|

Fusion360 is so powerful that it feels wrong to be using it for free. Feels like I pirated it or something

|

|

|

|

|

| # ? May 24, 2024 20:54 |

|

I'm hype to start toying with fusion. I'm gonna pick up a student copy next year when I start my CAD classes. Hopefully all those years of making goatse photoshops pays off.

|

|

|

|

Powerful is a misnomer for a lot of things I have ANSYS Multisim and while its "Powerful" its 40 years of kludged together modules with zero user friendliness. Some of the 'newer' modules like the workbench look good and have a fairly modern workflow setup, while some of the simulation ones still look like they're from windows 95 and run like hot garbage. And there are people who are used to that and think its good software because its Powerful, but its really just stockholm syndrom. (Fusion360 is a good product for real)

|

|

|

|

|

I've tried to get reasonably 'fluent' working in Fusion but something about the UI and the way it does things is hard for me to engage with, can't really say why. I've also gotta be zippy with Solidworks and Mastercam for school, and with those two in my pocket I don't think Fusion adds a ton so I haven't invested the effort. (e: altho if fusion360 legit does offer something neither of the above two combined do i'd love to know about it) Ambrose Burnside fucked around with this message at 00:20 on Oct 18, 2017 |

|

|

|

If you're just farting around, autodesk hands out three year educational licenses to anyone no .edu email required E: I mean, of EVERYTHING. Inventor design suite? Revit? sure knock yourself out

|

|

|

|

Yooper posted:Last time I hooked up a VFD to a Bridgeport single-phase there was a pretty significant de-rating. Though I think it's preferable to running one of those rotary converter systems. Then it was probably the wrong VFD/insufficient amperage. Rotary converters are lossy, but don't need to be as closely sized to the machine, so you can just oversize the crap out of them. They are also usually way cheaper if you don't actually care about the speed control.

|

|

|

|

I'd suggest checking with whatever VFD manufacturer you go with. The unit I derated, an AB Powerflex 523 VFD was 3-phase but being used single phase. Rockwell calls out only 35% output availability in that case.

|

|

|

|

|

I was asking about fusion a week ago I think. I've been using since then and for the price holy poo poo. I've been using edgecam for a year now and don't see any reason to stick with it.

|

|

|

|

Mudfly posted:Anyone know if there were low power cnc machines made? Like, around 2kw-3kw so I could restore something from the 80s/90s and work on it at home? CommieGIR posted:I'm currently on this quest as well. What's your preferred size? You could look at something like a home build it yourself kit?

|

|

|

|

My goal in life is to CNC conversion a horizontal shaper

|

|

|

|

Ahhh ffff now another good lathe popped up and quite near me too, perfect size and with a norton box. No price though, probably not in my budget range, haven't been able to get a hold of teh seller..... A swedish Storebro.... good brand! EDIT: ffff, seller wants 1900€ His Divine Shadow fucked around with this message at 13:53 on Oct 18, 2017 |

|

|

|

Yooper posted:I'd suggest checking with whatever VFD manufacturer you go with. The unit I derated, an AB Powerflex 523 VFD was 3-phase but being used single phase. Rockwell calls out only 35% output availability in that case. That's a possibility I hadn't considered - and makes sense. I mean - if you're pulling a single phase off of 3 phase it's logically gonna be 1/3 the power output assuming the VFD can't do any kind of weird phase rebalancing (unbalancing?).

|

|

|

|

What you describe sounds like what happens when you try and run a 3-phase motor on single phase (you only use one third of the windings). But a functioning VFD made to run 3ph equipment should create 3 phases from single phase, so if the unit is rated high enough for the motor it runs, there should be no de-rating. EDIT: Oh another possible reason for de-rating might be if the 3ph motor is made to run on a higher voltage than what the VFD can provide. Here most smaller 3-phase motors can be run in either delta or star, in star mode you have 400V between phases, in delta mode there it's 230v. A normal 1->3ph VFD I have been told can't create a proper 3-phase that has 400V between phases, so it has to be run in 230V delta mode. His Divine Shadow fucked around with this message at 16:26 on Oct 18, 2017 |

|

|

Motronic posted:That's a possibility I hadn't considered - and makes sense. I mean - if you're pulling a single phase off of 3 phase it's logically gonna be 1/3 the power output assuming the VFD can't do any kind of weird phase rebalancing (unbalancing?). This bulletin from ABB covers it a bit more. https://library.e.abb.com/public/610f2d332765615e85257d8d005c1475/LVD-EOTN71U-EN_REVA.pdf If you use a drive specifically designed for single phase input you should be fine with the rated output. But if you're doing a 3 Phase Input drive then you'll have to derate using it single phase. Anytime I've hooked up 3 phase drives in single phase it's been "free" VFD's that people got from salvage, auction, and we made it work.

