|

FogHelmut posted:I'm not an expert on shed framing, so this is just a question - should there be a full unaltered stud sistered up against the notched one on the window frame? As long as there is proper contact at the top and bottom of the notch it works as if it isn't notched - the let-in framing component mimics the structural function. Stack Machine posted:They're not installed yet. The joists are my next step, then the frame's finished and it's on to sheathing. This is a rebuild of a shed that used 1x4s near the apex as collar ties. I'm using 2x4 ceiling joists to stand in for those and provide some evenly-spaced members just above head level for storage. Ah, misread on my part.

|

|

|

|

|

| # ? Jun 3, 2024 10:44 |

|

FogHelmut posted:I'm not an expert on shed framing, so this is just a question - should there be a full unaltered stud sistered up against the notched one on the window frame? So much of what is customary (and has thus become code) about the way we build houses in the US is because for most of the last 150 years lumber has been much cheaper than labor. If you notched the headers into the studs on either side of a doorway, you probably donít really need a double stud there, but itís so much faster and easier to cut 2 jack studs to length and nail them on vs. carefully cutting 4 notches.

|

|

|

|

Stack Machine posted:I'm mostly using the ridge board because it seemed easy for amateur construction, i.e. no need for fasteners other than nails. The original shed on this slab had some collar ties high up just nailed in, but I don't know anything about the shear strength of nails so I wanted the ridge board too. Nails have great shear strength. Another alternative it to just use gusset plates. Cut up some plywood into triangles and bang em in with nails. If your trusses are only screwed down at this point, I'd also think about taking them off and adding a double top-plate. It's not super necessary in a shed that small, but overlapping the walls in all 4 directions helps to add rigidity to the walls.

|

|

|

|

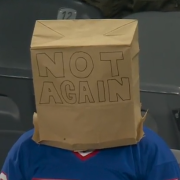

wait a minute Hobbies, Crafts & Houses: Thatís your ceiling

|

|

|

|

So, once again I'm compelled to do something completely outside my skillset and I've had good luck asking goons for advice in the past. So please forgive a complete amateur question. Very early last year my parent bought a new house (good timing, since they ended up spending a lot of time in it). It's a nice house and they enjoy it, but I've noticed they're still using the address sign out front with the previous owner's name; my mother doesn't really have any woodworking skills and while my father does, he has health issues and is unmotivated. My mother's birthday is coming up in a month and a half I thought it might be nice to replace it for her. Sign pic 1 Sign pic 2 Obviously I'm not going to be making a replacement sign myself - this is supposed to be a birthday present, and that should be more than a flat plank of wood with the address done in sharpie. Could anyone suggest where to look into purchasing custom signs? I tried google but it was surprisingly unhelpful. Also any general advice would be welcome. Considering it's not my house hiring someone to do it is awkward. I might be able to install it myself, but those screws look pretty rusted in and unless the replacement comes with screw holes pre-installed I'd probably have to obtain power tools somehow. If necessary I can always just give her the sign in a box with a coupon for a local handyman or something, though.

|

|

|

|

Etsy is perfect for things like this. Find a place that does signs you like and they will have it customizable in the checkout workflow. My parents have a lovely tile sign from there.actionjackson posted:wait a minute H110Hawk fucked around with this message at 20:52 on Jun 14, 2021 |

|

|

|

actionjackson posted:wait a minute

|

|

|

|

SouthShoreSamurai posted:Nails have great shear strength. Another alternative it to just use gusset plates. Cut up some plywood into triangles and bang em in with nails. If your trusses are only screwed down at this point, I'd also think about taking them off and adding a double top-plate. It's not super necessary in a shed that small, but overlapping the walls in all 4 directions helps to add rigidity to the walls. Unfortunately, most of the nails are already in on the rafters, so it wouldn't be that practical/safe with what I have on hand to lift off the roof and pop in a second top plate. I think at this point I'll rely on the sheathing and the ceiling joist/rafter combo for stiffening at the corners.

