|

|

|

|

|

|

| # ? May 25, 2024 03:00 |

|

shame on an IGA posted:ebay.ca has some for $20 or maybe you could grind down a tuning fork or something Cheapest set on ebay.ca is $1600.... http://www.ebay.ca/itm/Drill-Chuck-Removal-Wedges-J2-JT2-No2-2-Morse-Taper-/160480357587?hash=item255d5fecd3:g:cVwAAOSwBahUz~2h The drift style doesn't work on this setup, as there is no hole to put the drift. EDIT: I found them cheaper. Maybe I can modify something I already have for removing stuck trombone slides. Brekelefuw fucked around with this message at 01:23 on Dec 2, 2016 |

|

|

|

Brekelefuw posted:Cheapest set on ebay.ca is $1600.... http://www.ebay.ca/itm/JACOBS-2-Wedge-Set-/221578407534?hash=item33971a2e6e:g:IdAAAOSw8w1X-QtA They should be like $20 tops.

|

|

|

Brekelefuw posted:Cheapest set on ebay.ca is $1600.... McMaster Carr has them as well for $9. https://www.mcmaster.com/#chucks/=15ak5n2 No idea if Mcmaster ships to the US though.

|

|

|

|

|

Yooper posted:No idea if Mcmaster ships to the US though. I thought they didn't ship outside the US

|

|

|

|

Yooper posted:McMaster Carr has them as well for $9. They'll ship same day if you're close enough to a warehouse.

|

|

|

Super Waffle posted:I thought they didn't ship outside the US Derp, I meant Canada.

|

|

|

|

|

Finally getting back to metal casting - getting in on a secret santa inspired me to get my rear end back in gear. Need to build some crucible lifting tongs first though, because the idea of halfassing anything with... I think it's a #30 crucible I got? Anyway, the idea of halfassing anything when there's that much crap at 1500F or so is intimidating.

|

|

|

|

Yooper posted:Derp, I meant Canada. My company uses McMaster constantly because their catalogue is so easy to use. One day shipping to Edmonton when we need it, anyway.

|

|

|

|

Made my first successful soldering repair on a multithousand dollar piece of equipment today, feels good man. Still trying to figure out how someone yanked an ethernet cable hard enough to rip the jack off the circuit board without the cable lock tab failing first.

shame on an IGA fucked around with this message at 21:19 on Dec 2, 2016 |

|

|

|

Mr. Bill posted:My company uses McMaster constantly because their catalogue is so easy to use. One day shipping to Edmonton when we need it, anyway. They won't ship to new Canadian customers, but if you had an account with them in the past they still will work with you. why won't they take my money

|

|

|

|

Slung Blade posted:They won't ship to new Canadian customers, but if you had an account with them in the past they still will work with you. Damnit! n other news, my AvE ruler just showed up today. Now I can accurately measure C-Hairs.

|

|

|

|

Earlier this year I watched a 200 Kg Wood Lathe get delivered by a 20 ton Hiab truck. The blokes moving it knew it was overkill but it's what they where being paid to do. They slid it exactly where it needed to be while telling us about the heavier pieces of gear they normally deal with on a day to day basis. Most of it was in the multiple ton category where they had a 15mm envelope to line it up with.