|

|

|

|

|

shame on an IGA posted:My goal in life is to CNC conversion a horizontal shaper just think, you could pioneer HSM for shapers. get parts out the door 3x as fast as cutting-edge shaper machining circa 90 years ago e: for real tho a manual shaper is on my long-term Must-Have/Must-Build list, if you've frequently gotta face off stock/parts to a good finish in a hobby environment i bet they're not even totally obsolete https://www.youtube.com/watch?v=TEbyND4XK2A Ambrose Burnside fucked around with this message at 18:36 on Oct 18, 2017 |

|

|

Ambrose Burnside posted:just think, you could pioneer HSM for shapers. get parts out the door 3x as fast as cutting-edge shaper machining circa 90 years ago Since i'm uninformed as to edge shapers, what would be so good about HSM in this case that you can't just CNC? Is it just the precision and repeatability of the depth of cut?

|

|

|

|

|

I'm joking, high-speed machining is the new CNC productivity hotness and shapers are a profoundly-obsolete* machine tool. Applying HSM principles to a shaper would be like supercharging a Model T. * shapers really are obsolete for most modern manufacturing, but they legitimately have a few idiosyncrasies that make them useful or attractive for niche roles where productivity isn't the driving factor. Because of how they operate they're excellent for cutting keyways and linear channels/slots with weird and inconvenient geometries, and they can work effectively inside of deep holes or cavities in ways that would be very difficult or impossible on a mill or lathe. For the hobbyist they use single-point HSS tools which makes creating and maintaining tooling super easy and cheap, and they're well-known for giving a very high-quality finish with a decent cutter. Ambrose Burnside fucked around with this message at 22:27 on Oct 18, 2017 |

|

|

|

Ambrose Burnside posted:just think, you could pioneer HSM for shapers. get parts out the door 3x as fast as cutting-edge shaper machining circa 90 years ago Used a 70 year old Cinci all the way through my apprenticeship and enjoyed being super smug about the ZOMG CONSTANT CHIP LOAD to a bunch of vendors at SouthTEC one year

|

|

|

|

shame on an IGA posted:Used a 70 year old Cinci all the way through my apprenticeship and enjoyed being super smug about the ZOMG CONSTANT CHIP LOAD to a bunch of vendors at SouthTEC one year https://www.youtube.com/watch?v=PnE_h5qmjpk that's a respectable chip!!

|

|

|

|

I never went deeper than .200 at a time but I wanna say it was about a 10HP machine, should call up one of the ol instructors and see about really pushing the limits sometime.

|

|

|

|

Here's a This Old Tony video that features his shaper for the majority of it. https://www.youtube.com/watch?v=ZNWkhxKNHGM

|

|

|

|

Here's a cool Instagram if you want some long chips in your feed. https://www.instagram.com/p/BTsdQ86gizW/

|

|

|

|

From the tools thread, in response to my asking for alternatives to acid pickling for welding galvanized, continuing here because maybe some of y'all don't read that thread, and it's really more on-topic here anyway:sharkytm posted:You need P100 filters, I'm fond of the 3M mask with the two pancake filters. It'll filter out the zinc smoke.  I already had an off-brand one (US Safety, and even if it's a "real" brand, it's still off-brand. Minnesota Mining &c. has the same 500-pound gorilla market position as Kleenex, in their respective fields.) with round N95 cans, but I never could figure out how to get them off, so couldn't tell if they used a compatible mount, and why not have two? Save the P100s for when they're needed, use the N95 for everything else. Only thing is the off-brand one feels like it fits better (but purely subjective, I can still make my ears hurt by inhaling with my hands over the 3M's filters). Small problem, it doesn't really fit under my welding mask. The welding hat is flexible and can be forced over it, but it's uncomfortable and On that tangent, is there any downside (besides not being able to return it if it craps out) to giving the welding mask a Glaswegian smile, spreading the cheekpieces, and pop-riveting some scrap similar material in the gap to make it fit over the gas mask? Double tangent: anybody know where I can get fighter-plane sharkmouth decals to put on the welding mask? Surely they exist.  I guess I could paint it myself, but Edit: I want to steal that sign and mail it to Truck in a Field, Valentine, NE. Chillbro Baggins fucked around with this message at 23:53 on Oct 18, 2017 |

|

|

|

I use the miller mask when i'm welding galvanized (usually cars) and it fits under my hood.

