|

Rufio posted:That is a sexy cabinet. What wood is that? Thanks, the frame is cherry and all the panels/drawers are spalted chenchen.

|

|

|

|

|

| # ? Jun 6, 2024 18:32 |

|

That Works posted:I use mineral spirits and those blue shop paper towels. I do use the tack cloth after 400grit sanding after my 1st coats of wiping varnish (spirits + poly). Kaiser Schnitzel posted:I blow it off with an air compressor, but if that isn't an option a rag slightly dampened with naptha or mineral spirits. Water works too if you've already wetted it and raised and sanded down the grain. You can also vacuum it off with the brush attachment on a shop vac. If you're using shellac or lacquer, you don't really have to remove the dust from sanding between coats as it will melt back into the finish, but don't leave huge piles of it either. Thanks for the tips! Used mineral spirits for the first bit then got some tack cloth for the dusting after. How many coats of shellac is a good bet? I'm using 2lb with a palm pad. This is the third coat. Application was 800 grit sand on bare wood -> mineral spirits the dust -> first coat -> 800 grit -> second coat -> 800 grit -> third coat  Things I've learned: - Peel and stick veneer is incredibly easy to apply, but the joins on the corners of the box are hard to cover up compared to cement. If I had to do it again, I'd use cement for sure. However this is only my second time using veneer so there's always room for improvement with either application method - Shellac is super fun to apply - Reese's PIeces are coated in shellac - Don't skimp on tools For the cabinet vents at the bottom, as per recommendations here, I'm going to paint them black, however I want to make sure I seal / prime / smooth them correctly. What's the recommended method for creating a smooth surface prior to applying paint/spray paint with a hole like this?

|

|

|

|

Shellac rules. I do three coats, but that's on the thin side I think. I follow up with clear paste wax which I reapply when needed. Need to do my dining table now that spring is here.

|

|

|

|

Would paste wax make it harder to reapply shellac later if needed?

|

|

|

|

Knot My President! posted:Would paste wax make it harder to reapply shellac later if needed? Yes, you do need to remove the wax before you apply more shellac. Itís not that hard to get off with naphtha/mineral spirits, but itís a little bit of a pain.

|

|

|

|

What is the mythical "lint free" cloth that can labels refer to?

|

|

|

|

I think thats usually cloth like what you might use to clean glasses if you're not wearing a shirt, but if you need something more disposable or freer of lint you can also get 'cleanroom paper* towels'. There's a whole selection on Grainger that you can filter by how much you really hate lint, but Amazon has some limited options too. *actually polyester most of the time, but you can find cotton ones that are a bit less clean if you'd prefer not to generate so much plastic trash pygmy tyrant fucked around with this message at 01:23 on May 2, 2021 |

|

|

|

Kimwipes

|

|

|

|

NomNomNom posted:What is the mythical "lint free" cloth that can labels refer to? An old t-shirt.

|

|

|

|

Old cloth diaper inserts work as well.

|

|

|

|

|

I use old cotton sheeting. You can buy it in bulk or just steal it from the guestroom and hope your wife doesn't notice.

|

|

|

Thumposaurus posted:An old t-shirt. This and blue shop towels are what I use

|

|

|

|

|

NomNomNom posted:What is the mythical "lint free" cloth that can labels refer to? Surgical or huck towels

|

|

|

|

My buddy has a Jet benchtop mortise he is selling for $150. I really have no immediate need, and lack space in a big way, but really do not want him to settle for a lot less just to unload it on a stranger. Can the chuck be made to accept typical drill bits? I should buy this. CHANGE MY MIND

|

|

|

Hasselblad posted:CHANGE MY MIND why

|

|

|

|

|

Hasselblad posted:My buddy has a Jet benchtop mortise he is selling for $150. I really have no immediate need, and lack space in a big way, but really do not want him to settle for a lot less just to unload it on a stranger. Can the chuck be made to accept typical drill bits? Hand cutting mortises is not difficult and it's satisfying. Use the space for something more important.