|

|

|

|

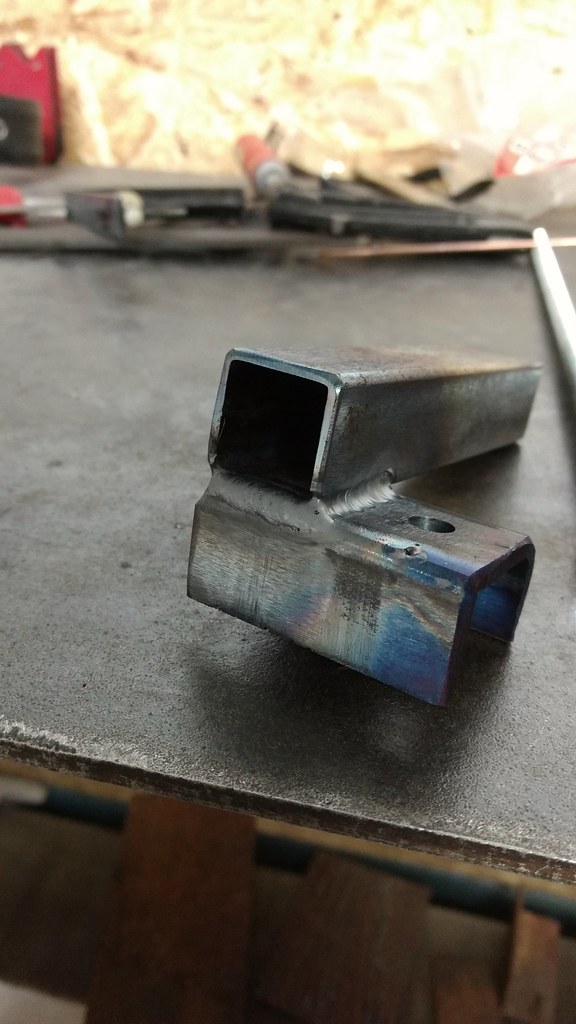

Building lower blade guides from metal for my wood cutting bandsaw. The wooden ones work but I want to build a set that's sturdier and most of all, easier to adjust and a larger adjustment range. I will use bearings in a carter style setup for this.   Haven't TIG welded in a good while, but it felt as if I had been practicing. Went easier and dipped less. Perhaps muscle memory needs some time off to sink in?

|

|

|

|

Clickspring just uploaded the last video for his clock. If you haven't seen this definitely go check it out. This guy has the most amazing workmanship I think I've ever seen. https://www.youtube.com/watch?v=J3ZGlpDa-0g < Last video Playlist

|

|

|

|

CBJamo posted:Clickspring just uploaded the last video for his clock. If you haven't seen this definitely go check it out. This guy has the most amazing workmanship I think I've ever seen. Been waiting a long time to see that payoff

|

|

|

|

if i had good knives worth taking care of i'd buy a nice diamond whetstone or waterstone set so i could sharpen in the tub and just slough the grit into the bathwater

|

|

|

|

As this year's AI secret santa project, I was assigned a gent named Keykey (hello Keykey  I am glad you like this thread.) This gift has been delivered, and now I can post about it in here. I am glad you like this thread.) This gift has been delivered, and now I can post about it in here.To match his name, I figured, why not make some keys in the shape of the bones from Skull and Crossbones. These cross keys are, I'm told, a legit Thing in jolly old england, apparently they have pubs all over with crosskeys as a logo, I had no idea until I showed an English fellow that I work with and he told me about it. I wanted to make two distinct keys roughly the same shape and size, so one is made from round stock, the other square, both are 1/2" (I think, maybe they're 7/16ths). Rectangular punched the square bar.  Drifted out so the round one could slip through.  Forged the 'ears' for each key, welded them on, tacked the shanks in the middle, added the teeth, and beeswaxed.  (I also drew him a giant dick but you'll have to check the AI thread for that) At the same time, someone from work asked me to make another brand. Formed the symbol from 1/4" barstock and the handle from 3/8ths again.  Of course, I had to test it. (twice, first time was a little hot and scorched the wood, oops)  Just a beeswax coating, but I'm pretty happy with this one.

|

|

|

|

I've always wanted to learn to weld, generally to make something life endangering. A bench press, a squat rack, a rock climbing wall, a go cart - something if, should one of my welds have been terrible, I'd get very hurt. I really want to make an electric go kart at the moment. I have all the knowledge but the welding - could I reasonably expect to be able to do this without doing a course? If so, in what time frame and how?

|

|

|

|

Mudfly posted:I've always wanted to learn to weld, generally to make something life endangering. A bench press, a squat rack, a rock climbing wall, a go cart - something if, should one of my welds have been terrible, I'd get very hurt. You could, time frame would depend on how much you put in and what sort of welder. In all honesty though, speaking from experience having a gokart break in half underneath you is not something you want to try. Start with a pushcart, ride down hills and poo poo for speed, practice welding on repairs, building a welding bench etc. If you get a MIG it's very possible to make lovely looking welds that do poo poo for strength too. How; buy welder of choice, I'd go with an Arc or a MIG, practice on scrap and making noncritical things like benches and decorative poo poo until you feel comfortable. Then make the pushcart, and if that holds together through a thrashing and steers/stops well enough and all that important poo poo then add a motor/build a motorised version. MIG is easier to learn to a certain extent, but Arc is a better allrounder for most people and doesn't cost anywhere near as much usually, just can be harder especially working with sheet/thinwalled materials (you can still do that though, it just takes more practice)

|

|

|

|

The prevailing opinion is starting with ARC will make you better at welding; starting with MIG will make you _think_ you are better at welding.