|

|

|

|

Delivery McGee posted:No offense, sharky, but I'd like some confirmation on this. Picked up a 3M mask with #60923 filters (P100+, if you will, it's good for acid gas and the regular P100 isn't). No offense taken. https://www.cdc.gov/niosh/npg/npgd0675.html https://www.millerwelds.com/safety/respiratory/half-mask-respirators-m00469 P100 filter, that's it. https://multimedia.3m.com/mws/media/5188O/particulate-filter-2097-p100.pdf

|

|

|

|

His Divine Shadow posted:Ahhh ffff now another good lathe popped up and quite near me too, perfect size and with a norton box. No price though, probably not in my budget range, haven't been able to get a hold of teh seller..... A swedish Storebro.... good brand! Got it down to 1700.... kinda considering it.... Fully equipped he says, HSS tool holders, 4-jaw chuck. Think I'll go and check it out in person with a friend who knows more about machining than I do.... Jeez the biggest issue if I can justify it to myself really, 1700 for a hobby... But if I get my old wood lathe sold this saturday, and maybe my hardly used benelli M1 I can recoup it, if someone is interested that is...

|

|

|

|

Congratulations on your new

|

|

|

|

My hobbies are literally the only reason I keep working a job.

|

|

|

|

Looked at the lathe last night, pics for the interested:          I had a friend along who is not a lathe owner, but good with machines and renovating them, and has used other peoples lathes. He commented that there is a sound in the headstock when running, not loud but indicative of a bearing going half-bad. There's some brutal looking way damage under the chuck but this should not affect the lathes operation, recommends taking off the high spots though. He says the saddle travel from end to end is fine without being noticeably easier or difficult which indicates little wear to him. From what we can see it has all the change wheels and it can do both 49 imperial pitches and 31 metric, as well as something called Module and DP threading. The previous workshop was an electrical workshop, some of the odd tooling he thinks means they've used it to wind magnet wire. There's a working coolant pump and nozzle too, not sure I need that though, there's a 2nd tool cabinet that comes with as you can see in the pictures but most of the interesting stuff is on top. It has a power feed and longitudinal power feed, no detectable play in the cross slide, everything moved real smoothly. I like the quick change tool holders, 4 total, I think that is what I like most about it. I think it has all the change wheels, I found 7 stacked ones and one must be in the lathe, so 8 total. I don't have the manual so I am guessing. I am honestly not sure but I promised to give an answer today, seller claims (I don't know if it's true though) there are others waiting in turn. He has a whole machine shop full of lathes, probably 10 lathes. Though my friend said he wouldn't buy a lathe renovated by this guy (thought he was too much of a caveman wrt his tools), this lathe hasn't been touched by him though. There was also an Arboga E100 drill press for sale for 800€, old and worn but in good shape. I might get it if I don't get this lathe. Anyone care to help me decide? His Divine Shadow fucked around with this message at 06:37 on Oct 21, 2017 |

|

|

His Divine Shadow posted:There was also an Arboga E100 drill press for sale for 800€, old and worn but in good shape. I might get it if I don't get this lathe. Anyone care to help me decide? Given the age I think it's a solid looking machine. Sure it's going to have some wear, the damage below the chuck for example, but you'd be hard pressed to find a perfect one anyhow. On the plus side I don't see any evidence of a tool post grinder being used. Those things absolutely destroy lathe ways, guarded or not. The chuck noise wouldn't worry me, it's going to be an old bearing, par for the course. Installing new angular contact bearings isn't the end of the world. Then get some turning work and let it pay for itself.

|

|

|

|

|

... get... some turning... work? I'm confused, I thought money only went into machine tools, not came out of...

|

|

|

|

mekilljoydammit posted:... get... some turning... work? you're not mistaken, i dont know what the gently caress he's talking about, everybody knows machine tools only function as continual fun-money sinks

|

|

|

|

JFC people, please please please cut out a piece of wood to throw on the ways under the chuck for when you are changing them out. This is not hard. Looks like a solid machine for it's age price though, and yeah......that way damage doesn't appear to be out too far as to cause you problems. If there's any chance of finding replacement bearings I'd be all over it, especially since it has all the change gears. Even without an easily workable bearing solution.......I mean, you're not opening a production workshop. If the headstock isn't running out and it's not an awful noise it's probably got another 40 years of hobby use in it.

|

|

|

|

Is that because of one fuckup or is damage like that the result of habit?

|

|

|

|

That looks like habitual dropping to me. One incident would just put a single dent in the ways, at worst. It doesn't matter all that much; it's rare that you'll be sliding the apron up under the chuck, and you can scrape or file off the high points and it'll be fine.

