|

Got my finger sucked in between the belt and roller on my stationary sander last night. I have a patch of nerve damage on one side of that finger, and doing some work at the bottom side of the outer roller, I didn't feel the belt touching my finger and one slight movement sucked it in. Didn't break anything, but I almost completely ripped off the nail and I mangled the border/tip and part of the nailbed. Don't work tired and always think through the implications of every process, kids.

|

|

|

|

|

| # ? Jun 5, 2024 17:25 |

|

At least you weren't on the table saw yikes

|

|

|

|

Feenix posted:Iíve sanded to 220. Iím reading different things on what to do next. Some people sand higher, but thatíll close pores. Some people flood it with water to raise the grain and then hit it with 300+. Some folks start in on various 300-and-up wet-sandings with mineral oil. Super Waffle posted:Has anyone ever experimented with vacuum sealing wood in an oil bath to get maximum penetration? TooMuchAbstraction posted:The first cutting board I ever made, I was following a guide that said to use thinned Salad Bowl Finish to soak through. It seems to have worked fine (the board is still in use and looks good), but later I read the can more carefully and it said specifically "do not thin" and "do not use for surfaces that are used for chopping". I'm guessing the concern is that you could get a film on top, like you said, which would get somewhat shredded by knifework and create vacancies for microbes to live in. So if you're dead-set on using it, I guess I'd just recommend sanding the hell out of the top after you're done applying finish. Hypnolobster posted:Got my finger sucked in between the belt and roller on my stationary sander last night. I have a patch of nerve damage on one side of that finger, and doing some work at the bottom side of the outer roller, I didn't feel the belt touching my finger and one slight movement sucked it in. I'll second that about not working tired or in a hurry. Every injury I've had has been at the end of a long day when I was trying to do more than I should have. Sometimes the most productive thing you can do is stop and start fresh in the morning.

|

|

|

|

Kaiser Schnitzel posted:

No poo poo, this should be sandblasted in a plaque over every shop. The last drat cut of the day, that's what pureed the side of my pinky finger in a shaper. And I was lucky.

|

|

|

|

Yep. This accident swung far more towards not thinking through the process rather than tired, but they're equally dangerous. Complacency is bad, and stopping to rework your approach to a task (any task) is important if something feels off.

|

|

|

|

I squared off the end of my thumb with a plane on a shooting board. It's easy to get complacent with hand tools but they can get you too. I learned not to try and stop a falling knife in the kitchen decades ago, but if you look at my other thumb you can still measure the exact set of the teeth on my carcass saw.

|

|

|

|

go for a stroll posted:I squared off the end of my thumb with a plane on a shooting board. It's easy to get complacent with hand tools but they can get you too. Related to that, I just saw an insane injury with a chisel from someone I follow on Instagram a few days ago (and then I proceeded to injure myself  ) )https://www.instagram.com/p/Blv6yucATrm/?taken-by=skanwoods And my own, because everyone likes hand damage pictures in the woodworking community. Not bbcoded because  https://i.imgur.com/wxvMeuY.jpg https://i.imgur.com/aaaKm0c.jpg The nail is detached from the bed and torn about a quarter of the way out of the root, the border is messed up and shredded at the tip pretty good. Weirdly, the most painful part is just the missing skin back by my cuticle.

|

|

|

|

Ok so Iíve got this board basically up to the point where itís sanded nicely and ready for finishing. I was kind of back and forth on whether I wanted to screw feet into the bottom side. Then I noticed a very, VERY minor rocking. Itís as small as humanly possible, but still detectable. This has me thinking maybe yes to feet? Are feet somehow less classy on a board? Are there other pros and cons? Will it dry better or potentially warp less because of the underside air gap? Will screws rust? Will screw holes degrade the integrity of the board?

|

|

|

|

Rather than screws, I'd glue feet on. Make the feet out of offcuts. In the past I've done feet by just ripping some ~1"-wide strips, so they're more like runners than feet. Hit 'em with a roundover bit, glue them on, then sand down until there's no more rocking. I wouldn't worry about classiness; you have an awesome handmade end-grain cutting board here, that's what people are going to be thinking about more than "hey why did this dude put feet on his board?" Plus the feet make it easier to pick the board up off a countertop/table, so there's legit value-add there.

