|

Guy Axlerod posted:My toilet supply currently looks like this: Finish the drywall around it better? A little spackle does wonders. There's not enough pipe behind the compression nut to put an escutcheon on anyway.

|

|

|

|

|

| # ? May 31, 2024 12:28 |

|

Guy Axlerod posted:My toilet supply currently looks like this: Personally? I'd go out & score a blown-injection-molded plastic toy or holiday /action / movie figure, cut out the side or back, and cover the whole thing. I vote for:

|

|

|

|

PitViper posted:I'd prefer that to the way ours are done. All ours come up out of the floor Yep I have this same issue. Two of three of mine stub right thru the floor and the one that comes from the wall is going to be relocated to the floor because I have to move the toilet to an outside wall for clearance issues. It'll be easier on the plumbing side and harder on the tiling and cleaning side. But that beats a frozen pipe when we have another three days at 15 below. My sink line kept icing up on the section on the outside wall and that was even after I Insulated the wall and pipe. It's just so drat ironic to me. The ones that are floor stubs are on interior walls too. I strongly recommend if anyone stubs one on a wall now to make it like 9" above the floor to avoid the base.

|

|

|

|

I'm partially finishing a basement and there's a section of copper line that exits to a hose bibb that will be covered up by drywall. I'll be replacing the leaky old bibb anyway and am wondering if the whole line out is a good candidate for replacement as long as I'm working there and it'll get covered up. The house is 60 years old and, to my knowledge, all of the plumbing is original. We've never had any issues with the plumbing -- but -- I'm starting to get a little nervous about the age of the system. That said everything looks fine. The replacement bibb has an integrated sharkbite, and I was just going to hook it to the original copper, but now I'm thinking about replacing everything back to the supply with PEX (and eventually replace everything with it over the next few years). I'm not too worried about the bibb itself or supply connection because they'll both ultimately accessible (access plate in drywall and accessible in a utility closet respectively), but the rest of the line will require tearing down a the wall if I need to change it. I am in the Chicagoland area but the basement stays fairly warm and we've never had (or seen any obvious evidence of past) burst pipes, and I'll be adding insulation to the new pipe. The full run I'm looking to replace will be about 25ft. Should I: 1) replace only the bibb and don't gently caress around with something that isn't broken 2) replace the line with PEX 3) replace the line, but with copper or something else (though PEX behind walls is ok in my county) thanks in advance!

|

|

|

|

Pentecoastal Elites posted:I'm partially finishing a basement and there's a section of copper line that exits to a hose bibb that will be covered up by drywall. I'll be replacing the leaky old bibb anyway and am wondering if the whole line out is a good candidate for replacement as long as I'm working there and it'll get covered up. Regardless of what you do, you're smart to put in an access hatch at any joint or valve. Plastic ones are pretty cheap, and they'll let you access whatever breaks in the future without cutting the ceiling. If the OG copper is in good shape, I'd leave it alone. There's no reason to ditch it. I'd get a solder-on bibb, rather than the Sharkbite. I'm not fond of them long-term. If you want to make it easy, put a valve with a drain in, and a threaded fitting for the bibb. You can spin on a replacement if you need to without soldering in the future. I don't get why you'd rip out perfectly good copper for PEX. sharkytm fucked around with this message at 18:25 on Jan 11, 2023 |

|

|

|

The only reason I'm considering tearing out the copper is that it's 60+ years old and this will be the only part of the basement where it'll be a real pain in the rear end to get to the pipe if it needs to be replaced. At any rate I really like the idea of adding a valve with a drain in. I'll go grab one of those later today. thanks!

|

|

|

|

Has anyone installed one of those little 2.5 or 4 gallon electric plug-in water heaters to supplement a sink? We have a half bath that is over a crawl space and even though it's not that far from our main tank, and i tried my best to wrap the pipes in insulation, the hot water is ice cold for the length of time you would wash your hands. So when I saw these it seemed like a great solution for a small upfront cost and minimal energy use. The most complex part (potentially) is I'll need to run another outlet downstream from the single GFCI that's already there to the wall behind the sink. What I'm not 100% sure of: In my laziness I'd like to do less work and feed the existing hot water line into it, and then out to the faucet. While this seems supported it's not in any of the install directions I've read. Also I'll need to figure out the best way to run the pressure relief discharge pipe. I guess into my basement (there's already access from the crawlspace) and following the wall to the sump pump well. Can I use PVC for that?

|

|

|

|

The Dave posted:Has anyone installed one of those little 2.5 or 4 gallon electric plug-in water heaters to supplement a sink? We have a half bath that is over a crawl space and even though it's not that far from our main tank, and i tried my best to wrap the pipes in insulation, the hot water is ice cold for the length of time you would wash your hands. You're either running a high amperage 240v outlet under that sink or running the thing all day to keep the water hot. Otherwise you're sill going to be waiting for hot water. I don't think this is a solution to your problem.