|

|

|

|

Motronic posted:If there's any chance of finding replacement bearings I'd be all over it, especially since it has all the change gears. Even without an easily workable bearing solution.......I mean, you're not opening a production workshop. If the headstock isn't running out and it's not an awful noise it's probably got another 40 years of hobby use in it. Since it's a swedish machine I am betting they use SKF standard metric bearings, I read someone talk to the manufacturer (still around) that it ought to use the same bearings as the slightly bigger sister machine, SKF 30209 and 30207. Those would be very easy to source. I am thinking to do a teardown, clean-up and see if anything needs any attention. My friend who was long to look at the lathe said I could borrow some scrapers to get rid of the high spots near the damaged areas, good to know a guy who has that skill. Also I am a bit curious why the lathe has a reversing gear, it was built in sweden and everyone has 3ph here and all lathes come with 3ph motors aside from the smallest chinese lathes. Seems easier to just swap the rotation on the motor with an electrical switch. I assume it's a design choice to have redundancy built in, this way it can be run on 1ph outlet if it was exported to another country where this was not an option. Unless there's some deeper hidden reason to use the gear to reverse the lathe that I am not aware of. e: This is the tenth time by the way, that I have been at the practicalmachinist forums and considered registering, but everytime I do I read a thread and it seems to be a boomer whine hole. His Divine Shadow fucked around with this message at 08:10 on Oct 22, 2017 |

|

|

|

His Divine Shadow posted:e: This is the tenth time by the way, that I have been at the practicalmachinist forums and considered registering, but everytime I do I read a thread and it seems to be a boomer whine hole. Oh, you have no idea. There's more old-man drama on the PM forum than at a multi-cultural VFW get-together in Topeka.

|

|

|

|

This is only somewhat related but hopefully covers the expertise of the thread. My new house has a wood burning stove in the livingroom, the chimney is swept and certified - but the stove itself is looking a little sad:  From what I can gather this is simply going to require washing with soap and water, letting it dry and wiping it down again - and then going over with some fresh heat resistant paint. Is that right?

|

|

|

|

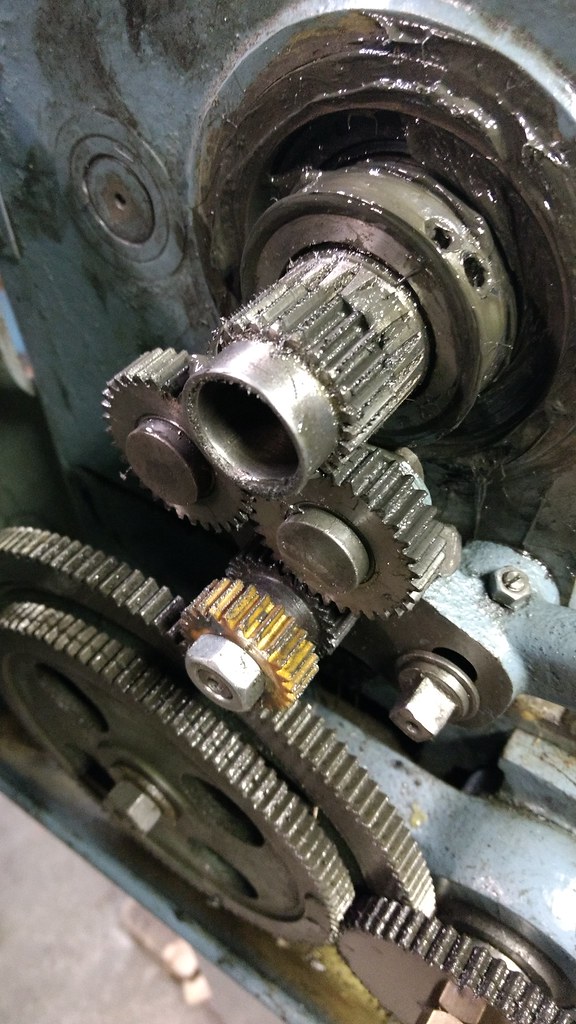

His Divine Shadow posted:

This one? That only reverses the lead screw. It's for left handed threading and feeding.

|

|

|

|

|

| # ? May 24, 2024 20:54 |

His Divine Shadow posted:Since it's a swedish machine I am betting they use SKF standard metric bearings, I read someone talk to the manufacturer (still around) that it ought to use the same bearings as the slightly bigger sister machine, SKF 30209 and 30207. Those would be very easy to source. I am thinking to do a teardown, clean-up and see if anything needs any attention. My friend who was long to look at the lathe said I could borrow some scrapers to get rid of the high spots near the damaged areas, good to know a guy who has that skill. I have an East German OD grinder and I can still buy workhead bearings for it. We have this crotchety old British thing and while the bearing numbers make no sense, 2 minutes with the bearing catalog and there we go. Practical machinist is a place where nostalgia, smugness, and good posts go to die. I asked a question once and the best response I received was "lol, you'll see." Southern Heel posted:This is only somewhat related but hopefully covers the expertise of the thread. My new house has a wood burning stove in the livingroom, the chimney is swept and certified - but the stove itself is looking a little sad:

|

|

|

|

Bad Angus! Bad!

Bad Angus! Bad!