|

|

|

|

I'm replacing my dinosaur 20 year old wired smoke detectors with sealed battery units. What do I need to do to the old wire stub-out to make it safe? Terminate each wire in it's own wire nut and leave in the junction box?

|

|

|

|

canyoneer posted:I'm replacing my dinosaur 20 year old wired smoke detectors with sealed battery units. What do I need to do to the old wire stub-out to make it safe? Terminate each wire in it's own wire nut and leave in the junction box? https://www.firstalertstore.com/store/products/brk-brands-hardwire-smoke-alarm-with-10-year-sealed-battery-9120lbl.htm Buy the correct product. (I didn't check if this is ionization or photo, just showing they make them that are both.)

|

|

|

|

canyoneer posted:I'm replacing my dinosaur 20 year old wired smoke detectors with sealed battery units. What do I need to do to the old wire stub-out to make it safe? Terminate each wire in it's own wire nut and leave in the junction box? Get a hardwired unit with a sealed battery. Don't get a battery-only, they're typically only allowed for retro-fits where a hardwired connection is not available. If you have hardwired power available, use it.

|

|

|

|

canyoneer posted:I'm replacing my dinosaur 20 year old wired smoke detectors with sealed battery units. What do I need to do to the old wire stub-out to make it safe? Terminate each wire in it's own wire nut and leave in the junction box? In many areas code requires that in residential construction after a certain year, all fire alarms go off when 1 is triggered. If that is the case in your area, you would not be allowed to ignore the hardwired aspect of the alarm unless your new sealed battery units have wireless interconnect functionality. Your best bet, unless you know exactly what you're dealing with, is to replace like-for-like and get a sealed battery unit that accepts all of your existing hardwired connections. (edit: quoted the wrong post) PremiumSupport fucked around with this message at 21:56 on Jun 14, 2021 |

|

|

|

PremiumSupport posted:In many areas code requires that in residential construction after a certain year, all fire alarms go off when 1 is triggered. If that is the case in your area, you would not be allowed to ignore the hardwired aspect of the alarm unless your new sealed battery units have wireless interconnect functionality. Your best bet, unless you know exactly what you're dealing with, is to replace like-for-like and get a sealed battery unit that accepts all of your existing hardwired connections. That too. IIRC you usually don't have to upgrade to current code when replacing old units, but you certainly can't downgrade. So yeah, double check if the interconnect is also there. If so, you need to get a unit that has that functionality as well. Wireless is available these days, but if wired is configured in your house then by all means use it. edit: to be sure, when I say "hardwired" I'm referring to power supply. Interconnect can be wired or wireless, but wired is going to be easier to set up.

|

|

|

|

Can anyone help me identify the material this shower drain flange is made of, and/or a method to remove it? It's not magnetic, and sounds metallic, but with the dust and that blue whatever on it I can't tell. It is attached to ABS via cement it seems. PO had the top two pieces of what seemed to be a different drain assembly just sitting on the flange with that stub of ABS, with the screw in drain top just sitting on that. Hoping to do better.

|

|

|

|

Stack Machine posted:[shed] Well, I haven't nailed them in but I did cut those ceiling joist members today and I think the resulting roof structure will be OK:  The ones on the front and back at least tie the top plates together at the corner somewhat like a doubled top plate would.

|

|

|

|

I think you'll be fine without the doubled top plate. By my understanding, that mostly serves to help connect adjacent wall panels, or especially to help connect interior walls to exterior walls where they meet at 90 degrees. Neither of these is really an issue with your shed, because it's small.

|

|

|

|

Jenkl posted:Can anyone help me identify the material this shower drain flange is made of, and/or a method to remove it?