|

|

|

|

I was thinking the screw types with rubber donut feet. I donít think I want to do runner or wood feet (nice as that would be.) maybe I can plan that into my next project, though.

|

|

|

|

Stainless doesn't rust. I think brass might not be great food safety wise, though.

|

|

|

|

Phone posted:Stainless doesn't rust. I think brass might not be great food safety wise, though. It tastes terrible (because it has copper in it), but as long as you aren't licking it you shouldn't have a problem. I know this because I used to make copper jewelry, and sometimes forgot to wash my hands before dinner. But yeah, if you insist on using screw-in rubber feet, then a) predrill your holes, and b) use stainless steel screws.

|

|

|

|

TooMuchAbstraction posted:It tastes terrible (because it has copper in it), but as long as you aren't licking it you shouldn't have a problem. I know this because I used to make copper jewelry, and sometimes forgot to wash my hands before dinner. Advice noted. Insist is such a strong word, I dunno, I just donít have it in me to make good wood feet right now AND account for the slight unevenness of the board. I just figured the rubber feet would solve the problem and look fine enough. Especially if I can find really short low-profile ones, perhaps?

|

|

|

|

You will regret putting feet on a cutting board.

|

|

|

|

A bit late at this stage buttttttt Run a block plane over the bottom to take out the high spot Chamfer the bottom edges so you have something pick up

|

|

|

|

Platystemon posted:You will regret putting feet on a cutting board. Could be. Could be not. Why do you think so? Iím all ears  I guess I just donít want it to rock or to have to resand it on the off chance I make it worse... [Edit] no planes. No experience planing. I should learn one day... Feenix fucked around with this message at 06:14 on Jul 30, 2018 |

|

|

|

I put feet on both of mine so they could dry out on both sides after washing without having to lean them on something. Home Depot has the rubber feet for like $2 or some poo poo. Definitely use stainless screws if they don't come with them, though. However, if the bottom is warped, feet might not help. Depends exactly how it bent. If it's perfectly cupped upwards it might be fine but if it's even a little bit twisted too, it'll still rock.

|

|

|

|

|

I'm trying to think up a screwless desk design, and I'm having trouble thinking of ways to affix the tabletop. Here's one design I've thought of, do you think this would have sufficient strength if it's just glued together? Measurements are in mm. Essentially, the legs would be 60x60 posts, with a cross shape cut out of the tops. Into the cross would slide the aprons with a halved joint. The four "prongs" of the legs would then protrude above the aprons just far enough to slot through four holes in the top. My concern is that the legs in particular may be too weak to support any lateral impact. The front legs in particular will be susceptible, since there won't be an apron piece at the front of the desk.

|

|

|

|

MaliciousOnion posted:I'm trying to think up a screwless desk design, and I'm having trouble thinking of ways to affix the tabletop. Here's one design I've thought of, do you think this would have sufficient strength if it's just glued together? You might want to check out some Classical Chinese/Ming furniture joinery. Much of it uses no metal fasteners and even no glue-just well constructed, interlocking mechanical joints. Often times stub tenons from the top of the leg into the top is what holds the entire piece together.

|

|

|

|

I'd also worry about the lack of allowance for movement in the top. If it's a typical 20-24" deep, you're right in the range where you might not get away with it.

|

|

|

|

wow. Mineral oiling this board really shows all the sanding scuffs and imperfections (belt sander, probably.) This has been a good learning experience. :p [Ed] also drat this black walnut is loving dark when oiled. :/ Feenix fucked around with this message at 19:03 on Jul 30, 2018 |

|

|

|

I think the main reason not to put feet on a cutting board is because then you can only ever use one side. If that's not going to bother you then it should be fine. As for slight imperfection that leads to a rock, if you're using rubber feet you can tighten or loosen the screw holding the feet in to adjust their height, probably? A soft rubber foot is going to give you a tiny bit of leeway as well. Of course you also want the board to be thick enough that having feet at the corners doesn't allow the board to flex in the center during use.