|

|

|

|

Motronic posted:You're either running a high amperage 240v outlet under that sink or running the thing all day to keep the water hot. Otherwise you're sill going to be waiting for hot water. drat I guess I really fell for all the marketing speak here: https://www.homedepot.com/p/Stiebel-Eltron-SHC-4-Gal-6-Year-Point-of-Use-Mini-Tank-Electric-Water-Heater-SHC-4/205836147 But yeah it's probably some sort of red flag that it takes so long to get hot water there. Also my pipe insulation job is absolutely not great there.

|

|

|

|

The Dave posted:drat I guess I really fell for all the marketing speak here: I mean, I'm sure it does what it says: keeps 4 gallons of water hot. But this means you're going to be running that water heater 24x7 unless you put it on a timer, so even if you don't use the sink you're going to have some amount of power usage all the time just for having that thing there. And because it's 120v it takes nearly 30 minutes to heat 4 gallons of water. That's why it has to keep it hot all the time. It's also 11.3 amps, so on a 15 amp circuit you're gonna need to be careful of what else is on that circuit. Not a lot of overheard there when that thing is calling for heat. The way this is normally solved is by getting rid of your low flow aerator on the sink so you don't have to stand there for 3 minutes trickling out .5 GPM until you finally flush the run from the heater to the faucet and get some hot water.

|

|

|

|

Motronic posted:The way this is normally solved is by getting rid of your low flow aerator on the sink so you don't have to stand there for 3 minutes trickling out .5 GPM until you finally flush the run from the heater to the faucet and get some hot water. Great to know, thanks.

|

|

|

|

I have a back yard mound septic system that was installed when I bought my house just over a year ago. The other night I heard a faint bubbling noise i had not heard before coming from the septic tank mound but left it alone because it was dark. I went out the next morning and found a flat cover about a foot square in the ground where the sound was coming from. I pulled the cover up and saw the ends of 3 big pipes with standing water right below them, but there was no moving water. I put the cover back in place and haven't heard the sound since. I don't know anything about septic systems, except that when I moved in the inspector said I'd need to get the tank pumped every 3-5 years. I called a local septic guy who is due in tomorrow to take a look. Is anything about that sound or the standing water concerning? The drains are working fine and I've been careful not to flush anything septic-unfriendly.

|

|

|

|

Eason the Fifth posted:Is anything about that sound or the standing water concerning? The drains are working fine and I've been careful not to flush anything septic-unfriendly. I'd need to see the system, but there really shouldn't be much of any standing water in a properly working sand mound. The bubbling was probably the lift pump shoving more effluent in there when the water level was standing even higher. Is it really cold where you're at? Did it just rain a lot? All of these are factors that could cause slow absorption in a septic field or mound and would be considered normal-ish and potentially not a problem. But someone is going to have to look at the specifics of YOUR SYSTEM to give you any real advice.

|

|

|

|

Motronic posted:I'd need to see the system, but there really shouldn't be much of any standing water in a properly working sand mound. The bubbling was probably the lift pump shoving more effluent in there when the water level was standing even higher. Thanks for the reply. I'm up in MA, where it has been very cold and somewhat snowy following a month of somewhat cold and very rainy weather, so that definitely tracks with what you're saying. The person who installed the septic will be out to take a look soon. I'll feel like an rear end for hauling him out here if it's nothing, but I'd rather have the peace of mind.

|

|

|

|

Eason the Fifth posted:Thanks for the reply. I'm up in MA, where it has been very cold and somewhat snowy following a month of somewhat cold and very rainy weather, so that definitely tracks with what you're saying. The person who installed the septic will be out to take a look soon. I'll feel like an rear end for hauling him out here if it's nothing, but I'd rather have the peace of mind. Nah, it's the right ting to do. You need someone to tell you if this is normal/expected. I had an entire extra storage tank at my last house that I could open for if and when the leech field was completely frozen and/or saturated in January/February. It's a rough time of the year for septic stuff that is close to or sticking out of the ground.

|

|

|

|

The installer said that what I opened up was the D-box and that the sound was effluent either getting pumped in or heading out through the drain pipes. The level was fine; it was just so quiet at night that I was able to hear the effluent moving. Turns out you were exactly right.