|

|

|

|

Rapulum_Dei posted:The prevailing opinion is starting with ARC will make you better at welding; starting with MIG will make you _think_ you are better at welding. This is very true, as far as learning goes I started with OA under dads tutelage when I was about 7 or 8, mostly cutting things and making messes. OA will set you up for anything if you get good at it but it's not easy to learn, and these days there's a bit of a lack of easily accessible resources for someone who doesn't know what they're looking for, probably due to the drop in popularity. Arcs cheap, simple and you know if you hosed up because you either made a bloody great hole, or the weld just won't start. I always recommend the cheap little buzzboxes for a beginner, unless they intend to do a course. Mudfly posted:I've always wanted to learn to weld, generally to make something life endangering. A bench press, a squat rack, a rock climbing wall, a go cart - something if, should one of my welds have been terrible, I'd get very hurt. If you do decide you want to do a course then try and see if you can find one that covers OA, it's a much more useful tool than just welding if you intend to do anything with metal. It can be expensive in the long run with the cost of gas rental and so on, but worth it if you can cover it. Apparently you can outright buy bottles from a lot of suppliers now too.

|

|

|

|

When I learned to weld, the attitude from the instructor was the OA welding is only really useful to learn if you're a sculptor. In every other professional setting, anything that used to be done with OA has been replaced with TIG, which is faster, safer, cleaner and more flexible. If you're only doing steel, a DC TIG is probably also cheaper than a basic gas setup these days. A cutting torch is super useful thing to have but honestly for the amount of metal-cutting that a hobbyist is likely to do, a hacksaw and angle grinder are suitable and a hell of a lot cheaper and more portable.

|

|

|

|

Sagebrush posted:When I learned to weld, the attitude from the instructor was the OA welding is only really useful to learn if you're a sculptor. In every other professional setting, anything that used to be done with OA has been replaced with TIG, which is faster, safer, cleaner and more flexible. If you're only doing steel, a DC TIG is probably also cheaper than a basic gas setup these days. Like I said there's been a drop in popularity, especially in professional circles. As far as a hobbyist goes you can't cut complicated curves as easily with a grinder and a hacksaw,nor can you bend heavy guage steel with a DC TIG and and a couple of hand tools. A pair of colt bottles take up fuckall space too, I still don't recommend it for a beginner without at least some instruction though, there's a definite learning curve to getting good with it.

|

|

|

|

My wife sent me this link. Partice-Hubert's stuff is ridiculously good. http://www.bleaq.com/2015/patrice-hubert

|

|

|

|

Leperflesh posted:My wife sent me this link. Partice-Hubert's stuff is ridiculously good.  jesus christ how does he make the glass bits? jesus christ how does he make the glass bits?

|

|

|

|

OA is good for fundamentals and is very good for mixed welding + bending work on smaller stock but falls short pretty much everywhere else (and gas is expensive as hell if you're rolling with the caddy tanks). The cutting torch is still the king of busting big steel poo poo down, which is why it's about the only thing oxyfuel gets used frequently in industry for any more. For doing finicky and delicate blacksmithing stuff, OA was irreplaceable; electric processes are so much easier, cheaper and faster for most anything else. I bought a MIG welder after coming home from blacksmithing school, returned it a little while later and got myself an arc/TIG machine in its place. Haven't regretted it yet (well, beyond "jesus christ how long has it been since you've struck an arc, how's that investment lookin now") Ambrose Burnside fucked around with this message at 05:28 on Dec 12, 2016 |

|

|

|

I really wanted todo O/A but after doing the math it would have been more expensive than getting this used but professional grade 300A DC stick/tig welder, and then factor in cost of usage and the safety aspect too. And I should then be replacing the flashback arrestors every other year which is 200€ for a pair of decent ones. I am really glad I got this machine in retrospect. It's quite a rarity with an SCR based inverter welder, like the old PowCons. Also broke my blade last night for my milwaukee, tried to TIG weld it but even at lowest amperage it just vaporized. I wonder if I should keep the blades detensioned or not. I never detensioned this one once I got it on.

