|

I need to find a 5c collet chuck that isn't hydraulicly tightened. Need to hold round stock on a rotary table. I've been googling it but idk poo poo about lathes and I'm missing some kind of terminology or something. Recommendations?

|

|

|

|

|

| # ? May 25, 2024 07:15 |

|

TooMuchAbstraction posted:Yeah, it's kind of like tying rubber bands together -- you make a closed loop, then stretch it out and thread it through the previous closed loop. I think that's a doubled through-two chain there? That is, you have two intersecting loop-in-loop chains at 90 degrees to each other, and each loop goes through two prior loops. This one is a single through-two. I'm working on a triple through-two, but it's going to take me forever.

|

|

|

|

honda whisperer posted:I need to find a 5c collet chuck that isn't hydraulicly tightened. Need to hold round stock on a rotary table. Found a couple listings to get you started. How nice are you looking for? There's the real lathe chucks that you could mount up on the rotary table. https://www.mscdirect.com/product/details/00228957 http://www.bison-america.com/public/data/resource/upload/00082/81296/bison-2016-usa-chapter-1-manual-chucks.pdf (start on page 61) If you're just trying to get a quick setup then depending on your budget I see a couple options. Air actuated, if that's your thing: https://www.mscdirect.com/product/details/00282152 Cam-actuated: https://www.mcmaster.com/#3174A42 Block chucks, would be terrible for repeat setups but are cheap: https://www.mscdirect.com/product/details/09670159 EDIT: Found the Kalamazoo air chucks on MSC again. I've used them a fair amount, they're actually not too bad. The paint tends to slough off, you shouldn't leave a collet in there too long or it can get stuck, and you do need to strip them down maybe once every 6 month-1 year to clean and relube them, but the price is good. Karia fucked around with this message at 05:21 on Mar 24, 2018 |

|

|

|

Anyone know where I could get some engineering info on how to build a grinding spindle? For surface grinding and perhaps cylindrical grinding. What sort of spindle runout is permissible to make a machine that can produce accurate surfaces to within tenths? What sort of bearings does this necessitate? Text references would be great. I have a background in mechanical engineering but when I was employed in the industry I didn't do much design - still, I have the basics.

|

|

|

|

Mudfly posted:Anyone know where I could get some engineering info on how to build a grinding spindle? For surface grinding and perhaps cylindrical grinding. What sort of spindle runout is permissible to make a machine that can produce accurate surfaces to within tenths? What sort of bearings does this necessitate? We considered trying to make our own st one point, but there were so many good examples on eBay for under 500 bucks that we couldnt justify it. What kind of parts are you making?

|

|

|

|

What kind of parts? Well, a surface grinder Options for spindles for grinding? Available internationally (in Aus)? Such as?  I also just want to know about spindle magics in general, they dont seem like very complex parts. Are they just precision made shafts with preloaded angular ball bearings? In any case it would be nice to read a chapter on how they're designed. I've found journalism articles so far but no engineering.

|

|

|

|

Hey metalworking thread, got an odd one for you. Anyone know of a good source for 3/4" width hexagonal plates in, say, 1.5-2.0 mm steel or aluminum? I've got an armoring project on the mind, and hell if I want to even consider trying to cut a couple hundred identical hex plates out with hand tools. Liquid Communism fucked around with this message at 12:02 on Mar 24, 2018 |

|

|

honda whisperer posted:I need to find a 5c collet chuck that isn't hydraulicly tightened. Need to hold round stock on a rotary table. Harig makes what you're looking for. Spin Indexer. We have a small fleet of these and I just ordered another set a couple of days ago. They see approximately 2000 cycles per day in a fairly dirty grinding application. We remove the indexing pin so the collet can free float. Once a year we ID grind the spindle nose and they run awesome again. https://www.mscdirect.com/browse/tn...8366+4294939690 If your rotary table is already the moving part and you just need a way to clamp a single 5C collet... https://www.mscdirect.com/product/details/09670118 Mudfly posted:What kind of parts? Well, a surface grinder I'd check the bearing manufacturer websites. I think SKF has a really good guide that covers a good deal. Last time we did a spindle we bought the hub from WM Sopko but most of that info is available from either grinding wheel manufacturers or machinists handbook. I've got some reference text in my office, on Monday I'll see if it covers what you need. Liquid Communism posted:Hey metalworking thread, got an odd one for you. Anyone know of a good source for 3/4" width hexagonal plates in, say, 1.5-2.0 mm steel or aluminum? Ryerson or Howard Precision Metals. https://www.ryerson.com/stocklist/detail/7ed77020-fcea-468e-8530-8cb55e95f2fb You can buy it as hex stock and have it cut as needed. They'll both cut it, and cut it nice, but you'll pay a cut fee.