|

|

|

|

Heyo thread, another question for you. I'm having my bathroom redone, and I want to install a ceiling vent. This is all within my skill set to do so I don't need to pay the bathroom guys for it. My question is this: I can't go up out the roof with the vent, so it has to go out the wall. The bathroom has an outer wall and the joists go the right way so I can just go parallel to them. If I pop it out of the wall, it's about 2 feet below the roof line and it's under a gutter. My house doesn't really have soffit (it's an old cape cod), it's ok to just vent it out right? The internet says that if we do this it will cause a bunch of mold in the roof, but I think that's just if you vent it under the soffit and it gets sucked back up.

|

|

|

|

It should be fine, with the proper exterior vent for wall mounting to keep random wind-blown rain out. I vented mine out through the soffit...ducting goes all the way out to the soffit face & blows out down. No problems with mold or moisture.

|

|

|

|

Small engine repair question. I have an old Toro snowblower. Really old. I'm replacing its wheels since it's difficult as poo poo to maneuver since its old wheels have seized to the axle.  I keep hearing that the way to separate the wheel from the axle is: heat, quench, sledge. I know how to heat (hit with MAPP torch til cherry red hot). I know how to sledge... sort of. But how do I quench.

|

|

|

|

melon cat posted:Small engine repair question. Assuming that steel ring and rod is a pin through the axle, and you've got those holes then going through the wheel and axle, I'd first just try wedging a breaker bar and a rod into that space and levering the wheel off the axle. Not all the way through, just enough that when you pull on it the end of the rod is in the axle and some part slightly closer to you is contacting the wheel, on the inside of the hole.

|

|

|

|

Quenching in that case might be spraying some form of penetrant / oil on it? Freeze spray if you're feeling particularly fancy. Just no brake cleaner or anything that combusts into very bad things.

|

|

|

|

IOwnCalculus posted:Freeze spray if you're feeling particularly fancy. Whenever this comes up I feel it's my duty to remind people that a can of air duster turned upside down is functionally equivalent to freeze spray.

|

|

|

|

I've got a dumb question about garage doors. So heres my issue - I want to lift in my new house in the garage, but it gets hot as poo poo. Like if it's 90 out like it has been, it's about 100+ in the garage. I have a portable a/c that is capable of cooling it down since it's not a big garage, but the issue is there are no windows. So my idea, I took some high density foam strips from work, and lined almost the whole area on the ground where the door closes, except just enough room for the a/c's vent hose to stick out. The garage can close down on top of the foam, and that'll mostly get rid of any gaps and let me pipe the hot air from the a/c outside. The only issue is my safety sensors at the bottom don't like it. Is it "bad" or difficult to set a garage door from automatic to manual mode often? I'd probably need to use the a/c about 4 times a week. If that's fine, I can just put it in manual mode and just close the door down on top of the foam and not worry about the sensors.

|

|

|

|

hey remember "that's your ceiling" update - they sent me a replacement part, but it's literally the same part, but now it doesn't even have the wire. Still no inner holes for the junction box mounting screws  this has got to be one of the most incompetent companies in existence edit: the company is Maxim Lightning, never use them actionjackson fucked around with this message at 23:16 on Jun 16, 2021 |

|

|

|

lol yikes.

|

|

|

|

actionjackson posted:hey remember "that's your ceiling" Wow, I think at that point I'd just make my own if I really liked the fixture. You can do a lot with a metal nibbler and tin snips and a drill.

|

|

|

|

Or could you find a cross bar that both fits with the holes in the box and can line up with slots in that mounting plate.

|

|

|

|

The Dave posted:Or could you find a cross bar that both fits with the holes in the box and can line up with slots in that mounting plate. I was just going to ask, there's gotta be something like that I can get at a hardware store right?

|

|

|

|

Amazon has a shitload of options if you search for something like "light fixture mounting bracket", just need to do some rough figuring out if the holes will line up where you need them.