|

|

|

|

It's still worth finding a course that covers it if Mudfly changes his mind and decides to do a course, as it's very useful in things like making oddly shaped mounting brackets for electric gokarts, but he probably won't really get his money's worth out of it without good instruction. Personally I have an ancient peerless arc which can apparently be setup for TIG (I haven't looked into this yet), an offbrand MIG thats a straight clone of me mates Cigweld unit, and OA on colt bottles which will be bought outright when I get around to filling them. Arc and oxy get absolutely the most use ATM, the MIG only really comes out doing sheetmetal on cars and poo poo like that (which admittedly I'll be doing a whole lot more of next year).

|

|

|

|

His Divine Shadow posted:Also broke my blade last night for my milwaukee, tried to TIG weld it but even at lowest amperage it just vaporized.

|

|

|

|

I ran it at the lowest setting my welder can put out, which is like 10-15 amps and a point ground to a bloodletting point, also tried a longer ramp up time. Perhaps if I had it clamped up with copper heatsinks right up close it might work.

|

|

|

|

Fire Storm posted:Those are usually (more or less) spot welded together when patched. I imagine it could be tigged with the settings JUST right (like maintain a puddle on a pop can), but annoying. Also, would the level of heat make it more prone to snapping in the future (hardened?) You can always anneal the blade after welding to give it more flexibility. I think that only requires propane-torch levels of heat.

|

|

|

|

Those blade-welders on big bandsaws do blades and just blades, you might look up the specs for one of those to see what ballpark settings you might need (and if your machine can put that out at all). And yeah, it'd have to be normalized after welding.

|

|

|

|

Mudfly posted:I've always wanted to learn to weld, generally to make something life endangering. A bench press, a squat rack, a rock climbing wall, a go cart - something if, should one of my welds have been terrible, I'd get very hurt. My friend showed me the very basics on a big old stick welder, I just hosed around for a couple of nights until I could draw a steady bead on a plate, join poo poo up and wail on it with a hammer without it breaking, etc. For home projects and loving around with go-karts and whatever you don't need a course. Youtube and trial-n-error will get you welding well enough that poo poo sticks and generally stays stuck. Find a cheap stick welder second-hand and make some arcs. The internet has become an echo chamber for weld-fetishists who won't be satisfied if your welds wont pass aerospace x-ray inspection.

|

|

|

|

Thanks for the advice, I'm tossing up between two welders and was after some more guidance: 1st choice: Cheaper, 140 amp welder, ~$150. 2nd option: Only 180 amp welder with a plug that I have in my house, it does MIG, stick and tig apparently: https://www.machineryhouse.com.au/K019E Here in Australia above 140 amps a welder almost always has a 15 amp plug fitted. For some reason the welder above gets to 180 amps and plugs into standard house sockets. It is a fairly big jump in price for me, but I'm ok with it if 140 amps is just too limiting. In 5 weeks I will have access to our school's welders (where I work) which are all probably expensive 3 phase units.

|

|

|

|

The budget buzzbox will just give you grief, especially if you're just learning, and cheap multiprocess machines tend to do a bunch of things but do none of them particularly well (and you'll almost certainly never find yourself actually using all the processes). The multiprocess machine can bring 180 amps, sure, but look at the duty cycle, you can barely get any work done like that. TBH I'd buy neither of those and wait to gently caress around on the school machines where the equipment isn't a limiting factor.

|

|

|

|

Speaking of AISS Gosh, I wonder what's in there... (I mean, aside from a couple pounds of plaster and sand)

|

|

|

|

Is it one of those clone-a-dick kits?

|

|

|

|

Nah, this is actually going to be cool. If it turns out, if I don't have steam explosions when I pour the aluminum, if the investment filled everything... But hey, that's part of the fun, right?

|

|

|

|

|

| # ? May 25, 2024 03:00 |

|

Ambrose Burnside posted:The budget buzzbox will just give you grief, especially if you're just learning, and cheap multiprocess machines tend to do a bunch of things but do none of them particularly well (and you'll almost certainly never find yourself actually using all the processes). The multiprocess machine can bring 180 amps, sure, but look at the duty cycle, you can barely get any work done like that. TBH I'd buy neither of those and wait to gently caress around on the school machines where the equipment isn't a limiting factor. Thanks, the only issue is when I return to work I won't have time to gently caress around, sort of trying to seize the school holiday opportunity to learn something. Among the other welders I've looked at are 140amp 20% duty cycle stick units, I might be forced into compromising and buying one of those.

|

|

|