|

|

|

|

Got the sewer line scoped on a house we are purchasing. Most of the line looks great, nice 6" pipe with minimal issues at the joints:  But there is a ~10' section right at the beginning that looks like... well... poo poo. Narrower pipe corroded to hell with very sharp bits flaking into the passage, lots of buildup:  The house was originally platted for septic in the 60s. Best I can figure is when they converted it to sewer they kept the original 4" pipe in the section from under the house into the yard because they didn't want to have to dig out that bit by hand I'm pretty set on replacing the first bit since it is going to be a magnet for clogs as is and I'm not sure that the 60 year old pipe will take kindly to descaling. But since the awful section is under the house it is the most expensive section to replace and replacing the whole thing is only marginally more expensive and I'm leaning towards just replacing the whole run. That would also get me a clean out not under the crawlspace. But more importantly we could get it done before we move in and it would mean not having to worry about the sewer line and the possibility of having to got several days without a shitter in the future. Crazy?

|

|

|

|

|

Shifty Pony posted:Got the sewer line scoped on a house we are purchasing. I'd probably hydrojet/descale and it see how it looks after that. We had some 60's era cast iron that cleaned up nicely according to the guys that did it (and they would have every reason to sell us more services - because they were doing cured in place lining for the rest of the old asbestos pipe. You're not crazy for doing it before you move in though. Get a backwater valve put in too, unless you're at like the top of a hill. Maybe $400 while you're doing all the rest of that work, and saves poop water from coming back into your house in the event the sewer system has issues. (may also get you an insurance discount!)

|

|

|

|

I need to connect the warm water line for our Tushy bidet (the cold line connected to the toilet supply, easy-peasy). My wife wants a new faucet in the bathroom "while I'm in there". The pipes under the sink are all hard copper lines. I don't want to call a plumber and I don't want to learn how to solder copper plumbing. I do want to add quarter-turn ball valves for the cold and hot lines. There are no valves for the bathroom faucet currently. Am I better off using compression fittings or Sharkbites to adapt to MNPT? I am aware that Sharkbites require cutting the pipe square and deburring the inside and outside of the pipe edge. I have tools for that. I work on my own old crappy cars, so the concept of compression fittings worries me a little (never use them on brake lines). PBCrunch fucked around with this message at 16:36 on Jan 17, 2023 |

|

|

|

PBCrunch posted:I need to connect the warm water line for our Tushy bidet (the cold line connected to the toilet supply, easy-peasy). My wife wants a new faucet in the bathroom "while I'm in there". The pipes under the sink are all hard copper lines. I don't want to call a plumber and I don't want to learn how to solder copper plumbing. I do want to add quarter-turn ball valves for the cold and hot lines. There are no valves for the bathroom faucet currently. I've done all three, and compression fittings are just fine in my opinion. Solder made me feel the best, sharkbites spin on the fitting and that's annoying to me. Compression does require you to put some beans into it when tightening, and I've never had an issue with it. The worst part of compression is replacing one and getting the old ring off, although someone probably has a good tip for that. I'm impressed there are no valves currently though. Is it just some reducer fitting soldered on?

|

|

|

|

Speaking of compression fittings - is it normal to have the pipe bulge around the ferrule from the fitting? I replace some of the angle stops on my toilets and had to use a mini-hack to get the ferrules off on all of the copper stubs. When I went to put on a new compression fitting, I couldn't get one to fit because of the pipe bulge made it a weird size. Ended up squeezing a sharkbite on there, but I'm not real confident those long-term though.

|

|

|

|

I've frankly never found a fitting that didn't bite me in the rear end eventually, bolted flange is my only friend

|

|

|

|

What is this massive pipe? 2” PVC 80?

Calidus fucked around with this message at 22:20 on Jan 17, 2023 |

|

|

|

To me it looks like 1.5" PVC with the collar of a fitting glued to it and cut off. Is this a cleanout? Sink drain? Maybe a cap or elbow has been cut in half.

|

|

|

|

bred posted:To me it looks like 1.5" PVC with the collar of a fitting glued to it and cut off. Is this a cleanout? Sink drain? Maybe a cap or elbow has been cut in half. IT’s laundry room sink drain that had been plugged previously. I think you might be right. I’m guessing the proper solution is cut open the wall and actually see what is going on.

|

|

|

|

Lord Wexia posted:Speaking of compression fittings - is it normal to have the pipe bulge around the ferrule from the fitting? I replace some of the angle stops on my toilets and had to use a mini-hack to get the ferrules off on all of the copper stubs. When I went to put on a new compression fitting, I couldn't get one to fit because of the pipe bulge made it a weird size. Ended up squeezing a sharkbite on there, but I'm not real confident those long-term though. Yes, they do indeed compress the pipe around the ferrule and make the tip bulge out a little. When you replace those valves, you're supposed to leave the old ferrule and nut, then use them with the new valve. Note that this doesn't always work out of the box. Sometimes the pipe tip sticks out too far and you'll need to trim a little off with a file.