|

|

|

|

The Dave posted:Amazon has a shitload of options if you search for something like "light fixture mounting bracket", just need to do some rough figuring out if the holes will line up where you need them. I'm wondering if it is actually just not compatible with a pancake box and needs a 4" junction box instead. It never said anything about this on the listing, but the fact that I've seen two different instruction manuals online, and that on their main site it says "discontinued" makes me wonder if only the older version worked with the pancake box. The reason is that if you look at how the mounting plate connects, you push up on the fixture and those four black clips are kind of spring loaded so they grab back on once enough force is used. But if I had two mounting holes in the right place for my box, this would interfere with these springs (the edges of the clips where the arrows point are about the same distance apart as my mounting holes - 2.75"). I'm guessing I'll just end up having to return it and get something else.

|

|

|

|

Door to my office at work is a standard hollow core interior door. It appears it is so well balanced and hinges lubricated that the slightest bit of air movement will encourage it to begin to close part of the way, even something as simple as walking past the door will do this. A doorstop would probably be the best solution, but I do close my office anytime I leave which is often, so I'd prefer if maybe the hinges were a little more "gummed" up. Is there a solution for this?

|

|

|

|

couldcareless posted:Door to my office at work is a standard hollow core interior door. It appears it is so well balanced and hinges lubricated that the slightest bit of air movement will encourage it to begin to close part of the way, even something as simple as walking past the door will do this. Wax on the hinge pin might be a good first try, easy to clean off if it doesn't provide enough friction. EDIT: If you don't have anything suitable already, most hardware stores will sell a little block of wax used to lubricate wooden drawer slides

|

|

|

|

couldcareless posted:Door to my office at work is a standard hollow core interior door. It appears it is so well balanced and hinges lubricated that the slightest bit of air movement will encourage it to begin to close part of the way, even something as simple as walking past the door will do this.

|

|

|

|

Does insulating a garage door make a big difference? I was thinking of spending the 100 bucks or however much it costs to get some DIY insulation to help with my hot garage issue.

|

|

|

|

Drunk Driver Dad posted:Does insulating a garage door make a big difference? I was thinking of spending the 100 bucks or however much it costs to get some DIY insulation to help with my hot garage issue. If it's otherwise got a good air seal it will slow the temperature change. It might keep it from hitting the top end of the temperature, but your "other 3 walls" will also impact it.

|

|

|

|

2 of the walls are shared with the house, 1 is an outside wall. If it's 90f outside, it feels about 105 in the garage.

|

|

|

|

melon cat posted:Small engine repair question. IOwnCalculus posted:Quenching in that case might be spraying some form of penetrant / oil on it? Freeze spray if you're feeling particularly fancy. Just no brake cleaner or anything that combusts into very bad things. actionjackson posted:hey remember "that's your ceiling" Drunk Driver Dad posted:Does insulating a garage door make a big difference? I was thinking of spending the 100 bucks or however much it costs to get some DIY insulation to help with my hot garage issue.

|

|

|

|

GWBBQ posted:Not that brake cleaner is a penetrant or oil, but I feel obliged to mention that in the presence of high heat or intense UV light (red hot parts, welding, etc.) it decomposes into phosgene, which you likely know better as mustard gas. Specifically stuff with something something chloroethylene in it. It will kill you before you know it's happening, even if it takes a day or two, and it will hurt the entire time you are dying. It's super fun! They make stuff without it these days. https://www.envirofluid.com/articles/tetrachloroethylene-a-deadly-danger-in-brake-cleaner/ And yeah - 90F insulation will make your garage take longer to heat up to full bore temp, and longer to cool down. A radiant barrier (the foil) coupled with foam will make it take the longest. Slap a cheap thermometer inside and whenever the temperature outside is lower than inside open your garage door for a few minutes to change out the air. If you can and do park cars inside your garage, don't prop open the door to your living space to let air exchange.

|

|

|

|

|

| # ? Jun 3, 2024 10:44 |

|

GWBBQ posted:

also I've been "disconnected" several times while on hold, and for some reason the person reading the menu options has absolutely terrible grammar

|

|

|