolutely use it. OPINION: You should NEVER under ANY circumstance EVER weld galvanized. Don't loving do it. You will die, the world will end. OPINION: Given proper precautions (Good ventilation (outside), a respirator with P100 filters that fits under a welding hood such as 3M half mask, a fan, and efforts be it mechanical and/or chemical to remove as much galvanization as possible) one can make the occasional galvanized weld while managing the risks if other options are not available.

|

|

|

|

Grinding and acid has worked for me *dies* Also, milwaukee portaband bought, corded model.

|

|

|

|

Sorry never got around to posting these, but for anyone else: US legal pad pictured for size

|

|

|

|

His Divine Shadow posted:Grinding and acid has worked for me *dies* I want a portaband!

|

|

|

|

His Divine Shadow posted:Grinding and acid has worked for me *dies* High five, I just bought one last Friday too, used it to cut down some 1/8th aluminium gussets for my truck's headache rack. Cuts so good, should have bought one years ago.

|

|

|

|

AbsentMindedWelder posted:The galvanized debate comes up every so often. agreed. What circumstances is it lethal under, though? Curious, I have never found actual evidence of that. I worry a whole hell of a lot more about manganism (any MIG welding fume, basically), hexavalent chrome, zinc chromate (commonly on grade 8 bolts), cadplate (commonly on AN-class fasteners and some metric), and all the horribly nasty poo poo from any paint that might catch fire when welding near it, though. Basically, welding fumes are bad for you and you shouldn't be breathing any of them.

|

|

|

|

kastein posted:agreed. What circumstances is it lethal under, though? Curious, I have never found actual evidence of that. The case that comes up frequently (i remember the actual post but dunno how to find it) is some old-hand metalworker decided to burn the zinc off of some large plated parts by just dumping them in his forge in his poorly-ventilated shop and hotboxing the smoke for an hour or whatever, developing pneumonia and dying shortly afterwards. Which, imo, isn't so much "zinc fume fever will kill you" as "pneumonia is one of the leading causes of death for people already in ill health and can be caused by a range of respiratory irritants/issues". but yeah, cadmium in particular is some scary poo poo in the immediate-acute-health-danger way, it's extremely dope that it's a vanishingly-rare plating choice nowadays

|

|

|

|

What's the best eye protection for those who need glasses? I'm willing to spend decent money to keep my eyes safe, but so far I've been disappointed. First I tried these http://www.zennioptical.com/702023-prescription-goggles.html They worked, but weren't very comfortable, and they broke after a month. Next I tried these goggles and they fog up pretty quickly. I figured the full seal would protect from debris, but if I can't see, it's not all that useful. So, what is my best option for prescription eye protection? Looks are a distant third to Effective and Comfortable.

|

|

|

|

|

| # ? May 23, 2024 15:54 |

|

Pagan posted:What's the best eye protection for those who need glasses? I'm willing to spend decent money to keep my eyes safe, but so far I've been disappointed. First I tried these Side shields are fine for most applications.

|

|

|