|

|

|

|

|

Karia posted:Found a couple listings to get you started. How nice are you looking for? There's the real lathe chucks that you could mount up on the rotary table. This is perfect, thanks!

|

|

|

|

Mudfly posted:What kind of parts? Well, a surface grinder Whoops, I totally misunderstood what you were asking. I thought you were looking for a rotary fixture to use on a surface grinder for grinding round parts.

|

|

|

|

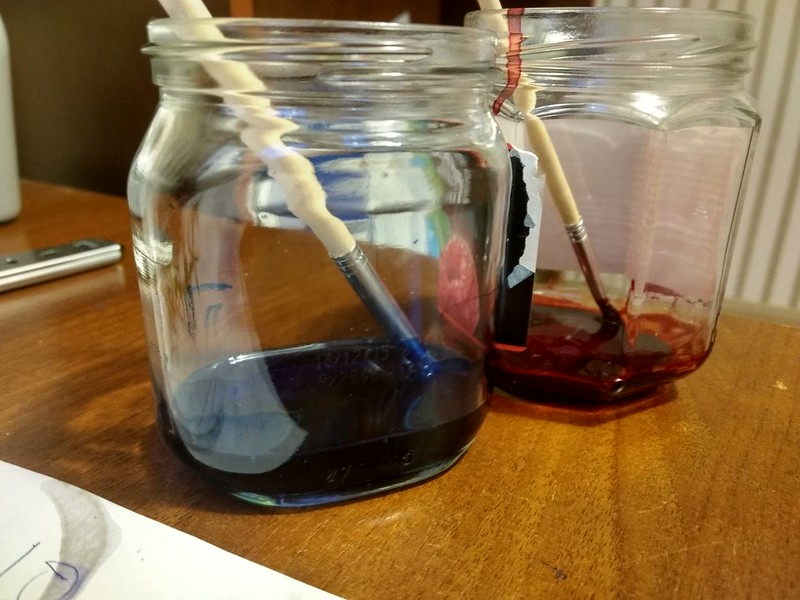

I made my own layout fluid. I guess you americans think it's silly since you can buy Dykem for ultra cheap. But over here I've not been able to find any locally and spending like 30-40 euros to get a small bottle home from amazon germany doesn't appeal. I stumbled on someone making his own and it sounded pretty simple, thin shellac and a dye. I got shellac by the loads though. For dye I tried some red leather dye and some fountain pen ink I know is a brilliant as gently caress blue.  The blue stuff looks way better and makes more visible marks, both dried pretty fast. And alcohol dissolves it.

|

|

|

|

armorer posted:It's a loop in loop chain actually, not chainmail. Oh, sweet. The technique is real interesting but I never tackled it myself because of the non-negotiable soldering.

|

|

|

|

Ambrose Burnside posted:Oh, sweet. The technique is real interesting but I never tackled it myself because of the non-negotiable soldering. It's about the gentlest introduction to jewelry soldering/fusing that you could hope for. Every loop is its own unit and can be worked with well away from the rest of the piece, so you don't need to worry about accidentally destroying anything more than an inch or two worth of wire.

|

|

|

|

That's good hustle, altho I've personally found that a sacrificial Sharpie (the tip gets hosed up + dirty) can do, like, 90% of the usual layout fluid's work for smaller parts/surface areas with a lot less hassle and mess. It's less persistent and impractical for bigger surface areas but it's stupid cheap in comparison. I've also seen someone use a range of sharpie colours beyond just the standard blue/red to colour-code their layout lines for all the different holes accomodating like 5 types of fastener for a tooling plate, which is pretty smart.

|

|

|

|

TooMuchAbstraction posted:It's about the gentlest introduction to jewelry soldering/fusing that you could hope for. Every loop is its own unit and can be worked with well away from the rest of the piece, so you don't need to worry about accidentally destroying anything more than an inch or two worth of wire. I've done my share of silver soldering back when I did a lot of jewellery, I just avoided it wherever possible because I never got set up with the equipment needed to make it painless enough to tackle dozens of joins. Once every few projects I'd need to solder a joint or two and I could get by with a sputtery flareout-prone plumbing torch and a lot of patience but I never budgeted for a real torch with a line and caddy tanks.