|

|

|

|

The kind of feet I'm thinking of don't adjust. The screw is either in or not. E: these things: https://www.homedepot.com/p/Everbilt-7-8-in-Rubber-Screw-On-Bumpers-4-per-Pack-49131/203661032

|

|

|

|

|

My brother made me a cutting board with a bevel on the underside edge to make it easy to pick up, I've never missed being able to use the other side. If you want legs fit legs

|

|

|

|

Javid posted:The kind of feet I'm thinking of don't adjust. The screw is either in or not. I think the prevailing belief is that being rubber, they are more forgiving, and also probably not manufactured 100% uniformly. Also, i think if you screw one in HARDER than another you could kinda make it sit more snugly. But even if not, you could probably sand/shave down the side that touches the board by a fraction of a fraction and make it counter-act the wobble.

|

|

|

|

Update, I'm nearly done. I put some nice feet on it. (really low profile, not tall rubber ones) but i wanted to show you guys a photo because I was not expecting black walnut to live up to its name so aptly once oiled. This is just one coat of mineral oil. It's darker than the purpleheart!

|

|

|

|

Is there a way to expedite offgassing? Maybe a fan? My cursed charcuterie board (which had tung over dried Odieís oil over mineral oil) (which i sanded down to dryness and just did mineral oil, STILL has a strong odor (from the Odieís oil.) and itís been like over a month... Iím beginning to think I just need to sand the gently caress out of it again.

|

|

|

|

I have no idea if it would work, but my best guess would be gentle heat and good ventilation. I wouldn't put it over 100F at the very most, probably more like 90. More realistically, put it near a fan and leave it in a room that gets plenty of sunlight (but don't put it in direct sun).

|

|

|

|

If it's a chemical reaction producing the fumes you can accelerate it by applying heat, uv light, or catalyst. I don't think there's an easy way to introduce a catalyst here, and it's also hard to use uv light to get to all spots without affecting the wood, so heat would be best. Every ten degrees centigrade you add will roughly double the reaction speed. Ventilation will help remove reaction products and speed up things. I would think moisture would also help, but again, it might adversely affect the wood. If it's not a chemical reaction but just gas that's trapped and being slowly released you can also increase the rate of offgassing by applying heat and ventilation. This works the same as drying your clothes: extra heat will vaporize more, and ventilation will reduce local buildup of gas so more can be released. E: if the gas is physically blocked from escaping and is slowly seeping out wood pores or something you're basically poo poo out of luck, most things that will keep your wood intact won't speed up that process.

|

|

|

|

MaliciousOnion posted:I'm trying to think up a screwless desk design, and I'm having trouble thinking of ways to affix the tabletop. Here's one design I've thought of, do you think this would have sufficient strength if it's just glued together? If you happen to follow Phillip Morely on instagram he just made a dining table with this exact joinery.

|

|

|

|

TooMuchAbstraction posted:I have no idea if it would work, but my best guess would be gentle heat and good ventilation. I wouldn't put it over 100F at the very most, probably more like 90. More realistically, put it near a fan and leave it in a room that gets plenty of sunlight (but don't put it in direct sun). Hm so fan is good but also you think 90 is safe in the oven? How long? An hour? More? poo poo I need to see if my oven even goes that low lol.

|

|

|

|

So a while ago I was looking through some old stuff and I found these really cool wooden figurines. Turns out it was stuff my grandfather carved back in the day, really inspired me to put my time to use and I want to take up woodworking. At the moment though I'm abroad for another year so I don't want to buy a load of tools just to have to leave them behind. Anyone got any recommendations for a good knife? What sort of easy stuff should I start carving with? Basically any tips for a beginner with bare minimum equipment.

|

|

|

|

If you want absolute minimalism then one of the flexcut multi knives like the carvin jack. If you dont mind having a few knives, then a small set of individual knives from flexcut, or a set of crook and straight sloyd knives are probably what you are looking for.

|

|

|

|

MaliciousOnion posted:I'm trying to think up a screwless desk design, and I'm having trouble thinking of ways to affix the tabletop. Here's one design I've thought of, do you think this would have sufficient strength if it's just glued together? I'm a total beginner to this, so this is more of a question than a critique, but wouldn't having the aprons locked to the four corners of the desk cause issues as the desk expanded and contracted at different rates to the aprons? This is probably not an issue if you're using ply of some kind for the desk top. E: or have the legs attach through a breadboard end?