|

|

|

|

I'm working on a shelf. Three components: the shelf itself (about 14" deep), the triangular braces that support it (maybe 8" deep), and the wall mounts that the braces attach to. The braces and wall mounts both have vertically-oriented grain, and attach to each other using sliding dovetails. That lets me hide the screws that hold the mounts to the wall inside of the dovetail slot. The problem I'm struggling with is how to attach the braces to the shelf. In the past I've used screws, but that really isn't satisfying after I went to all that effort to hide the wall mount screws. Just glue would be a long grain / end grain joint, and I don't trust its strength because the braces don't cover the full length of the shelf. The big thing I worry about is that someone might put downforce on the front of the shelf, where it's not supported by the braces, and whatever attachment method I use wouldn't be able to resist the leverage. At the moment I'm thinking of using wedged dowel pegs. That is, drill through the shelf and into the brace, cut a slot in a dowel, stick the dowel in the hole, then hammer a wedge into the slot so that it grips the shelf. I'm not sure how well a pair of dowels will hold the shelf down, though. The dowels would be quite secure in the braces, since they'd both be vertical grain...my concern would be more that wood movement might cause the dowel to stop gripping the shelf. Any better ideas?

|

|

|

|

My gf has an old lathe she hasnít used in a while and is having trouble, Iím trying to help but donít know what to do now. The locking lever is spinning freely and not loosening the tool rest assembly. I would like to just take it off so I can figure out what is broken. But I'm not really sure how it's attached and I don't want to break it more. Do you guys know how to get that working by any chance?

|

|

|

|

Stultus Maximus posted:Hand cutting mortises is not difficult and it's satisfying. Use the space for something more important. Completely agree. I was in timber framing for a while, and it was indeed satisfying. He sold them since that last post and got what he was originally asking, so all's well that ends with cash!

|

|

|

|

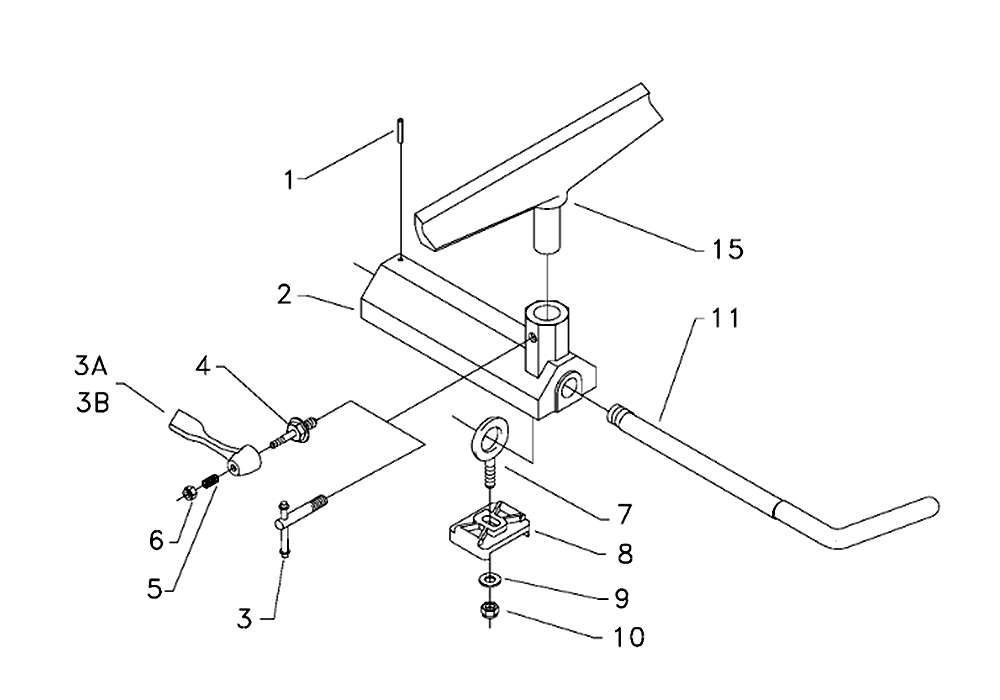

Snowy posted:My gf has an old lathe she hasnít used in a while and is having trouble, Iím trying to help but donít know what to do now. This is basically what it looks like:

|

|

|

|

Kaiser Schnitzel posted:It may be the pin that connects the handle to the round shaft has sheared? Thank you very much, that was helpful and yes the pin sheared. Do you know where we could get a replacement? I donít know how to find the right one, Iím looking at this page but itís pretty confusing: https://www.toolpartsdirect.com/lathe-turning/lathe/delta.html

|

|

|

|

Snowy posted:Thank you very much, that was helpful and yes the pin sheared. Do you know where we could get a replacement? I donít know how to find the right one, Iím looking at this page but itís pretty confusing: https://www.toolpartsdirect.com/lathe-turning/lathe/delta.html I would just measure it and get a standard replacement. https://www.mcmaster.com/pins/dowel-pins-7/ A spring pin might work better, and is probably plenty strong: https://www.mcmaster.com/spring-pins/slotted-spring-pins-6/

|

|

|

|

Kaiser Schnitzel posted:I would just measure it and get a standard replacement. Thanks again!! Much appreciated!

|

|

|

|

Slapped a Woodriver iron in this little type 18 no 3 and gave it a really brief lap. Had to open up the mouth slightly for the thicker iron. Most of my old planes are pre adjustable frog/short knob, so this post-war plane is the newest I've got. First no 3 I've used and despite being absolutely tiny, it's quite nice. The only ergonomic weirdness is that I can't put my thumb behind the knob like I do with most others. There's just no room between the back of the knob and the throat.  The orange lever cap and chrome chipbreaker are hideous, but that's a problem for another time. Really impressed with the Woodriver iron. Back had a mild hollow behind the cutting edge which means it took a whopping 30 seconds to get it flat. Original paper-thin iron was way too short and pretty badly bent, so this was totally worth the $30.

|

|

|

|

New irons in old planes rule.

|

|

|

|

The pin in the lateral adjuster of my lovely Footprint #4 fell out. Looks like it was a rivet, but there's not enough meat for me to peen it back over. Any cheap ideas for a fix? I paid $5 for it so if it's relegated to scrub duty that's fine, I have an ebay stanley no 4 on the way now.

|

|

|

|

Wrapped up that shelf I was working on.   Walnut, with beech for the dowels; finish is "The Good Stuff", a gel urethane. Only metal is four screws holding it to the wall, and those are completely hidden. It's totally solid and could probably support more than 50 pounds. The only concern I have is that I only glued the ends of the dowels, not their sides, so the only thing holding them to the shelf is the wedge. Hopefully that'll be enough.

|

|

|

|

Leperflesh posted:50% of the skill of using a hand plane is learning to read the grain of wood and not trying to plane against the grain, even when the grain switches direction twice or more times in the same plank. This is making me want to die right now. I'm surfacing/flattening a lot of maple right now and I swear the grain changes direction between passes.

|

|

|

z0331 posted:This is making me want to die right now. I'm surfacing/flattening a lot of maple right now and I swear the grain changes direction between passes. Oh thank God Im not the only one who has this issue. Make up your loving mind board

|

|

|

|

|

Between being not all that stable, hard enough to be a pain to sand but not always all that pretty and wonky grain that really likes to chip out, soft maple is one of my least favorite hardwoods really. Hard maple at least seems to be a lot more stable and consistent.

|

|

|

|

Iíve got a carpenter square, a pencil, some clamps, and a power drill. What I donít have is space or a hand saw. Iíve made a few practice cuts with friends and would like to try some simple pieces on my own. What kind of a hand saw should I get, and how do I take care of it?

|

|

|

Kaiser Schnitzel posted:Between being not all that stable, hard enough to be a pain to sand but not always all that pretty and wonky grain that really likes to chip out, soft maple is one of my least favorite hardwoods really. Hard maple at least seems to be a lot more stable and consistent. I bought a big batch of it all at once and I really like it. I got it pretty cheap because it was only partly spalted and only partly quilted and not really enough of either to go for a premium but has enough variation that it's not boring and has a lot of neat different character in it for every board I grab. If it was just straight clear maple then yeah it would be really boring and not very fun to work with

|

|

|

|

|

Centrist Committee posted:Iíve got a carpenter square, a pencil, some clamps, and a power drill. What I donít have is space or a hand saw. Iíve made a few practice cuts with friends and would like to try some simple pieces on my own. What kind of a hand saw should I get, and how do I take care of it? i got the set of 3 japanese pull saws from lee valley and it has been reasonably needs suiting for basically everything I've needed to cut and pretty reasonably priced imo for what you get https://www.leevalley.com/en-us/shop/tools/hand-tools/saws/japanese/111445-set-of-three-japanese-saws?item=60T0333 all I've done for maintenance to date is occasionally oiling or waxing the blade/plate. they aren't sharpenable so ultimately the blades are replaceable.