|

|

|

|

Ambrose Burnside posted:I've done my share of silver soldering back when I did a lot of jewellery, I just avoided it wherever possible because I never got set up with the equipment needed to make it painless enough to tackle dozens of joins. Once every few projects I'd need to solder a joint or two and I could get by with a sputtery flareout-prone plumbing torch and a lot of patience but I never budgeted for a real torch with a line and caddy tanks. For what it's worth, I did all my jewelry soldering with a creme brulee torch running off of butane, and it worked fine. Definitely more consistent flame than you get from those big propane tank torches.

|

|

|

|

I always stayed away from those because I've never owned any sort of butane jet torch that didn't clog up and stop working after no more than one, maybe two refills. Apparently that's down to using cheap hardware store butane but I never cared enough to give something fancier a spin.

|

|

|

|

I've used an acetylene / atmosphere plumbers torch for years with good results. That said, I just bought an oxy/acetylene Smith little torch and holy poo poo it's a night and day difference. I've done fairly small soldered sterling chainmail work before, but it's just way easier with this torch.

|

|

|

|

His Divine Shadow posted:I made my own layout fluid. I guess you americans think it's silly since you can buy Dykem for ultra cheap. But over here I've not been able to find any locally and spending like 30-40 euros to get a small bottle home from amazon germany doesn't appeal. I stumbled on someone making his own and it sounded pretty simple, thin shellac and a dye. I got shellac by the loads though. For dye I tried some red leather dye and some fountain pen ink I know is a brilliant as gently caress blue. That looks a hell of a lot better than dykem tbh. Such smooth coverage!

|

|

|

|

Liquid Communism posted:Hey metalworking thread, got an odd one for you. Anyone know of a good source for 3/4" width hexagonal plates in, say, 1.5-2.0 mm steel or aluminum? If slices of hex stock won't work could you get a hex punch made?

|

|

|

|

Or just get a big sheet water jet cut? 2mm is thin.

|

|

|

|

|

Yeah, waterjet seems like the most painless route here. Sawing up stock is hobbyist-accessible if you've got a bandsaw but at least as much bar will turn into swarf as will turn into hex plates, the finish on the faces will be bad, and operating the saw + advancing the stock by very consistent increments will involve a ton of labour babying the thing. A hex blanking die will do a nice, consistent job of it as well and will let you make as many plates as you need as fast as the necessary press can be operated, but if you can't get something that meets your needs off the shelf it'll be $$$ that's probably better-spent just getting an aluminum sheet shot through with a hex grid, unless you think you might need to make lots of these into the indefinite future.

|

|

|

|

I've gotta design and machine a 5-axis CNC part in the next few weeks. I can do something cosmetic, orrrrr something that's a huge pain to get a hold of otherwise, so I'm kind of wanting to pick up a big ol tool steel round bar to make a leadscrew + matching nuts tailored to a small-medium size fly press. Don't have any serious ambitions to build one soon, but getting an appropriate steep multiple-turn screw seems like the hardest part of making one, so it'd be nice to knock that out so the balance of the work is just straightforward fabrication as per purchased plans.

|

|

|

|

Yea, waterjet or laser cutting seems like it would be best. Obviously the main issue is how much money you want to commit.

|

|

|

|

If you can back off the material thickness or use thin al + softer backing material you might be able to do it with a steel rule die

|

|

|

|

shame on an IGA posted:That looks a hell of a lot better than dykem tbh. Such smooth coverage! Thanks it worked out quite well, I diluted the final product a bit so it's not quite as intensely blue. I am now considering if you can use a pen like this with the layout fluid: https://justwrite.com.au/pens-and-pencils/Brush-Pens/Sakura-Water-Brush-Pen-Set Have to be dilligent with the cork to not let it dry out I guess but it i theory it looks interesting way to apply the fluid. I think I got an old pen like this somewhere, I should see if it survives alcohol solvent.

|

|

|

|

Does it smell like dead bodies and cancer? If not, I will stick with Dykem.