|

|

|

|

GEMorris posted:If you want absolute minimalism then one of the flexcut multi knives like the carvin jack.

|

|

|

|

Sharpening is a critical part of using any bladed tool, so yeah youre going to need a solution for sharpening as well.

|

|

|

|

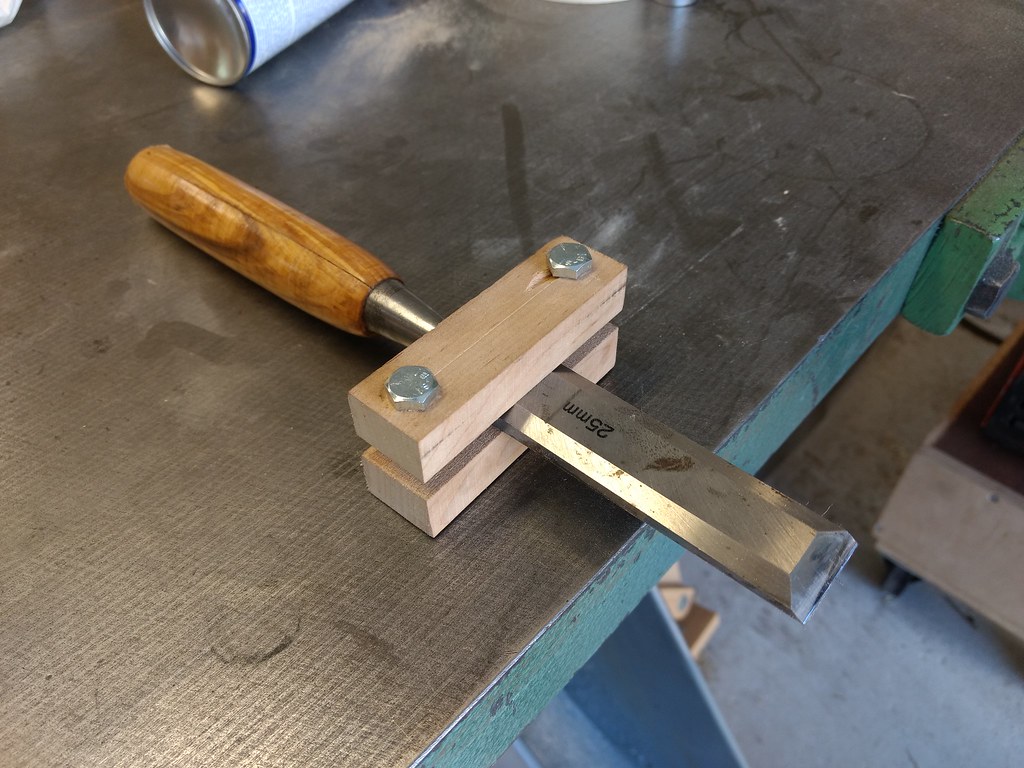

Today I made a couple of jigs for the grinder. An extremely simple one for the chisels, just two pieces of wood, cut threads right into the wood on one piece.  Then a bit more advanced one for axes, copied tormeks jig for this:    I have freehanded a knife and chisel so far and I seem to be able to get a good hair shave sharpness pretty easily after I hone it. Next up is a knife jig.

|

|

|

|

72 hours of a point-blank fan over my smelly charcuterie board. I mean, I think it smells IMPROVED, but it could be my mind playing tricks on me. How long should I expect to run air over it before I realize it's not the solution I seek?

|

|

|

|

71 hours ago

|

|

|

|

|

| # ? Jun 5, 2024 17:25 |

|

Feenix posted:72 hours of a point-blank fan over my smelly charcuterie board. I mean, I think it smells IMPROVED, but it could be my mind playing tricks on me. How long should I expect to run air over it before I realize it's not the solution I seek? You put a lot of stuff onto it, and you've done a lot of sanding etc. It's probably just going to take longer than you expect to stop off gassing. I had a stool that I expected to be done in a week and it took well over a month. It helped that I moved it to a warm place with good ventilation, but aside from that it was mostly just the time. Mine was just a standard stain/poly sanded to 220. One thing I've found is that the more I try to mess with things, the longer it takes to actually turn out.

|

|

|