|

|

|

|

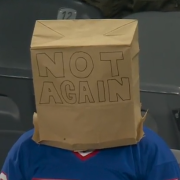

StormDrain posted:I'm impressed there are no valves currently though. Is it just some reducer fitting soldered on?  Copper lines going straight into the bottom of the faucet. No valves. You want to shut off the sink water supply? You are cutting off the whole house.

|

|

|

|

PBCrunch posted:

I'd make a project of putting a shutoff valve in that line just because, as insurance against ever having a leak at the sink where you don't have to go running for the main shutoff outside to stop.

|

|

|

|

What does the other end look like? I hope it isn't just soft copper disappearing into a hole in the wall. Are other sinks in the house the same way? I would definitely add a valve, this is one of those situations where you'd be doing future-you a solid. FWIW Soldering copper pipe is easier than you'd think. With the proper prep and a small amount of good flux the solder gets sucked right into the joint but won't wet where it shouldn't go. If the flux runs onto the pipe when it starts to melt wipe off the excess before resuming heat and trying to add solder, that will help keep the solder from flowing where you don't want it to go.

|

|

|

|

|

Any recommendations for books (or online courses) that show you how to properly layout PVC and other plumbing systems? Like how to better find centre-points on round pipes, how to properly measure using common walls, how to line up pipes etc. I've found a few YouTube videos but they aren't very detailed. I have the Pipe Fitters Blue Book on the way but it seems to be more of a reference guide than a "how-to". I'm hoping to find a really comprehensive book with lessons that I can follow so I can get better at accurately measuring and laying out my pipe setups.

melon cat fucked around with this message at 04:56 on Jan 20, 2023 |

|

|

|

PBCrunch posted:

This is where push connect valves are the most useful, just get the sharkbite or whatever brand is available near you. You'll be done in no time

|

|

|

|

Nitrox posted:This is where push connect valves are the most useful, just get the sharkbite or whatever brand is available near you. You'll be done in no time Sort of? That doesn't look stubbed far enough out to put a valve directly onto the pipe, so you're looking at a union, scrap of pipe, then a valve. Provided there's even a big enough hole to get the union through the wall. And. it wasn't until now that I realized that's a photo up at the bottom of the sink and I have no idea what the wall connection looks like, that could just as well be the supply line going through drywall to a mystery connection!

|

|

|

|

Hang on we’re not really recommending people use sharkbites for anything other than a temporary hack right

|

|

|

|

Infinotize posted:Hang on we’re not really recommending people use sharkbites for anything other than a temporary hack right Yes, some people repeatedly recommend exactly that fantastically bad idea in this thread and others. Usually with a "but but if the pipe is cut exactly square they're fine."

|

|

|

|

One of my toilets has been flushing weak, I don't think it's a clog because it only flushes weak sometimes. It's a dual flush toilet, so Im thinking it's possibly the flapper seal or the flush valve itself. Should I go ahead and replace the whole flush valve or does it make sense to start with the flapper seal and go from there?

|

|

|

|

On the topic of temporary hacks, are those flexible couplings with the stainless steel clamps a long term solution? I picked one up it seems to have a good seal. I have debated about siliconing it for some extra protection. I really don’t want to open up my wall to deal with my weird pvc drain situation (see earlier post) right now.

|

|

|

|

Like a Fernco? In some applications they can be your only (sensible) solution, so yes you can use them long term, but if another option exists I would recommend doing that. EI cutting open the wall, cutting off the old fitting and replacing it.

|

|

|

|

Motronic posted:Yes, some people repeatedly recommend exactly that fantastically bad idea in this thread and others. Usually with a "but but if the pipe is cut exactly square they're fine."

|

|

|

|

Keep telling yourself that while you recommend a product that relies on a seal and a quick prayer that it went on right. That's not what building infra should look like. If you really can't learn how to solder at lest splash out for crimp (which has been successfully been getting used for refrigeration level pressures for more than a decade). Sharkbites are for unskilled handymen and emergencies. They will fail, they will leak. On timelines and in quantities that are not acceptable for structural plumbing. This is a known quantity. They absolutely have their place. It's great they are a thing. But "put it in a wall as a permanent repair" is not that place.

|

|

|

|

|

| # ? May 31, 2024 12:28 |

|

StormDrain posted:Sort of? That doesn't look stubbed far enough out to put a valve directly onto the pipe, so you're looking at a union, scrap of pipe, then a valve. Provided there's even a big enough hole to get the union through the wall. The pipe comes down from the sink, there is a 90* bend, and then it goes right through the wall.

|

|

|