|

|

|

|

Speaking of things that stink, I'm testing coolants! We have a new alloy that is proving to be ridiculous to grind. Our standard coolant gave us 2 parts per dress, we tested straight oil (icky) and we got 14 parts per dress. But as we don't want to use oil I'm experimenting with emulsions, micro emulsions, synthetics, semi-synthetics, hybrids, and whatever else I can find. So far micro emulsion #1 gave us 5-6 pieces, so a pretty good improvement over standard soluble oil. Anyone have a favorite for titanium/gummy alloys?

|

|

|

|

|

honda whisperer posted:I need to find a 5c collet chuck that isn't hydraulicly tightened. Need to hold round stock on a rotary table. What you really want if money is no object is a harig ultra grind 5c http://www.harigmfg.com/ultragrind5cv.html Keep your eye out, you can find them used for about a grand, but they only pop up a few times a year Suburban Tool also makes a real precise 5c indexer, https://www.subtool.com/st/mg5cvs1_master-grind_spin_index_fixture.html Our shop uses a harig for ejector pins and some electrode work. Edit: I realized I sound like a dumbass with my “really want” poo poo. The harig and subtool are just super precise. If you need a tool with good precision for long term use, give them a look. rump buttman fucked around with this message at 19:38 on Mar 26, 2018 |

|

|

|

Does anyone dabble in casting silver? I have a lighter case that holds a mini bic that I want done in silver but I don't have the stuff to make a mold l, then a positive, then another mold. I have the case and a hunk of scrap sterling. I would have asked in the jewelry thread but it's locked.

|

|

|

|

Looked around for a while and went with this one anyway. Half the price from grizzly or travers. Wtf msc. Still a good source for part numbers I guess. Thanks again for the help. Any interest in a 4th axis effort post? I'm still very new to it, I can count the parts I've made with it on my fingers still.

|

|

|

|

I boered my 4 jaw chuck with a carbide boring bar today, been setting up for it quite a while, drilled holes in the jaws so I could mount m8 threaded rod and use a bearing race of suitable size to clamp down on. Then I tested with a piece of ground precision shafting I got and I am feeling pretty pleased, the needle doesn't move (1 tick = less than half a thou) until the very end were there is some gunk on the shaft. I think I went maybe 25cm or so. the shaft is not any longer. But yeah to me this looks good: https://www.youtube.com/watch?v=BS27p_rSHkE

|

|

|

|

Something followed me home today...

|

|

|

|

His Divine Shadow posted:I boered my 4 jaw chuck with a carbide boring bar today, been setting up for it quite a while, drilled holes in the jaws so I could mount m8 threaded rod and use a bearing race of suitable size to clamp down on. Then I tested with a piece of ground precision shafting I got and I am feeling pretty pleased, the needle doesn't move (1 tick = less than half a thou) until the very end were there is some gunk on the shaft. I think I went maybe 25cm or so. the shaft is not any longer. But yeah to me this looks good: That's a nice job. Nice and true rotating too?

|

|

|

|

Finally got it temporarily hooked up on the VFD and operating. Still needs a little bit of TLC and an enclosure for the VFD but this is it for now! Its a South Bend 13" made somewhere around 1942-1943.

|

|

|

|

Sweet. Needs a modern tool post, but that's a nice setup. Looks like a short bed, too.

|

|

|

|

A Proper Uppercut posted:That's a nice job. Nice and true rotating too? I got the 4-jaw to within a few hundreths (of a millimeter), so like a thousand of an inch or so, but I am no Abom79 on that thing so it took me a while.

|

|

|

|

Whoever painted that lathe did an awesome job!

|

|

|

|

iForge posted:Finally got it temporarily hooked up on the VFD and operating. Still needs a little bit of TLC and an enclosure for the VFD but this is it for now! Its a South Bend 13" made somewhere around 1942-1943. SWEET

|

|

|

|

|

| # ? May 25, 2024 07:15 |

|

sharkytm posted:Sweet. Needs a modern tool post, but that's a nice setup. Looks like a short bed, too. What's the downside to that old style of toolpost if you're only running HSS and wouldn't be doing much quick changing of anything regardless of the toolholder style? Less rigidity, I'd guess? More of a headache to adjust the tool height? I learned turning on a hale old flatbelt-driven South Bend that had that style of toolholder and was never particularly frustrated with it for the entry-level turning I was doing with it.

|

|

|