|

|

|

|

Centrist Committee posted:Iíve got a carpenter square, a pencil, some clamps, and a power drill. What I donít have is space or a hand saw. Iíve made a few practice cuts with friends and would like to try some simple pieces on my own. What kind of a hand saw should I get, and how do I take care of it? What do you want to make? What wood are you cutting? A lot of us like to use a two-sided japanese pull saw, like this one. It has a rip cut edge and a cross cut edge. It does not fold down, although you can remove the blade every time if you absolutely have to store it in a smaller space. It's only going to make mostly-straight cuts once you practice a bit on the pull, but is too floppy for e.g. making dovetails or other super-accurate cutwork. I like it as a good saw to own if I'm only going to own one saw, though. You can't really re-sharpen these saws so when the blade wears out you replace it (they sell replacement blades so you don't have to buy a new handle). If you want to be like, ripping tons of planks, an American-style push-saw that can fit through its kerf is good. Push saws typically have sharpenable blades, so a single blade can theoretically last for lifetimes, assuming you're willing to buy saw files and learn how to use them. If you want to be making fine cuts with a stiffened blade, a push or pull saw with a spine/back is good - it won't flop around, but won't fit through its kerf so you cannot saw deeper than the blade is tall. There's loads more specialty saws. Coping saws, flush cut saws, etc. All depends on your projects.

|

|

|

|

Thanks thatís helpful. I donít really know what types of wood I want to cut, probably plywood or cheap 2x4s so I can make simple things like a plain cabinet or table with simple joinery.

|

|

|

|

A thing to note regarding Japanese saws, it's important to try to cut on the pull because not only does that naturally keep the blade straight through tension, it also is just how they're supposed to work due to the orientation of the teeth. If you go hog wild with it you're going to end up with cuts that aren't even close to straight, and the thing is going to end up binding because of the cut not being straight. The blades are pretty floppy but that's by design because of that straightening on the pull, and that's how they get a thin kerf. Regardless though, you're not going to get straight cuts with hand tools if you aren't paying attention. If you wanna try out a ryoba but don't want to pay more just to try it out, this one is 10 dollars on amazon in the US. https://www.amazon.com/dp/B08CHH1GXX/ Specifically the blue handled one. I bought it on a whim because hey, it's 10 dollars. It works fine. For a grip, it came with one of those wraps for tennis racket handles. It'll give you a bit thicker kerf because there is some set to the teeth, but you can change that if you feel like it and the blade is replaceable with the same style of connector as is used for other brands, so you could slot a suizan blade in there if you want.

|

|

|

|

Doug fir is $2 / board foot right by my (maybe? Wrong? ) math My local rockler has a big fuckin pile of ambrosia maple for $4 / bdft Iím taking my truck to rockler tomorrow and going to loving town on that maple

|

|

|

|

Started fitting a handle to the hewing axe. This is the 2nd handle I started on, I got the angle wrong on the first one, and the axe head was leaning "forwards", good for a conventional billnšs (the axe to the right) but a hewing axe needs to have the head leaning in the other direction, to achieve a slicing cut.  I think I can reuse the handle I discarded later for a normal axe.

|

|

|

|

That Works posted:Make up your loving mind, board Good title material there.

|

|

|

|

|

| # ? Jun 6, 2024 18:32 |

|

I made a sheath for my chef's knife (gyoto) which didn't have one so it always had to live on the counter.  Just a scrap bin piece of hard maple, resawed in half with and offset of the blade thickness. . I routed out the shape of the knife on one half. I put a small magnet in a recess by the tip, but it doesn't feel like it really holds. Finished with mineral oil and beeswax.

|

|

|